Professional Documents

Culture Documents

Suction Regulators-Service-Manual

Uploaded by

evanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Suction Regulators-Service-Manual

Uploaded by

evanCopyright:

Available Formats

Thoracic Vacuum

Regulators

Service Manual

O(Off)

|(On)

30 35 40

25

20 _ cmH O 45

15

2 50

30

10 55 40

60 3

5 4 20

High Flow 2

50 Low Vacuum

5

1

10

6

60

a

-kP

O

H2

-cm

R E A

C S

E

N

I

Thoracic

Thoracic

6700-0011-000 (Rev. 8.1) 08/19

Table of Contents

Safety Instructions.......................................................... 2 8/Service Checkout Procedure.................................... 21

Receiving / Inspection.................................................... 2 8.1 Set-Up....................................................................... 21

User Responsibility ........................................................ 3

8.2 Flow Test................................................................... 21

1/Precautions................................................................... 4 8.3 Gauge Test................................................................ 21

1.1 Definitions.................................................................... 4 8.4 Regulation Test.......................................................... 21

1.2 Warnings..................................................................... 4 8.5 Vacuum Limit Test..................................................... 21

1.3 Cautions...................................................................... 5 8.6 Positive Pressure Relief Test..................................... 22

1.4 Intended Use............................................................... 5 8.7 Leak Test................................................................... 22

2/Scope............................................................................. 6 9/Maintenance................................................................ 23

2.1 North American Thoracic Vacuum Regulator.............. 6 9.1 General Maintenance of Suction Equipment............. 23

2.2 English Thoracic Vacuum Regulator........................... 6 9.2 Recommended Maintenance.................................... 23

2.3 French Thoracic Vacuum Regulator............................ 6 9.3 Repair Policy............................................................. 24

2.4 Spanish Thoracic Vacuum Regulator.......................... 6 9.4 Technical Assistance................................................. 24

3/Description and Specifications................................... 7 9.5 Return Instructions.................................................... 24

3.1 Description................................................................. 7 9.6 Installation Procedure for Adapters/Probes............... 24

3.2 Specifications............................................................. 8 9.7 Disposal Instructions................................................. 24

3.2.1 Technical Specifications.................................... 8 Safety Instructions

3.2.2 Environmental Specifications............................ 8 This manual provides you with important information about the

3.2.3 Standards.......................................................... 8 Thoracic Vacuum Regulators. To ensure the safe and proper

use of this device, READ and UNDERSTAND all of the safety

4/Operation...................................................................... 9 and operating instructions. IF YOU DO NOT UNDERSTAND

4.1 Equipment Set-Up....................................................... 9 THESE INSTRUCTIONS, OR HAVE ANY QUESTIONS,

4.1.1 Attaching the Overflow Safety Trap (OST)....... 10 REFER TO THIS SERVICE MANUAL, CONTACT YOUR

SUPERVISOR, DEALER OR THE MANUFACTURER

4.2 Operation................................................................... 10 BEFORE ATTEMPTING TO USE THE DEVICE.

4.2.1 Mode Selection............................................... 10

Receiving / Inspection:

4.2.2 Setting the Suction Level................................ 10

Remove product from package and inspect for damage. If

4.2.3 Pre-use Checkout Procedure.......................... 10

product is damaged, DO NOT USE and contact your dealer

4.2.4 Patient Set-Up................................................. 11 or equipment provider.

5/Cleaning, Disinfection and Sterilization................... 13 WARNINGS

⚠

5.1 Cleaning.................................................................... 13

This device is to be used ONLY by persons who

5.1.1 Routine Exterior Cleaning & Disinfection......... 13 have been properly trained on the operation of the

5.1.1.1 Approved Cleaning Solutions.............. 13 device. Incorrect use of this device may cause

serious injury to a patient.

5.1.2 Internal Component Cleaning & Disinfection... 13

5.1.2.1 Approved Flush Solutions.................... 13 ⚠ DO NOT operate this device in the presence of

flammable anesthetics. Static charges may not

5.1.3 Cold Flush Procedure ..................................... 13 dissipate and a possible explosion hazard exists

5.2 Sterilization................................................................ 13 in the presence of these agents.

6/Troubleshooting......................................................... 14 ⚠ Thoracic Vacuum Regulator vacuum pressures

used should not exceed the recommendations of

7/Service – Disassembly and Assembly..................... 15 the Chest Drainage System Manufacturer. Use of

7.1 Service Tools and Equipment.................................... 15 excessive vacuum pressure may render the Chest

Drainage System ineffective and may result in

7.2 Disassembly.............................................................. 15

patient harm.

