Professional Documents

Culture Documents

Thermal Expansion: X LX (T - T) X C X L T T C

Uploaded by

ManiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermal Expansion: X LX (T - T) X C X L T T C

Uploaded by

ManiCopyright:

Available Formats

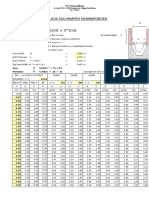

Thermal Expansion

Because of the temperature of the flowing media or the surrounding ambient temperature (including solar gain and wind chill), all vessels

and pipes ensure a direct proportion of expansion or contraction. This rate of expansion or contraction can be mathematically calculated via

this formula:

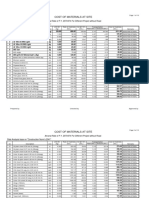

X = L x (T1 - T2) x CExp Coefficients Of Thermal Expansion For Common Pipe Materials

Where: Metals Plastics

X = Expansion or contraction (m)

Material Coefficient Material Coefficient

L = Length of pipe or vessel (m)

T1 = Starting temperature (°C) Copper 16.4 x 10-6

ABS 100 x 10-6

T2 = Final temperature (°C)

Carbon Steel 12.2 x 10-6 PVCU 80 x 10-6

CExp = Coefficient of Thermal Expansion

-6

Stainless Steel (Austenitic) 16.3 x 10 PVCC 70 x 10-6

The table to the right shows the Coefficients Of

Thermal Expansion for various common materials. Stainless Steel (Ferritic) 10.9 x 10-6 PE 200 x 10-6

-6

Cast Iron 11.0 x 10 PP 150 x 10-6

EXAMPLES

Examples of thermal expansion rates over a temperature range of 0°C to 82°C:

Carbon Steel = 1.00mm/mtr

Copper = 1.34mm/mtr

Stainless Steel (Austenitic) = 1.34mm/mtr.

Expansion rates of the common materials shown in the table above, after various temperature changes, are as follows:

Temperature Change Rates Of Thermal Expansion For Common Pipe Materials (mm/m)

°C Copper Carbon Steel Stainless Steel Cast Iron ABS PVCU PVCC PE PP

10 0.16 0.12 0.16 0.11 1.00 0.80 0.70 2.00 1.50

20 0.33 0.24 0.33 0.22 2.00 1.60 1.40 4.00 3.00

30 0.49 0.37 0.49 0.33 3.00 2.40 2.10 6.00 4.50

40 0.66 0.49 0.65 0.44 4.00 3.20 2.80 8.00 6.00

50 0.82 0.61 0.82 0.55 5.00 4.00 3.50 10.00 7.50

60 0.98 0.73 0.98 0.66 6.00 4.80 4.20 12.00 9.00

70 1.15 0.85 1.14 0.77 4.90 10.50

80 1.31 0.98 1.30 0.88 5.60 12.00

90 1.48 1.10 1.47 0.99

100 1.64 1.22 1.63 1.10

110 1.80 1.34 1.79 1.21

120 1.97 1.46 1.96 1.32

130 2.13 1.59 2.12 1.43

140 2.30 1.71 2.28 1.54

150 2.46 1.83 2.45 1.65

160 2.62 1.95 2.61

170 2.79 2.07 2.77

180 2.95 2.20 2.93

190 3.12 2.32 3.10

200 3.28 2.44 3.26

210 2.56 3.42

220 2.68 3.59

230 2.81 3.75

240 2.93 3.91

250 3.05 4.08

260 3.17 4.24

270 3.29 4.40

280 3.42 4.56

290 3.54 4.73

300 3.66 4.89

You might also like

- Resistance SpreadsheetDocument5 pagesResistance SpreadsheetANo ratings yet

- TABELA Promom 61Document1 pageTABELA Promom 61marantelNo ratings yet

- Cable Sizing With Voltge Drop CalclulationDocument84 pagesCable Sizing With Voltge Drop CalclulationtajudeenNo ratings yet

- Siap Cam N TappetsDocument18 pagesSiap Cam N TappetsMuhammad Taufiq YusofNo ratings yet

- Stainless Steel Pipe Fittings Product GuideDocument1 pageStainless Steel Pipe Fittings Product GuideRICHARDNo ratings yet

- Centricast CL 1520 Data SheetDocument6 pagesCentricast CL 1520 Data SheetOlmer Romero MendezNo ratings yet

