Professional Documents

Culture Documents

Uniocel Big en PDF

Uploaded by

Teodor EzaruOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uniocel Big en PDF

Uploaded by

Teodor EzaruCopyright:

Available Formats

Yo u r p a r t n e r i n s t e e l

2009

UniOcel Big_kat_2009_A.indd 1 2.3.2009 12:02:33

UnionOcel, company limited was founded in October 2001 as a metallurgical

wholesale dealing with:

– Metal plates

– Flame cut elements

Following our customer’s wishes, we offer the above-mentioned goods both

from our warehouse and production. The offered goods comes from our sto-

rage and service center in Kopřivnice. If the required goods is not available at

our Kopřivnice center or in the warehouse of our sister company, UnionStahl,

Duisburg, Germany, we are still able to offer and deliver it at your destination

in a short delivery time, thanks to an extensive network of our business part-

ners all over Europe. This, of cours, depends on the nature of your order.

The Kopřivnice storage and service center was opened in September 2005.

It ranges among the state-of-the-art establishments of this kind in Central

and Eastern Europe, and extends the offered services of UnionOcel by addi-

tional activities, such as flame cutting, plasma-arc cutting, hydraulic shears

cutting, and laser cutting considered for the future.

We can also offer ex-works deliveries from renowned European producers.

This appliers especially in case of extensive orders with the required delivery

time within a few weeks or months.

As far as the variety of the offered goods is concerned, this is discussed in

details on the following pages. There you will find detailed specifications con-

Company Profile

cerning the quality, dimensions, chemical composition and mechanical proper-

ties. All specifications comply with the related European standards or the

works standards.

Attest documents, arrangement of independent inspection, ultrasonic tests,

import customs clearence, delivery to the destination, and arranging of other

services according to customer’s wishes is a matter of course.

We can also offer our professional knowledge and counseling with our

suppliers’ distinguished profesionals.

We are looking to co-operation with you and we are fully at your disponal.

You, as a satisfied client, are the highest motivation in our efforts.

Do not hesitate to call us.

UnionOcel – your steel partner.

UnionOcel s.r.o.

Radlická 740/113c

158 00 PRAHA 5 - Nové Butovice

tel.: +420 251 013 011

fax: +420 251 013 050

e-mail:info@unionocel.cz

02 www.unionocel.cz

www.unionocel.sk

www.unionocel.eu

www.unionocel.com

UniOcel Big_kat_2009_A.indd 2 2.3.2009 12:02:35

Plates

EN 10025-2 plates from non-alloy

[EN 10025]

constructional steels

EN 10025-3 plates from non-alloy constructional fine-grain steels

[EN 10113-2]

normalised

EN 10025-4 plates from non-alloy constructional fine-grain steels

[EN 10113-3]

thermomechanical rolled

EN 10025-5 plates from constructional steels resistant to climatic

[EN 10155]

effects - Corten A, Corten B

Product Range - on the Stock

EN 10025-6 plates from high-strength fine-grain steels

[EN 10137]

heat treated

EN 10028-2 boiler plates

EN 10028-3 plates from fine-grain steels

EN 10083 plates from steels designated for heat treatment

EN 10084 plates from carburising steels

EN 10149-2 hot-rolled plates with high yield strength for cold forming

0000000 abrasion-resistant plates

0000000 plates resistant to effects of hydrogen atmosphere

0000000 plates from steels according to ASME standard

0000000 ship building quality plates

0000000 stainless steel plates

Further possibilities:

- cut sizes and forgings from plates – separation by cutters,

blowtorch, plasma and laser according ISO EN 9013

- fixed dimensions from unreeling equipment

- edging up to 16 m of individual lengths

- blasting and conservation

- examination by ultrasound in accordance

with SEL 072/77, EN 10160

- acceptance by all known attesting companies,

e.g.: DB/TÜV/LRS/GL/ČD

We substantiate each order with inspection certificates

in accordance with EN 10204/3.1 or 2.2

We assure you reliable and timely processing of your order.

Figures in the tables given in this catalogue are for informational purposes only.

UnionOcel s.r.o.

Panská 1444/14

742 21 KOPŘIVNICE

tel.: +420 556 209 911

fax: +420 556 209 955

e-mail:info@unionocel.cz

www.unionocel.cz

03

www.unionocel.sk

www.unionocel.eu

www.unionocel.com

UniOcel Big_kat_2009_A.indd 3 2.3.2009 12:02:39

Metal plate processing

Flame cutting of shaped elements

Flame cutting with an autogenous flame cutting machine ESAB SUPRATEX SXE-P 6000

Plate thickness [mm] Table Dimensions [mm]

3 - 310 4 000 x 24 000

Flame cutting with aa plasma arc-cutting machine ESAB EAGLE 3500 and PIERCE RUM 3500

Plate thickness [mm] Table Dimensions [mm]

1,5 - 50 3 000 x 24 000

Shear cutting

Hydraulic shear CNC HGM 3020

Max. sheet width Max. sheet thickness Max. sheet thickness Max. sheet weight

[mm] Re 450 MPa [mm] Re 700 MPa [mm] [t]

3 080 20 13 21

On the Stock

04

UniOcel Big_kat_2009_A.indd 4 2.3.2009 12:02:44

Plates from non-alloy constructional steels EN 10025-2 [EN 10025]

Inspection certificates in accordance with EN 10204/3.1

MATERIAL DIMENSIONS

Material Dimensions [mm] Non-standard

Marking number thickness

Thickness Width Length to

7,9,11,13,14,16,17,

S 235 JR 1.0038 3 - 250 1 000 - 4 000 16 000

18,22,26,28,32

S 355 J2 1.0577 3 - 300 1 000 - 3 500 16 000 7,13,14,18,22,28,32

S 355 J2C 1.0579 3 - 30 1 000 - 3 500 16 000

CHEMICAL COMPOSITION

Content of C [%max.] Content of elements - mass [%max.]

Marking Material for nominal thick. [mm]

number ≤16 > 16 > 40 Si Mn P S N Cu

≤ 40

S 235 JR 1.0038 0,19 0,19 0,23 0,045 0,045 0,014

S 235 J0 1.0114 0,19 0,19 0,19 - 1,50 0,040 0,040 0,014 0,60

S 235 J2 1.0117 0,19 0,19 0,19 0,035 0,035 -

S 275 JR 1.0044 0,24 0,24 0,25 0,045 0,045 0,014

S 275 J0 1.0143 0,21 0,21 0,21 - 1,60 0,040 0,040 0,014 0,60

S 275 J2 1.0145 0,21 0,21 0,21 0,035 0,035 -

S 355 JR 1.0045 0,27 0,27 0,27 0,045 0,045 0,014

S 355 J0 1.0553 0,23 0,23 0,24 0,040 0,040 0,014

0,60 1,70 0,60

S 355 J2 1.0577 0,23 0,23 0,24 0,035 0,035 -

S 355 K2 1.0596 0,23 0,23 0,24 0,035 0,035 -

MECHANICAL PROPERTIES

Min. yield strength R eH [MPa] Tensile strength R m [MPa]

for nominal thick. [mm] for nominal thick. [mm]

Marking

≤16 ≤> 40

16 > 40 > 63 > 80 > 100 > 150 > 200 > 250 3 > 100 > 150 > 250

≤ 63 ≤ 80 ≤ 100 ≤ 150 ≤ 200 ≤ 250 ≤ 400 ≤ 100 ≤ 150 ≤ 250 ≤ 400

S 235 JR - -

S 235 J0 235 225 215 215 215 195 185 175 - 360-510 350-500 340-490 -

S 235 J2 165 330-480

S 275 JR - -

On the Stock

S 275 J0 275 265 255 245 235 225 215 205 - 410-560 400-540 380-540 -

S 275 J2 195 380-540

S 355 JR - -

S 355 J0 - -

355 345 335 325 315 295 285 275 470-630 450-600 450-600

S 355 J2 265 450-600

S 355 K2 265 450-600

Min. ductility [%] Lo=5,65 √ So Testing Min. impact energy

Orient. for nominal thick. [mm] tempe- KV [J]

Marking of test rature

≥ 3,0 > 40 > 63 > 100 > 150 > 250 > 150 > 250

≤ 40 ≤ 63 ≤ 100 ≤ 150 ≤ 250 ≤ 400 [°C] ≤ 150 ≤ 250 ≤ 400

S 235 JR l 26 25 24 22 21 - 20

-

S 235 J0 - 0 27 27

S 235 J2 t 24 23 22 22 21 21[l+t] - 20 27

S 275 JR l 23 22 21 19 18 - 20

-

S 275 J0 - 0 27 27

S 275 J2 t 21 20 19 19 18 18[l+t] - 20 27

S 355 JR l 22 21 20 18 17 - 20

S 355 J0 - 0 27 27

S 355 J2 17[l+t] - 20 27

S 355 K2 t 20 19 18 18 17 17[l+t] - 20 40 33 33

05

UniOcel Big_kat_2009_A.indd 5 2.3.2009 12:02:54

Abrasion resistant plates

Inspection certificates in accordance with EN 10204/2.2/3.1

MATERIAL DIMENSIONS

Material Dimensions [mm]

Marking number Thickness Width Length to

XAR 300 1.8704 3 - 50 1 000 - 2 500 12 000

XAR 400 1.8714 3 - 100 1 000 - 3 000 12 000

XAR 400 W - 4 - 40 1 000 - 2 500 12 000

XAR 450 1.8722 3 - 100 1 000 - 3 000 12 000

XAR 500 1.8734 3 - 100 1 000 - 3 000 12 000

XAR 600 1.8735 4 - 40 1 000 - 2 500 12 000

Fora 400 - 4 - 100 1 000 - 3 000 14 000

Durostat 400 - 6 - 100 1 000 - 2 500 12 000

Durostat 500 - 10 - 50 1 000 - 2 500 12 000

Dillidur 325 L 1.8705 5 - 50 1 000 - 3 000 12 000

Dillidur 400 V 1.8715 6 - 150 1 000 - 3 000 12 000

Dillidur 500 V 1.8721 8 - 100 1 000 - 3 000 12 000

Brinar 400 Cr 1.8709 5 - 25 1 000 - 2 500 12 000

X 120 Mn 12 1.3401 1,5 - 40 1 000 - 2 000 6 000

Domex Wear (welded) - 3 - 6 1 000 - 2 500 13 000

ALTRIX / SP Further details s. special prospectuses.