7.2.1. Part Numbers................................................. 16

7.3 Assembly................................................................... 20

2 6700-0011-000 (Rev. 8.1) 08/19

User Responsibility

This Product will perform as described in this operating to the nearest Ohio Medical Regional Service Center. This

manual and accompanying labels and/or inserts, when product and any of its parts should only be repaired using

assembled, operated, maintained and repaired in accordance written instructions provided by Ohio Medical or by Ohio

with the instructions provided. This Product must be checked Medical trained personnel. The Product must not be altered

periodically. A defective product should not be used. Parts that without the prior written approval of Ohio Medical’s Quality

are broken, missing, worn, distorted or contaminated should Assurance Department. The user of this Product shall have

be replaced immediately. Should such repair or replacement the sole responsibility for any malfunction which results from

become necessary, see the Ohio Medical service manual for improper use, faulty maintenance, improper repair, damage,

service or repairs to this product. For service advice, Ohio or alteration by anyone other than Ohio Medical.

Medical recommends that a telephone request be made

Technical Competence

The procedures described in this service manual should Genuine replacement parts manufactured or sold by Ohio

be performed by trained and authorized personnel only. Medical must be used for all repairs.

Maintenance should only be undertaken by competent

individuals who have a general knowledge of and Read completely through each step in every procedure

experience with devices of this nature. No repairs should before starting the procedure; any exceptions may result

ever be undertaken or attempted by anyone not having such in a failure to properly and safely complete the attempted

qualifications. procedure.

Abbreviations used in this manual

O OFF

| ON (Regulate)

CCW Counter-clockwise (decrease)

CW Clockwise (increase)

in Inches

kPa Kilopascals (kPa x 7.50 = mmHg) (kPa x 10.197 = cmH2O)

LPM Liters per minute

mm Millimeters

mL Milliliters

mmHg Millimeters of mercury (mmHg x 0.133 = kPa ) (mmHg x 1.3595 = cmH2O)

cmH2O Centimeters of water (cmH2O x 0.098 = kPa) (cmH2O x 0.7355= mmHg)

°C Degrees Celsius

°F Degrees Fahrenheit

N-m Newton-Meter (N-m x .737 = ft-lb)

ft-lb Foot-Pound Force (ft-lb x 1.356 = N-m)

oz Ounces

NPTF National Pipe Thread Female (USA)

MPTS Multi-Purpose Therapy Stand

g grams

m meters

6700-0011-000 (Rev. 8.1) 08/19 3

1/Precautions

1.1 Definitions Connect the vacuum regulator to the vacuum source only.

Connection to positive pressure sources, even momentarily,

Note: A Note provides additional information to clarify a could injure the patient or operator and damage the

point in the text. equipment.

Important: An Important statement is similar to a note but of Always connect the regulator to the vacuum source and

greater emphasis. check its operation before attaching the patient connection.

⚠ CAUTION: A CAUTION statement is used when the Do not use this device in the presence of flammable

possibility of damage to the equipment exists. anesthetics. Static charges may not dissipate and a possible

explosion hazard exists in the presence of these agents.

⚠ WARNING: A WARNING statement is used when the

possibility of injury to the patient or the operator exists. Following sterilization with ethylene oxide, quarantine parts

in a well ventilated area to allow dissipation of residual

1.2 Warnings ethylene oxide gas absorbed by the material. Aerate for 8

hours at 130°F (54°C).

This device is to be used only by persons who have been

If the vacuum regulator is repaired or disassembled in any

adequately instructed in its use.

manner, the service checkout procedure (Section 8 Service

After patient use, regulators may be contaminated. Handle Checkout Procedure) must be performed before using the

in accordance with your hospital’s infection control policy. equipment on a patient.

Clean and disinfect all suction equipment before shipment The pre-use checkout procedure (Section 4.2.3 Pre-use

for service to ensure transportation personnel and/or service Checkout Procedure) must be performed before using this

personnel are not exposed to any hazardous contamination. equipment on each patient. If the regulator fails any part of

the pre-use checkout procedure, it must be removed from

Clamping the tubing between the patient and the collection service and repaired by qualified service personnel.

bottle may result in pressure buildup in the catheter and

tubing.

When using a disposable chest drainage system, the

atmospheric vent at the top of the suction control chamber

must be occluded for proper suction regulation with the

Thoracic regulator.

The patient port of the regulator must be occluded when

setting the prescribed suction level so that the patient does

not receive higher than required suction levels.

A water seal system must be used with the Thoracic

Regulator to prevent atmospheric air from entering the

pleural cavity, and to show the presence of air movement

into the collection system.