- End Caps ANSI B16.9Document1 pageEnd Caps ANSI B16.9Thappatla IndurNo ratings yet

- Restoration of Conrete PavementDocument4 pagesRestoration of Conrete PavementfrederickNo ratings yet

- Refrigerant Piping PDFDocument9 pagesRefrigerant Piping PDFzikhail93No ratings yet

- H.W of The Statistics: Republic of Yemen Sana'a University Faculty of Engineering Department of Mechanical EngineeringDocument7 pagesH.W of The Statistics: Republic of Yemen Sana'a University Faculty of Engineering Department of Mechanical Engineeringعبدالملك جمالNo ratings yet

- Particle size analysis of Inicio DSM Tolva materialDocument7 pagesParticle size analysis of Inicio DSM Tolva materialCarlos M. LópezNo ratings yet

- EDM Surface Finish Charts 12-09.36214442Document2 pagesEDM Surface Finish Charts 12-09.36214442ical iculNo ratings yet

- Data Lab - Tanah DidilDocument97 pagesData Lab - Tanah DidilRikiRidwanHabibNo ratings yet

- PasadorDocument6 pagesPasadorAndres Byke SepulvedaNo ratings yet

- n07v K EngDocument1 pagen07v K EngJUANQUIREALNo ratings yet

- n07v K Eng PDFDocument1 pagen07v K Eng PDFJean Pierre GoossensNo ratings yet

- Calculos EléctricosDocument7 pagesCalculos Eléctricosjohn rangelNo ratings yet

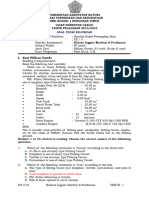

- Proyek Lokasi Material: Dynamic Cone Penetrometer Test (DCPT)Document4 pagesProyek Lokasi Material: Dynamic Cone Penetrometer Test (DCPT)Ikhromul Khoirul AqshomNo ratings yet

- Jis C 3406Document2 pagesJis C 3406Chul Woong SonNo ratings yet

- 2 Soil Test Result at ParoleumDocument10 pages2 Soil Test Result at ParoleumWinNo ratings yet

- Measurement of The Drag Coefficients of Spherical ParticlesDocument10 pagesMeasurement of The Drag Coefficients of Spherical Particlessr3shNo ratings yet

- AMADA - Parameter HandbookDocument8 pagesAMADA - Parameter HandbookNirman Mujkic50% (2)

- Grade Tonne ReportDocument2 pagesGrade Tonne ReportShakur ContrerasNo ratings yet

- Pages From Ashrae 1997 Hvac Fundamentals HandbookDocument21 pagesPages From Ashrae 1997 Hvac Fundamentals HandbookAnkurNo ratings yet

- Pipe DonghwaDocument1 pagePipe DonghwaNguyễn Văn TâyNo ratings yet

- Friotek-Transductor de AltaDocument1 pageFriotek-Transductor de AltaFredy MurilloNo ratings yet

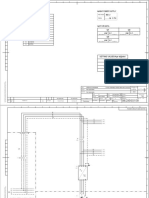

- Copia de PlanoDocument17 pagesCopia de Planoaa_odtNo ratings yet

- Test Safe DistanceDocument2 pagesTest Safe DistanceEmirhan PayNo ratings yet

- Egg Shape - 305mm - Rubble Wall 970707Document4 pagesEgg Shape - 305mm - Rubble Wall 970707Gan Chin PhangNo ratings yet

- Precast Concrete Block Egg-Shaped Drain (Pcbesd) : SY PerundingDocument4 pagesPrecast Concrete Block Egg-Shaped Drain (Pcbesd) : SY PerundingGan Chin PhangNo ratings yet

- Hydraulic Loss Calculation Sheet by Hazen William's FormulaDocument4 pagesHydraulic Loss Calculation Sheet by Hazen William's FormulaKh HafezNo ratings yet

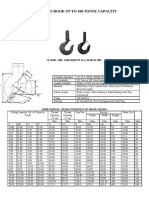

- Shanks Hook Up To 160 Tonne Capacity: IS 15560: 2005 AMENDMENT No:1 MARCH 2007Document2 pagesShanks Hook Up To 160 Tonne Capacity: IS 15560: 2005 AMENDMENT No:1 MARCH 2007liftline engineersNo ratings yet

