Professional Documents

Culture Documents

RCC Box Culvert Design Calculations

Uploaded by

mohana tOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RCC Box Culvert Design Calculations

Uploaded by

mohana tCopyright:

Available Formats

Vax Consultants Pvt. Ltd., Detailed Design Calculations for 1 x 2.0m x 2.

lations for 1 x 2.0m x 2.0m RCC BOX CULVERT without earth cushion

Foundation & Structural Engineers

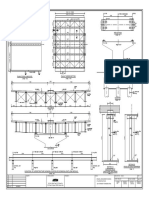

DETAILED DESIGN CALCULATIONS FOR 1 x 2.0m x 3.0m (Vent Height) SIZE RCC BOX CULVERT

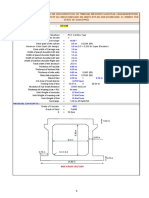

Data:

Inner dimensions of the box

Width = 2.000 m

Depth = 2.000 m

Thickness of the top slab = 0.250 m

Thickness of bottom slab = 0.250 m

Thickness of side walls = 0.250 m

Size of fillet at top = 0.15 x 0.15 m

Size of fillet at bottom = 0.15 x 0.15 m

Earth Cushion = 0.00 m

Av. Wearing Coat Cushion = 0.065 m to 0.2025 m

PCC Fill over Soffit Slab = 0.15 m

Earth Filling on Bottom Slab = 0.000 RL (+)

RL (+)

Av. Wearing Coat Cushion 0.065 m

0.25 RL (+)

0.25 1.600

RL (+)

2.000

0.150 RL (+)

0.25 RL (+)

Center line dimensions of box = 2.25 x 2.400 m

Loaded length = 2.25 m Projection of Bottom Slab on Each Side = 0.00 m

Width of Bottom Slab = 2.1 m

1) Dead Laod Calculations:

On Top Slab

Load due to top slab = 0.25 x 25 = 6.25 kN/m 2

Side Walls

2

Load Due to Side Walls

= 0.25 x 25 = 6.25 kN/m

Bottom Slab

2

Load due to bottom slab= 0.25 x 25 = 6.25 kN/m

2) Superimposed Dead Load Calculations:

Av. Wearing Coat Cushion = 0.1338 m

Density of Wearing Coat Material = 25.00 kN/m 3

Density of Soil Fill Material = 18.00 kN/m 3

Load due to Wearing Coat= 0.13375 x 25 = 3.34 kN/m 2

Load Due to Earth Cushion

= 0 x 18 0.00 kN/m 2

Total SIDL on the top slab = 3.344 + 0 = 3.344 kN/m 2

Government of Tamil Nadu

Highway Department

Vax Consultants Pvt. Ltd., Detailed Design Calculations for 1 x 2.0m x 2.0m RCC BOX CULVERT without earth cushion

Foundation & Structural Engineers

3) Earth pressure & Surcharge Prsuure calculations:

Active Earth Pressure at any depth = = ka x g x h

Angle of repose of soil (φ ) = = 30 Deg

Density of soil ( g ) = 18 kN/m 3

Rankin's earth pressure 1 - sinφ

= 0.334

coefficient (k a ) = 1 + sinφ

=

However, take Earth pressure coefficient at rest 0.5

a) Earth Pressure Calculations:

2

At the middle of top slab0.5 x 18 x 0.3275 = 2.948 kN/m

2

at the middle of bottom 0.5

slabx 18 x 2.7275 = 24.548 kN/m

b) Surcharge pressure calculations:

As per IRC, 1.20m height of soil pressure shall be considered as surcharge pressure.

ka = 0.50

2

Surcharge pressure = = 0.5 x 18 x 1.2 = 10.8 kN/m

2

Earth Pressure + Surcharge Pressure at the C/L of top slab = 13.748 kN/m

2

Earth Pressure + Surcharge Pressure at the C/L of bot. slab = 35.348 kN/m

5) Live Load calculations:

The following assumptions were made in the live load calculations

1 The live load case to produce maximum moments in the top slab assuming the top slab as a fixed beam.

2 The equavalent uniformly distributed load shall be worked out to produce the moments specified above.

Following loads speciifed in IRC were considered in the design:

As the intensity of 70R - Track Loading is less than that due to Class AA - Track Loading, Class AA -

Track Loading only is considered. Detailed calculations are presented below.

a. Class 70 R - Wheeled Loading

b. Class 70 R - Tracked Loading

c. Class 70 R - Bogie loading

a. Class 70R Wheeled Loading:

Maximum Axle Load = 170 kN

Contact width of the Wheel

= (Transverse

0.86Direction)

m

Width of the Vehicle = 2.79 m (outer to outer of wheels of an axle)

C/C of Tyres in transverse direction (perpendicular to Traffic Direction) =

Dispersion width 1930 mm

As per cl.305.16.2 of IRC:21-2000, dispersion width is

b eff = a a (1 - a/l o ) + b 1

Where, b eff = Effective width of slab on which the load acts.

l o = effective span = 1.60 m, as per Clause 305.4 of IRC:21

a = distance of the C.G of the concentrated load from the nearer support

b 1 = Breadth of concentration of load.

b = With of the Slab = 12 m

b/l o = 7.50

Support Condition 1 Simply Supported Slab 2 Continuous Slab

Present Condition 2

a = 2.6 From Table in Clause No. 305.16 of IRC:21

lo = 2.25 m

b1 = 0.99 m

Government of Tamil Nadu

Highway Department

Vax Consultants Pvt. Ltd., Detailed Design Calculations for 1 x 2.0m x 2.0m RCC BOX CULVERT without earth cushion

Foundation & Structural Engineers

Impact factor:

As per Cl. 208.3 of IRC:6-2010, impact factor for Class AA and 70R loading

For tracked vehicles

a) 25% for spans upto 12.0m

b) For spans more than 12.0m, in accordance with Figure 5 of IRC:6 - 2010

Hence, Impact Factor = 25 %

And as per Cl. 208.6 of IRC:6-2010, if filling is more than 0.6m including road crust, the impact

factor is 50% of that calculated as per Cl. 208.3 of IRC:6-2010.