The vacuum relief valve must be tested to ensure compliance

with the manufacturer’s specifications before the unit is

placed in service. Remove the unit from service if it fails

the test, otherwise, excessive suction can cause injury to

a patient. Excess Loctite® may seal the steel ball to the

seat. This will disable the vacuum relief valve and may allow

suction to exceed the pre-set limit.

With the patient tubing occluded, all the bubbling in the water

seal system should stop. If bubbling does not stop, check all

connections to troubleshoot and eliminate leaks.

When a leak-free collection system connected to a patient

is turned on, after initial air in the system is eliminated, only

patient air will produce bubbles in the water seal.

4 6700-0011-000 (Rev. 8.1) 08/19

1/Precautions

1.3 Cautions 1.4 Intended Use

Cleaning the gauge may cause damage which will result in The Ohio Medical® Thoracic Vacuum Regulator is a vacuum-

inaccurate readings. powered suction apparatus that is intended for use with Chest

Drainage Systems in Thoracic, Cardiovascular, Trauma and

Do not steam autoclave or liquid sterilize the regulator. Critical Care applications.

Severe impairment of the operation of the regulator will

result. The only acceptable method of sterilization is with gas

(ethylene oxide).

To help prevent aspirate from entering the regulator, the

Thoracic Vacuum Regulator should always be used as part

of a water seal drainage system. If as a result of misuse,

water or aspirate gets into the regulator, it may impair the

regulator’s operation.

Do not use any Loctite® products, or any products which

contain methacrylate ester as an active ingredient to seal

the threads on the adapter/probe and fittings.

Only competent individuals trained in the repair of this

equipment should attempt to service it.

Sterilization with ethylene oxide mixtures may cause crazing

(minute superficial cracking) of some plastic parts. Crazing

will be more pronounced when mixtures containing Freon®

are used.

Prior to placing the unit back into service, after disassembly

or cleaning, perform the service checkout procedure (Section

8 Service Checkout Procedure).

The gauge assembly must be handled with utmost care to

retain its precision. If the lens is removed, do not rest the

gauge on its face.

Use care when unhooking the tension spring from the

regulator. Excessive tension on the spring can crack the

plastic at the base of the mounting post.

To prevent stripping of the plastic threads, place the screw

in the hole and turn counter-clockwise until it drops into the

original threads, then tighten the screw.

Use of lubricants other than those recommended may

degrade plastic or rubber components (Section 7.1 Service

Tools and Equipment).

Not for field or transport use*.

* The categories of Field and Transport Use are specifically defined in ISO

10079-3 (Section 5.1.2), “Field” means use at accidents or emergencies

outside a hospital. “Transport” means use in ambulances, cars or airplanes.

These situations may expose the equipment to uneven support, dirt,

water, mechanical shock and temperature extremes. Ohio Medical suction

equipment has not been tested to comply with the specific requirements of

these categories.

6700-0011-000 (Rev. 8.1) 08/19 5

2/Scope

This service manual contains service, maintenance and

parts information for four models of the Thoracic Vacuum

2.3 French

Regulator. Thoracic Vacuum Regulator

Note: Parts numbers are for vacuum regulators without

adapters/probes.

|(On)

30

2.1 North American

40

3

4 20

High Flow 2

50

Thoracic Vacuum Regulator

Low Vacuum

5

1

10

6

60

a

-kP

O

H2

-cm

O(Off)

30 35 40

25

20 45

_ cmH O

15

2 50

10 55

60

5

Thoracique

C

R E A

S 6700-1277-901

E

N

I

Thoracic

2.4 Spanish

Thoracic Vacuum Regulator

6700-1275-901

|(On)

30

40

3

4 20

2.2 International

High Flow 2

50 Low Vacuum

5

1

10

Thoracic Vacuum Regulator

6

60

a

-kP

O

H2

-cm

|(On)

30

40

3

4 20

High Flow 2

50 Low Vacuum

5

6

1

10 Thorácico

60

a

-kP

O

H2

-cm

6700-1278-901

Thoracic

6700-1276-901

6 6700-0011-000 (Rev. 8.1) 08/19

3/Description and Specifications

3.1 Description In the | (ON) mode, the vacuum source is connected through

the regulator module which functions as an automatic valve.

⚠ WARNING: Do not use this device in the presence Turning the suction control knob adjusts the position of the

of flammable anesthetics. Static charges may not regulator module and allows selection of a predetermined

dissipate and a possible explosion hazard exists in level of suction.

the presence of these agents.

During use, as the flow requirement increases, the valve

The Thoracic Vacuum Regulator is a lightweight, compact automatically opens to maintain suction at the pre-set level.

unit used throughout the hospital for chest and mediastinal Conversely, when the flow requirement decreases, the valve

drainage. automatically closes to maintain suction at the pre-set level.