On the Stock

06

UniOcel Big_kat_2009_A.indd 6 2.3.2009 12:03:01

CHEMICAL COMPOSITION

Material Content of elements - mass [%max.]

Marking number C Si Mn P S Cr Mo Cu Ni B

max. max. max. max. max. max.

XAR 300 1.8704 max.0,21 max.0,65 max.1,50 0,025 0,025 max.1,20 0,30 - - 0,005

XAR 400 1.8714 max.0,20 max.0,80 max.1,50 0,025 0,010 max.1,00 0,50 - - 0,005

XAR 400 W - max.0,26 max.0,80 max.1,30 0,025 0,025 max.1,20 0,60 - - 0,005

XAR 450 1.8722 max.0,21 max.0,80 max.1,50 0,025 0,012 max.1,30 0,50 0,30 - 0,005

XAR 500 1.8734 max.0,28 max.0,80 max.1,50 0,025 0,010 max.1,00 0,50 - - 0,005

XAR 600 1.8735 max.0,40 max.0,80 max.1,50 0,025 0,010 max.1,50 0,50 - 1,50 0,005

Fora 400 - max.0,20 - max.1,40 0,020 0,003 max.1,00 0,20 - - 0,003

Durostat 400 - max.0,18 max.0,60 max. 2,10 0,025 0,010 max.1,00 0,50 - - 0,005

Durostat 500 - max.0,30 max.0,60 max. 2,10 0,025 0,010 max.1,00 0,50 - - 0,005

Dillidur 325 L 1.8705 max.0,23 0,30-0,70 1,20-1,70 0,025 0,010 1,00-1,60 0,50 0,60 0,60

Dillidur 400 V 1.8715 max.0,20 max.0,50 max.1,80 0,025 0,010 max.1,50 0,50 - 0,80 0,005

Dillidur 500 V 1.8721 max.0,30 max.0,50 max.1,60 0,025 0,010 max.1,50 0,50 - 1,00 0,005

Brinar 400 Cr 1.8709 max.0,18 max.0,50 ~1,40 0,015 0,005 ~1,50 0,60 - 1,20 -

X 120 Mn 12 1.3401 1,10-1,30 0,30-0,50 12,0-13,0 0,100 0,040 max.1,50 - - - -

Domex Wear - ~ 1,17 ~ 0,30 ~ 1,80 0,010 0,010 ~ 0,30 ~ 0,10 - - -

ALTRIX / SP Further details s. special prospectuses.

MECHANICAL PROPERTIES

Marking Mat. Yield strength Tensile strength Ductility A Hardness accor-

number R eH [MPa] R m [MPa] [%] ding to Brinell

XAR 300 1) 1.8704 ~ 700 1000 12 270 - 340

XAR 400 2 ) 1.8714 ~ 1050 ~ 1250 min. 12 360 - 440

XAR 400 W 2 ) 4) - ~ 1100 ~ 1250 ~ 12 360 - 430

XAR 450 2 ) 1.8722 ~ 1200 ~ 1350 ~ 10 410 - 490

XAR 500 2 ) 1.8734 ~ 1300 ~ 1600 min. 9 450 - 530

XAR 600 2 ) 1.8735 ~ 1700 ~ 2000 ~ 10 min. 550

Fora 400 2 ) - ~ 1100 ~ 1350 ~ 13 360 - 440

Durostat 400 2 ) - ~ 1000 ~ 1250 ~ 10 360 - 440

Durostat 500 2 ) - ~ 1200 ~ 1550 ~8 460 - 540

On the Stock

Dillidur 325 L 1.8705 ~ 650 ~ 1000 ~ 13 325

Dillidur 400 V 2 ) 1.8715 ~ 1000 ~ 1300 ~ 12 370 - 430

Dillidur 500 V 2 ) 1.8721 ~ 1300 ~ 1650 ~8 450 - 530

Brinar 400 Cr 1) 1.8709 ~ 900 ~ 1200 ~ 12 340 - 440

X 120 Mn 12 2 ) 1.3401 min. 350 800 -1100 min. 40 200 - 500

Domex Wear 1) - ~ 800 800 - 950 ~ 15 ~ 285

ALTRIX / SP Further details s. special prospectuses.

1 2 3

) - Normalising, ) - Hardened in water, ) - Hardened in atmosphere, 4) - Abrasion resistance guaranteed up to 400°C

07

UniOcel Big_kat_2009_A.indd 7 2.3.2009 12:03:06

Boiler plates EN 10028-2

Inspection certificates in accordance with EN 10204/3.1. and 3.2. TÜV

MATERIAL DIMENSIONS

Material Dimensions [mm] Non-standard

Marking number thicknesses

Thickness Width Length to

P 265 GH 1.0425 3 - 250 1 000 - 4 000 14 000 P 265 GH: 7,9,11,13,

P 295 GH 1.0481 5 - 120 1 000 - 3 500 12 000 14,17,26,28,32,42,

16 Mo 3 1.5415 1,5 - 200 1 000 - 3 000 12 000 52,75,85,95,125

13 Cr Mo 4-5 1.7335 3 - 160 1 000 - 3 000 12 000 P 295 GH: 13,14,18,

10 Cr Mo 9-10 1.7380 3 - 120 1 000 - 2 500 12 000 26,28

Delivery conditions according to ADW 1/10, TRB 100, TRD 101, VD-TÜV-WLB 354/1 and 357/1.

Impact energy substantiated in inspection certificate

Tensile test at temperature of +300°C conducted for each cast

CHEMICAL COMPOSITION

Material Type Content of elements 2 ) - mass [%max.]

Marking number

division

1

] C Si Mn P S Al

max. max. max. in all

P 265 GH 1.0425 UQ max.0,20 0,400 0,50-1,40 0,030 0,025 min.0,020

P 295 GH 1.0481 UQ 0,08-0,20 0,400 0,90-1,50 0,030 0,025 min.0,020

4

16 Mo 3 1.5415 LE 0,12-0,20 0,350 0,40-0,90 0,030 0,025 ]

4

13 Cr Mo 4-5 1.7335 LE 0,08-0,18 0,350 0,40-1,00 0,030 0,025 ]

10 Cr Mo 9-10 1.7380 LE 0,08 6)-0,147) 0,500 0,40-0,80 0,030 0,025 4

]

Content of elements 2 ) - mass [%max.]

Marking

Cr Cu Nb Ni Ti V Cr+Cu+Mo+Ni

max. 3 ) Mo max. max. max. max. max.

P 265 GH max.0,30 0,300 max.0,08 0,020 0,300 0,300 0,020 0,700

P 295 GH max.0,30 0,300 max.0,08 0,020 0,300 0,300 0,020 0,700

16 Mo 3 max.0,30 0,300 0,25-0,35 - 0,300 - - -

13 Cr Mo 4-5 0,70-1,15 3) 0,300 0,40-0,60 - - - - max.0,5

10 Cr Mo 9-10 2,00-2,50 0,300 0,90-1,10 - - - - -

1

) - UQ = non-alloy quality steel, LE = alloy quality steel.

2

) - Elements not shown in this table must not be intentionally added to steel without the consent of the customer, with

the exception of those necessary for the manufacturing process. It is necessary to conduct all relevant measures in order

to prevent transfer of metal elements from metal waste or other materials used in manufacture which have a negative impact

On the Stock

on the mechanical properties and usability of the steel.

3

) - Upon ordering a lower content of Cu and higher admissible content of Sn may be agreed upon e.g. with regard to malleability.

4

) - Stipulate content of Al in cast and state in certification.

5

) - Should resistance to compressed hydrogen be important, a minimum content of Cr 0.80% may be agreed upon ordering.

6

) - For thicknesses of products less than 10 mm a minimum content of C 0.06% may be agreed upon ordering.

7

) - For thicknesses of products over 150 mm a maximum content of C 0.17% may be agreed upon ordering.

08

UniOcel Big_kat_2009_A.indd 8 2.3.2009 12:03:10

MECHANICAL PROPERTIES

Impact energy

Nominal Yield Tensile Ductility [KV] + [J]

W.Nr. Thermal thick. [mm] strength strength A min.

Marking material proces- R eH Rm at a temperature

[%] in °C of

number sing

[MPa] [MPa] min.

