Professional Documents

Culture Documents

Design Codes & Standarts & Specifications: Plan View

Uploaded by

Ionut FloricaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Codes & Standarts & Specifications: Plan View

Uploaded by

Ionut FloricaCopyright:

Available Formats

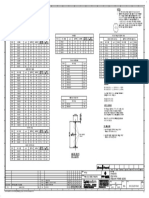

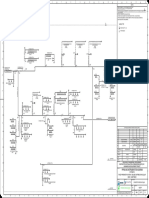

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

UH_BO_ISO_A1_L_E_KXEO-00045.dwg / AG03_UH_BO_ISO_A2-1-0_L.dwg / 12.12.2017

V01

8

2,5 1,0 1,0 1,0 1,0 1,0

A) GENERAL NOTES:

MATERIAL

C03

3

DESIGN CODES & STANDARTS & SPECIFICATIONS

2,0 1,5 1,5 1,0 0,7 0,7

1) All dimensions are in mm unless otherwise specified.

A

B01

6

3,0 3,0 3,0 3,0 4,0 4,0

2) Reinforcement pads shall be fabricated in single piece.

3) For welding applications, API 650 requirements shall be followed.

4) All temporary welds shall be entirely removed by carefully, ensurely that the reduced

plate thickness does not fall below the tank wall min. design thickness.

5) For dimensional tolerances, API 650 / GES requirements shall be followed.

6) All bolt holes shall be straddle main center line.

MAX. NOZZLE LOAD

7) Shell & Roof manholes fabricated from plate shall be 100% radiographed.

C02

M03

A04

8) Before hydrostatic test the tank shall be cleaned & all sand, dirt, debris which have

accumulated inside tank shall be removed.

A03

9) Water used for hydrostatic test shall be potable & treated containing atleast 0.2 ppm free

A02 L02 T01 V01

C01

M01

A01

chlorine. Chloride content of water shall be < 50 ppm after hydrotest tank shall be flushed with

water containing < 1 ppm chloride any residual water shall be wiped off.

10) All internal shall have sharp edges rounded or chamfered to min radius of 3 mm

11) All stainless & duplex steel plates shall be no. 1 finish & hot rolled , annealed & descaled

as per ASTM A480.

12) All plates equal to or greater than 20 mm thk shall be UT tested for lamination defects acc

to ASTM A 435 considering 100 mm mesh size.

13) for duplex plates tests for detrimental intermetallic phase shall be carried out as per clause

B

X.2.3 of API 650.

14) Impact requirements for duplex steel plates as per X.2.3.3 of API 650.

SA403 TP304L

SA312 TP304L / SA240 Type304L

15) Statutory approvals & compliance to Hungarian norms & regulations is vendors

DETAIL A

responsibility

SA312 TP304L / SA240 Type304L

DESIGN DATA

B) NOTES ( FOR INSULATION ) As per PDE-CMG-G000-EC-00002 Spiral wound with PTFE (with inner and outer ring)

AISI 304/304L strip with PTFE filler

External (Roof) NONE (Un-insulated)

External (Shell) NONE (Un-insulated)

L01 Spiral wound with PTFE(with inner and outer ring)

AISI 304/304L strip with PTFE filler

External (Bottom)

50 mm mastic asphalt (Chloride-free)

C) NOTES ( FOR SURFACE TREATMENT)

Yes.

INTERNAL

N.A.

PDE-EQP-G000-DZ-00030-0034

(Process Side)

Surface Treatment Procedure

C

Yes.

PDE-EQP-G000-DZ-00030-0034

EXTERNAL

N.A.

Surface Treatment Procedure

(Shell)

(Excluding bottom thk)

Yes.

EXTERNAL

N.A.