The same mechanism compensates for changes in supply

Each regulator contains a vacuum gauge which indicates vacuum and automatically maintains the pre-set suction

suction supplied by the regulator. level.

The Thoracic Vacuum Regulator operates only in a regulated 1. Suction Control Knob - Allows adjustment of suction to

vacuum mode. The unit has a diaphragm-type regulator the patient.

which provides an adjustable vacuum of 0 to 50 cmH2O (0 to

4.9 kPa). The regulator has a vacuum gauge with increments 2. Mode Selector Switch - Allows quick mode changes.

to 60 cmH2O (5.9 kPa) and is housed in impact-resistant

a. | (ON) - Suction can be adjusted with the suction

plastic for durability.

control knob.

A vacuum limiting valve is incorporated which limits the

b. O (OFF) - No suction is supplied to the patient.

maximum vacuum between 50 and 60 cmH2O (4.9 and 5.9

kPa). If positive pressure is applied to the patient port (e.g. 3. Vacuum Gauge - Displays the suction level to the patient

patient coughing) a positive pressure relief valve operates to during use.

relieve the pressure.

Mode

O(Off)

Selector

Switch

Adapter/

25

30 35 40

45

Probe

20 _ cmH O

2 50 Port

Vacuum 15

55

10

Gauge 5

60

R E A

Suction

C S

E

N

I

Control

Knob

Thoracic

Patient

Port

6700-0011-000 (Rev. 8.1) 08/19 7

3/Description and Specifications

3.2 Specifications

3.2.1 Technical Specifications

Gauge: Accuracy ± 3 cmH2O (± 0.3 kPa)

Flow Rate: 0 to 40 LPM without fittings at full increase setting

depending on the supply vacuum and open air flow

Positive Pressure Safety Relief Valve: Located in patient circuit to prevent pressurization of

patient chest cavity in excess of 10 cmH2O (1.0 kPa)

Regulated Suction Range: 0 to 50 cmH2O (0 to 4.9 kPa)

Vacuum Relief Valve: 55 cmH2O ± 5 cmH2O (5.4 kPa ± 0.5 kPa)

Weight: 24 oz (680 g)

(less fittings)

Dimensions Height: 7.2 in (185 mm)

(less fittings) Width: 3.5 in (90 mm)

Depth: 4.3 in (108 mm)

Latex tubing 0 to full vacuum

0.25 in (6.4 mm) ID Flow dependent on source and set-up

Disposable tubing 0 to full vacuum

(available separately in some markets; Flow dependent on source and set-up

6 mm ID x 450 mm, 750 mm and 2 m) to connect regulator and collection bottle

Disposable Suction Filter: 0 to full vacuum

0 to 100 LPM @ 650 mmHg (86.7 kPa)

3.2.2 Environmental Specifications

Operating Temperature Range: 40°F to 120°F (4°C to 49°C)

Storage Temperature Range: 0°F to 160°F (–18°C to 71°C)

Operating and Storage Relative Humidity: 5 to 95%

3.2.3 Standards

ISO 10079-3 (Section 5.1.2)

8 6700-0011-000 (Rev. 8.1) 08/19

4/Operation

4.1 Equipment Set-Up Note: A positive pressure relief valve in the Thoracic Vacuum

Regulator will prevent pressure buildup in the system if

If the regulator is equipped with a adapter/probe for wall suction is turned off using the mode selector switch.

outlets, insert the adapter/probe into the vacuum wall outlet.

If the regulator is mounted elsewhere, connect a vacuum ⚠ WARNING: Clamping the tubing between the

supply hose between the regulator’s adapter/probe port and patient and the collection bottle may result in

the wall outlet. pressure buildup in the catheter and tubing.

⚠ WARNINGS: Always connect the regulator to a ⚠ When using a disposable system, the atmospheric

vacuum source and check its operation before vent at the top of the suction control chamber must

attaching the patient connection (Section 4.2.3 be occluded for proper suction regulation with the

Pre-use Checkout Procedure). Thoracic Vacuum Regulator.

⚠ Connection to positive pressure sources such as Important: Once the atmospheric vent is occluded,

oxygen and medical air, even momentarily, could the Thoracic Vacuum Regulator controls vacuum level

injure the patient or operator. regardless of the presence or amount of water in the suction

control chamber.

⚠ CAUTION: Connection to positive pressure sources Note: A positive pressure relief valve in the disposable

such as oxygen and medical air, even momentarily,

collection system will prevent pressure buildup in the system

could damage the equipment.

if the system is clamped between the vacuum regulator and

Use hospital-supplied suction tubing between the end piece the collection device.