> ≤ min. - 20 0 + 20

16 265

16 40 255

410-530

40 60 245

P 265 GH 1.0425 +N 22 27 34 40

60 100 215

100 150 200 400-530

150 250 185 390-530

16 295

16 40 290

460-580

40 60 285

P 295 GH 1.0481 +N 21 27 34 40

60 100 260

100 150 235 440-570

150 250 220 430-570

16 275

16 40 270 440-590

40 60 260

16 Mo 3 1.5415 +N 22 a) a) 31

60 100 240 430-580

100 150 220 420-570

150 250 210 410-570

16 300

450-600 a) a) 31

+NT 16 60 290

13 Cr Mo 4-5 1.7335 60 100 270 440-590 19 a) a) 27

+NT/+QT 100 150 255 430-580

a) a) a)

+QT 150 250 245 420-570

16 310

+NT 16 40 300 480-630 18 a) a) 31

40 60 290

10 Cr Mo 9-10 1.7380

+NT/+QT 60 100 280 470-620

100 150 260 460-610 17 a) a) 27

On the Stock

+QT

150 250 250 450-600

+N - normalized

+NT - normalized and tempered

+QT - quenched and tempered

a) - A value may be agreed at the time of enquiry and order

09

UniOcel Big_kat_2009_A.indd 9 2.3.2009 12:03:14

Plates from fine-grain steels EN 10028 - 3

Inspection certificates in accordance with EN 10204/3.1. and 3.2. TÜV

MATERIAL DIMENSIONS

Material Dimensions [mm]

Marking number Thickness Width Length to

P 275 NH 1.0487 5 - 120 1 000 - 4 000 14 000

P 275 NL 1 1.0488 5 - 120 1 000 - 4 000 14 000

P 275 NL 2 1.1104 5 - 120 1 000 - 4 000 14 000

P 355 N 1.0562 3 - 220 1 000 - 3 500 13 000

P 355 NH 1.0565 3 - 220 1 000 - 3 500 13 000

P 355 NL 1 1.0566 3 - 220 1 000 - 3 500 13 000

P 355 NL 2 1.1106 3 - 220 1 000 - 3 500 13 000

P 460 NH 1.8935 4 - 180 1 000 - 3 000 13 000

P 460 NL 1 1.8915 4 - 180 1 000 - 3 000 13 000

P 460 NL 2 1.8918 4 - 180 1 000 - 3 000 13 000

Delivery conditions according to ADW 1/10, TRB 100, TRD 101, VD-TÜV-WLB 354/1 and 357/1

Impact energy substantiated in inspection certificates

Values of impact energy for quality P 275 - P 460 are attested at temperature of - 50°C

Tensile test at temperature of +400°C conducted for each cast

CHEMICAL COMPOSITION

Material Type Content of elements - mass [%max.]

Marking number

division

1

] C Si Mn P S Al

max. max. max. max. in all

P 275 NH 1.0487

UQ 0,025 0,015

P 275 NL 1 1.0488 0,16 0,40 0,80-1,50 min.0,020 2 )

P 275 NL 2 1.1104 UE 0,020 0,010

P 355 N 1.0562

P 355 NH 1.0565 UQ 0,025 0,015

0,18 0,50 1,10-1,70 min.0,020 2 )

P 355 NL 1 1.0566

P 355 NL 2 1.1106 UE 0,020 0,010

P 460 NH 1.8935

0,025 0,015

P 460 NL 1 1.8915 LE 0,20 0,60 1,00-1,70 min.0,020 2 )

P 460 NL 2 1.8918 0,020 0,010

On the Stock

Content of elements - mass [%max.]

Marking

Cr Cu Mo N Nb Ni Ti V Nb+Ti+V

max. max. 3 ) max. max. max. max. max. max. max.

P 275 NH

P 275 NL 1 0,30 3) 0,30 3) 0,08 3) 0,012 0,05 0,50 0,03 0,05 0,05

P 275 NL 2

P 355 N

P 355 NH

0,30 3) 0,30 3) 0,08 3) 0,012 0,05 0,50 0,03 0,10 0,12

P 355 NL 1

P 355 NL 2

P 460 NH

P 460 NL 1 0,30 0,70 4) 0,10 0,025 0,05 0,80 0,03 0,20 0,22

P 460 NL 2

1

) - UQ = non-alloy quality steel, UE = non-alloy hardened steel, LE = alloy hardened steel.

2

) - If nitrogen is additionally bound by columbium, titanium or vanadium, the stipulation for minimum aluminium content does not apply.

3

) - The total of mass contents of chrome, copper and molybdenum may be maximum 0.45 %.

4

) - If the mass content of copper is greater than 0.30 %, the mass content of nickel must be minimally one half greater than

the mass content of copper.

10

UniOcel Big_kat_2009_A.indd 10 2.3.2009 12:03:20

MECHANICAL PROPERTIES

Thermal Min. yield strength R eH [MPa]

Marking Material treat- for. nominal thick. [mm]

number ment > 16 > 40 > 60 > 100 > 150

1

) ≤16 ≤ 40 ≤ 60 ≤ 100 ≤ 150 ≤ 250

P 275 NH 1.0487

P 275 NL 1 1.0488 275 265 255 235 225 215

P 275 NL 2 1.1104

Normalizing

P 355 N 1.0562

P 355 NH 1.0565

355 345 335 315 305 295

P 355 NL 1 1.0566

P 355 NL 2 1.1106

P 460 NH 1.8935

1 1

P 460 NL 1 1.8915 460 445 430 400 ) )

P 460 NL 2 1.8918

Tensile strength R m [MPa] Min. ductility A [%]

for. nominal thick. [mm] for. nominal thick. [mm]

Marking

> 60 > 100 > 150 > 60 > 150

≤60 ≤ 100 ≤ 150 ≤ 250 > 60 ≤ 150 ≤ 250

P 275 NH

P 275 NL 1 390-510 370-490 360-480 350-470 24 23 23

P 275 NL 2

P 355 N

P 355 NH 1

490-630 470-610 460-600 450-590 22 21 )

P 355 NL 1

P 355 NL 2

P 460 NH 16

P 460 NL 1 570-720 2 ) 540-710 1

) 1

) 17 in only 1

)

P 460 NL 2 100 mm

1

) According to negotiation,

2

) For thicknesses up to 16 mm is acceptable the highest value 730 MPa

Impact energy KV min. [J] at temperatures [ o C]

Nominal

Thermal

Marking thicknesses

treatment Test in crosswise direction Test in lenghtwise direction 2 )

[mm]

-50 -40 -20 0 +20 -50 -40 -20 0 +20

On the Stock

P ... N

- - 30 40 50 - - 45 65 75

P ... NH

5 -250 1) Normalizing

P ... NL 1 - 27 35 50 60 30 40 50 70 80

P ... NL 2 27 30 40 60 70 42 45 55 75 85

1

) For the steel P460NH, P460NL1 and P460NL2 with the thicknesses up to 100 mm

2

) Up to 40 mm

11

UniOcel Big_kat_2009_A.indd 11 2.3.2009 12:03:25

Plates from high-strength fine-grain steels EN 10025-6

Heat treated [EN 10137]

Inspection certificates in accordance with EN 10204/3.1

MATERIAL DIMENSIONS

Material Dimensions [mm]

Marking number Thickness Width Length to

S 690 Q 1.8931

S 690 QL 1.8928 2 - 200 1 000 - 3 500 13 000

S 690 QL1 1.8988

S 890 Q 1.8940

S 890 QL 1.8983 4 - 120 1 000 - 3 000 12 000

S 890 QL1 1.8925

S 960 Q 1.8941

4 - 100 1 000 - 3 000 12 000

S 960 QL 1.8933

CHEMICAL COMPOSITION

Content of elements - mass [%max.]

Marking

C Si Mn P S N B Cr

max. max. max. max. max. max. max. max.

S 690 Q 0,025 0,015

S 690 QL

0,020 0,010

S 690 QL1

S 890 Q 0,025 0,015

0,20 0,80 1,70 0,015 0,0050 1,50

S 890 QL

0,020 0,010

S 890 QL1

S 960 Q 0,025 0,015

S 960 QL 0,020 0,010

Content of elements - mass [%max.]

Marking

Cu Mo Nb Ni Ti V Zr

max. max. max. max. max. max. max.