As hight of fill is < 0.6 m

Hence,Clause

From for an 208.7

Effective Span of

of IRC:6 - 2010,2.25 m,bottom

if the ImpactSlab

Factor

is =deeper by

25 3.0m

% below soffit of the Top

Slab, Impact Effects need not be considered

Max. load placed at extream position :

Loads 85 85 85 85 60 60 40

Distances 1.37 3.05 1.37 2.13 1.52 3.96

85 85 85 85 60

1.37 3.05 1.37 2.13

2.25

INPUT DETAILS FOR CLASS 70R WHEEL LOADING:

Load 1 Load 2 Load 3 Load 4 Load 5

Total Tyre Load 85 85 85 85 60 kN

Width of tyre perpendicular to traffic 860 mm

b1 990 mm

The Wheels are moved by an interval of 0.25 m

Load 1 Load 2

Load Point

Case Point

Load,

No. a1 a 11 b eff, b eff1 Load, a2 a2 1 b eff, b eff1

kN,

kN, W1

W2

1 0.00 0.00 0.990 0.990 107.32 1.37 0.88 2.383 4.313 49.27

2 0.25 0.25 1.568 1.568 67.77 1.62 0.63 2.169 4.099 51.84

3 0.50 0.50 2.001 3.931 54.06 1.87 0.38 1.811 1.811 58.66

4 0.75 0.75 2.290 4.220 50.36 2.12 0.13 1.308 1.308 81.20

5 1.00 1.00 2.434 4.364 48.69

6 1.25 1.00 2.434 4.364 48.69

7 1.50 0.75 2.290 4.220 50.36

8 1.75 0.50 2.001 3.931 54.06

9 2.00 0.25 1.568 1.568 67.77

10 2.25 0.00 0.990 0.990 107.32

b. 70 R Track loading:

Total load = 700 kN

Contact length of track = 4.57 m

Contact width of track = 0.85 m

width of vehicle =

2.900 m (outer to outer of tracks)

C/C of Tracks in transverse direction (perpendicular to Traffic) = 2050 mm

Dispersion width of track:

As per cl.305.16.2 of IRC:21-2000, dispersion width is

Government of Tamil Nadu

Highway Department

Vax Consultants Pvt. Ltd., Detailed Design Calculations for 1 x 2.0m x 2.0m RCC BOX CULVERT without earth cushion

Foundation & Structural Engineers

b eff = a a (1 - a/l o ) + b 1

Where a = distance of the C.G of the concentrated load from the nearer support

a = 2.6 From Table in Clause No. 305.16 of IRC:21

lo = 1.60 m

b1 = 0.98 m

Impact factor:

As per Cl. 208.3 of IRC:6-2010, impact factor for Class AA and 70R loading

For tracked vehicles

a) 25% for spans upto 5.0m

b) Linearly varying from 25% for 5m spans to 10% for spans of 9m

Impact Factor = 25 %

As hight of fill is < 0.6 m

Hence, Impact Factor = 25 %

Total length of the track is assumed to be divided into 5 equal concentrated Loads

Each Concentrated Load = 70 kN

Distance between the loads0.914

= m

Max. load placed at extream position :

Loads 70 70 70 70 70

Distances 0.914 0.914 0.914 0.914

70 70 70 70 70

0.914 0.914 0.914 0.914

2.25

INPUT DETAILS FOR CLASS 70R TRACK LOADING:

Load 1 Load 2 Load 3

Load

Case Poi

Point

No. Point nt

a a1 b eff, b eff1 Load, a a1 b eff, b eff1 a a1 b eff, b eff1

Load, kN Loa

kN

d,

11 0.00 0.00 0.980 0.980 89.29 0.914 0.914 1.999 1.999 43.77 1.828 0.422 1.79 1.79 49

12 0.25 0.25 1.528 1.528 57.25 1.164 1.086 1.887 1.887 46.37 2.078 0.172 1.38 1.38 63

13 0.50 0.50 1.874 1.874 46.70 1.414 0.836 2.018 2.018 43.36

14 0.75 0.75 2.016 2.016 43.40 1.664 0.586 1.946 1.946 44.97

15 1.00 1.00 1.955 1.955 44.76 1.914 0.336 1.670 1.670 52.39

16 1.25 1.00 1.955 1.955 44.76 2.164 0.086 1.192 1.192 73.43

17 1.50 0.75 2.016 2.016 43.40

18 1.75 0.50 1.874 1.874 46.70

19 2.00 0.25 1.528 1.528 57.25

20 2.25 0.00 0.980 0.980 89.29

Government of Tamil Nadu

Highway Department

Vax Consultants Pvt. Ltd., Detailed Design Calculations for 1 x 2.0m x 2.0m RCC BOX CULVERT without earth cushion

Foundation & Structural Engineers

C. 40T Bogie loading:

Total load = 400 kN

Contact length of tye is calculated on the basis of 5.273kg/cm 2 for 5ton load on 410 x

610mm

Contact tyre

width of tyre (Perpendicular to traffic) = 360 mm

Contact length of tyre (Along the Traffic Direction)

= = 263.40 mm Say 264 mm

Contact length of tyre (Traffic Direction) = 0.264 m

Contact width of tyre (Transverse Direction) = 0.86 m

C/C of wheels in Transverse Direction = 1.93 m

C/C of axiles = 1.22 m

lo = 1.60 m

b1 = 0.99 m

a= 2.6 From Table in Clause No. 305.16 of IRC:21

i) Max. load placed at extream position :

Loads 100 100

Distances 1.22

100 100

1.22

2.25

INPUT DETAILS FOR CLASS 70R BOGEI LOADING:

Dispersion with of each concentrated load in span direction is calculated below:

Load 1 Load 2

Load

Case Point

Point

No. a a1 b eff, b eff1 a a1 b eff, b eff1 Load,

Load, kN

kN

21 0.00 0.00 0.990 0.990 126.26 1.22 1.03 1.944 3.874 32.27

22 0.25 0.25 1.538 1.538 81.25 1.47 0.78 2.029 3.959 31.57

23 0.50 0.50 1.884 1.884 66.36 1.72 0.53 1.912 1.912 65.39

24 0.75 0.75 2.026 3.956 63.20 1.97 0.28 1.591 1.591 78.59

25 1.00 1.00 1.965 3.895 64.18 2.22 0.03 1.067 1.067 117.2

26 1.25 1.00 1.965 3.895 64.18

27 1.50 0.75 2.026 3.956 63.20

28 1.75 0.50 1.884 1.884 66.36

29 2.00 0.25 1.538 1.538 81.25

30 2.25 0.00 0.990 0.990 126.26

Government of Tamil Nadu

Highway Department

Vax Consultants Pvt. Ltd., Detailed Design Calculations for 1 x 2.0m x 2.0m RCC BOX CULVERT without earth cushion

Foundation & Structural Engineers

Sub-Soil Data:

3

Modulus of Sub-Grade Reaction = 5000 kN/m

2

SBC Of Sub-soil = 225 kN/m

Estimation of Spring Constants

0.125 0.34 0.34 0.34 0.34 0.34 0.275 0.125

0.275

1 2 3 4 5 6 7 8

SPRING VALUES ARE DETERMINED BELOW:

Spring No. Node No. Effectibve Width, m Spring Value, kN/m

1 1 0.2625 1312.50

2 2 0.3075 1537.50

3 3 0.34 1700.00

4 4 0.34 1700.00

5 5 0.34 1700.00

6 6 0.34 1700.00

7 7 0.3075 1537.50

8 8 0.2625 1312.50

Plane Frame Analysis is performed using STAAD package and SUMMARY OF RESULTS are Tabulated Below. And, steel

design at the critical Sections is also provided in the table below:

From Clause 208.7 of IRC:6 - 2010, if the bottom Slab is deeper by 3.0m below soffit of the Top Slab, Impact Effects need not

be considered, otherwise 50% of Impact Effects shall be considered.

Depth of Bottom of base Slab below Soffit of Top Slab = 2.2750 m

Effective Impact Factor for Bottom Slab = 20.221 % of actual Impact Factor

i.e. 5.055 %

Hence Multiflying Factor = 0.840

Government of Tamil Nadu

Highway Department

Vax Consultants Pvt. Ltd., Detailed Design Calculations for 1 x 2.0m x 2.0m RCC BOX CULVERT without earth cushion

Foundation & Structural Engineers

VARIATION OF IMPACT EFFECTS ACROSS DEPTH

1.000 0.000

0.50 0.25

0.202 2.2750

3.650

Materials adopted:

Grade of Concrete M 30

Grade of steel Fe 500

t cmax = 2.2 N/mm 2

s cbc = 10 N/mm 2

s st = 240 N/mm 2

m = 10

k = 1/(1+(s st /m s cbc ))

k = 0.295

j = 0.902

2

Q = 1.331 N/mm

The Spring Values are taken from the STAAD OUT-PUT and the base pressures are estimated as below:

SPRING FORCES

LOAD CASE

1 2 3 4 5 6 7 8

VLL - Case 1 34.76 34.58 29.89 21.67 13.62 5.69 -1.98 -6.61

VLL - Case 2 17.17 18.11 17.32 14.72 12.22 9.83 6.80 4.36

VLL - Case 3 8.26 10.07 11.69 12.32 13.05 13.90 13.41 12.04

VLL - Case 4 0.05 3.29 8.04 12.52 17.11 21.83 24.11 23.62

VLL - Case 5 5.55 6.09 6.20 5.70 5.24 4.85 4.05 3.24

VLL - Case 6 3.24 4.05 4.85 5.24 5.70 6.20 6.09 5.55

VLL - Case 7 0.94 2.07 3.61 4.97 6.36 7.82 8.42 8.14

VLL - Case 8 -1.56 -0.05 2.37 4.83 7.34 9.90 11.31 11.30

VLL - Case 9 -5.19 -2.92 1.09 5.44 9.83 14.30 17.03 17.38

VLL - Case 10 -13.35 -9.14 -1.24 7.63 16.58 25.64 31.47 32.62

VLL - Case 11 30.34 31.17 28.55 22.77 17.16 11.70 5.72 1.53

VLL - Case 12 12.08 14.61 16.81 17.57 18.47 19.52 18.71 16.72

VLL - Case 13 10.78 11.63 11.51 10.22 9.02 7.90 6.18 4.62

VLL - Case 14 6.12 7.46 8.67 9.14 9.71 10.35 9.99 8.98

VLL - Case 15 1.52 3.60 6.46 9.00 11.63 14.35 15.50 14.99

Government of Tamil Nadu

Highway Department

Vax Consultants Pvt. Ltd., Detailed Design Calculations for 1 x 2.0m x 2.0m RCC BOX CULVERT without earth cushion

