Professional Documents

Culture Documents

3d Printing Technologies

Uploaded by

malowaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3d Printing Technologies

Uploaded by

malowaCopyright:

Available Formats

All Posts

GUIDES

3D Printing Technology

Comparison: FDM vs. SLA

vs. SLS

Guides 5 minute read

Additive manufacturing, or 3D printing, lowers costs,

saves time, and transcends the limits of fabrication

processes for product development. From concept

models and functional prototypes in rapid

prototyping to jigs, fixtures, or even end-use parts

in manufacturing, 3D printing technologies offer versatile

solutions in a wide variety of applications.

Over the last few years, high-resolution 3D printers have

become more affordable, easier to use, and more

reliable. As a result, 3D printing technology is now

accessible to more businesses, but choosing between

the various competing 3D printing solutions can be

difficult.

Which technology is suitable for your particular

application? What materials are available? What

equipment and training do you need to get started? How

about costs and return on investment?

In this article, we’ll take a closer look at the three most

established plastic 3D printing processes today: fused

deposition modeling (FDM), stereolithography (SLA), and

selective laser sintering (SLS).

Trying to decide between FDM and SLA 3D printers?

Check out our in-depth FDM vs. SLA comparison.

Download the high-resolution version of this

infographic here.

VIDEO GUIDE

How to Choose a Desktop 3D

Printing Technology

Having trouble finding the best 3D printing technology

for your needs? In this video guide, we compare FDM,

SLA, and SLS technologies across popular buying

considerations.

Watch the Videos

Fused Deposition Modeling

(FDM)

Fused deposition modeling (FDM), also known as fused

filament fabrication (FFF), is the most widely used form of

3D printing at the consumer level, fueled by the

emergence of hobbyist 3D printers. FDM 3D printers

build parts by melting and extruding thermoplastic

filament, which a printer nozzle deposits layer by layer in

the build area.

FDM works with a range of standard thermoplastics, such

as ABS, PLA, and their various blends. The technique is

well-suited for basic proof-of-concept models, as well as

quick and low-cost prototyping of simple parts, such as

parts that might typically be machined.

FDM parts tend to have visible layer lines and might

show inaccuracies around complex features. This

example was printed on a Stratasys uPrint industrial FDM

3D printer with soluble supports (machine starting at

$15,900).

FDM has the lowest resolution and accuracy when

compared to SLA or SLS and is not the best option for

printing complex designs or parts with intricate features.

Higher-quality finishes may be obtained through chemical

and mechanical polishing processes. Industrial FDM 3D

printers use soluble supports to mitigate some of these

issues and offer a wider range of engineering

thermoplastics, but they also come at a steep price.

FDM printers struggle with complex designs or parts with

intricate features (left), compared to SLA printers (right).

Stereolithography (SLA)

Stereolithography was the world’s first 3D printing

technology, invented in the 1980s, and is still one of the

most popular technologies for professionals. SLA resin

3D printers use a laser to cure liquid resin into hardened

plastic in a process called photopolymerization.

The Ultimate Guide to Stereolithograp…

Watch later Share

See how stereolithography works.

SLA parts have the highest resolution and accuracy, the

clearest details, and the smoothest surface finish of all

plastic 3D printing technologies, but the main benefit of

SLA lies in its versatility. Material manufacturers have

created innovative SLA photopolymer resin formulations

with a wide range of optical, mechanical, and thermal

properties to match those of standard, engineering, and

industrial thermoplastics.

SLA parts have sharp edges, a smooth surface finish,

and minimal visible layer lines. This example part was

printed on a Formlabs Form 3 desktop SLA 3D

printer (machine starting at $3,499).

SLA is a great option for highly detailed prototypes

requiring tight tolerances and smooth surfaces, such as

molds, patterns, and functional parts. SLA is widely used

in a range of industries from engineering and product

design to manufacturing, dentistry, jewelry, model

making, and education.

W H I T E PA P E R

Introduction to 3D Printing With

Desktop Stereolithography

(SLA)

Download our extended white paper to learn how SLA

printing technologies work, why thousands of

professionals use this process today, and what you

need to know to explore how this 3D printing process

can benefit your work.

Download White Paper

Request a Sample Part

See and feel Formlabs quality firsthand. We’ll ship a

free 3D printed sample part to your office.

Request a Free Sample Part

Selective Laser Sintering (SLS)

Selective laser sintering is the most common additive

manufacturing technology for industrial applications.

SLS 3D printers use a high-powered laser to fuse small

particles of polymer powder. The unfused powder

supports the part during printing and eliminates the need

for dedicated support structures. This makes SLS ideal

for complex geometries, including interior features,

undercuts, thin walls, and negative features. Parts

produced with SLS printing have excellent mechanical

characteristics, with strength resembling that of injection-

molded parts.