S 690 Q

S 690 QL

S 690 QL1

S 890 Q

On the Stock

0,50 0,70 0,06 2,0 0,05 0,12 0,15

S 890 QL

S 890 QL1

S 960 Q

S 960 QL

MECHANICAL PROPERTIES

Min. yield strength Tensile strength Duct. Impact energy KV min. [J]

ReH[MPa] for th. [mm] Rm[MPa] for thick. [mm] A [%] at temperatures

Marking

≥3 > 50 > 100 ≥3 > 50 > 100

≤ 50 ≤ 100 ≤ 150 ≤ 50 ≤ 100 ≤ 150 min. 0 oC - 20 o C - 40 o C - 60 o C

S 690 Q 40 30 - -

S 690 QL 690 650 630 770-940 760-930 710-900 14 50 40 30 -

S 690 QL1 60 50 40 30

S 890 Q 40 30 - -

S 890 QL 890 830 - 940-1100 880-1100 - 11 50 40 30 -

S 890 QL1 60 50 40 30

S 960 Q 40 30 - -

960 - - 980-1150 - - 10

S 960 QL 50 40 30 -

Delivery program: NA-XTRA, Dillimax, ALDUR, Supralsim, X ABO

12

UniOcel Big_kat_2009_A.indd 12 2.3.2009 12:03:30

Hot-rolled plates with high yield strength for cold forming EN 10149-2

Inspection certificates in accordance with EN 10204/3.1

MATERIAL DIMENSIONS

Material Dimensions [mm]

Marking number Thickness Width Length to

S 355 MC 1.0976 2 - 25 1 000 - 2 500 12 000

S 420 MC 1.0980 2 - 25 1 000 - 2 500 12 000

S 460 MC 1.0982 2 - 25 1 000 - 2 500 12 000

S 500 MC 1.0984 2 - 25 1 000 - 2 500 12 000

S 550 MC 1.0986 2 - 25 1 000 - 2 500 12 000

S 650 MC 1.8976 2 - 25 1 000 - 2 500 12 000

S 700 MC 1.8974 2 - 25 1 000 - 2 500 12 000

CHEMICAL COMPOSITION

Content of elements - mass [%max.]

Marking

C Si Mn P S Al - celk. Nb Ti

max. max. max. max. max. min. max. max.

S 315 MC 0,12 0,50 1,50 0,025 0,020 0,015 0,09 0,15

S 355 MC 0,12 0,50 1,50 0,025 0,020 0,015 0,09 0,15

S 420 MC 0,12 0,50 1,60 0,025 0,015 0,015 0,09 0,15

S 460 MC 0,12 0,50 1,60 0,025 0,015 0,015 0,09 0,15

S 500 MC 0,12 0,50 1,70 0,025 0,015 0,015 0,09 0,15

S 550 MC 0,12 0,50 1,80 0,025 0,015 0,015 0,09 0,15

S 600 MC 0,12 0,50 1,90 0,025 0,015 0,015 0,09 0,22

S 650 MC 0,12 0,60 2,00 0,025 0,015 0,015 0,09 0,22

S 700 MC 0,12 0,60 2,10 0,025 0,015 0,015 0,09 0,22

MECHANICAL PROPERTIES

Min. yield Ductility [%]

Marking strength Tensile strength A 80 A6

1

Rm ) [MPa] < 3 mm ≥ 3 mm

ReH 1) [MPa] min. min.

S 315 MC 315 390 - 510 20 24

S 355 MC 355 430 - 550 19 23

On the Stock

S 420 MC 420 480 - 620 16 19

S 460 MC 460 520 - 670 14 17

S 500 MC 500 550 - 700 12 14

S 550 MC 550 600 - 760 12 14

S 600 MC 600 650 - 820 11 13

S 650 MC 650 700 - 880 10 12

S 700 MC 700 750 - 950 10 12

Delivery program: ALFORM, DOMEX, PAS

13

UniOcel Big_kat_2009_A.indd 13 2.3.2009 12:03:38

Plates from non-alloy constructional fine-grain EN 10025-3

Normalised [EN 10113-2]

Inspection certificates in accordance with EN 10204/3.1

MATERIAL DIMENSIONS

Material Dimensions [mm]

Marking number Thickness Width Length to

S 355 NL 1.0546 3 - 220 1 000 - 4 000 16 000

S 420 NL 1.8912 8 - 120 1 000 - 3 500 16 000

S 460 NL 1.8903 4 - 180 1 000 - 3 500 16 000

CHEMICAL COMPOSITION

Material Content of elements - mass [%max.]

Marking number C Si Mn P S Nb V

max. max. max. max. max. max.

S 355 NL 1.0546 0,20 0,55 0,85-1,75 0,14

S 420 NL 1.8912 0,22 0,65 0,95-1,80 0,030 0,025 0,06 0,22

S 460 NL 1.8903 0,22 0,65 0,95-1,80 0,22

Material Content of elements - mass [%max.]

Marking number Al Ti Cr Ni Mo Cu N

min. max. max. max. max. max. max.

S 355 NL 1.0546 0,55 0,017

S 420 NL 1.8912 0,015 0,06 0,35 0,85 0,13 0,60 0,027

S 460 NL 1.8903 0,85 0,027

MECHANICAL PROPERTIES

Min. yield strength ReH[MPa] Tensile strength Rm[MPa]

for thick. [mm] for thick. [mm]

Marking

> 16 > 40 > 63 > 80 > 100 > 150 > 200 > 100 > 200

≤16 ≤ 100

≤ 40 ≤ 63 ≤ 80 ≤ 100 ≤ 150 ≤ 200 ≤ 250 ≤ 200 ≤ 250

S 355 NL 355 345 335 325 315 295 285 275 470-630 450-600 450-600

S 420 NL 420 400 390 370 360 340 330 320 520-680 500-650 500-650

S 460 NL 460 440 430 410 400 380 370 - 550-720 530-710 -

Min. ductillity [%] Lo=5,65 √ So Min. impact energy KV [J]

for thick. [mm] Testing temperature [°C]

On the Stock

Orient.

Marking of test

≤ 16 > 16 > 40 > 63 > 80 > 200

+20 0 -10 -20 -30 -40 -50

≤ 40 ≤ 63 ≤ 80 ≤ 200 ≤ 250

S 355 NL 22 22 22 21 21 21 lengthwise 63 55 51 47 40 31 27

S 420 NL 19 19 19 18 18 18

S 460 NL 17 17 17 17 17 - crosswise 40 34 30 27 23 20 16

14

UniOcel Big_kat_2009_A.indd 14 2.3.2009 12:03:42

Plates from non-alloy constructional fine-grain EN 10025-4

Termomechanical rolled [EN 10113-3]

Inspection certificates in accordance with EN 10204/3.1

MATERIAL DIMENSIONS

Material Dimensions [mm]

Marking number Thickness Width Length to

S 355 ML 1.8834 8 - 120 1 000 - 4 000 16 000

S 420 ML 1.8836 8 - 120 1 000 - 3 500 16 000

S 460 ML 1.8838 8 - 120 1 000 - 3 500 16 000

CHEMICAL COMPOSITION

Material Content of elements - mass [%max.]

Marking number C Si Mn P S Nb V

max. max. max. max. max. max.

S 355 ML 1.8834 0,16 0,55 1,70 0,12

S 420 ML 1.8836 0,18 0,55 1,80 0,030 0,025 0,06 0,14

S 460 ML 1.8838 0,18 0,65 1,80 0,14

Material Content of elements - mass [%max.]

Marking number Al Ti Cr Ni Mo Cu N

min. max. max. max. max. max. max.

S 355 ML 1.8834 0,55 0,13 0,017

S 420 ML 1.8836 0,015 0,06 0,35 0,85 0,23 0,60 0,027

S 460 ML 1.8838 0,85 0,23 0,027

MECHANICAL PROPERTIES

Min. yield strength ReH[MPa] Tensile strength Rm[MPa]

for thick. [mm] for thick. [mm]

Marking

≤16 > 16 > 40 > 63 > 80 > 100 ≥ 40 > 40 > 63 > 80 > 100

≤ 40 ≤ 63 ≤ 80 ≤ 100 ≤ 150 ≤ 63 ≤ 80 ≤ 100 ≤ 150

S 355 ML 355 345 335 325 325 320 470-630 450-610 440-600 440-600 430-590

S 420 ML 420 400 390 380 370 365 520-680 500-660 480-640 470-630 460-620

S 460 ML 460 440 430 410 400 385 540-720 530-710 510-690 500-680 490-660

Min. impact energy KV [J]

Testing temperature [°C]

On the Stock

Orient.

Marking Min. ductillity [%] Lo=5,65 √ So of test

+20 0 -10 -20 -30 -40 -50

S 355 ML 22 lengthwise 63 55 51 47 40 31 27

S 420 ML 19

S 460 ML 17 crosswise 40 34 30 27 23 20 16

15

UniOcel Big_kat_2009_A.indd 15 2.3.2009 12:03:47

Plates resistant to effects of hydrogen atmosphere

Inspection certificates in accordance with EN 10204/3.1

MATERIAL DIMENSIONS

Material Dimensions [mm]

Marking number Thickness Width Length to

12 Cr Mo 19 5 1.7362 5 - 60 1 000 - 2 500 12 000

CHEMICAL COMPOSITION

Material Content of elements - mass [%max.]

Marking number C Si Mn P S Cr Mo

max. max. max.

12 Cr Mo 19 5 1.7362 0,08-0,15 0,50 0,30-0,60 0,025 0,020 4,00-6,00 0,45-0,65

MECHANICAL PROPERTIES

Yield Tensile Ductility A Hardness

Marking strength strength R m [%] KV [J] according

R eH [MPa] [MPa] to Brinell

12 Cr Mo 19 5 min. 390 590 - 740 min. 17 min. 62 175 - 220

Riffled plates according to DIN 59 220

Inspection certificates in accordance with EN 10204/3.1

- for qualities S 235 JRG2 and S 355 J2G3 in accordance with EN 10025

Inspection certificates in accordance with EN 10204/3.1 C LRS

- for shipbuilding qualities Grad A and EHS 36

MATERIAL DIMENSIONS

Material Dimensions [mm]

Marking number Thickness Width Length to

S 235 JRG2 1.0038 3/5 - 25/27 1 500 - 2 500 12 000

S 355 J2G3 1.0570 4/6 - 15/17 1 500 - 2 500 12 000

On the Stock

16

UniOcel Big_kat_2009_A.indd 16 2.3.2009 12:03:52

Plates from steels designated for heat treatment EN 10083

Inspection certificates in accordance with EN 10204/3.1

MATERIAL DIMENSIONS

Material Dimensions [mm]

Marking number Thickness Width Length to

2 C 45 1.1191 2 - 150 1 000 - 3 000 12 000

2 C 60 1.1221 2 - 150 1 000 - 2 000 12 000

25 Cr Mo 4 1.7218 3 - 150 1 000 - 2 000 8 000

42 Cr Mo 4 1.7225 3 - 200 1 000 - 2 500 10 000

CHEMICAL COMPOSITION

Material Content of elements - mass [%max.]