PDE-EQP-G000-DZ-00030-0034

T02

(Roof)

Surface Treatment Procedure

PICKLING & PASSIVATION

PART PAINTING

As per PDE-EQS-G000-EC-00007

D

D

M02

T03

C03 SP01 TESTING & INSPECTION

X03 X02 X01 at lower side below

shell loaction

E

B01 E

DETAIL B

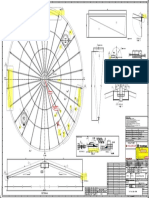

Hemispherical Head

Head, 8 thk (min)

20 NOS ANCHOR CHAIR

M56 ANCHOR BOLT

NOZZLE TABLE

EQUI-SPACED AND OFF

Typ

F

CENTER AT 9250 BCD

. 18 Nos RAFTER

F

U140x70x8

Typ EQUI-SPACED AND OFF

.

CENTER

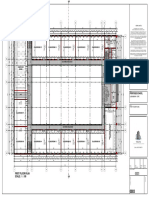

A01 Process Inlet Roof 6 40s 150 B16.5 WN RF 17200 4200 with Dip Pipe 1)

with Blind Flange

A01 / X Dip pipe

Roof 8 40s 150 B16.5 WN RF 16950 4200 drilled for 6"

GR1 GR2

A02 Process Inlet Roof 4 40s 300 B16.5 WN RF 17200 3500

with Blind Flange

A02/ X Dip pipe Roof 6 40s 150 B16.5 WN RF

16950 3500 drilled for 4"

18 Nos INTER.GIRDER

20-M56

U 80x50x8

A03 Process Inlet Roof 4 40s 150 B16.5 WN RF 17200 3500

ANCHOR B/N

with Blind Flange

A03 / X Dip pipe Roof 10 40s 150 B16.5 WN RF

16950 3500 drilled for 4"

EXTRA GIRDER LOCATIONS

A04 Process Inlet Roof 2 80s 150 B16.5 WN RF 17200 4200 with Dip Pipe 3)

with Blind Flange

A04 / X Dip pipe Roof 4 40s 150 B16.5 WN RF

16950 4200 drilled for 2"