Foundation & Structural Engineers

VLL - Case 16 -5.23 -1.82 3.87 9.80 15.82 21.95 25.49 25.68

VLL - Case 17 0.77 1.69 2.95 4.06 5.20 6.40 6.89 6.66

VLL - Case 18 -1.29 -0.04 1.97 4.00 6.08 8.19 9.37 9.35

VLL - Case 19 -4.33 -2.44 0.91 4.53 8.19 11.92 14.20 14.49

VLL - Case 20 -11.11 -7.61 -1.03 6.35 13.79 21.33 26.19 27.14

VLL - Case 21 40.51 39.64 33.21 22.73 12.41 2.21 -7.19 -12.51

VLL - Case 22 21.31 21.54 19.18 14.63 10.20 5.86 1.42 -1.46

VLL - Case 23 12.67 13.56 13.25 11.58 10.01 8.53 6.43 4.61

VLL - Case 24 4.27 7.16 10.88 13.93 17.09 20.39 21.53 20.53

VLL - Case 25 -7.15 -1.98 6.57 15.40 24.36 33.49 38.69 38.88

VLL - Case 26 3.93 4.92 5.89 6.39 6.93 7.55 7.42 6.75

VLL - Case 27 1.13 2.48 4.33 5.95 7.63 9.38 10.10 9.76

VLL - Case 28 -1.86 -0.07 2.82 5.73 8.71 11.75 13.43 13.41

VLL - Case 29 -6.14 -3.45 1.29 6.43 11.63 16.92 20.15 20.57

VLL - Case 30 -15.71 -10.76 -1.47 8.98 19.51 30.16 37.03 38.37

DL 7.52 8.73 9.56 9.50 9.50 9.56 8.73 7.52

SIDL 1.69 1.97 2.16 2.16 2.16 2.16 1.97 1.69

EP -0.25 -0.08 0.12 0.22 0.22 0.12 -0.08 -0.25

Max due to VLL 40.51 39.64 33.21 22.77 24.36 33.49 38.69 38.88

Min due to VLL -15.71 -10.76 -1.47 4.00 5.20 2.21 -7.19 -12.51

Net Max 49.47 50.26 45.05 34.65 36.24 45.33 49.31 47.84

Net Min -6.75 -0.14 10.37 15.88 17.08 14.05 3.43 -3.55

Area 0.263 0.3075 0.34 0.34 0.34 0.34 0.3075 0.2625

Pressure, Min -25.71 -0.45 30.50 46.71 50.24 41.32 11.14 -13.51

Pressure, Max 188.5 163.46 132.51 101.90 106.58 133.33 160.37 182.24

Abs. Max. Pr. 188.45

Abs. Min Pr. -25.71

DESIGN FORCES

BOTTOM SLAB

BM, kNm/m Shear, kN/m

Load

Load Description LCs Right Units

Factor Support Span Left Support

Support

Dead Load 1.35 LC1 -5.21 8.28 -13.75 13.75

SIDL 1.35 LC2 -0.49 1.13 -1.13 1.13

EP 1.50 LC3 -14.79 -14.54 -0.33 0.33

LLSP 1.20 LC4

VLL Case 1 1.50 LC5 -12.40 22.66 -37.39 33.47

VLL Case 2 1.50 LC6 -13.41 24.98 -41.38 38.79

VLL Case 3 1.50 LC7 -13.12 20.46 -38.00 42.30

LC8 LC8 -48.49 24.88 -76.67 70.78

LC9 LC9 -50.00 28.36 -82.66 78.76

LC10 LC10 -49.56 21.59 -77.58 84.03

Design Force -50.00 28.36 -82.66 84.03

Government of Tamil Nadu

Highway Department

Vax Consultants Pvt. Ltd., Detailed Design Calculations for 1 x 2.0m x 2.0m RCC BOX CULVERT without earth cushion

Foundation & Structural Engineers

SIDE WALL

Dead Load 1.35 LC1 5.21 2.61 1.53

SIDL 1.35 LC2 0.49 0.53 -0.03

EP 1.50 LC3 14.79 -26.64 57.46

LLSP 1.20 LC4

VLL Case 1 1.50 LC5 12.40 7.66 3.33

VLL Case 2 1.50 LC6 13.41 9.14 2.50

VLL Case 3 1.50 LC7 13.12 7.10 3.92

LC8 48.49 -24.23 93.21

LC9 50.00 -22.00 91.97

LC10 49.56 -25.06 94.09

Design Force 50.00 -25.06 94.09

TOP SLAB

Dead Load 1.35 LC1 0.02 -3.94

SIDL 1.35 LC2 0.58 -1.54

EP 1.50 LC3 16.53 16.53

LLSP 1.20 LC4

VLL Case 1 1.50 LC5 6.42 -19.74

VLL Case 2 1.50 LC6 7.00 -22.94

VLL Case 3 1.50 LC7 7.55 -24.73

LC8 35.23 -12.22

LC9 36.10 -17.02

LC10 36.92 -19.70

Design Force 36.92 -19.70

LC8 = 1.35 x LC1 + 1.35 x LC2 + 1.5 x LC3 + 1.2 x LC4 + 1.5 x LC5

LC9 = 1.35 x LC1 + 1.35 x LC2 + 1.5 x LC3 + 1.2 x LC4 + 1.5 x LC6

LC10 = 1.35 x LC1 + 1.35 x LC2 + 1.5 x LC3 + 1.2 x LC4 + 1.5 x LC7

Design Forces

Ultimate Moment, M u , kNm/m Ultimate Shear Force, Vu, kN/m

Element Thickness,

Description mm

At Support At Mid Span At Support At Mid Span

Top Slab 36.92 -19.70 250

Side Wall 50.00 -25.06 94.09 250

Bottom Slab -50.00 28.36 84.03 250

Government of Tamil Nadu

Highway Department

Vax Consultants Pvt. Ltd., Detailed Design Calculations for 1 x 2.0m x 2.0m RCC BOX CULVERT without earth cushion

Foundation & Structural Engineers

DETAILED DESIGN OF CROSS SECTIONS

Top Slab Wall Bottom Slab Units

Item Description Mid Mid Mid

Support Support Support

Span Span Span

Depth of Section 250 250 250 250 250 250 mm

Width of Wall Considered 1000 1000 1000 1000 1000 1000 mm

Design Factored BM 36.92 19.70 50.00 25.06 50.00 28.36 kNm

Design Factored Shear Force 0.00 0.00 94.09 0.00 84.03 0.00 kN/m

Concrete 30 30 30 30 30 30 N/mm 2

Steel 500 500 500 500 500 500 N/mm 2

Design Factored BM 36.92 19.70 50.00 25.06 50.00 28.36 kNm/m

Strength of Concrete 30 30 30 30 30 30 N/mm 2

Strength of Steel 500 500 500 500 500 500 N/mm 2

Clear Cover 50 50 75 75 75 75 mm

Diameter of Ties 0 0 0 0 0 0 mm

No. of Layers 1 1 1 1 1 1 No.