Marking number C Si Mn P S Cr Mo

max. max. max.

2 C 45 1.1191 0,42-0,50 0,40 0,50-0,80 0,035 0,035 max. 0,40 max. 0,10

2 C 60 1.1221 0,57-0,65 0,40 0,60-0,90 0,035 0,035 max. 0,40 max. 0,10

25 Cr Mo 4 1.7218 0,22-0,29 0,40 0,60-0,90 0,035 0,035 0,90-1,20 0,15-0,30

42 Cr Mo 4 1.7225 0,38-0,45 0,40 0,60-0,90 0,035 0,035 0,90-1,20 0,15-0,30

MECHANICAL PROPERTIES NORMALISED CONDITION

Min. yield strength ReH[MPa] Min. tensile strength Rm[MPa]

for thick. [mm] for thick. [mm] Min. ductility A [%]

Marking

≤ 16 ≤ 100 ≤ 250 ≤ 16 ≤ 100 ≤ 250 ≤ 16 ≤ 100 ≤ 250

2 C 45 340 305 275 620 580 560 16 16 16

2 C 60 380 340 310 710 670 650 10 11 11

25 Cr Mo 4 380 - 550 600 - 850 ~ 22 ~ 22 ~ 22

42 Cr Mo 4 600 - 800 750 - 1000 ~ 15 ~ 15 ~ 15

Normalising of these steels improves workability without affecting hardenability.

Plates from carburising steel EN 10084

Inspection certificates in accordance with EN 10204/3.1

MATERIAL DIMENSIONS

On the Stock

Material Dimensions [mm]

Marking number Thickness Width Length to

16 Mn Cr 5 1.7131 3 - 200 1 000 - 2 000 12 000

20 Mn Cr 5 1.7147 3 - 200 1 000 - 2 000 12 000

CHEMICAL COMPOSITION

Material Content of elements - mass [%max.]

Marking number Si P S

C max. Mn max. max. Cr

16 Mn Cr 5 1.7131 0,14-0,19 0,40 1,00-1,30 0,035 0,035 0,80-1,10

20 Mn Cr 5 1.7147 0,17-0,22 0,40 1,10-1,40 0,035 0,035 1,00-1,30

HARDNESS - THERMAL TREATMENT - SOFT ANNEALING

Marking Hardness according to Brinell

16 Mn Cr 5 max. 207

20 Mn Cr 5 max. 217

17

UniOcel Big_kat_2009_A.indd 17 2.3.2009 12:03:56

Ship building quality plates

According to prescriptions of classification companies

MATERIAL DIMENSIONS

Dimensions [mm]

Marking

Thickness Width Length to

GL - A,B,D,E

GL - A 32, D 32, E 32 3 - 200 1 000 - 4 000 16 000

GL - A 36, D 36, E 36

MECH. PROPERTIES FOR NORMAL STEEL, THICK. UP TO 50 mm

Testing Minimum impact energy

Yield Tensile

Ductility A tempera- KV [J]

Marking strength R eH strength R m [%] min. ture

[MPa] [MPa] lengthwise crosswise

[°C] direction direction

GL - A - - -

GL - B 0 27 20

min. 235 400-490 22

GL - D -20 27 20

GL - E -40 27 20

MECH. PROPERTIES FOR NORMAL STEELS WITH INCREASED STRENGTH, THICK. UP TO 50 mm

Testing Minimum impact energy

Yield Tensile KV [J]

Ductility A tempera-

Marking strength R eH strength R m

[%] min. ture

[MPa] [MPa] lengthwise crosswise

[°C] direction direction

GL - A 32 0 31 22

GL - D 32 min. 315 440-590 22 -20 31 22

GL - E 32 -40 31 22

GL - A 36 0 34 24

GL - D 36 min. 355 490-620 21 -20 34 24

GL - E 36 -40 34 24

Plates from steel according to ASME - standard

On the Stock

MATERIAL DIMENSIONS

Dimensions [mm] Non - standard

Marking thickness

Thickness Width Length to

7,9,11,13,14,17,26,28,

SA 516 Grade 60 3 - 130 1 000 - 4 000 14 000

32,42,52,75,85,95,125

SA 516 Grade 70 3 - 200 1 000 - 3 500 13 000 13,14,17,26,28

SA 387 Grade 12 CL 2 3 - 150 1 000 - 3 000 12 000

SA 387 Grade 22 CL 2 4 - 80 1 000 - 2 500 12 000

SA 283 Grade C 3 - 15 1 000 - 2 500 12 000

SA 285 Grade C 3 - 15 1 000 - 2 500 12 000

SA 387 Grade 5 5 - 60 1 000 - 2 500 12 000

SA 203 Grade E 5 - 30 1 000 - 2 000 6 000

18

UniOcel Big_kat_2009_A.indd 18 2.3.2009 12:04:01

Plates resistant to atmospheric effects EN 10025-5 [EN 10155]

Inspection certificates in accordance with EN 10204/3.1

MATERIAL DIMENSIONS

Material Dimensions [mm]

Marking number Thickness Width Length to

S355J0WP 1.8945 1 - 12 1 000 - 2 500 max. 12 000

S355J2WP 1.8946 1 - 12 1 000 - 2 500 max. 12 000

S355J0W 1.8959 3 - 50 1 000 - 2 500 max. 12 000

S355J2W 1.8965 3 - 50 1 000 - 2 500 max. 12 000

CHEMICAL COMPOSITION

Material Content of elements - mass [%max.]

Marking number C Si Mn P S Cr Cu N Addition of nitro-

max. max. max. max. gen binding elem.

max. 0,05 0,25 0,20

S355J0WP 1.8945 0,15 0,80 0,035 0,010 yes

1,10 0,16 1,35 0,60

max. 0,05 0,25 0,20

S355J2WP 1.8946 0,15 0,80 0,030 - yes

1,10 0,16 1,35 0,60

0,45 max. 0,35 0,20

S355J0W 1.8959 0,19 0,55 0,035 0,010 yes

1,60 0,040 0,85 0,60

0,45 max. 0,35 0,20

S355J2W 1.8965 0,19 0,55 0,030 - yes

1,60 0,035 0,85 0,60

MECHANICAL PROPERTIES

Orient. of test

Yield strength Tensile strength Ductility A

ReH [MPa] Rm [MPa] [%] min.

Marking Material Nominal thickness [mm] Nominal thick. [mm] L o=80 mm L o=5,65 √ So

number

>16 >40 >63 >80 >3 >1,5 >2 >2,5 >3 >40 >63

≤16 <3

≤40 ≤63 ≤80 ≤100 ≤100 ≤2 ≤2,5 ≤3 ≤40 ≤63 ≤100

l 16 17 18 22 - -

S355J0WP 1.8945 355 345 2) - - - 510-680 470-630

t 14 15 16 20 - -

l 16 17 18 22 - -

On the Stock

S355J2WP 1.8946 355 345 2) - - - 510-680 470-630

t 14 15 16 20 - -

l 16 17 18 22 21 20

S355J0W 1.8959 355 345 335 325 315 510-680 470-630

t 14 15 16 20 19 18

l 16 17 18 22 21 20

S355J2W 1.8965 355 345 335 325 315 510-680 470-630

t 14 15 16 20 19 18

Delivery program:

CORTEN A, CORTEN B,

DOCOL 355W - (cold rolling)

19

UniOcel Big_kat_2009_A.indd 19 2.3.2009 12:04:05

Dimensions norm EN 10051 continously hot-rolled uncoated plate

Table 2 Table 3

TOLERANCE OF THICKNESS Dimensions in [mm] TOLERANCE OF THICKNESS Dimensions in [mm]

Continously hot-rolled low carbon steel sheet/plate for Sheet/plate made OF steels with a normal deformation

cold forming resistance AT elevated temperatures [ Class A ]

Tolerances for a nominal width Tolerances for a nominal width

Nominal Nominal

thickness ≤ 1200 > 1200 > 1500 > 1800 thickness ≤ 1200 > 1200 > 1500 > 1800

≤ 1500 ≤ 1800 ≤ 1500 ≤ 1800

≤ 2,00 ± 0,13 ± 0,14 ± 0,16 - ≤ 2,00 ± 0,17 ± 0,19 ± 0,21 -

> 2,00 ≤ 2,50 ± 0,14 ± 0,16 ± 0,17 ± 0,19 > 2,00 ≤ 2,50 ± 0,18 ± 0,21 ± 0,23 ± 0,25

> 2,50 ≤ 3,00 ± 0,15 ± 0,17 ± 0,18 ± 0,20 > 2,50 ≤ 3,00 ± 0,20 ± 0,22 ± 0,24 ± 0,26