- Sem 3 - Lab Thermal ExpansionDocument10 pagesSem 3 - Lab Thermal ExpansionLuqman HakimNo ratings yet

- Precast Concrete Block Egg-Shaped Drain (Pcbesd) : SY PerundingDocument4 pagesPrecast Concrete Block Egg-Shaped Drain (Pcbesd) : SY PerundingGan Chin PhangNo ratings yet

- Precast Concrete Block Egg-Shaped Drain (Pcbesd) : SY PerundingDocument4 pagesPrecast Concrete Block Egg-Shaped Drain (Pcbesd) : SY PerundingGan Chin PhangNo ratings yet

- KBT Tugas 1Document13 pagesKBT Tugas 1Fadhilah DevaniNo ratings yet

- LT231218A 10umDocument2 pagesLT231218A 10umharoldcaNo ratings yet

- Grafico Del Calculo de HidrogramasDocument2 pagesGrafico Del Calculo de HidrogramasEstefaniNo ratings yet

- Water Distribution Network Analysis and OptimizationDocument6 pagesWater Distribution Network Analysis and OptimizationnurvaniNo ratings yet

- HW3 - Chapter 3 PDFDocument5 pagesHW3 - Chapter 3 PDFNadia Karima100% (1)

- Matching Transformer Design Specification and Core Loss DataDocument3 pagesMatching Transformer Design Specification and Core Loss DataNaeemo IraqiNo ratings yet

- Shallow Foundation SettlementDocument27 pagesShallow Foundation SettlementMatthew KedeNo ratings yet

- Aries HWD TDocument13 pagesAries HWD TMarco Ðavid Garrido FuentesNo ratings yet

- CoefficientDocument103 pagesCoefficientpanji uteNo ratings yet

- Miracle Uninyvin CablesDocument4 pagesMiracle Uninyvin CablesDharmesh ChanawalaNo ratings yet

- Analisis Granulometrico #De Mallas Abertura Peso Gr. % Peso Ret. % Ac (+) % Ac (-)Document4 pagesAnalisis Granulometrico #De Mallas Abertura Peso Gr. % Peso Ret. % Ac (+) % Ac (-)AnthoniNo ratings yet

- Galvanized Pipe Friction LossDocument5 pagesGalvanized Pipe Friction Lossdaud heruNo ratings yet

- Penetration Conus Test: (ASTM D 3441 - 86)Document3 pagesPenetration Conus Test: (ASTM D 3441 - 86)Eswin SoslindoNo ratings yet

- Electric and Electronic Course: Sensor SpecificationDocument7 pagesElectric and Electronic Course: Sensor SpecificationNova KurniawanNo ratings yet

- ANSI Pipe Schedule SI UNITS METRIC PDFDocument1 pageANSI Pipe Schedule SI UNITS METRIC PDFmm100% (4)

- 03 Maturity Expulsion PDFDocument56 pages03 Maturity Expulsion PDFYuzak Firdaus AmrullohNo ratings yet

- Instrumentation Lab 3Document9 pagesInstrumentation Lab 3ryan warisNo ratings yet

- Conc. vs. Enthalpy Plot.: 2.5 X y X y y XDocument8 pagesConc. vs. Enthalpy Plot.: 2.5 X y X y y XakhilNo ratings yet

- Uninyvin: Certified CompanyDocument4 pagesUninyvin: Certified CompanyDEEPAKNo ratings yet

- DPL N 03 COLEGIO POLITECNICO LOS ANDES JULIACA 15 DE SETIEMBRE DEL 2011 (Autoguardado)Document13 pagesDPL N 03 COLEGIO POLITECNICO LOS ANDES JULIACA 15 DE SETIEMBRE DEL 2011 (Autoguardado)Andre AngelNo ratings yet

- 11kV or 33kV Cable Sizing CalculationDocument1 page11kV or 33kV Cable Sizing Calculationanamulk-183% (18)

- Reinforcing Bar Area Chart for Various Bar Sizes and SpacingsDocument3 pagesReinforcing Bar Area Chart for Various Bar Sizes and SpacingsTri Angga Dio SimamoraNo ratings yet

- Hydrogeology PDFDocument16 pagesHydrogeology PDFJenyy JenyyNo ratings yet

- Subjects Verbs PrepositionsDocument11 pagesSubjects Verbs Prepositionsგუგა ნოსელიძეNo ratings yet