⚠ CAUTION: To help prevent aspirate from entering

and the collection container, and between the patient port

and the patient (minimum inside diameter is 0.25 in. [6 mm]).

the regulator, the Thoracic Vacuum Regulator should

An Ohio Medical high flow suction filter and overflow safety always be used as part of a water seal drainage system.

trap should be used between the collection container and If as a result of misuse, water or aspirate gets into the

regulator to prevent contamination of the regulator. regulator, it may impair the regulator’s operation.

ISO 10079-3 (Section 5.1.2) states “...the usable volume of

the collection container shall be not less than 500 mL.”

Setup with Disposable

Collection System | (On)

(for reference only. Unit not supply

by Ohio Medical)

Setup with Reusable

Collection System | (On) Thoracic

Vacuum

Regulator

High Flow

Thoracic

Suction

Vacuum

Filter

Regulator

Overflow

Safety

High Flow Trap

Suction Overflow

Filter Safety Atmospheric

Trap Patient

Vent

Drainage Port

Vacuum Port

Patient

Drainage Suction Control

Port Chamber (shown

with no water in

chamber)

Collection

Drainage Chamber

Water

Collection

Seal

Bottle with

Bottle

Shut-off

Valve

2 cm Water Seal 2 cm Water Seal

6700-0011-000 (Rev. 8.1) 08/19 9

4/Operation

High Flow Suction Filters 4.2.2 Setting the Suction Level

Hydrophilic:

Nipple | (On)

1. Clamp the connective tubing to

20 Pack 6730-0350-800 occlude the patient port.

200 Pack 6730-0351-800

2. Turn the mode selector switch to

Hydrophobic: | (ON).

Nipple Threaded

3 Pack 6700-0570-800 6700-0580-800 3. Rotate the suction control knob

10 Pack 6700-0571-800 6700-0581-800 until the vacuum gauge indicates

50 Pack 6700-0572-800 6700-0582-800 the required setting.

4.1.1 Attaching the Overflow Safety

Trap (OST)

CAUTION

⚠ To help prevent aspirate from entering the regulator, wall

outlet and pipeline equipment, a safety trap should be

⚠ WARNING The regulator must be occluded when

attached prior to its use. Aspirate in the regulator, wall

setting the prescribed suction level so that the patient

outlet and pipeline equipment may impair its operation.

does not receive higher than required suction.

The use of the safety trap and suction filter will help

prevent this and extend the life of suction equipment.

4.2.3 Pre-use Checkout Procedure

The Pre-use Checkout Procedure must be performed before

1. Raise the sleeve and insert the trap into the regulator using this equipment on each patient. All tests must be

fitting. performed with a supply vacuum of 300 mmHg (40.0 kPa)

2. Turn the trap clockwise about one minimum.

and a half turns to engage the 1. Turn the mode selector switch to O (Off)

threads. The trap does not need O (OFF).

to be screwed tight; an O-ring in

the regulator fitting provides a 2. Rotate the suction control knob

vacuum seal. The trap should rotate one full turn clockwise (increase).

freely to allow the desired tubing

3. Clamp the connective tubing to

positioning.

occlude the fitting port. The gauge

needle should not move.

3. Lower sleeve to lock trap in position.

Regulator

Sleeve

4.2 Operation 4. Turn the mode selector switch to | (On)

| (ON).

4.2.1 Mode Selection 5. Rotate the suction control knob

| (ON) - Suction can be adjusted with the suction control fully counter-clockwise (decrease).

knob.

6. Clamp the connective tubing. The

gauge needle should not move.

O (OFF) - No suction is supplied to the patient.

10 6700-0011-000 (Rev. 8.1) 08/19

4/Operation

7. With the tubing still clamped, 4.2.4 Patient Set-Up

increase the suction to 35 cmH2O

(3.4 kPa). 1. Make sure the pre-use checkout procedure (Section

O (Off)

4.2.3 Pre-use Checkout Procedure) has been performed.

8. Slowly open and close the

clamped tubing to create various 2. Clamp the connective tubing and turn the mode selector

flow rates through the regulator. switch to | (ON).

Check that the suction level is

maintained when the tubing is 3. Set the prescribed suction level.

clamped.

⚠ WARNING: The patient port of the regulator must

9. Clamp the connective tubing. be occluded when setting the prescribed suction

level so that the patient does not receive higher

than required suction levels.

Important: Add the 2 cm water seal amount to the level set

on the regulator gauge to determine the total suction level.

| (On)

10. Rotate the suction control knob

fully clockwise (increase) to | (On)

verify that the relief valve opens

(begins to flow) at 55 cmH2O ± 5

cmH2O (5.4 kPa ± 0.5 kPa). As

suction is increased, the relief

valve should not allow levels of

more than 60 cmH2O (5.9 kPa).