> 3,00 ≤ 4,00 ± 0,17 ± 0,18 ± 0,20 ± 0,20 > 3,00 ≤ 4,00 ± 0,22 ± 0,24 ± 0,26 ± 0,27

> 4,00 ≤ 5,00 ± 0,18 ± 0,20 ± 0,21 ± 0,22 > 4,00 ≤ 5,00 ± 0,24 ± 0,26 ± 0,28 ± 0,29

> 5,00 ≤ 6,00 ± 0,20 ± 0,21 ± 0,22 ± 0,23 > 5,00 ≤ 6,00 ± 0,26 ± 0,28 ± 0,29 ± 0,31

> 6,00 ≤ 8,00 ± 0,22 ± 0,23 ± 0,23 ± 0,26 > 6,00 ≤ 8,00 ± 0,29 ± 0,30 ± 0,31 ± 0,35

> 8,00 ≤ 10,00 ± 0,32 ± 0,33 ± 0,34 ± 0,40

> 10,00 ≤ 12,50 ± 0,35 ± 0,36 ± 0,37 ± 0,43

> 12,50 ≤ 15,00 ± 0,37 ± 0,38 ± 0,40 ± 0,46

> 15,00 ≤ 25,00 ± 0,40 ± 0,42 ± 0,45 ± 0,50

Table 4

TOLERANCE OF THICKNESS TOLERANCE OF LENGTH Dimensions in [mm]

Steels exhibiting a high deformation resistance at Nominal Tolerances

elevated temperatures length Lower Upper

Tolerances for a nominal width < 2000 0 + 10

Class B Class C Class D ≥ 2000 < 8000 0 + 0,005 x jm. dél.

expansion 15% expansion 30% expansion 40% ≥ 8000 0 + 40

Tables - Calculations

TOLERANCE OF WIDTH Dimensions in [mm]

Nominal Mill edges Trimmed edges

width Lower Upper Lower Upper

≤ 1200 0 + 20 0 +3

> 1200 ≤ 1500 0 + 20 0 +5

> 1500 0 + 25 0 +6

Tolerances for trimmed edges apply to products with nominal thicknesses ≤ 10 mm, for nominal thickness > 10 mm

the upper tolerances shall be agreed at the time of enquiry and order.

TOLERANCE OF FLATNESS Class A Dimensions in [mm]

Nominal Nominal Tolerances on flatness

thickness width Normal Special

≤ 1200 18 9

≤ 2,00 > 1200 ≤ 1500 20 10

> 1500 25 13

≤ 1200 15 8

> 2,00 ≤ 25 > 1200 ≤ 1500 18 9

> 1500 23 12

TOLERANCE OF FLATNESS - Class B, C, D Dimensions in [mm]

Nominal Nominal Tolerances on flatness for classes

thickness width Class B Class C Class D

≤ 1200 18 23 Shall be agreed at

≤ 25 > 1200 ≤ 1500 23 30 the time of enquiry

> 1500 28 38 and order

Classes B, C, D - are defined in EN 10051, table 4

20

UniOcel Big_kat_2009_A.indd 20 2.3.2009 12:04:09

Dimensions norm EN 10029 hot rolled plates

TOLERANCE OF THICKNESS Dimensions in [mm]

Nominal Class A Class B Class C Class D

thickness Lower Upper Lower Upper Lower Upper Lower Upper

≥3 <5 - 0,4 + 0,8 - 0,3 + 0,9 0 + 1,2 - 0,6 + 0,6

≥5 <8 - 0,4 + 1,1 - 0,3 + 1,2 0 + 1,5 - 0,75 + 0,75

≥8 < 15 - 0,5 + 1,2 - 0,3 + 1,4 0 + 1,7 - 0,85 + 0,85

≥ 15 < 25 - 0,6 + 1,3 - 0,3 + 1,6 0 + 1,9 - 0,95 + 0,95

≥ 25 < 40 - 0,8 + 1,4 - 0,3 + 1,9 0 + 2,2 - 1,1 + 1,1

≥ 40 < 80 - 1,0 + 1,8 - 0,3 + 2,5 0 + 2,8 - 1,4 + 1,4

≥ 80 < 150 - 1,0 + 2,2 - 0,3 + 2,9 0 + 3,2 - 1,6 + 1,6

≥ 150 < 250 - 1,2 + 2,4 - 0,3 + 3,3 0 + 3,6 - 1,8 + 1,8

TOLERANCE OF LENGTH TOLERANCE OF WIDTH

Nominal Lower Upper Nominal Lower Upper

lenght width

< 4000 0 + 20 ≥ 600 < 2000 0 +20

≥ 4000 < 6000 0 +30 ≥ 2000 < 3000 0 +25

≥ 6000 < 8000 0 +40 ≥ 3000 0 +30

≥ 8000 < 10000 0 +50

≥ 10000 < 15000 0 +75

≥ 15000 < 20000 0 +100

Tables - Calculations

TOLERANCE OF FLATNESS Class N TOLERANCE OF FLATNESS Class S

Measuring length Measuring length

Nominal Steel group L Steel group H Steel group L Steel group H

thickness Re≤ 460 MPa Re≤ 700 MPa Nominal Re≤ 460 MPa Re≤ 700 MPa

1000 2000 1000 2000 thickness width

≥3 <5 9 14 12 17 < 2750 ≥ 2750

≥5 <8 8 12 11 15 1000 2000 1000 2000 1000 2000

≥8 < 15 7 11 10 14 ≥3 <8 4 8 5 10 values accor-

≥ 15 < 25 7 10 10 13 ≥8 < 250 3 6 3 6 ding to order

≥ 25 < 40 6 9 9 12

≥ 40 < 250 5 8 8 11

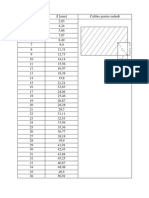

WEIGHT kg/m 2

thickness mass peer sq. thickness mass peer sq. thickness mass peer sq. thickness mass peer sq. thickness mass peer sq.

[mm] m. [kg] [mm] m. [kg] [mm] m. [kg] [mm] m. [kg] [mm] m. [kg]

3 24 16 128 38 304 95 760 160 1280

4 32 17 136 40 320 100 800 165 1320

5 40 18 144 45 360 105 840 170 1360

6 48 19 152 46 368 110 880 175 1400

7 56 20 160 50 400 115 920 180 1440

8 64 22 176 55 440 120 960 185 1480

9 72 25 200 60 480 125 1000 190 1520

10 80 26 208 65 520 130 1040 195 1560

11 88 28 224 70 560 135 1080 200 1600

12 96 30 240 75 600 140 1120 210 1680

13 104 32 256 80 640 145 1160 220 1760

14 112 35 280 85 680 150 1200 230 1840

15 120 36 288 90 720 155 1240 240 1920

21

UniOcel Big_kat_2009_A.indd 21 2.3.2009 12:04:15

Comparison of norms - EN / GOST / Other

W. Nr. EN GOST Other

1.0037 S 235 JR Ст3сп St 37-2

1.0553 S 355 J0 St 52-3

1.0577 S 355 J2 17Г1С

1.0579 S 355 J2C

1.0425 P265GH 16К H II

1.0481 P295GH 17Г 17Mn4

1.5415 16Mo3 15М 15Mo3

1.7335 13CrMo4-5 13ХМ 13CrMo44

1.7380 10CrMo9-10 10Х2М 10CrMo9.10

1.7362 12 CrMo19 5 12CrMo19.5

1.0488 P275N/NH/NL1/NL2 StE/WStE/TStE/EStE 285

1.0566 P355N/NH/NL1/NL2 StE/WStE/TStE/EStE 355

1.8915 P460N/NH/NL1/NL2 18Г2АФпс StE/WStE/TStE/EStE 460

1.8928 S690QL StE 690

1.8983 S890QL StE 890

1.8933 S960QL StE 960

Comparsion of norms

1.8942 S1100QL StE 1100

1.0978 S355MC QStE 380 TM

1.0980 S420MC QStE 420 TM

1.8974 S700MC QStE 690 TM

1.1141 2 C15 15 Ck 15

1.1191 2 C45 45 Ck 45

1.1221 2 C60 60 Ck 60

1.7131 16MnCr5 16ХГ 16MnCr5

1.7147 20MnCr5 18ХГТ 20MnCr5

1.7218 25CrMo4 25ХМ 25CrMo4

1.7225 42CrMo4 40XФА 42CrMo4

1.3401 X120 Mn 12

1.8704 X AR 300

1.8714 / - / 1.8715 X AR, Durostat, Dillidur 400

1.8709 Brinar 400 Cr

1.8734 / - / 1.8721 X AR, Durostat, Dillidur 500

- X AR 600

1.0546 S 355 NL TStE 355

1.8912 S 420 NL TStE 420

1.8903 S 460 NL TStE 460

1.8834 S 355 ML TStE 355 TM

1.8836 S 420 ML TStE 420 TM

1.8838 S 460 ML TStE 460 TM

1.8945 S355J0WP

1.8946 S355J2WP

1.8959 S355J0W

1.8965 S355J2W W TSt 52-3

22

UniOcel Big_kat_2009_A.indd 22 2.3.2009 12:04:19

Summary of inspection documents EN 10204

Refe- Designation of the document type Document Document

rence Czech ver. English ver. German ver. French ver. content validated by

2.1 Prohlášení Declaration of Werksbeschei- Attestation de Statement of The manufacturer

o shodě compliance with nigung conformité à la compliance with

s objednávkou the order commande the order

2.2 Zkušební Test report Werkszeugnis Relevé Statement of The manufacturer

zpráva de contrôle compliance with

the order, with indication

of results of non- specific

inspection

3.1 Inspekční Inspection Abnahmeprüf- Certificat de Statement of The manufacturer‘s

certifikát 3.1 certificate 3.1 zeugnis 3.1 réception 3.1 compliance with authorized inspection

the order, with indica- repersentative

tion of results of specific independent of

inspection the manufacturing

department

3.2 Inspekční Inspection Abnahmeprüf- Certificat de Statement of The manufacturer‘s

certifikát 3.2 certificate 3.2 zeugnis 3.2 réception 3.2 compliance with authorized inspection

the order, with indication repersentative

of results of non- specific independent of

inspection the manufacturing

department and either

the purchaser‘s authori-

zed inspection represen-

tative or the inspector

designated by the official

regulations

Tables - Calculations

Calculation CEV Certificate ISO 9001:2000

Mn Cr+Mo+V Cu+Ni

CEV = C + –––––– + –––––––––– + ––––––––

6 5 15

Content of elements - weight [% max.]