Layer 1 - Diameter 12 10 12 10 12 10 mm

Layer 2 - Diameter 0 0 0 0 0 0 mm

Effective Cover 56 55 81 80 81 80 mm

Effective Depth 194 195 169 170 169 170 mm

2

M u /bd 0.981 0.518 1.751 0.867 1.751 0.981 N/mm 2

Percentage Steel required 0.270 0.140 0.499 0.237 0.499 0.270 %

Minimum steel required 0.0013 0.0013 0.0012 0.0012 0.0013 0.001 %

Steel required 524 273 843 404 843 459 mm 2

Steel Provided

Layer 1 - Diameter 12 10 16 16 12 10 mm

Spacing 140 140 140 140 140 140 mm c/c

Layer 2 - Diameter 16 0 12 0 16 0 mm

Spacing 140 250 140 250 140 200 mm c/c

Quantity of Steel Provided 2243 561 2243 1435 2243 561 mm 2 /m

Check SAFE SAFE SAFE SAFE SAFE SAFE

Provided Steel, p t 1.156 0.288 1.327 0.844 1.327 0.330 %

Limiting Depth of Neutral axis, x u,limit 88 89 77 78 77 78 mm

Assumed x u 22.00 22.00 45.00 22.00 45.00 22.00 mm

ξ st 0.027 0.028 0.010 0.024 0.010 0.024 mm/mm

f st 434.8 434.8 434.8 434.8 434.8 434.8 N/mm 2

x u check 89.80 22.45 89.80 57.47 89.80 22.45 mm

Check 1 REVISE SAFE REVISE SAFE REVISE SAFE

M ur 152.76 45.26 128.38 91.18 128.38 39.2 kNmm

Check 2 SAFE SAFE SAFE SAFE SAFE SAFE

Effective Depth for Shear 194.0 195.0 169.0 170.0 169.0 170.0 mm

Nominal Shear Stress 0 0.000 0.557 0.000 0.497 0.000 N/mm 2

N ed 0.000 0.000 0.000 0.000 0.000 0.000 kN

Ac 194000 195000 169000 170000 169000 170000 mm 2

σ cp 0.000 0.000 0.000 0.000 0.000 0.000 N/mm 2

Partial Safety Factor on Concrete, ϒ m 1.5 1.5 1.5 1.5 1.5 1.5

f cd 0.67 x f ck /ϒ m

13.40 13.40 13.40 13.40 13.40 13.40 N/mm 2

Government of Tamil Nadu

Highway Department

Vax Consultants Pvt. Ltd., Detailed Design Calculations for 1 x 2.0m x 2.0m RCC BOX CULVERT without earth cushion

Foundation & Structural Engineers

0.2 x f cd 2.680 2.680 2.680 2.680 2.680 2.680 N/mm 2

σ cp shall be least of N ED /A c or 0.2f cd

Hence, σ cp 0.000 0.000 0.000 0.000 0.000 0.000 N/mm 2

0.5

K = 1 + (200/d) 2.015 2.013 2.088 2.085 2.088 2.085

ν 0.724 0.457 0.785 0.675 0.785 0.495 N/mm 2

3/2 1/2

ν min = 0.031 x K x f ck 0.486 0.485 0.512 0.511 0.512 0.511 N/mm 2

Shear Strength of Concrete 0.724 0.485 0.785 0.675 0.785 0.511 N/mm 2

V RD.c 140.5 94.5 132.7 114.8 132.7 86.9 kN

NOT

NOT NOT NOT NOT NOT

Requirement of Shear Reinforcement REQD

REQD. REQD. REQD. REQD. REQD.

.

Notes:

1 The above mentioned diameter of bars and spacings may be changed in the drawings maintaining the required

total steel at the cross sections

2 As the Internal Forces in Top Slab are arrived at based on the distribution of VLL as per Clause of IRC:21,

Shear Check need not be done

3 Maximum Spacing of bars in Slabs for main reinforcement is 250mm or 2h which ever is less and for distribution

steel it is 400mm or 3h which ever is less as per Cl.16.6.1.1 of IRC:112-2011.

4 Minimum Grade of Concrete in Severe Atmosphere is M30 as per Table 14.2 of IRC:112-2011.

5 Clear cover for elements with soil faces is of 75mm and for elements with other than soil faces is 50mm.

6 The development length and lap length are in accordence with Cl.15.2.3 and Table 15.4 of IRC:112-2011.

7 Maximum Spacing of vertical bars in walls shall not be more than 200mm and for horizontal bars it should not be

more than 300mm as per clause 16.3.1 and 16.3.2 of IRC:112-2011.

8 The total area of vertical reinforcement should be between 0.0024Ac and 0.04Ac outside the locations of laps of

vertical steel. This reinforcement should be provided on both sides but area of steel in each side should not be

less than 0.0012Ac, as per Cl. 16.3.1 of IRC:112-2011.

