Professional Documents

Culture Documents

Ken Weaver Mechanical Engineer Resume

Uploaded by

api-308328805Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ken Weaver Mechanical Engineer Resume

Uploaded by

api-308328805Copyright:

Available Formats

KENNETH WEAVER

Pullman, WA 99163 • Kenneth.D.Weaver@Gmail.com • 208-310-2281

MECHANICAL ENGINEER

Personable Mechanical Engineer with 5+ years of experience working in teams and groups using

quick learning and innovative thinking to develop novel ways of solving problems and creating

solutions. Contributes strong prototyping and manufacturing experience to create streamlined

product assembly. Strong interpersonal skills paired with dynamic critical thinking support

customer focused and relational approach to service. Areas of expertise include:

SolidWorks | AutoCAD | MATLab | Visual Basic | FEA | Adobe | Soldering | Assembly | Machining

Project Management | Prototyping | Microsoft AX | 3d Printing | Communication Skills | Teamwork

International Team Collaboration | Customer Service | Quick Learner | Microsoft Office

RELEVANT EXPERIENCE

ASSOCIATE MANUFACTURING ENGINEER OCTOBER 2018 – PRESENT

SCHWEITZER ENGINEERING | LEWISTON, ID

• Managed and organized proto and pilot builds on over 20 ECOS

• Organized meetings with R&D and the production floor to ensure each team was supported

in the development of new processes and products

• Designed production support tools in SolidWorks and used a Prusa 3d printer to expedite

use on the floor

• Supported proto builds at sister plant, in San Luis Potosi, virtually and locally

• Utilized Microsoft Office Suite to present and store information in a manageable and orderly

manner

• Managed deadlines between multiple projects and deliverable dates to ensure prompt

service and project progress

• Developed work instructions for harness development and meters enclosure builds

MECHANICAL DESIGN CONSULTANT JULY 2017 – NOVEMBER 2018

MODERN AWNING | SEATTLE, WA

• Reverse engineered 21 parts, using SolidWorks, from samples and fit those samples to

current working models

• Modified and fixed broken SolidWorks models from previous engineers in order to run

simulation on complete models

• Made simulation data for crucial elements in the model using Solidworks FEA

• Created manufacturing drawings from SolidWorks parts for manufacturing in China

• Designed parts for efficiency in machining and minimizing environmental impact

• Scheduled and coordinated meetings with 2 clients to ensure consistent progress with

various projects

MECHANICAL DESIGN CONSULTANT SEPTEMBER 2016 – DECEMBER 2016

KATALYST FITNESS INC. | SEATTLE, WA

• Worked in a team of 4 to build multiple components for a new full-body EMS machine

• Participated in weekly project update meetings to present the work accomplished during

the previous week

• Worked in a startup with fast moving targets where each person wore multiple hats and

problem solving was integral to product development

KENNETH WEAVER PAGE TWO

Kenneth.D.Weaver@Gmail.com • 208-310-2281

RELEVANT EXPERIENCE (CONTINUED)

MECHANICAL ENGINEERING INTERN JUNE 2016 – SEPTEMBER 2016

SCHWEITZER ENGINEERING LABS | PULLMAN, WA

• Improved manufacturing process to reduce time from 90 minutes to 10 minutes leading to

a savings of 400 man hours per year

• Utilized Microsoft AX to receive and transfer shipments along with updating picking lists,

boms, and cycle counting

• Routed and assembled enclosures and networking racks based on previously designed and

drafted designs

• Developed Excel tables to calculate and measure wire lengths and routing distances for

enclosures to expedite the wire cutting process

MECHANICAL ENGINEERING INTERN JUNE 2014 – SEPTEMBER 2014

SCHWEITZER ENGINEERING LABS | PULLMAN, WA

• Redrafted and replaced all PEM’s in Manufacturing Mechanical Support models using

SolidWorks to streamline processes for future projects

• Managed Manufacturing Mechanical Support’s SolidWorks PDM by deleting over 200

outdated parts and repairing 400+ broken files

PROJECTS

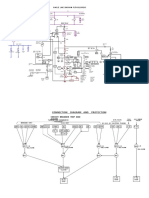

SENIOR DESIGN PROJECT SEPTEMBER 2016 – JUNE 2017

SEATTLE UNIVERSITY | SEATTLE, WA

• Worked in a team of six Seattle University students (4 mechanical engineering and 2

electrical engineering) to design, manufacture, and fabricate a working electrical

generator, control system, and data logger

• Designed 4 different revisions including a plastic 3d printed prototype, and 3 metal plastic

working models

• Led the team along while fulfilling duties as the Mechanical Design and Fabrication Lead