23

UniOcel Big_kat_2009_A.indd 23 2.3.2009 12:04:25

UnionOcel s.r.o.

Radlická 740/113c

CZ-158 00 PRAHA 5 - Nové Butovice

Telefon: +420 251 013 011

Telefax: +420 251 013 050

UnionOcel s.r.o.

Panská 1444/14

CZ-742 21 KOPŘIVNICE

Telefon: +420 556 209 911

Telefax: +420 556 209 955

e-mail: info@unionocel.cz

www.unionocel.cz

www.unionocel.sk

www.unionocel.eu

www.unionocel.com

UniOcel Big_kat_2009_A.indd 24 2.3.2009 12:04:31

You might also like

- Unionocel Big-New enDocument24 pagesUnionocel Big-New encristi_amaNo ratings yet

- HARDOX - OznakebDocument24 pagesHARDOX - OznakebPuđa TomicaNo ratings yet

- EUROFER Brochure Quality Tracking FinalDocument4 pagesEUROFER Brochure Quality Tracking FinalmgalltestNo ratings yet

- Katalog Vbs 2012 Connection and Fastening enDocument488 pagesKatalog Vbs 2012 Connection and Fastening enadrianahoukiNo ratings yet

- Hollow Steel Catalog PDFDocument44 pagesHollow Steel Catalog PDFaiyubi2No ratings yet

- Product Catalog THFDocument48 pagesProduct Catalog THFEdy Quispe QuentaNo ratings yet

- Development of Steel-Glass Structures-RTSSDDocument158 pagesDevelopment of Steel-Glass Structures-RTSSDEggMan100% (1)

- Steel Pipes RulmanDocument123 pagesSteel Pipes RulmanChristy MaxwellNo ratings yet

- Pipes CatalogueDocument48 pagesPipes CatalogueChristy MaxwellNo ratings yet

- Spirally Welded PipesDocument20 pagesSpirally Welded PipesRoman100% (2)

- ElecSteels 110408 Final Brochure PDFDocument52 pagesElecSteels 110408 Final Brochure PDFpminhhienNo ratings yet

- Cable Instrumentos KerpenDocument56 pagesCable Instrumentos KerpenAlexander Ariza NadjarNo ratings yet

- Fatigue Behaviour of High-Strength Steel-Welded Joints in Offshore and Marine Systems (FATHOMS)Document183 pagesFatigue Behaviour of High-Strength Steel-Welded Joints in Offshore and Marine Systems (FATHOMS)frvdabeeNo ratings yet

- Technofondi General CatalogDocument28 pagesTechnofondi General CatalogYein YeeNo ratings yet

- IMU Basic Knowledge English Final 11-03-14Document102 pagesIMU Basic Knowledge English Final 11-03-14ramchandra rao deshpandeNo ratings yet

- Welding News 2016-II ENG LowDocument16 pagesWelding News 2016-II ENG Lowtekstep7No ratings yet

- DIN en 10250-2 1999 Open Die Steel Forgings For General Engineering Purposes-Part 2 Non-Alloy Quality and Special SteelsDocument10 pagesDIN en 10250-2 1999 Open Die Steel Forgings For General Engineering Purposes-Part 2 Non-Alloy Quality and Special SteelsBui Chi TamNo ratings yet

- Stainless Steel Flat Products For Building - The Grades in EN 10088-4 ExplainedDocument28 pagesStainless Steel Flat Products For Building - The Grades in EN 10088-4 ExplainedLeo TuckerNo ratings yet

- Catalogue 2007: European Manufacturer of Hand Tools SINCE 1919Document12 pagesCatalogue 2007: European Manufacturer of Hand Tools SINCE 1919Igor RadmanovicNo ratings yet

- Din en Iso 9015 1pdfDocument19 pagesDin en Iso 9015 1pdfabdou benNo ratings yet

- Construction Products Directive: Customer InformationDocument4 pagesConstruction Products Directive: Customer InformationzaheerNo ratings yet

- En 10025-2Document4 pagesEn 10025-2Sebastián Araya MoraNo ratings yet

- Aluminium Heat ExchangersDocument6 pagesAluminium Heat ExchangersSachin KheveriaNo ratings yet

- Duplex Stainless Steels by ArcelorMittal - 930koDocument11 pagesDuplex Stainless Steels by ArcelorMittal - 930koSampath Kumar YerraNo ratings yet

- Twi Announces Composurf Technology For Applying Coatings To CompositesDocument8 pagesTwi Announces Composurf Technology For Applying Coatings To CompositesNirmal GhoshNo ratings yet

- BS en 10028-5-2009Document19 pagesBS en 10028-5-2009anupsharma2522_98756No ratings yet

- Aalco CatalogueDocument72 pagesAalco CataloguedisasterdazNo ratings yet

- 2010 enDocument12 pages2010 encristi_mt100% (1)

- Allied International Group 2014Document44 pagesAllied International Group 2014Enoch TwumasiNo ratings yet

- SCI 160 - Structural Fire Design IntumescentDocument74 pagesSCI 160 - Structural Fire Design IntumescentAshwin B S Rao100% (2)

- Cold ForgingDocument12 pagesCold Forgingkasana100% (1)

- Measurement of Toughness in High Strength Steels Sheets To Improve Material Selection in Cold Forming and Crash-Resistant ComponentsDocument131 pagesMeasurement of Toughness in High Strength Steels Sheets To Improve Material Selection in Cold Forming and Crash-Resistant ComponentsiggyNo ratings yet

- ElecSteelsMagnAlloys Brochure enDocument52 pagesElecSteelsMagnAlloys Brochure enjmacarroNo ratings yet

- Brochure NLMK Europe Plate - UKDocument12 pagesBrochure NLMK Europe Plate - UKunnamed90No ratings yet

- Steel Grades en 10028 ASTMDocument24 pagesSteel Grades en 10028 ASTMGeorge_Wabag_2014No ratings yet

- Hazardous Engineering Solutions - Feb 2013Document40 pagesHazardous Engineering Solutions - Feb 2013michael3511No ratings yet

- En 10024-1995 - Hot Rolled Taper Flange I Sections - Tolerances On Shape and DimensionsDocument10 pagesEn 10024-1995 - Hot Rolled Taper Flange I Sections - Tolerances On Shape and DimensionsjekabsjNo ratings yet

- Self-Healing at The Cut Edge of Coil-Coated Galvanised SteelDocument145 pagesSelf-Healing at The Cut Edge of Coil-Coated Galvanised SteelEwo50 NewNo ratings yet

- HB D KomplettDocument181 pagesHB D KomplettGabriel BourguignonNo ratings yet

- 1484 V0qusf PL Impexmetal Katalog en 09-WwwDocument32 pages1484 V0qusf PL Impexmetal Katalog en 09-Wwwmuamer1No ratings yet

- Electrical TransformersDocument96 pagesElectrical TransformersclovisrodNo ratings yet

- BS en 10225 - 2009Document81 pagesBS en 10225 - 2009Md Azahary100% (3)

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- EPD Padana Tubi Black Carbon Steel Tube ENDocument16 pagesEPD Padana Tubi Black Carbon Steel Tube ENBruno MarquesNo ratings yet

- 1 50ug Pipe and TubesDocument92 pages1 50ug Pipe and TubesTC İsmail TalayNo ratings yet

- Seamless Boiler Tubes and Pipes: Vallourec&MannesmanntubesDocument0 pagesSeamless Boiler Tubes and Pipes: Vallourec&MannesmanntubesVenugopal HonavanapalliNo ratings yet

- Company ProfileDocument4 pagesCompany Profilededikartiwa_dkNo ratings yet

- DinDocument13 pagesDinRakesh Srivastava50% (2)

- Standardised Solutions For Steel in Low Rise BLDGS PRF - 136-04 PDFDocument177 pagesStandardised Solutions For Steel in Low Rise BLDGS PRF - 136-04 PDFSameer SawantNo ratings yet