SLS parts have a slightly rough surface finish, but almost

no visible layer lines. This example part was printed on

a Formlabs Fuse 1 benchtop SLS 3D printer (machine

starting at $9,999).

The most common material for selective laser sintering is

nylon, a popular engineering thermoplastic with excellent

mechanical properties. Nylon is lightweight, strong, and

flexible, as well as stable against impact, chemicals, heat,

UV light, water, and dirt.

The combination of low cost per part, high productivity,

and established materials make SLS a popular choice

among engineers for functional prototyping, and a cost-

effective alternative to injection molding for limited-run or

bridge manufacturing.

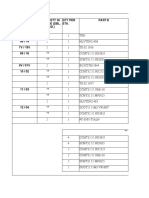

Compare FDM, SLA, and SLS

3D Printing Technologies

Each 3D printing technology has its own strengths,

weaknesses, and requirements, and is suitable for

different applications and businesses. The following table

summarizes some key characteristics and considerations.

FUSED ST E R E O L I T H O G R A P H Y SELECTIVE

DEPOSITION (SLA) L AS E R

MODELING (FDM) SINTERING

(SLS)

Resolution

Accuracy

Surface

Finish

Throughput

Complex

Designs

Ease of Use

Pros Fast Great value Strong

Low-cost consumer High accuracy functional parts

machines and Smooth surface finish Design

materials Range of functional freedomNo

applications need for

support

structures

Cons Low accuracy Sensitive to long Rough surface

Low details exposure to UV light finish

Limited design Limited

compatibility material

options

Applications Low-cost rapid Functional prototyping Functional

prototyping Patterns, molds, and prototyping

Basic proof-of- tooling Short-run,

concept models Dental applications bridge, or

Jewelry prototyping and custom

casting manufacturing

Modelmaking

Print Volume Up to ~200 x 200 x Up to 300 x 335 x 200 Up to 165 x 165

300 mm (desktop mm (desktop and x 320 mm

3D printers) benchtop 3D printers) (benchtop 3D

printers)

Materials Standard Varieties of resin Engineering

thermoplastics, (thermosetting plastics). thermoplastics.

such as ABS, PLA, Standard, engineering Nylon 11, Nylon

and their various (ABS-like, PP-like, 12, and their

blends. flexible, heat-resistant), composites.

castable, dental, and

medical (biocompatible).

Training Minor training on Plug and play. Minor Moderate

build setup, training on build setup, training on

machine operation, maintenance, machine build setup,

and finishing; operation, and finishing. maintenance,

moderate training machine

on maintenance. operation, and

finishing.

Facility Air-conditioned Desktop machines are Workshop

Requirements environment or suitable for an office environment

preferably custom environment. with moderate

ventilation for space

desktop machines. requirements

for benchtop

systems.

Ancillary Support removal Post-curing station, Post-

Equipment system for washing station processing

machines with (optionally automated), station for part

soluble supports finishing tools. cleaning and

(optionally material

automated), recovery.

finishing tools.

WEBINAR

Introduction to 3D Printing for

Engineers and Manufacturers

In this webinar, learn how parts created from various

printing technologies differ across functionality and

appearance, and how these differences impact

product development and production workflows for

engineers and manufacturers.

Watch the Webinar Now

3D Printing Costs and Return

on Investment With FDM, SLA,

and SLS Technologies

Ultimately, you should choose the technology that makes

the most sense for your business. Prices have dropped

significantly in recent years, and today, all three

technologies are available in compact, affordable

systems.

Calculating 3D printing costs does not end with upfront

equipment costs. Material and labor costs have a

significant influence on cost per part, depending on the

application and your production needs.

Here’s a detailed breakdown by technology:

FUSED ST E R E O L I T H O G R A P H Y SELECTIVE

DEPOSITION (SLA) L AS E R

MODELING (FDM) SINTERING

(SLS)

Equipment Budget printers and Professional desktop Benchtop

Costs 3D printer kits start printers start at $3,500, systems start at

at a few hundred large-format benchtop $10,000, and

dollars. Higher printers at $10,000, and industrial printers

quality mid-range large-scale industrial are available

desktop printers start machines are available from $100,000.

around $2,000, and from $80,000.

industrial systems

are available from

$15,000.

Material $50-$150/kg for $149-$200/L for most $100/kg for

Costs most standard and standard and nylon. SLS

engineering engineering resins. requires no

filaments, and $100- support

200/kg for support structures, and

materials. unfused powder

can be reused,

which lowers

material costs.