O (Off)

11. Reduce the suction level

to zero and turn the mode

selector switch to O (OFF).

6700-0011-000 (Rev. 8.1) 08/19 11

4/Operation

4. Turn the mode selector switch to O (OFF). 9. Clamp the patient tubing.

⚠ WARNING: A water seal system must be used 10. Turn the mode selector switch to | (ON).

with the Thoracic Vacuum Regulator to prevent

11. After a brief period, all bubbling in the water seal should

atmospheric air from entering the pleural cavity,

stop.

and to show the presence of air movement into the

collection system. ⚠ WARNING: With the patient tubing occluded, all

5. Fill the water seal to its designated level. bubbling in the water seal system should stop. If

bubbling does not stop, check all connections to

6. Connect the regulator to a reusable water seal or a troubleshoot and eliminate leaks.

disposable system with a water seal.

12. Release the clamp on the patient tubing.

7. Connect the water seal to the collection bottle’s vacuum

port. ⚠ WARNING: When a leak-free collection system

connected to a patient is turned on, and after initial

8. Attach the patient tubing to the collection bottle’s patient air in the system is eliminated, only thoracic air

port. should produce bubbles in the water seal.

O(Off)

| (On)

Clamp

Release

Clamp

12 6700-0011-000 (Rev. 8.1) 08/19

5/Cleaning, Disinfection and Sterilization

5.1 Cleaning and Disinfection 4. Perform service checkout procedure (Section 8 Service

Checkout Procedure).

⚠ WARNING: After patient use, regulators may be

contaminated. Handle in accordance with your 5.1.2.1 Approved Flush Solutions

hospital’s infection control policy. Warm water and mild detergent.

⚠ WARNING: Perform a service checkout procedure

(Section 8 Service Checkout Procedure) following

5.1.3 Cold Flush Procedure

cold flushing. Validate the selected cleaning/ ⚠ CAUTION: Unit failure due to cold flushing is not the

disinfection procedure. Failure to do so may result responsibility of Ohio Medical and may invalidate

in patient use of a product which is assumed to be the warranty. Failure to adequately dry the product

clean/disinfected but is not. following a cold flush may damage the working parts

⚠ CAUTION: Suctioned fluids drawn into a vacuum which are designed for pneumatic air-flow only. Failure

to disassemble to check O-ring and filter status may

regulator do not stop in the regulator. They proceed

render the unit inoperative.

through it into the wall outlet and pipeline system.

Failure to clean and disinfect the wall outlet and pipeline If desired, the vacuum regulator can be cold-flushed as part

system may result in damage to this equipment. of a cleaning or disinfecting procedure. Set up a collection

canister or liner between the vacuum source and the

5.1.1 Routine Exterior Cleaning & adapter/probe port of the vacuum regulator to receive the

Disinfection flush solution. To satisfy the infection control requirements of

the hospital, suction an adequate amount of cold disinfectant

Routine cleaning of the regulator is recommended as through the vacuum regulator. Use only approved flushing

a standard procedure after each use. Wipe all exterior solutions. Make sure solutions that are made from

surfaces with a solution of water and mild detergent and/or concentrates are newly-mixed to ensure effectiveness.

an approved cleaning solution.

Flush the vacuum circuits thoroughly. Allow the specified

5.1.1.1 Approved Cleaning Solutions time required for your cold solution to ellapse to achieve

• Virex® (Quaternary Ammonium 0.2%): Mixture of 1 fl. disinfection. Adequately aerate the circuits with vacuum flow

oz. of Virex® to 1 gallon (128 fl. oz.) tap water using or compressed air until all internal channels, switches, gauge

Virex®128 ports and regulating mechanisms are dry. Disassemble to

check O-rings for adequate lubricant and filters for proper

• Kleenaseptic® Full strength from spray can function following any cold flush procedure. Perform

• Bleach (Sodium Hypochlorite 0.5%): Mixture of 13 fl. service checkout procedure (Section 8 Service Checkout

oz. of Clorox household bleach to 1 gallon (128 fl. oz.) Procedure).

tap water

5.2 Sterilization

• Betco® TB Plus Mixture of 1 fl. oz. to 1 gallon (128 fl.

oz.) tap water Should misuse occur, resulting in accidental flooding of the

regulator, the regulator may be sterilized using ethylene

• Glutaraldehyde oxide (ETO). After sterilization, follow the service checkout

• Isopropyl Alcohol 70% procedures (Section 8 Service Checkout Procedure).

• Hydrogen Peroxide 3% ⚠ WARNING: Following sterilization with ethylene

oxide, parts should be quarantined in a well

• Cavicide®: Ready to use full strength ventilated area to allow dissipation of residual

ethylene oxide gas absorbed by the material.