G

GIRDER NO. GIRDER TYPE LOCATION

B01 Process Outlet Shell 6 40s 150 B16.5 WN RF -325 5075

G

GR17 GR15

GR16

C01 Spare 2 80s 150 B16.5 WN RF 17200 3000 with Blind Flange

GR18

Roof

GR1 U140x70x8 R=3990

C02 Spare Roof 3 40s 150 B16.5 WN RF 17200 3000 with Blind Flange

GR2 U140x70x8 R=3990

GR9

GR3

C03 Spare Shell 3 40s 150 B16.5 WN RF 940 4710 with Blind Flange

GR3 U140x70x8 R=4200

GR14

L01 Level 3071LS0501 2

150 B16.5 WN RF 15675 4710

GR20

GR4 U140x70x8 R=4200

Shell

80s

GR19

L02 Level 3071LT0502 Roof 3 40s 150 B16.5 WN RF 17133 2250

GR5 U140x70x8 R=4315

M01 Manhole on roof Roof 32 5mm API 650 18050 3500 with Cover and Hinge

GR8

GR6 U80x50x8 R=4200

M02 Manhole

Shell 24 8mm API 650

930 4760 with Cover and Davit

GR7 2*U140x70x8 R=4200

GR13 GR4

18050 3500

ROOF PLATE

M03 Manhole on roof Roof 32 5mm API 650

with Cover and Hinge

GR8 U140x70x8 R=4200

WIND GIRDER

t=5mm

SP01 Sampling Point 3071SC005

2 150 B16.5 WN RF 500 4710 with Blind Flange

Shell

80s

L100x100x8 GR9 U140x70x8 R=3100

H

GR10

GR10 U80x50x8 R=3000

T01 Temperature 3071TT0501 Roof 2 80s 150 B16.5 WN RF 16920 3500

H

T02 Temperature 3071TW0502 2 80s 300 B16.5 WN

RF 2000

Ref. Detail

GR7

U140x70x8 R=3000

Shell

GR12

GR11

T03 Temperature 3071TW0503

Shell

2 80s 300 B16.5 WN

RF 300

Ref. Detail

GR12 U80x50x8 R=4100

Industrial Solutions

8 150 B16.5

GR22

V01 Vent Roof 40s WN RF 18400 0

Acceptance Code

1

GR21

GR13 U140x70x8 R=3150

GR11

X01 Leakage detection Shell 1 80s 150 B16.5 WN RF 5075 with Blind Flange

APPROVED

GR14 U140x70x8 R=3255

X02 Leakage detection Shell 1 80s 150 B16.5 WN RF 5075 with Blind Flange

thyssenkrupp

GR6

GR15 U140x70x8 R=2160

RAFTER

GR5

X03 Leakage detection Shell 1 80s 150 B16.5 WN RF 5075 with Blind Flange

This approval does not release the vendor / supplier

U140x70x8

GR16 U140x70x8 R=1780

from full responsibility for his design and fabrication.

GR17 U80x50x8 R=1780

Remarks:

GR18 U80x50x8 R=1780

1) With 8" (ANSI class 150-RF) blind flange drilled for 6" (ANSI class 150-RF) internal dip pipe.

07-11-2019 zafar.sayed@thyssenkrupp.com

GR19 U140x70x8 R=2225

2) With 10" (ANSI class 150-RF) blind flange drilled for 4" (ANSI class 150-RF) internal dip pipe.

J

GR20 U140x70x8 R=960

3) With 4" (ANSI class 150-RF) blind flange drilled for 2" (ANSI class 150-RF) internal dip pipe.

Date Name J

VRG/ZSS

4) With 6" (ANSI class 150-RF) blind flange drilled for 4" (ANSI class 300-RF) internal dip pipe.

GR21 U140x70x8 R=1590

[ PP GLDP DQWL VLSKRQLQJ KROHV VWDJJHUHG

GR22 U140x70x8 R=1500

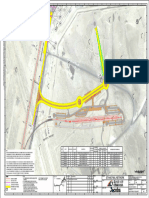

PLAN VIEW

(EXCEPT NOZZLES)

K

K

S

PDE-EQP-G000-DZ-00034-0020

EF/2018-036-3071T002/BoM000 BOM List

SHELL

R

PDE-EQP-G000-DZ-00034-0019

EF/2018-036-3071T002/017 Insulation Details

INSIDE

P

PDE-EQP-G000-DZ-00034-0018

EF/2018-036-3071T002/016 Name plate

O

PDE-EQP-G000-DZ-00034-0017

EF/2018-036-3071T002/015 Internals, clips, earthing lug and others

RING PLATE t=8mm

N

PDE-EQP-G000-DZ-00034-0016

EF/2018-036-3071T002/014 Handrailing & platform details

M

PDE-EQP-G000-DZ-00034-0015

EF/2018-036-3071T002/013 Ladder (stairway) details

BOTTOM

PLATE t=8mm

L

PDE-EQP-G000-DZ-00034-0014

EF/2018-036-3071T002/012 Anchorage details

ANNULAR

PLATE

66 5(%$5

K

PDE-EQP-G000-DZ-00034-0013

EF/2018-036-3071T002/011 Roof manhole

t=6mm

L

J

PDE-EQP-G000-DZ-00034-0012

EF/2018-036-3071T002/010-1 Roof nozzles

I

PDE-EQP-G000-DZ-00034-0011

EF/2018-036-3071T002/009 Shell Manhole

SHELL COURSE

50 mm

BOTTOM (MAIN)