• Collaborated with the Electrical Design Lead to create a preliminary design for the

generator and for all components involved in the fabrication of the generator

• Presented design work completed throughout year in both formal and casual settings

• Developed innovative ways to maximize efficiency and output of the generator while also

minimizing cost and fabrication time

EDUCATION

BACHELOR OF SCIENCE IN MECHANICAL ENGINEERING GRADUATED JUNE 2017

SEATTLE UNIVERSITY | SEATTLE, WA

CERTIFICATIONS

ENGINEER IN TRAINING APRIL 2017

LICENSE 35685

SOLIDWORKS – CSWA OCTOBER 2016

You might also like

- Resume For A Recently Passed Out Engineering FresherDocument3 pagesResume For A Recently Passed Out Engineering FresherSatish Kumar0% (1)

- APPLICATION FOR EMPLOYMENT AT HELIOS AND MATHESONDocument6 pagesAPPLICATION FOR EMPLOYMENT AT HELIOS AND MATHESONsubbujantu0% (1)

- Power Gating - Power Management Technique: VLSI Basics and Interview QuestionsDocument12 pagesPower Gating - Power Management Technique: VLSI Basics and Interview QuestionsRohith RajNo ratings yet

- List of Osho's Complete Audio-Video DVD CollectionDocument15 pagesList of Osho's Complete Audio-Video DVD CollectionOsho Bengaluru100% (2)

- RTC Invoice 2965 Gj29es2223100505Document1 pageRTC Invoice 2965 Gj29es2223100505Alok PandeyNo ratings yet

- Tharun S.J: ObjectiveDocument2 pagesTharun S.J: Objectiveharry tharunNo ratings yet

- Sample Mechanical Engineer ResumeDocument1 pageSample Mechanical Engineer ResumeKen Johnson83% (6)

- Mechanical Engineering ResumeDocument2 pagesMechanical Engineering ResumeZohaib KhanNo ratings yet

- Job Application PDFDocument2 pagesJob Application PDFSharath PNo ratings yet

- ResumeDocument7 pagesResumePriyanka ChaudharyNo ratings yet

- Application For Transfer CertificateDocument2 pagesApplication For Transfer CertificateÒli Ulla MollaNo ratings yet

- Same Day Resume by Michael FarrDocument20 pagesSame Day Resume by Michael FarrKarl NeoNo ratings yet

- Professional ResumeDocument3 pagesProfessional ResumechodekiranNo ratings yet

- Reena Mahato's Bio-DataDocument1 pageReena Mahato's Bio-DataArihant Jain K DigitalNo ratings yet

- Architect ResumeDocument4 pagesArchitect Resumebabu100% (2)

- Bonafide Certificate RequestDocument1 pageBonafide Certificate RequestAkshit PatelNo ratings yet

- Jane Resumgo: Graphic DesignerDocument2 pagesJane Resumgo: Graphic DesignerZaka ZaheeriNo ratings yet

- Harish Resume UKDocument3 pagesHarish Resume UKChittoor Vibhakaran HarishNo ratings yet

- Fresher Resume 1Document3 pagesFresher Resume 1Ajit JenaNo ratings yet

- Architect/Interior Designer ResumeDocument1 pageArchitect/Interior Designer ResumeIshita Mirajgaoker100% (1)

- Janice Soriano, Senior Recruiter ResumeDocument2 pagesJanice Soriano, Senior Recruiter ResumerecruiterjaniceNo ratings yet

- Fresher Engineer ResumeDocument10 pagesFresher Engineer Resumesatoni12100% (1)

- Resume Format 2Document3 pagesResume Format 2api-3802379100% (4)

- 3.3 Video Sobre Las Temáticas AbordadasDocument2 pages3.3 Video Sobre Las Temáticas AbordadasBriseyde SilvaNo ratings yet

- Employee Appreciation Letter: This Package ContainsDocument3 pagesEmployee Appreciation Letter: This Package ContainsnumlumairNo ratings yet

- Payment receipt and crew release letterDocument1 pagePayment receipt and crew release letterreka ShippingNo ratings yet

- Resume Power WordsDocument2 pagesResume Power Wordswhite.angelNo ratings yet

- Venegas ResumeDocument2 pagesVenegas ResumeDayo IdowuNo ratings yet

- Date and Place of Birth: . Nationality: .: Address Phone Number EmailDocument2 pagesDate and Place of Birth: . Nationality: .: Address Phone Number EmailAlexandru LucianNo ratings yet

- Sample Resume For Engineering Students: Gregory T. JonesDocument1 pageSample Resume For Engineering Students: Gregory T. Jonesprince kdNo ratings yet