5.1.2 Internal Component Cleaning & Aerate parts for 8 hours at 130°F (54°C). Follow

Disinfection your hospital sterilization procedure.

⚠ CAUTION: Cleaning the gauge may cause damage ⚠ CAUTION: Do not steam autoclave or liquid sterilize the

which will result in inaccurate readings. vacuum regulator. Severe impairment to the operation

1. To disassemble the unit, refer to Section 7 Service - of the regulator will result. The only acceptable method

Disassembly and Assembly for instructions. of sterilization is with gas (ethylene oxide).

2. All internal components, with the exception of the gauge, ⚠ CAUTION: Sterilization with ethylene oxide mixtures

may be cleaned with a solution of warm water and mild may cause crazing (minute superficial cracking) of

detergent. some plastic parts. Crazing will be more pronounced

when mixtures containing Freon® are used.

3. Dry all components with a lint free cloth before assembly.

Dry internal passages using vacuum flow or compressed Note: The vacuum regulator should only be sterilized if it is

air. contaminated or maintenance is to be performed.

6700-0011-000 (Rev. 8.1) 08/19 13

6/Troubleshooting

Problem Possible Causes Remedy

A. No gauge indication and no 1. No supply vacuum 1. Correct supply problems

suction in any setting 2. Poor connection 2. Check all connections and seals

3. Blocked adapter/probe port 3. Clean port

4. Blocked adapter/probe 4. Clean or replace adapter/probe

5. Blocked wall outlet 5. Clean outlet

B. No gauge indication but 1. Blocked gauge pressure sensing 1. Clean orifice and/or gauge tubing

suction is being delivered orifice and/or gauge tubing

2. Dust in gauge mechanism 2. Gently blow out dust

3. Gauge mechanism jammed 3. Replace gauge

C. Gauge indication but no 1. Blocked patient port 1. Clean port

suction is being delivered 2. Blocked external filter 2. Replace external filter

3. Blocked fitting 3. Clean or replace fitting

4. Gauge jammed/damaged 4. Replace gauge

D. Suction level cannot be 1. Regulator diaphragm rupture 1. Replace diaphragm

adjusted 2. Broken or stripped control shaft 2. Replace control shaft

3. Piston stuck in baffle guide plate 3. Dislodge piston

E. Insufficient flow through 1. Partial blockage in wall outlet 1. Remedy:

regulator i. Confirm wall supply open air

flow meets minimum hospital

requirements

ii. Clean if necessary

2. Partial blockage in regulator 2. Remedy:

i. Perform the flow test in the

service checkout procedure

section of this manual (Section

8.2 Flow Test)

ii. Clear blockage if necessary

F. Inaccurate gauge reading 1. Damaged gauge 1. Replace gauge

Note: All gauge needles

should come to rest at the stop

pin when no suction is being

supplied.

G. No suction in any setting 1. Vacuum relief valve failure 1. Replace rubber sleeve and ensure

and whistling or vibrating that the steel ball is present and clean

noise from inside the regulator 2. Positive pressure safety relief 2. Replace positive pressure safety relief

valve failure valve

14 6700-0011-000 (Rev. 8.1) 08/19

7/Service - Disassembly and Assembly

7.1 Service Tools and Equipment 2. Pull the knob off of the control shaft, as well as the

washer and plastic spacer on the shaft under the knob.

⚠ CAUTION: Use of lubricants other than recommended

may degrade plastic or rubber components. 3. Gently slide the gauge out of its mounting and disconnect

from tubing.

The following items should be on hand during any service

procedure: Note: The plastic gauge lens should remain attached to

the gauge.

• Supply vacuum: 300 mmHg (40.0 kPa) minimum with 80

LPM open air flow minimum. 4. Remove the connecting tube with the restricting orifice

from the regulator assembly.

• Bubble leak tester

5. Unhook the tension spring (if present) from the mode

• 50 LPM flowmeter (6700-0355-800) selector switch.

• Water manometer or calibrated vacuum gauge, 0 to 70 ⚠ CAUTION: Use care when unhooking the tension

cmH2O (± 1 cmH2O) spring from the regulator. Excessive tension on the

spring can crack the plastic at the base of the mounting

• Water manometer or calibrated pressure gauge, 0 to 70 post.

cmH2O (± 1 cmH2O)

6. Remove the mounting screw and spring washer from the

• Dow Corning No. 111 lubricant (6700-0074-200) center of the mode selector switch. Lift the switch from

• Pliers the unit and unplug its connecting line to the regulator

assembly. Use a toothpick to remove the O-ring from its

• Loctite® 242 removable thread locker (6600-0058-300) recess in the back plate.