H

PDE-EQP-G000-DZ-00034-0010

EF/2018-036-3071T002/008-1 Shell Nozzles

PLATE

G

PDE-EQP-G000-DZ-00034-0009

EF/2018-036-3071T002/006 Roof (Cone) structure details

t=5mm

F

PDE-EQP-G000-DZ-00034-0008

EF/2018-036-3071T002/005 Roof (Cone) plate details

BASED ON: UF A151-02 (2015-12) EN

E

PDE-EQP-G000-DZ-00034-0007

EF/2018-036-3071T002/004 Shell Plate Details

D

PDE-EQP-G000-DZ-00034-0006

EF/2018-036-3071T002/003

Bottom Plate (double) layout

C

PDE-EQP-G000-DZ-00034-0005

EF/2018-036-3071T002/002

Annular & Bottom Plate (main) layout

B

PDE-EQP-G000-DZ-00034-0004

EF/2018-036-3071T002/001

ISO A1

Nozzle Orientation

M

A

PDE-EQP-G000-DZ-00034-0003

EF/2018-036-3071T002/000 General Arrangement Drawing

Pos tkIS - Dwg Number

Efor - Dwg Number Drawing Name

REFERENCE DRAWINGS

1 2 3 4 5 6 7 8 9 10 11 12 13 50 mm 14 Copyright reserved 16

You might also like

- How to Give a Woman the Most Powerful OrgasmDocument10 pagesHow to Give a Woman the Most Powerful OrgasmFederico Ceferino BrizuelaNo ratings yet

- Instant Assessments for Data Tracking, Grade 5: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 5: Language ArtsNo ratings yet

- 10 DNA Testing Myths Busted, and Other Favorite Posts: by Blaine T. BettingerDocument11 pages10 DNA Testing Myths Busted, and Other Favorite Posts: by Blaine T. BettingerSexy888No ratings yet

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFDocument1 page4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFRonald ValenciaNo ratings yet

- (BS 4592-5-2006) - Industrial Type Flooring and Stair Treads. Solid Plates in Metal and Glass RDocument20 pages(BS 4592-5-2006) - Industrial Type Flooring and Stair Treads. Solid Plates in Metal and Glass RIonut Florica100% (1)

- (BS 4592-5-2006) - Industrial Type Flooring and Stair Treads. Solid Plates in Metal and Glass RDocument20 pages(BS 4592-5-2006) - Industrial Type Flooring and Stair Treads. Solid Plates in Metal and Glass RIonut Florica100% (1)

- Caterpillar C18 ACERTDocument2 pagesCaterpillar C18 ACERTMauricio Gomes de Barros60% (5)

- Scarborough Fair TabDocument2 pagesScarborough Fair TabHarry JonesNo ratings yet

- M&e Electrical AccessoriresDocument11 pagesM&e Electrical Accessorirespetroyston909937100% (5)

- Risk Evaluation/Assessment List EF/2018-036-GENERAL/rec023Document39 pagesRisk Evaluation/Assessment List EF/2018-036-GENERAL/rec023Ionut FloricaNo ratings yet

- 10083a 1X M6 Ab 00007 04Document1 page10083a 1X M6 Ab 00007 04wael zakariaNo ratings yet

- AHS 4 Rolls Hydraulic Plate Bending Machine Operation and Maintenance ManualDocument90 pagesAHS 4 Rolls Hydraulic Plate Bending Machine Operation and Maintenance ManualIonut Florica100% (5)

- Xstrata Bechtel Alliance: A. Gonzalez A. GonzalezDocument1 pageXstrata Bechtel Alliance: A. Gonzalez A. GonzalezjhonNo ratings yet

- Unit 4 - Site PlanningDocument22 pagesUnit 4 - Site PlanningvgdarchNo ratings yet

- Welders Certification Designation Acc. To EN ISO 9606-1Document1 pageWelders Certification Designation Acc. To EN ISO 9606-1vonipko100% (9)

- 10083a 1X M6 Ab 00006 04Document1 page10083a 1X M6 Ab 00006 04wael zakariaNo ratings yet

- No Requiere Aprobación Del Cliente: in WorkDocument1 pageNo Requiere Aprobación Del Cliente: in Worknestor159357No ratings yet