- Engineering Statics FundamentalsDocument28 pagesEngineering Statics FundamentalsurwaNo ratings yet

- A Feminist Analysis of Habba Khatoon'S Poetry: Dr. Mir Rifat NabiDocument7 pagesA Feminist Analysis of Habba Khatoon'S Poetry: Dr. Mir Rifat NabiShabir AhmadNo ratings yet

- Algebra 1 FINAL EXAM REVIEW 2Document2 pagesAlgebra 1 FINAL EXAM REVIEW 2Makala DarwoodNo ratings yet

- Philips HD5 enDocument5 pagesPhilips HD5 enmohamed boufasNo ratings yet

- Bipolar I Disorder Case ExampleDocument6 pagesBipolar I Disorder Case ExampleGrape JuiceNo ratings yet

- Effect of Water Immersion On Mechanical Properties of Polyurethane ...Document8 pagesEffect of Water Immersion On Mechanical Properties of Polyurethane ...konshoeNo ratings yet

- Practical 7 - Angiosperms Marking Guide Exercise 1: Class DicotyledonsDocument3 pagesPractical 7 - Angiosperms Marking Guide Exercise 1: Class DicotyledonsDitiro Maletsanake50% (2)

- Entrepreneurship Macro Environment ForcesDocument26 pagesEntrepreneurship Macro Environment ForcesSivaNo ratings yet

- 3 Soal Ganjil Inggris MaritimDocument8 pages3 Soal Ganjil Inggris MaritimFikri Mu'izNo ratings yet

- Catalogo Tecnico Gb-S v07Document29 pagesCatalogo Tecnico Gb-S v07farou9 bmzNo ratings yet

- Entry-Exit Arrangement With Service RoadDocument1 pageEntry-Exit Arrangement With Service RoadRamBhuvan SonkarNo ratings yet

- TheologicalDiscipleship English 2011-1Document144 pagesTheologicalDiscipleship English 2011-1bilnyangnatNo ratings yet

- LUKAS Product Information-2Document2 pagesLUKAS Product Information-2Flavian ZfmNo ratings yet

- GypsumDocument79 pagesGypsumMansi GirotraNo ratings yet

- Separation and Purification TechnologyDocument10 pagesSeparation and Purification TechnologyPedro Henrique MagachoNo ratings yet

- Fundamental Calculations To Convert Intensities Into Concentrations in Optical Emission Spectrochemical AnalysisDocument14 pagesFundamental Calculations To Convert Intensities Into Concentrations in Optical Emission Spectrochemical AnalysisPYDNo ratings yet

- Analog Layout Design (Industrial Training)Document10 pagesAnalog Layout Design (Industrial Training)Shivaksh SharmaNo ratings yet

- AstigmatismDocument1 pageAstigmatismAmmellya PutriNo ratings yet

- EKO75 KW VST Air Cooled Electrical DiagramDocument13 pagesEKO75 KW VST Air Cooled Electrical DiagramBerat DeğirmenciNo ratings yet

- 60d068822a861e19f4179ec9 - 11. Consensus - Local Cerberus - CompressedDocument1 page60d068822a861e19f4179ec9 - 11. Consensus - Local Cerberus - Compressedhombre pocilgaNo ratings yet

- ES vs SIGINT: Understanding the DifferencesDocument9 pagesES vs SIGINT: Understanding the DifferencesYasir ShigileeniNo ratings yet

- Foundation of EducationDocument31 pagesFoundation of EducationM T Ząřřąř100% (1)

- Rate Analysis-Norms 1Document10 pagesRate Analysis-Norms 1yamanta_rajNo ratings yet

- Medical Terminology TermsDocument28 pagesMedical Terminology TermsNikka Moreen DagdagNo ratings yet

- Belazo Elastomeric Roof PaintDocument2 pagesBelazo Elastomeric Roof PaintrumahsketchNo ratings yet

- MIND - BODY RelationshipDocument18 pagesMIND - BODY RelationshipvishwabhashaNo ratings yet

- PDM TempDocument2 pagesPDM Tempamit rajputNo ratings yet

- ZTE UMTS KPI Optimization Analysis Guide V1 1 1Document62 pagesZTE UMTS KPI Optimization Analysis Guide V1 1 1GetitoutLetitgo100% (1)

- API Calcs Rev1 (Version 2)Document112 pagesAPI Calcs Rev1 (Version 2)Jake Sparrow100% (1)