Government of Tamil Nadu

Highway Department

You might also like

- Pile Retaining Wall - With Wind..Document6 pagesPile Retaining Wall - With Wind..epe civilNo ratings yet

- Box Culvert Without CushionDocument23 pagesBox Culvert Without CushionPrafulla Malla100% (1)

- VRB CurvilinearFINALDocument32 pagesVRB CurvilinearFINALRahul GhoshNo ratings yet

- Pearson Knowledge Management An Integrated Approach 2nd Edition 0273726854Document377 pagesPearson Knowledge Management An Integrated Approach 2nd Edition 0273726854karel de klerkNo ratings yet

- Design of CulvertDocument9 pagesDesign of CulvertRupesh KoyandeNo ratings yet

- Design of 3-Cell Box Culvert: 1. Base Pressure CheckDocument2 pagesDesign of 3-Cell Box Culvert: 1. Base Pressure Checkmanoj_mousamNo ratings yet

- Detailed Design Calculations For 1 X 2.0M X 2.0M Size RCC Box CulvertDocument1 pageDetailed Design Calculations For 1 X 2.0M X 2.0M Size RCC Box Culvertnandu523No ratings yet

- 5X2-0 2m (Earth)Document26 pages5X2-0 2m (Earth)santosh yevvariNo ratings yet

- Input DataDocument3 pagesInput DataVarun VermaNo ratings yet

- Design of Claritube SettlerDocument19 pagesDesign of Claritube SettlerGomatesh PatilNo ratings yet

- RCC Drain Design for 0.9m HeightDocument7 pagesRCC Drain Design for 0.9m Heightvasantharaja rajasekarNo ratings yet

- Bucket DesignDocument6 pagesBucket Designוויסאם חטארNo ratings yet

- Foundation Design f1Document2 pagesFoundation Design f1Sampath Kumar KandasamyNo ratings yet

- Design ReportDocument62 pagesDesign Reportsubhankar biswasNo ratings yet

- Road Estimate FormatDocument7 pagesRoad Estimate Formatalok jhaNo ratings yet

- FINAL Box CulvertDocument149 pagesFINAL Box CulvertMayank AgrawalNo ratings yet

- 3 Analysis and Design of Deck SlabDocument14 pages3 Analysis and Design of Deck SlabPrafulla MallaNo ratings yet

- Retaining WallDocument3 pagesRetaining WallAkshay KumarNo ratings yet

- Combine FootingDocument4 pagesCombine FootingBibek BasnetNo ratings yet

- SEO Structural Design of Box CulvertsDocument8 pagesSEO Structural Design of Box CulvertscoreteamNo ratings yet

- Design of Overhead Intz tank with 150,000 litre capacityDocument22 pagesDesign of Overhead Intz tank with 150,000 litre capacityshivanandarcotNo ratings yet

- One Way Slab Design 3Document3 pagesOne Way Slab Design 3Kenneth Peña JavierNo ratings yet

- Counterfort Retaining WallDocument16 pagesCounterfort Retaining Wallvidhiyadav1021No ratings yet

- Isolated PAD FootingDocument8 pagesIsolated PAD Footingarshad aliNo ratings yet

- Summary of IS 3370 Detailing RequirementsDocument2 pagesSummary of IS 3370 Detailing RequirementsKanaiyalal N. ShethNo ratings yet

- Box Culvert Section: 4 Input Data 4.1 Geometry of The SectionDocument7 pagesBox Culvert Section: 4 Input Data 4.1 Geometry of The SectionmidhunvarNo ratings yet

- RCC RETAINING WALL H-5mDocument21 pagesRCC RETAINING WALL H-5mramanNo ratings yet

- Concrete Retaining Wall DesignDocument7 pagesConcrete Retaining Wall DesignnazrawiNo ratings yet

- Design of 2 Vents Box Culvert 2 X 4.5 X 3.50: General DataDocument55 pagesDesign of 2 Vents Box Culvert 2 X 4.5 X 3.50: General DataBhaskar ReddyNo ratings yet

- Design of cross regulator at RD 368.500 of Bikaner CanalDocument10 pagesDesign of cross regulator at RD 368.500 of Bikaner Canalਹਰਪ੍ਰੀਤ ਗਿੱਲNo ratings yet

- T-BEAM BRIDGE DESIGNDocument16 pagesT-BEAM BRIDGE DESIGNshashi rajhansNo ratings yet

- Design For RR Stone Masonary Retaining Wall: General DataDocument2 pagesDesign For RR Stone Masonary Retaining Wall: General DataRajesh GangwalNo ratings yet

- C) IRC Class 70R Load (Wheeled Vehicle) (L-type) Bending Moment and Reinforcement DesignDocument12 pagesC) IRC Class 70R Load (Wheeled Vehicle) (L-type) Bending Moment and Reinforcement DesignTashi TamangNo ratings yet

- Design of Abutment PDFDocument4 pagesDesign of Abutment PDFChManikumarNo ratings yet

- Bridge Design v1.1 enDocument125 pagesBridge Design v1.1 enTulsi LakhaniNo ratings yet

- Live Load CalculationDocument1 pageLive Load CalculationSuman NakarmiNo ratings yet

- Wing wall design and reinforcement calculationDocument4 pagesWing wall design and reinforcement calculationFaizal AryanovNo ratings yet

- 70R_TRACKED LOAD DISPERSION CALCULATIONSDocument17 pages70R_TRACKED LOAD DISPERSION CALCULATIONSHimal KafleNo ratings yet

- Stair CaseDocument19 pagesStair CaseVanu VamalaiNo ratings yet

- BoxCul Class A 4 x3.5Document9 pagesBoxCul Class A 4 x3.5navneet3bawaNo ratings yet

- Canal RegulatorDocument13 pagesCanal RegulatorBibhuti Bhusan Sahoo100% (1)

- Well Foundation DesignDocument4 pagesWell Foundation DesignArpan SahaNo ratings yet

- Design of U Type Return Wall - 10.9mDocument15 pagesDesign of U Type Return Wall - 10.9mdipoksinghaNo ratings yet

- Calculating Intake Pile CapacityDocument4 pagesCalculating Intake Pile Capacitykridhakarya kriyakarsaNo ratings yet

- Retaining Wall With Pile FoundationDocument42 pagesRetaining Wall With Pile FoundationPrashant JhaNo ratings yet

- TH - 2 (Floor Slab) : Wall 68.00 500.00 1000.0 50.00 12.00 150.00 2E+5 2E+5 10.98Document2 pagesTH - 2 (Floor Slab) : Wall 68.00 500.00 1000.0 50.00 12.00 150.00 2E+5 2E+5 10.98UjwalaNo ratings yet