- Katalog Baylan Vodomjer 1-2Document1 pageKatalog Baylan Vodomjer 1-2Edin Dervishi100% (1)

- Stop/ Control Valves: 1X-M6-AB-00006Document1 pageStop/ Control Valves: 1X-M6-AB-00006wael zakariaNo ratings yet

- 220 M6 0310 00032Document1 page220 M6 0310 00032nestor159357No ratings yet

- Design & Analysis of ASME Boiler and Pressure Vessel Components in The Creep Range 2009 PDFDocument229 pagesDesign & Analysis of ASME Boiler and Pressure Vessel Components in The Creep Range 2009 PDFIonut FloricaNo ratings yet

- Welding Procedure Specification StandardDocument18 pagesWelding Procedure Specification StandardIonut Florica100% (1)

- GSI SLV Duisburg - International Welding Engineer-2015Document2,485 pagesGSI SLV Duisburg - International Welding Engineer-2015yutwelding83% (12)

- ADAB Member List Provides Contact Details for Development OrganizationsDocument8 pagesADAB Member List Provides Contact Details for Development OrganizationsShipon GhoshNo ratings yet

- I I I I: No Requiere Aprobación Del ClienteDocument1 pageI I I I: No Requiere Aprobación Del Clientenestor159357No ratings yet

- Eep 000097 0102148005 3 ST Det 0702 R02Document1 pageEep 000097 0102148005 3 ST Det 0702 R02Vikram DalalNo ratings yet

- Eep 000097 0102148005 3 ST Det 0669 R02Document1 pageEep 000097 0102148005 3 ST Det 0669 R02Vikram DalalNo ratings yet

- Louver framing and grating detailsDocument1 pageLouver framing and grating detailsmhazarath murariNo ratings yet

- 00251034badm12144 Cdfe03 01 02Document1 page00251034badm12144 Cdfe03 01 02prasadcspNo ratings yet

- Black Liquor Index DescriptionDocument78 pagesBlack Liquor Index Descriptioneng_saNo ratings yet

- PR 321-11 (R60)Document72 pagesPR 321-11 (R60)Abdi.w KresnaNo ratings yet

- VVVVDocument1 pageVVVVSanjoy SanyalNo ratings yet

- S-21 - WH03-C-138 - COLUMN - Rev 1Document1 pageS-21 - WH03-C-138 - COLUMN - Rev 1TAMILarasuNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Concrete reinforcement detailsDocument1 pageConcrete reinforcement detailsJonathanSaucedoNo ratings yet

- LCD Inverter - 715t2266-1 - Oz9938gnDocument2 pagesLCD Inverter - 715t2266-1 - Oz9938gntavi100% (1)

- 1824 000 SS DST 0040 - 2 - IfcDocument1 page1824 000 SS DST 0040 - 2 - IfcAquiles MartinezNo ratings yet

- 1824 000 SS DST 0040 - 2 - IfcDocument1 page1824 000 SS DST 0040 - 2 - IfcAquiles MartinezNo ratings yet

- BC-5600&5800 NewDocument2 pagesBC-5600&5800 Newsamuel debebeNo ratings yet

- IQ360-000-M6-SG-00001_04Document1 pageIQ360-000-M6-SG-00001_04mustafa1989ocNo ratings yet

- 220 M6 0330 00005 - Rev5Document1 page220 M6 0330 00005 - Rev5Cristhian Alexander Aguilar ChavezNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Detail A: Shuqaiq 3 Independent Water ProjectDocument1 pageDetail A: Shuqaiq 3 Independent Water ProjectABAID ULLAHNo ratings yet

- IQ360-000-M6-SG-00004 02Document1 pageIQ360-000-M6-SG-00004 02mustafa1989ocNo ratings yet

- 0003 - First Floor PlanDocument1 page0003 - First Floor PlanDavid KayeyaNo ratings yet

- Note Generale: Key NotesDocument1 pageNote Generale: Key NotesPablo BenedettoNo ratings yet