- Job Promotion LetterDocument2 pagesJob Promotion LetterArunaNo ratings yet

- Chartered Accountant resume Poonam SharmaDocument2 pagesChartered Accountant resume Poonam Sharmamonika9716557915No ratings yet

- Resume Template HelenDocument2 pagesResume Template HelenDani Moreira100% (1)

- How To Answer 14 Common But Tricky Interview QuestionsDocument5 pagesHow To Answer 14 Common But Tricky Interview Questionsjennifer L. TUtorNo ratings yet

- Teacher Resume 2010Document2 pagesTeacher Resume 2010trenttNo ratings yet

- Er. Kishor Kumar Panthi :: CVDocument4 pagesEr. Kishor Kumar Panthi :: CVengineeringwatchNo ratings yet

- Sample Fresh Graduate ResumeDocument2 pagesSample Fresh Graduate ResumeShenghai YuanNo ratings yet

- RESUME (M.Pharm-Pharmaceutics) : Ashishkumar N. PanchalDocument3 pagesRESUME (M.Pharm-Pharmaceutics) : Ashishkumar N. PanchalAshish100% (1)

- Mechanical Engineering Resume TemplateDocument1 pageMechanical Engineering Resume Templategio_5000No ratings yet

- Key Responsibilities of The Position Include But Are Not Limited To The FollowingDocument2 pagesKey Responsibilities of The Position Include But Are Not Limited To The FollowingjoserturnerNo ratings yet

- Srikanth GangarajuDocument3 pagesSrikanth GangarajuVirupakshudu KodiyalaNo ratings yet

- Electrician Resume ExampleDocument1 pageElectrician Resume ExampleMOHAMMED SAZZAD HOSSAINNo ratings yet

- Job Application Letter for Business Economics GraduateDocument1 pageJob Application Letter for Business Economics GraduateMohammadShehzadNo ratings yet

- Rws Las Resume Part2Document2 pagesRws Las Resume Part2Michelle Faith BenitezNo ratings yet

- Mechanical Design Engineer Resume Sample - LiveCareerDocument4 pagesMechanical Design Engineer Resume Sample - LiveCareerचन्दनप्रसादNo ratings yet

- Career Changer Resume SusanDocument2 pagesCareer Changer Resume SusanDarryl WallaceNo ratings yet

- Mark Halverson PHD Data Scientist ResumeDocument1 pageMark Halverson PHD Data Scientist Resumeapi-269922428No ratings yet

- Nikin Jain's Resume - Strategy and Business Development ProfessionalDocument3 pagesNikin Jain's Resume - Strategy and Business Development ProfessionalNikin Kumar Jain100% (1)

- Analyst Cover LetterDocument3 pagesAnalyst Cover Letterarion barryNo ratings yet

- CSR Resignation Letter Digicon TechnologiesDocument1 pageCSR Resignation Letter Digicon TechnologiesKanchan BaruaNo ratings yet

- Profile: Electronics TechnologistDocument1 pageProfile: Electronics TechnologistEstherCalvoGómezNo ratings yet

- Giles Kelly ResumeDocument1 pageGiles Kelly ResumeKelly GIles100% (10)

- IT Graduate Resume C# Programming SkillsDocument2 pagesIT Graduate Resume C# Programming SkillsTrexie De Vera JaymeNo ratings yet

- Currículos Vitae: Year Name of The Degree Name of The Institution UniversityDocument3 pagesCurrículos Vitae: Year Name of The Degree Name of The Institution UniversityMani YadhaveNo ratings yet

- Resume IT ProfessionalDocument2 pagesResume IT ProfessionalPravin Joshi0% (1)

- State Bank of IndiaDocument6 pagesState Bank of IndiaJaydeepdasforeverNo ratings yet

- 6 Fresher Engineer Resume SamplesDocument14 pages6 Fresher Engineer Resume SamplesSiddeshwarNo ratings yet

- Digital Marketing CVDocument2 pagesDigital Marketing CVAnonymous mFAN58No ratings yet

- Asad Irfan CV For CSR TeraDataDocument3 pagesAsad Irfan CV For CSR TeraDataAsad IrfanNo ratings yet

- Mohammed Fasil. K. K: Career Objective Professional Attributes SkillsDocument2 pagesMohammed Fasil. K. K: Career Objective Professional Attributes Skillsmohammed3fasilNo ratings yet

- Resume SampleDocument2 pagesResume Sample18TUEC119 Kiran SeshiNo ratings yet

- Project Coordinator AUG 2023Document3 pagesProject Coordinator AUG 2023ezechukwu tochukwu brightNo ratings yet