- Pier Cap Plan: Project:-Client: - ConsultantsDocument1 pagePier Cap Plan: Project:-Client: - ConsultantsShaileshRastogiNo ratings yet

- Design Concrete Box CulvertsDocument9 pagesDesign Concrete Box CulvertsSUPERINTENDING ENGINEER100% (1)

- Design of 4m retaining wallDocument13 pagesDesign of 4m retaining wallsiddharth yadavNo ratings yet

- Summary of Structural Calculation of 1-Barrel Box CulvertDocument30 pagesSummary of Structural Calculation of 1-Barrel Box CulvertTony Hartono BagioNo ratings yet

- Retaining Wall DesignDocument18 pagesRetaining Wall DesignGalih PutraNo ratings yet

- Check-Dam Stability 1Document4 pagesCheck-Dam Stability 1naseebNo ratings yet

- Cantilever Retaining WallDocument4 pagesCantilever Retaining Wallsharath mathewNo ratings yet

- Known Data: H Z 2 I R S GDocument6 pagesKnown Data: H Z 2 I R S GUjol PraNo ratings yet

- IRC 5 Amendment Silt Factor May 2021Document1 pageIRC 5 Amendment Silt Factor May 2021Biswaprakash DasNo ratings yet

- Irc 112Document24 pagesIrc 112Bharath Reddy ChinthiReddy100% (1)

- Design of SyphonDocument7 pagesDesign of SyphonraghurmiNo ratings yet

- 1 X 2 X 2 DESIGNDocument34 pages1 X 2 X 2 DESIGNmohana tNo ratings yet

- Design of RCC Box 2 X 4.0 M X 4.5mDocument17 pagesDesign of RCC Box 2 X 4.0 M X 4.5mvinoraam100% (1)

- Skew Box 1 X 7.0 X 7.5m - DesignDocument58 pagesSkew Box 1 X 7.0 X 7.5m - DesignPrabhakaran KarunanithiNo ratings yet

- RCC Box Culvert DesignDocument27 pagesRCC Box Culvert DesignPraveen Cyssan0% (1)

- Design of Pier System - GROUP - PD2: Vax Consultants Pvt. LTD.Document17 pagesDesign of Pier System - GROUP - PD2: Vax Consultants Pvt. LTD.mohana tNo ratings yet

- Chennai Metro Detailed Design Calculations Pier Group PD4Document1 pageChennai Metro Detailed Design Calculations Pier Group PD4mohana tNo ratings yet

- DETAILED DESIGN CALCULATIONS & DRAWINGS FOR PIER GROUP - PD3Document115 pagesDETAILED DESIGN CALCULATIONS & DRAWINGS FOR PIER GROUP - PD3mohana tNo ratings yet

- Vax Consultants Pvt. LTD.,: Pier Column Desig DetailsDocument4 pagesVax Consultants Pvt. LTD.,: Pier Column Desig Detailsmohana tNo ratings yet

- 2Document2 pages2mohana tNo ratings yet

- DETAILED DESIGN CALCULATIONS & DRAWINGS FOR PIER GROUP - PD3Document115 pagesDETAILED DESIGN CALCULATIONS & DRAWINGS FOR PIER GROUP - PD3mohana tNo ratings yet

- DETAILED DESIGN CALCULATIONS & DRAWINGS FOR PIER GROUP - PD3Document115 pagesDETAILED DESIGN CALCULATIONS & DRAWINGS FOR PIER GROUP - PD3mohana tNo ratings yet

- Design of Pier System - GROUP - PD2: Vax Consultants Pvt. LTD.Document17 pagesDesign of Pier System - GROUP - PD2: Vax Consultants Pvt. LTD.mohana tNo ratings yet

- 2Document2 pages2mohana tNo ratings yet

- Vax Consultants Pvt. LTD.,: G1 Self Weight of Pier System G2 Super-Structure Dead LoadDocument4 pagesVax Consultants Pvt. LTD.,: G1 Self Weight of Pier System G2 Super-Structure Dead Loadmohana tNo ratings yet

- Vax Consultants Pvt. LTD.,: G1 Self Weight of Pier System G2 Super-Structure Dead LoadDocument4 pagesVax Consultants Pvt. LTD.,: G1 Self Weight of Pier System G2 Super-Structure Dead Loadmohana tNo ratings yet

- Vax Consultants Pvt. LTD.: Foundation & Structural EngineersDocument1 pageVax Consultants Pvt. LTD.: Foundation & Structural Engineersmohana tNo ratings yet

- Construction of Grade Separator Pier Cap Beam DesignDocument4 pagesConstruction of Grade Separator Pier Cap Beam Designmohana tNo ratings yet

- Design of Grade Separator Foundation at MedavakkamDocument9 pagesDesign of Grade Separator Foundation at Medavakkammohana tNo ratings yet

- 2Document2 pages2mohana tNo ratings yet

- Vax Consultants Pvt. LTD.,: Pier Column Desig DetailsDocument4 pagesVax Consultants Pvt. LTD.,: Pier Column Desig Detailsmohana tNo ratings yet

- Vax Consultants Pvt. LTD.,: Pier Column Desig DetailsDocument4 pagesVax Consultants Pvt. LTD.,: Pier Column Desig Detailsmohana tNo ratings yet

- Vax Consultants Pvt. LTD.: Foundation & Structural EngineersDocument1 pageVax Consultants Pvt. LTD.: Foundation & Structural Engineersmohana tNo ratings yet

- Vax Consultants Pvt. LTD.,: G1 Self Weight of Pier System G2 Super-Structure Dead LoadDocument4 pagesVax Consultants Pvt. LTD.,: G1 Self Weight of Pier System G2 Super-Structure Dead Loadmohana tNo ratings yet

- Design of Pier System - GROUP - PD2: Vax Consultants Pvt. LTD.Document17 pagesDesign of Pier System - GROUP - PD2: Vax Consultants Pvt. LTD.mohana tNo ratings yet