- Concrete pavement layout and detailsDocument1 pageConcrete pavement layout and detailsSwati DhurpateNo ratings yet

- Matchline N 8234.400 See DWG 3420-65H-001Document1 pageMatchline N 8234.400 See DWG 3420-65H-001JonathanSaucedoNo ratings yet

- 220 M6 0330 00001 - Rev4Document1 page220 M6 0330 00001 - Rev4Cristhian Alexander Aguilar ChavezNo ratings yet

- Do You Want To Build A Snowman Frozen Guitar ChordsDocument5 pagesDo You Want To Build A Snowman Frozen Guitar ChordsJoseNo ratings yet

- Denah Tampak Stupadu 2 NEW-Layout1Document1 pageDenah Tampak Stupadu 2 NEW-Layout1Romii PradiswaraNo ratings yet

- P 2Document1 pageP 2AZTRID PEREZNo ratings yet

- CMN.18.477 Smart Plant Documentation Ruwais NGL Train 3: EL. 98250 TO EL. 106000 Piping Ga Area WC 743Document1 pageCMN.18.477 Smart Plant Documentation Ruwais NGL Train 3: EL. 98250 TO EL. 106000 Piping Ga Area WC 743steepa22No ratings yet

- CH 52 PennsylvaniaDocument1 pageCH 52 PennsylvaniaTonyNo ratings yet

- Ifc 130 LCD Main SCH 500Document7 pagesIfc 130 LCD Main SCH 500Ionica BolbosNo ratings yet

- 10083a 9X M6 XN 00001 01Document1 page10083a 9X M6 XN 00001 01wael zakariaNo ratings yet

- BTH Hinigaran - Site Drainage Plan February 8,2023-RevisionsDocument1 pageBTH Hinigaran - Site Drainage Plan February 8,2023-RevisionsJet ArcaNo ratings yet

- Piping and Instrumentation Diagram: Fixed Firewater System - Deluge Distribution Cellar Deck / Sump Deck System 53Document1 pagePiping and Instrumentation Diagram: Fixed Firewater System - Deluge Distribution Cellar Deck / Sump Deck System 53Mohd KhaidirNo ratings yet

- Petronas Carigali SDN BHD: Document Review StatusDocument1 pagePetronas Carigali SDN BHD: Document Review StatusMohd KhaidirNo ratings yet

- No Requiere Aprobación Del Cliente: Responsabilidad Exclusiva Del Autor U Originador, Según ContratoDocument1 pageNo Requiere Aprobación Del Cliente: Responsabilidad Exclusiva Del Autor U Originador, Según Contratonestor159357No ratings yet

- Danza Mora TabDocument2 pagesDanza Mora TabHarry JonesNo ratings yet

- S230 - Column & Base Plate Plan - R2Document1 pageS230 - Column & Base Plate Plan - R2Reza MohseniNo ratings yet

- 4V Circuit DiagramDocument1 page4V Circuit DiagramwjcbaaNo ratings yet

- Safety gate installation drawingDocument1 pageSafety gate installation drawingMary DenizeNo ratings yet

- Albeniz, Isaac - AsturiasDocument14 pagesAlbeniz, Isaac - Asturiasjoaquin.ca.garciaNo ratings yet

- Yas MZ Acm ST C40 B1 DT 06002 (A)Document1 pageYas MZ Acm ST C40 B1 DT 06002 (A)hemanthsridharaNo ratings yet

- Astronomy (ACORDES) : G Em11/F em D6add9/F C/E Cmaj7/E AmDocument1 pageAstronomy (ACORDES) : G Em11/F em D6add9/F C/E Cmaj7/E AmAlvin Magnani Bajo FianzaNo ratings yet

- Eep 000097 0102148005 3 ST Det 0682 R02Document1 pageEep 000097 0102148005 3 ST Det 0682 R02Vikram DalalNo ratings yet