- The New Copper Casting-Machine: Experiences at FerroatlanticaDocument8 pagesThe New Copper Casting-Machine: Experiences at FerroatlanticaJuan Bautista HernándezNo ratings yet

- Wrought Ironwork - A Manual of Instruction for Rural CraftsmenFrom EverandWrought Ironwork - A Manual of Instruction for Rural CraftsmenRating: 5 out of 5 stars5/5 (1)

- Home Instruction for Sheet Metal Workers - Based on a Series of Articles Originally Published in 'Metal Worker, Plumber and Steam Fitter'From EverandHome Instruction for Sheet Metal Workers - Based on a Series of Articles Originally Published in 'Metal Worker, Plumber and Steam Fitter'No ratings yet

- Tool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforFrom EverandTool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Trilogy of Connectors: Basic Principles and Connector Design ExplanationsFrom EverandTrilogy of Connectors: Basic Principles and Connector Design ExplanationsRating: 5 out of 5 stars5/5 (1)

- Sexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicFrom EverandSexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicNo ratings yet

- Triangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsFrom EverandTriangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsRating: 5 out of 5 stars5/5 (1)

- Workpiece Materials Web PDFDocument82 pagesWorkpiece Materials Web PDFTeodor EzaruNo ratings yet

- Hardox 450: General Product DescriptionDocument2 pagesHardox 450: General Product DescriptionTeodor EzaruNo ratings yet

- SS316 Corrosion RateDocument13 pagesSS316 Corrosion Ratenarayana reddy100% (1)

- Welding TechniquesDocument23 pagesWelding TechniquesTeodor EzaruNo ratings yet

- Testing of Austenitic Stainless SteelsDocument64 pagesTesting of Austenitic Stainless SteelsmirelamanteamirelaNo ratings yet

- 151 Hardox 400 Uk Data-SheetDocument2 pages151 Hardox 400 Uk Data-Sheetanon_94641581No ratings yet

- ABS Steels GradeDocument1 pageABS Steels GradeyulistanaNo ratings yet

- LP UsDocument1 pageLP UsTeodor EzaruNo ratings yet

- Principal Application Fields Ferritic Pearlitic Steel:: Technical CardDocument1 pagePrincipal Application Fields Ferritic Pearlitic Steel:: Technical CardTeodor EzaruNo ratings yet

- 19 MN VS6Document3 pages19 MN VS6Teodor EzaruNo ratings yet

- Quality 1.4362 Chemical Composition: Technical CardDocument2 pagesQuality 1.4362 Chemical Composition: Technical CardTeodor EzaruNo ratings yet

- Compresor AB 200 - 410 MCDocument1 pageCompresor AB 200 - 410 MCTeodor EzaruNo ratings yet

- Hollow Bar Ovako 280Document3 pagesHollow Bar Ovako 280fernandojNo ratings yet

- Harta Cot Gama 2011010050Document1 pageHarta Cot Gama 2011010050Teodor EzaruNo ratings yet

- (Iso/tr 17671-5) (Iso/tr 17671-6) (Iso/tr 17671-7) (Iso/tr 17671-8)Document1 page(Iso/tr 17671-5) (Iso/tr 17671-6) (Iso/tr 17671-7) (Iso/tr 17671-8)Ivan Briscoe100% (7)

- Harti Coloane DuplexDocument1 pageHarti Coloane DuplexTeodor EzaruNo ratings yet

- Material List Interconnecting Piping Support: Client: PO NoDocument1 pageMaterial List Interconnecting Piping Support: Client: PO NoTeodor EzaruNo ratings yet

- Harta Corp Pompa 1180901001Document1 pageHarta Corp Pompa 1180901001Teodor EzaruNo ratings yet

- Plan de Control NDTDocument2 pagesPlan de Control NDTTeodor Ezaru100% (1)

- Harta Cot RefulareDocument1 pageHarta Cot RefulareTeodor EzaruNo ratings yet

- Harti Coloane TMP 316lDocument1 pageHarti Coloane TMP 316lTeodor EzaruNo ratings yet

- Detalii Cot de Refulare 1180901010Document3 pagesDetalii Cot de Refulare 1180901010Teodor EzaruNo ratings yet

- Metale de Baza GrupeDocument37 pagesMetale de Baza GrupeTeodor EzaruNo ratings yet

- Welder CertificationDocument1 pageWelder CertificationTeodor EzaruNo ratings yet

- Sudura CalibruDocument1 pageSudura CalibruTeodor EzaruNo ratings yet

- Harta Sudurii Brat MacaraDocument1 pageHarta Sudurii Brat MacaraTeodor EzaruNo ratings yet

- Pipline Protection SystemDocument54 pagesPipline Protection SystemTeodor EzaruNo ratings yet

- Field Joint CoatingDocument7 pagesField Joint CoatingTeodor EzaruNo ratings yet

- WeldingDocument73 pagesWeldingTeodor EzaruNo ratings yet

- As 2292.1-1979 Methods For The Analysis of Solders Determination of Tin (Volumetric Method)Document5 pagesAs 2292.1-1979 Methods For The Analysis of Solders Determination of Tin (Volumetric Method)SAI Global - APACNo ratings yet

- Updated Mohs Scale PDFDocument2 pagesUpdated Mohs Scale PDFHarshNo ratings yet

- 1045 Steel Flat BarDocument4 pages1045 Steel Flat BarFebri SSNo ratings yet

- S 1166501305921Document8 pagesS 1166501305921Raj RajeshNo ratings yet

- Potassium Nitrate Without Anticaking (BP, Ph. Eur.) Pure, Pharma GradeDocument1 pagePotassium Nitrate Without Anticaking (BP, Ph. Eur.) Pure, Pharma GradeMiguel CruzNo ratings yet

- Evoquip Wear Parts Guide WebDocument23 pagesEvoquip Wear Parts Guide WebPrekel100% (1)

- Eemua 218Document20 pagesEemua 218skishark100% (1)

- Pre-Treatments of Iron or Steel For Reducing Risk of Hydrogen EmbrittlementDocument3 pagesPre-Treatments of Iron or Steel For Reducing Risk of Hydrogen EmbrittlementDanZel DanNo ratings yet

- High Strength Low Alloy Steel: 1. AISI 9254Document4 pagesHigh Strength Low Alloy Steel: 1. AISI 9254Himanshu PawarNo ratings yet

- Teknis Dan Pelaksanaan Eksplorasi Timah Berdasarkan Tahap Eksplorasinya-1Document11 pagesTeknis Dan Pelaksanaan Eksplorasi Timah Berdasarkan Tahap Eksplorasinya-1Rinaldo CandraNo ratings yet

- Ductile or Partial Ductile Mode Machining of Brittle MaterialsDocument7 pagesDuctile or Partial Ductile Mode Machining of Brittle MaterialsHangi TakimlisinNo ratings yet

- ESAB Catalogue - Overview of ESAB Stainless Steel Welding ConsumablesDocument12 pagesESAB Catalogue - Overview of ESAB Stainless Steel Welding Consumablestoxicity23No ratings yet

- EW NickelDocument19 pagesEW NickelAde SatriaNo ratings yet

- ASME Material Numbers PDocument2 pagesASME Material Numbers PVivek S SurendranNo ratings yet

- Esab Marathon PacDocument2 pagesEsab Marathon PacRAJAN BABU M100% (1)

- Cico Consulting EngineersDocument13 pagesCico Consulting Engineerssam_antony2005No ratings yet

- MCQ Practice Test Set 01to20Document41 pagesMCQ Practice Test Set 01to20Chan Myae Aung100% (1)

- Sheet Metal OperationDocument17 pagesSheet Metal Operationsekar_scribd60% (5)

- Chapter2 - 2nd LectureDocument22 pagesChapter2 - 2nd LectureKAMALJEET SINGHNo ratings yet

- Data Sheet 4340-AMS-6414-UNSG43406Document4 pagesData Sheet 4340-AMS-6414-UNSG43406rodryguo74No ratings yet

- Astm A153Document5 pagesAstm A153Gurkan100% (1)

- A Metallographic Examination of Fracture Splitting C70S6 Steel Used in Connecting RodsDocument14 pagesA Metallographic Examination of Fracture Splitting C70S6 Steel Used in Connecting RodsSujay NahaldeNo ratings yet

- NOR - Steel Sucker Rods and Pony Rods - V2Document8 pagesNOR - Steel Sucker Rods and Pony Rods - V2Cosersum Int C ANo ratings yet

- Tugas 10 - Chapter 15Document6 pagesTugas 10 - Chapter 15hana haddadNo ratings yet

- Nitrogen FamilyDocument2 pagesNitrogen FamilyArnolNo ratings yet

- SSFPL Forgings Profile CurrentDocument16 pagesSSFPL Forgings Profile CurrentMahendra PatilNo ratings yet

- TTT DiagramDocument6 pagesTTT DiagramDeepa PujariNo ratings yet

- The Style, Technology and Organization of Sicán Mining and Metallurgy, Northern Peru: Insights From Holistic StudyDocument30 pagesThe Style, Technology and Organization of Sicán Mining and Metallurgy, Northern Peru: Insights From Holistic StudyCesar Augusto Velandia SilvaNo ratings yet

- Material Downloaded From - 1 / 5Document5 pagesMaterial Downloaded From - 1 / 5KARTHIK MNo ratings yet

- 05 Askeland ChapDocument10 pages05 Askeland ChapWeihanZhang100% (1)