- Joseph Kochevar: Summary of Qualifications ExperienceDocument1 pageJoseph Kochevar: Summary of Qualifications ExperienceAnonymous d4JNXpDC7No ratings yet

- Thermal Analysis of An Ohmic Heater Applied To Mango Pulp Through CFD in Ansys ApdlDocument11 pagesThermal Analysis of An Ohmic Heater Applied To Mango Pulp Through CFD in Ansys ApdlOLANIYINo ratings yet

- Aetna Dental Low DmoDocument9 pagesAetna Dental Low DmoBeau PeskaNo ratings yet

- Conclusion FdiDocument2 pagesConclusion FdiYo PaisaNo ratings yet

- PU Timing Belt-SINOCONVE Belt 2022Document25 pagesPU Timing Belt-SINOCONVE Belt 2022Marcelo Renteria VidaurreNo ratings yet

- Computer Integrated ManufacturingDocument7 pagesComputer Integrated ManufacturingNarendra PalacharlaNo ratings yet

- Equity ValuationDocument18 pagesEquity ValuationAbhishek NagpalNo ratings yet

- Desing Criteria For A Controlled DemolitionDocument12 pagesDesing Criteria For A Controlled Demolitionajmc1No ratings yet

- Diagram PLTA SLJDocument4 pagesDiagram PLTA SLJMEi Cuiet Luph-LuPhNo ratings yet

- Lesson 8 Homework Practice Volume and Surface Area of Composite Figures AnswersDocument8 pagesLesson 8 Homework Practice Volume and Surface Area of Composite Figures Answerscfg1ngzn100% (1)

- Level 2 Repair: 7-1. Components On The Rear CaseDocument8 pagesLevel 2 Repair: 7-1. Components On The Rear CaseNguyễn Duy LinhNo ratings yet

- Industrial Coupling and HoseDocument57 pagesIndustrial Coupling and HoseCesar CoronelNo ratings yet

- Capacitive Touch Sensing, MSP430™ Slider and Wheel Tuning GuideDocument18 pagesCapacitive Touch Sensing, MSP430™ Slider and Wheel Tuning GuideFábio Carvalho FurtadoNo ratings yet

- (Ebook - PDF - Hack) Advanced Hardware HackingDocument20 pages(Ebook - PDF - Hack) Advanced Hardware HackingogmpsqjuNo ratings yet

- BD-90 75 Dekanter DE-EN 905-738-1 02-16Document4 pagesBD-90 75 Dekanter DE-EN 905-738-1 02-16RasoolKhadibiNo ratings yet

- 38th Workshop On Geothermal PDFDocument25 pages38th Workshop On Geothermal PDFAulia KurniaNo ratings yet

- Ce6101 Problem Sheet 3Document4 pagesCe6101 Problem Sheet 3HT BinhNo ratings yet

- Estimation of Closed Hotels and Restaurants in Jakarta As Impact of Corona Virus Disease Spread Using Adaptive Neuro Fuzzy Inference SystemDocument11 pagesEstimation of Closed Hotels and Restaurants in Jakarta As Impact of Corona Virus Disease Spread Using Adaptive Neuro Fuzzy Inference SystemIAES IJAINo ratings yet

- Trắc nghiệm phần thì trong tiếng anh tổng hợp with keysDocument3 pagesTrắc nghiệm phần thì trong tiếng anh tổng hợp with keysMs ArmyNo ratings yet

- Welcome To Primary 1!Document48 pagesWelcome To Primary 1!Zoe WangNo ratings yet

- Prota - Stiffness FactorDocument7 pagesProta - Stiffness FactorA K100% (1)

- Skies of Arcadia - Lists (Cham, Moonfish, Discoveries)Document9 pagesSkies of Arcadia - Lists (Cham, Moonfish, Discoveries)123142asdadNo ratings yet

- JohnDocument18 pagesJohnRobert EscuadroNo ratings yet

- Akanānuru - Some Poems (2012 - 10 - 29 02 - 55 - 25 UTC)Document9 pagesAkanānuru - Some Poems (2012 - 10 - 29 02 - 55 - 25 UTC)Ravi SoniNo ratings yet

- Troubleshooting GuideDocument88 pagesTroubleshooting GuideFrancisco Diaz56% (9)

- Vào Lớp 10 Lần 9 Năm 2019 Tiếng Anh 9 Đề BDocument3 pagesVào Lớp 10 Lần 9 Năm 2019 Tiếng Anh 9 Đề BNguyễn Huyền MyNo ratings yet

- DC TC 600 L, 01.00, enDocument61 pagesDC TC 600 L, 01.00, enDarkNo ratings yet

- 5S Office OrganizationDocument14 pages5S Office Organizationthuy linh phamNo ratings yet