- Ed 0900 PRS Pid 000 09041CDocument1 pageEd 0900 PRS Pid 000 09041CMohamed ArafaNo ratings yet

- G N E D: Electrical Room Sag Mill # 1 0310-MLS-0001-ERRDocument1 pageG N E D: Electrical Room Sag Mill # 1 0310-MLS-0001-ERRnestor159357No ratings yet

- Des Fer Ger 001 F01 62 R01Document60 pagesDes Fer Ger 001 F01 62 R01Pedro Almi da Costa FreireNo ratings yet

- X0231 PDW Eut DG 20007 AaDocument1 pageX0231 PDW Eut DG 20007 AajianranrenNo ratings yet

- BC-6200 Liquid MapDocument1 pageBC-6200 Liquid Mapacarrillo84No ratings yet

- Gabinete de fabricacion especial para estaciones eol tester de 1000mmDocument3 pagesGabinete de fabricacion especial para estaciones eol tester de 1000mmRobertoNo ratings yet

- 12.PDE-CMG-G000-EC-00003 - 000 - 02 - ES Welding of Storage TanksDocument12 pages12.PDE-CMG-G000-EC-00003 - 000 - 02 - ES Welding of Storage TanksIonut FloricaNo ratings yet

- E+Aod E+Aod E+Aod E+AodDocument2 pagesE+Aod E+Aod E+Aod E+AodIonut FloricaNo ratings yet

- E+Aod E+Aod E+Aod E+AodDocument2 pagesE+Aod E+Aod E+Aod E+AodIonut FloricaNo ratings yet

- PDE-EQP-G000-DZ-00030-0003 P000 - R03 - Edition - 0 - 3011T001Document1 pagePDE-EQP-G000-DZ-00030-0003 P000 - R03 - Edition - 0 - 3011T001Ionut FloricaNo ratings yet

- Design Codes & Standarts & Specifications: Plan ViewDocument1 pageDesign Codes & Standarts & Specifications: Plan ViewIonut FloricaNo ratings yet

- PDE-EQP-G000-DZ-00033-0005 P000 - R03 - Edition - 0 - 3071T001A - Annular - BottomDocument1 pagePDE-EQP-G000-DZ-00033-0005 P000 - R03 - Edition - 0 - 3071T001A - Annular - BottomIonut FloricaNo ratings yet

- E+Aod E+Aod E+Aod E+AodDocument2 pagesE+Aod E+Aod E+Aod E+AodIonut FloricaNo ratings yet

- PDE-EQP-G000-DZ-00033-0008 P000 - R02 - Edition - 0 - 3071T001A - RoofDocument1 pagePDE-EQP-G000-DZ-00033-0008 P000 - R02 - Edition - 0 - 3071T001A - RoofIonut FloricaNo ratings yet

- PDE-EQP-G000-DZ-00033-0008 P000 - R02 - Edition - 0 - 3071T001A - RoofDocument1 pagePDE-EQP-G000-DZ-00033-0008 P000 - R02 - Edition - 0 - 3071T001A - RoofIonut FloricaNo ratings yet

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFDocument11 pagesEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaNo ratings yet

- Diagram of Bending ParametersDocument5 pagesDiagram of Bending ParametersIonut FloricaNo ratings yet

- Diagram of Bending ParametersDocument5 pagesDiagram of Bending ParametersIonut FloricaNo ratings yet

- Chap 7Document23 pagesChap 7Mohammed FarisNo ratings yet

- PV Elite Tips and TricksDocument50 pagesPV Elite Tips and TricksIonut FloricaNo ratings yet

- Conico CilindriceDocument14 pagesConico CilindriceradumarianNo ratings yet

- Storage Tank Specification SheetDocument4 pagesStorage Tank Specification SheetIonut FloricaNo ratings yet

- DON-20050-F75 - Panou Vertical Otel NR 1-ModelDocument1 pageDON-20050-F75 - Panou Vertical Otel NR 1-ModelIonut FloricaNo ratings yet