Labor Manual support Washing and post-curing Simple cleaning

Needs removal (can be (both can be mostly to remove excess

mostly automated for automated). Simple powder.

industrial systems post-processing to

with soluble remove support marks.

supports). Lengthy

post-processing is

required for a high-

quality finish.

Calculate Your ROI and Time

Savings With 3D Printing

Try our simple, interactive tool to calculate cost per

part and lead time when 3D printing on the Form 2,

and to compare time and cost savings to other

production methods.

Calculate Your ROI

Learn More About 3D Printing

Prototypes of a ski goggles' frame printed with FDM, SLA

and SLS technology (from left to right).

We hope this article has helped you focus your search for

You might also like

- After The Basics A 3D Printing HandbookDocument49 pagesAfter The Basics A 3D Printing HandbookMarcio José de Oliveira67% (3)

- Types of 3D Printers - Complete Guide - SLA, DLP, FDM, SLS, SLM, EBM, LOM, BJ, MJ PrintingDocument12 pagesTypes of 3D Printers - Complete Guide - SLA, DLP, FDM, SLS, SLM, EBM, LOM, BJ, MJ PrintingCherif100% (2)

- How To Design For FFF 3d PrintingDocument20 pagesHow To Design For FFF 3d Printing11CL2-21 Châu Hoàng Tú100% (1)

- NIP - Weld Check SheetDocument1 pageNIP - Weld Check SheetAlanka Prasad100% (2)

- FDM FFF 3D Printing Quick Start Guide Nov21 Release MakersmuseDocument15 pagesFDM FFF 3D Printing Quick Start Guide Nov21 Release Makersmusemike vidalNo ratings yet

- 3sp White Paper 2017 The Ultimate Guide To 3d Printing For Manufacturing and ProductionDocument9 pages3sp White Paper 2017 The Ultimate Guide To 3d Printing For Manufacturing and ProductionJosé Carlos100% (1)

- Introduction To 3D PrintingDocument10 pagesIntroduction To 3D PrintingsvirkomartinkoNo ratings yet

- 3D Printing of Sand MouldsDocument17 pages3D Printing of Sand MouldsAni AniNo ratings yet

- 3D Printing in Construction and ArchitectureDocument6 pages3D Printing in Construction and ArchitectureHendElgendy92No ratings yet

- Laser Engraving Rubber StampsDocument4 pagesLaser Engraving Rubber StampsAnonymous hpUVR2No ratings yet

- Dautsons Infratech India Private Limited: Gold Piping WorksDocument59 pagesDautsons Infratech India Private Limited: Gold Piping WorksDautsons InfratechNo ratings yet

- Guide of UltmkrDocument13 pagesGuide of UltmkrkunteshradadiyaNo ratings yet

- Draft Wps Astm A 743 GR - Ca6nmDocument2 pagesDraft Wps Astm A 743 GR - Ca6nmIlham PaneNo ratings yet

- Types of Additive Manufacturing TechnologyDocument7 pagesTypes of Additive Manufacturing Technologydeekamittal100% (1)

- Explore 3D Printing Solutions: EbookDocument34 pagesExplore 3D Printing Solutions: EbookMustaffa IbrahimNo ratings yet

- PPSC - Product Data Sheet Fusion Bonded EpoxyDocument1 pagePPSC - Product Data Sheet Fusion Bonded EpoxyjulianpirahNo ratings yet

- EGW Welding Wire Guide for 490MPa SteelDocument2 pagesEGW Welding Wire Guide for 490MPa SteelpratishgnairNo ratings yet

- Learning From Animations in Science Education: Len Unsworth EditorDocument325 pagesLearning From Animations in Science Education: Len Unsworth EditorDraghiciFlorentina100% (1)

- 3D Printing Technology Comparison: FDM vs. Sla vs. SLS: Written By: FormlabsDocument8 pages3D Printing Technology Comparison: FDM vs. Sla vs. SLS: Written By: Formlabseitan-dalia4971No ratings yet

- 3d Printing Techniques For Dental ProductsDocument3 pages3d Printing Techniques For Dental ProductsAli BirNo ratings yet

- Electromagnetics Fields and WavesDocument11 pagesElectromagnetics Fields and WavesAmirul IslamNo ratings yet

- 00-3D Printing1-StudentsDocument47 pages00-3D Printing1-StudentsEddehbiNo ratings yet

- 3d Printing For Manufacture A Basic Design Guide Download OriginalDocument26 pages3d Printing For Manufacture A Basic Design Guide Download OriginalritamendesNo ratings yet