- Vax Consultants Pvt. LTD.: Foundation & Structural EngineersDocument1 pageVax Consultants Pvt. LTD.: Foundation & Structural Engineersmohana tNo ratings yet

- Design of Pier System - GROUP - PD1: Vax Consultants Pvt. LTD.Document17 pagesDesign of Pier System - GROUP - PD1: Vax Consultants Pvt. LTD.mohana tNo ratings yet

- Design of Abutment Group, GA1Document85 pagesDesign of Abutment Group, GA1mohana t100% (1)

- Vax Consultants Pvt. LTD.Document2 pagesVax Consultants Pvt. LTD.mohana tNo ratings yet

- Vax Consultants Pvt. LTD.Document2 pagesVax Consultants Pvt. LTD.mohana tNo ratings yet

- Grade Separator Foundation Design CalculationsDocument5 pagesGrade Separator Foundation Design Calculationsmohana tNo ratings yet

- Vax Consultants Pvt. LTD.,: Pier Column Desig DetailsDocument4 pagesVax Consultants Pvt. LTD.,: Pier Column Desig Detailsmohana tNo ratings yet

- Vax Consultants Pvt. LTD.,: Loads & Combinations at Top of Foundation, RL (+)Document6 pagesVax Consultants Pvt. LTD.,: Loads & Combinations at Top of Foundation, RL (+)mohana tNo ratings yet

- Construction of Grade Separator Detailed Design CalculationsDocument20 pagesConstruction of Grade Separator Detailed Design Calculationsmohana tNo ratings yet

- Detailed Design Calculations for Medavakkam Grade Separator AbutmentDocument3 pagesDetailed Design Calculations for Medavakkam Grade Separator Abutmentmohana tNo ratings yet

- Arduino PWM To DC Voltage Op Amp Converter - Henry's BenchDocument8 pagesArduino PWM To DC Voltage Op Amp Converter - Henry's BenchAlan A. TorresNo ratings yet

- Writing Visual Basic ProjectsDocument1 pageWriting Visual Basic ProjectsAmmuKuttyNo ratings yet

- Four Process StrategyDocument10 pagesFour Process StrategyChandria FordNo ratings yet

- Reliability Centered Maintenance (RCM)Document6 pagesReliability Centered Maintenance (RCM)Hoang Thanh VanNo ratings yet

- Chapter 5 PresentationDocument35 pagesChapter 5 PresentationSabeur Dammak100% (1)

- Foundation Fieldbus: Dataguard™ - Iec61158-2 - Isa/Sp50 - Type A - Extended TemperatureDocument1 pageFoundation Fieldbus: Dataguard™ - Iec61158-2 - Isa/Sp50 - Type A - Extended TemperatureJosé CallisayaNo ratings yet

- Teaser Rheosolve D 15ASDocument2 pagesTeaser Rheosolve D 15ASwahyuni raufianiNo ratings yet

- Piperack Design PhiloshipyDocument10 pagesPiperack Design PhiloshipyGautam PaulNo ratings yet

- Alejandro D. Ramos - Tourism Development Economics, Management - 2008 PDFDocument258 pagesAlejandro D. Ramos - Tourism Development Economics, Management - 2008 PDFSanjiv RudrakarNo ratings yet

- TMDI Lesson Plan in Storing and Reconstituting StocksDocument5 pagesTMDI Lesson Plan in Storing and Reconstituting StocksDiane VillNo ratings yet

- Squidpy: A Scalable Framework For Spatial Omics Analysis: ArticlesDocument14 pagesSquidpy: A Scalable Framework For Spatial Omics Analysis: ArticlesXin XuNo ratings yet

- HoraceDocument8 pagesHoraceapolonius31No ratings yet

- Mercury MasterDocument18 pagesMercury MastersatishmuggulaNo ratings yet

- G8 - Light& Heat and TemperatureDocument49 pagesG8 - Light& Heat and TemperatureJhen BonNo ratings yet

- Gen Math Module 6 Solving Exponential Equation and Inequalities - 112920 PDFDocument18 pagesGen Math Module 6 Solving Exponential Equation and Inequalities - 112920 PDFMGrace P. VergaraNo ratings yet

- Sheet 5 SolvedDocument4 pagesSheet 5 Solvedshimaa eldakhakhnyNo ratings yet

- SchoolopeningdocxDocument1 pageSchoolopeningdocxElena BarsukovaNo ratings yet

- Bi006008 00 02 - Body PDFDocument922 pagesBi006008 00 02 - Body PDFRamon HidalgoNo ratings yet

- This Content Downloaded From 3.6.73.78 On Wed, 21 Dec 2022 07:40:53 UTCDocument81 pagesThis Content Downloaded From 3.6.73.78 On Wed, 21 Dec 2022 07:40:53 UTCabcdNo ratings yet

- ouchureIC 7000Document4 pagesouchureIC 7000iti_na8567No ratings yet

- PassionForProcesse en 04-13Document20 pagesPassionForProcesse en 04-13Mutas MattaNo ratings yet

- Phrase Structure AnalysisDocument2 pagesPhrase Structure Analysismerlino99No ratings yet

- Proportional Valves: Adjustment ProcedureDocument11 pagesProportional Valves: Adjustment Procedureyaniprasetyo12No ratings yet

- Philippine Legal CitationDocument72 pagesPhilippine Legal CitationArwella GregorioNo ratings yet

- KiaOptima Seccion 002Document7 pagesKiaOptima Seccion 002Luis Enrique PeñaNo ratings yet

- CSR of DABUR Company..Document7 pagesCSR of DABUR Company..Rupesh kumar mishraNo ratings yet

- How to Critique a Work in 40 StepsDocument16 pagesHow to Critique a Work in 40 StepsGavrie TalabocNo ratings yet

- TOS - MathDocument4 pagesTOS - MathGeorge Ezar N. QuiriadoNo ratings yet

- Manual HandlingDocument14 pagesManual Handlingkacang mete100% (1)