- Page 1 of 1 Fin Tube Products, Inc. - "L" Foot: All CategoriesDocument1 pagePage 1 of 1 Fin Tube Products, Inc. - "L" Foot: All CategoriesIonut FloricaNo ratings yet

- 5 MaterialDocument7 pages5 MaterialMOHAMMAD ASIFNo ratings yet

- ReadmeDocument1 pageReadmeIonut FloricaNo ratings yet

- Organozinc CompoundDocument8 pagesOrganozinc Compoundamanuel tafeseNo ratings yet

- CIE IGCSE BiologyDocument25 pagesCIE IGCSE Biologytgdzbspikio.comNo ratings yet

- English Hand Out for Class 3Document19 pagesEnglish Hand Out for Class 3Pat WibawaNo ratings yet

- TL102 0 2024 Che3701 0Document12 pagesTL102 0 2024 Che3701 0sollomontlou06No ratings yet

- New Grad RN Resume ObjectiveDocument5 pagesNew Grad RN Resume Objectiveafjzcgeoylbkku100% (2)

- Customer Role in Service DeliveryDocument13 pagesCustomer Role in Service DeliveryDevinder ChoudharyNo ratings yet

- Monnal T50 VentilatorsDocument2 pagesMonnal T50 VentilatorsInnovate IndiaNo ratings yet

- Phytochemical Analysis of Plant of Cissus QuadrangularisDocument7 pagesPhytochemical Analysis of Plant of Cissus QuadrangularisIJRASETPublicationsNo ratings yet

- Can You Distinguish Neutral, Formal and Informal Among The Following Groups of WordsDocument3 pagesCan You Distinguish Neutral, Formal and Informal Among The Following Groups of WordsВікторія РудаNo ratings yet

- Diagnostic Test Science 5Document7 pagesDiagnostic Test Science 5Rex Russel SalemNo ratings yet

- Statin RisksDocument2 pagesStatin RisksYazen JoudehNo ratings yet

- KOLHAN UNIVERSITY B.Sc Zoology Semester I Exam 2021 Provisional Marks CardDocument2 pagesKOLHAN UNIVERSITY B.Sc Zoology Semester I Exam 2021 Provisional Marks CardSmritiNo ratings yet

- If You Have Guts Then Dare To Be DIFFERENTDocument20 pagesIf You Have Guts Then Dare To Be DIFFERENTChirag Saiya (PHILOSOPHER) - SPIRITUAL Speaker and Writer100% (1)

- بﻮﺤﻟا ﻦﺤﻃ ﺔﻧﺎﻘﺗ - Cereal Milling Technology: · January 2013Document202 pagesبﻮﺤﻟا ﻦﺤﻃ ﺔﻧﺎﻘﺗ - Cereal Milling Technology: · January 2013Moh Al Basher BabikerNo ratings yet

- Cariology-9. SubstrateDocument64 pagesCariology-9. SubstrateVincent De AsisNo ratings yet

- Surgical Handpiece Maintenance PosterDocument2 pagesSurgical Handpiece Maintenance PosterHayes MaineNo ratings yet

- Market Sorvey On PlywoodDocument19 pagesMarket Sorvey On PlywoodEduardo MafraNo ratings yet

- Labor Law in United KingdomDocument108 pagesLabor Law in United KingdomPanagiotis OptionalNo ratings yet

- Removal of A Pinned Spiral by Generating Target Waves With A Localized StimulusDocument5 pagesRemoval of A Pinned Spiral by Generating Target Waves With A Localized StimulusGretymjNo ratings yet

- Goat anatomy and physiology guideDocument8 pagesGoat anatomy and physiology guideLochi GmNo ratings yet

- Ethnomusicology in Times of TroubleDocument15 pagesEthnomusicology in Times of TroubleLéo Corrêa BomfimNo ratings yet

- Perlos HistoryDocument21 pagesPerlos HistoryRiyali TardyNo ratings yet