- 3DS Thermoplastic-Manufacturing Whitepaper en FINALDocument12 pages3DS Thermoplastic-Manufacturing Whitepaper en FINALjaimeNo ratings yet

- Nha Khoa Kyì Thuaì Ì T Soì Ì (PhaÌ Ì N 1 - ChuÌ Oì NG 1-3)Document23 pagesNha Khoa Kyì Thuaì Ì T Soì Ì (PhaÌ Ì N 1 - ChuÌ Oì NG 1-3)nb.nguyen.vinhNo ratings yet

- 3d PrintingDocument54 pages3d PrintingCrazy Khan BolteNo ratings yet

- A Presentation ON Prototype: Dimensional Accuracy: Dr. D.Y PATIL College of Engineering Akurdi, Pune Maharashtra - 411044Document10 pagesA Presentation ON Prototype: Dimensional Accuracy: Dr. D.Y PATIL College of Engineering Akurdi, Pune Maharashtra - 411044AkshayJadhavNo ratings yet

- Unit - 1 IntroductionDocument26 pagesUnit - 1 IntroductionAbinaya VarmaNo ratings yet

- 3D Printing Seminar InsightsDocument19 pages3D Printing Seminar InsightsVipul VaibhavNo ratings yet

- 3d Printing PresentationDocument27 pages3d Printing PresentationaftabNo ratings yet

- 3D PrintingDocument16 pages3D Printingsagar_sgrNo ratings yet

- Advances in 3D Printing TechnologiesDocument9 pagesAdvances in 3D Printing TechnologiesShubham JainNo ratings yet

- Trade 2 PDFDocument7 pagesTrade 2 PDFRajveer Singh SachdevNo ratings yet

- Overview: Ime TechnologyDocument10 pagesOverview: Ime TechnologySaud FlashNo ratings yet

- 3D Printing: A SeminarDocument17 pages3D Printing: A SeminarRajesh SahuNo ratings yet

- Rapid Prototyping GuideDocument26 pagesRapid Prototyping GuideShubham ChomalNo ratings yet

- AMT Notes Unit-2Document27 pagesAMT Notes Unit-2Suddapally VIVEK ReddyNo ratings yet

- Aplicaciones en Fortus 380.Document8 pagesAplicaciones en Fortus 380.Diego Fernando Vázquez BravoNo ratings yet

- SLM 3D Printing - A Guide to Selective Laser Melting TechnologyDocument8 pagesSLM 3D Printing - A Guide to Selective Laser Melting TechnologyIonuț UțăNo ratings yet

- Design Essentials: For 3D PrintingDocument16 pagesDesign Essentials: For 3D PrintingAnthony StamatisNo ratings yet

- 3D PrintDocument11 pages3D PrintHieu DinhNo ratings yet

- 3 D Printing TechnologyDocument17 pages3 D Printing TechnologyClassic PrintersNo ratings yet

- Rapid Prototyping: & Its ApplicationsDocument21 pagesRapid Prototyping: & Its ApplicationsNaveen TatawatNo ratings yet

- 3DP DesignTip Essentials 03Document22 pages3DP DesignTip Essentials 03DaniloCardenasNo ratings yet

- Design Essentials: For Injection MoldingDocument17 pagesDesign Essentials: For Injection MoldingDekeNo ratings yet

- SLA 3D Printing For Educators and ResearchersDocument18 pagesSLA 3D Printing For Educators and ResearchersSadeq NeiroukhNo ratings yet

- DMP Factory 350: Robust, High Quality Metal AM With Integrated Powder ManagementDocument2 pagesDMP Factory 350: Robust, High Quality Metal AM With Integrated Powder ManagementNalla ThambiNo ratings yet

- Pss FDM Uprintseplus 0117aDocument2 pagesPss FDM Uprintseplus 0117aAlkım AydınNo ratings yet

- 3D Printing Materials ReportDocument14 pages3D Printing Materials ReportKamal NabilNo ratings yet

- Kaushalendra PDFDocument24 pagesKaushalendra PDFharshNo ratings yet

- Impresora 3d Ingles TecnicoDocument9 pagesImpresora 3d Ingles TecnicoAdriana RosasNo ratings yet

- SeminarDocument19 pagesSeminarSharath Kumar100% (1)

- Rapid Tooling Manufacturer for Low Volume ProductionDocument31 pagesRapid Tooling Manufacturer for Low Volume Productionزياد بوعلاڨيNo ratings yet

- Seminar Report Streolithography NNDocument23 pagesSeminar Report Streolithography NNShubham DesaiNo ratings yet

- Dimitrov, DimitarDocument12 pagesDimitrov, DimitarguissimoesNo ratings yet

- 3D Printing TechnologyDocument68 pages3D Printing Technologyben abrahamNo ratings yet

- Three Dimention Printing: What Is 3D Printing?Document6 pagesThree Dimention Printing: What Is 3D Printing?Aakarsh VermaNo ratings yet

- The Best 3D Printers For 2021Document26 pagesThe Best 3D Printers For 2021AveNo ratings yet

- 3D Printing in Prosthodontics: Additive Manufacturing TechnologyDocument6 pages3D Printing in Prosthodontics: Additive Manufacturing TechnologyRiya KvNo ratings yet

- 3D PrintingDocument54 pages3D PrintingMegha NeelgarNo ratings yet

- Zmorph FAB 2in1Document11 pagesZmorph FAB 2in1Bhavin VadgamaNo ratings yet

- Benefits: /fablabDocument2 pagesBenefits: /fablabArjay Amora (Non-professional Account)No ratings yet

- Metal 3d Printing Services in MumbaiDocument15 pagesMetal 3d Printing Services in MumbaiInnovae3dNo ratings yet

- OTPL - Introduction PDFDocument31 pagesOTPL - Introduction PDFAnil Kumar H CNo ratings yet

- Thermoplastics: The Strongest Choice For: 3D PrintingDocument14 pagesThermoplastics: The Strongest Choice For: 3D PrintingRui MatiasNo ratings yet

- Steel, Stainless Steel, Related Alloys, and Ferroalloys: Standard Terminology Relating ToDocument8 pagesSteel, Stainless Steel, Related Alloys, and Ferroalloys: Standard Terminology Relating TomithileshNo ratings yet

- Tolerance For ElevatorDocument2 pagesTolerance For ElevatorshashiNo ratings yet

- Steel Castings, Surface Acceptance Standards, Visual ExaminationDocument3 pagesSteel Castings, Surface Acceptance Standards, Visual ExaminationRamzi BEN AHMEDNo ratings yet

- T500 VeeyesDocument5 pagesT500 VeeyesTimothy TaylorNo ratings yet

- X12CrNiMoV12 3Document3 pagesX12CrNiMoV12 3manjunath k sNo ratings yet

- Chapter 3Document47 pagesChapter 3eiman bataNo ratings yet

- Clarke Engine Painting With RAL 3001Document2 pagesClarke Engine Painting With RAL 3001Kisinda SasolaNo ratings yet

- Peeled Round Steel BarsDocument9 pagesPeeled Round Steel BarsaxgasaNo ratings yet

- Manufacturing Process Routes For Reinforcing Steels: CaresDocument6 pagesManufacturing Process Routes For Reinforcing Steels: CaresMustafaNo ratings yet

- NAS1836Document3 pagesNAS1836Ray DutchmanNo ratings yet

- MP405 Tool EngineeringDocument2 pagesMP405 Tool EngineeringAbhay SajeevNo ratings yet

- Inspection Tally Sheet of For Summary Report #001Document1 pageInspection Tally Sheet of For Summary Report #001JIHED PRIMA PHONESTORENo ratings yet

- Surface Preparation For Carbon SteelDocument2 pagesSurface Preparation For Carbon Steelgovimano100% (1)

- SLD UpdateDocument8 pagesSLD UpdateDian PrasetyawanNo ratings yet

- Cutting Tools List - 01.25.23Document3 pagesCutting Tools List - 01.25.23Luis OntiverosNo ratings yet

- Tugas 1 40040117060067 SyadilalutfimDocument6 pagesTugas 1 40040117060067 SyadilalutfimSyadila LutfiNo ratings yet

- Work ProgramDocument1 pageWork ProgramSyazwani NordinNo ratings yet

- How To Identify Metal Surface Preparation Standards GradesDocument2 pagesHow To Identify Metal Surface Preparation Standards GradesMahmoud GwailyNo ratings yet

- Surface Dressing of Grinding WheelsDocument10 pagesSurface Dressing of Grinding WheelsMardhieyah JamaluddinNo ratings yet

- Last Name, First Name: - UMD Directory IDDocument8 pagesLast Name, First Name: - UMD Directory IDYealshaday BirhanuNo ratings yet

- Product data sheet for creep resisting steel electrodeDocument3 pagesProduct data sheet for creep resisting steel electrodesoft4gsmNo ratings yet

- Resume summary of monthly sparepart costs and production in 2021Document590 pagesResume summary of monthly sparepart costs and production in 2021winda listya ningrumNo ratings yet

- Gas Welding DefectsDocument8 pagesGas Welding DefectsRyu HimuraNo ratings yet

- Material SpecificationDocument5 pagesMaterial SpecificationMuthu GaneshNo ratings yet