• 1/4 inch flathead screwdriver 7. Unbolt the adapter/probe connector from the back plate.

Use a tooth pick to remove the O-ring.

• No. 2 Phillips screwdriver

8. Pull the vacuum relief valve off its mounting vent (cup

• Internal snap ring pliers your hand under the valve to catch the ball as it falls out

• 5/16” and 9/16” open end wrenches while unscrewing the adjustment screw).

• Positive pressure source delivering 10 LPM open flow 9. Remove the regulator assembly mounting screws and

lift the assembly off the back plate.

• Toothpick (O-ring removal)

10. Take the diaphragm off the back plate.

7.2 Disassembly Note: The metal disc at the center of the diaphragm may

be removed for further cleaning if necessary.

⚠ WARNINGS: If the vacuum regulator is repaired or

disassembled in any manner, the service checkout 11. Separate the regulator assembly and remove the large

procedure (Section 8 Service Checkout Procedure) O-ring seal.

must be performed before using the equipment on

a patient. 12. Unscrew the patient port fitting from the regulator

assembly, and remove the O-ring.

⚠ After patient use, regulators may be contaminated.

Handle in accordance with your hospital’s infection 13. Using the snap ring pliers, remove the snap ring that

control policy. retains the control shaft in the regulator assembly. Pull

out the control shaft, and remove the spring, nut and

⚠ To reduce service personnel exposure to hazardous O-ring.

contamination, clean and disinfect all suction

Note: The spring button and piston should be left

equipment before disassembly.

assembled in the baffle guide plate.

⚠ CAUTION: The gauge assembly must be handled

with utmost care to retain its precision. If the lens is

removed, do not rest the gauge on its face.

1. Remove the four cover mounting screws and lift off the

front cover.

6700-0011-000 (Rev. 8.1) 08/19 15

7/Service - Disassembly and Assembly

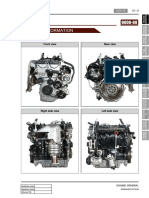

8

6 10

4 7 11

12

14

13

2

7.2.1. Part Numbers

1. Control Knob.......................................... 0212-0806-100

2. Bent Metal Washer................................. 0202-3042-300

3. Plastic Spacers (2)................................. 0202-0063-300

4. Cover Mounting Screws (4)................... 0142-4113-108

5. Restrictor tubes and orifice kit

(Includes items 6, 7, and 8).................... 6700-0429-850

6. Restrictor Mounting Tube

7. Restrictor Orifice

8. Tube

9. Gauge kit (Includes items 10, 11, and 12)

Domestic............................................ 6700-0430-850

International....................................... 6700-0431-850

10. Barbed Fitting

11. Vacuum Gauge

12. Lens Cover....................................... 6700-0087-500

13. Label

Domestic................................................ 0205-4366-300

International........................................... 6700-0224-100

14. Front Cover

English................................................... 6700-0155-400

French.................................................... 6700-0155-401

Spanish.................................................. 6700-0155-402

16 6700-0011-000 (Rev. 8.1) 08/19

7/Service - Disassembly and Assembly

5

7

6

8

1

9

1. Vacuum Tube.........................................0211-0072-300

2. Adapter/probe Mounting Screws (2)..... 0140-6624-108

3. Adapter/probe connector...................... 0206-5149-300

4. O-ring.................................................... 6700-0131-500

5. Nuts (2)................................................. 6700-0175-400

6. O-ring.................................................... 6700-0131-500

7. Mode Selector switch

(International – I/O)............................... 6700-0092-701

(Domestic – ON/OFF)........................... 6700-0092-700

8. Spring washer....................................... 0202-3030-300

9. Screw.................................................... 6700-0208-400

6700-0011-000 (Rev. 8.1) 08/19 17

7/Service - Disassembly and Assembly

8 7

11

10

1. Vacuum Relief Adjustment Kit 6

(Includes items 2 and 3)........................ 6700-0432-850 3

2. Vacuum Relief Adjustment Screw

3. Vacuum Relief Body 2

4. Ball........................................................ 6700-0248-400

5

5. Patient port fitting.................................. 0204-9046-535

6. O-ring.................................................... 6700-0130-500

7. Diaphragm............................................ 0210-7300-100

8. Disc....................................................... 0214-3212-300

9. Backplate - English .............................. 6700-0643-850 1

French .............................. 6700-0633-850

Spanish............................. 6700-0634-850

German ............................. 6700-0635-850

Italian ............................... 6700-0636-850

Swedish............................ 6700-0637-850

Japanese .......................... 6700-0638-850

Russian............................. 6700-0639-850

Greek................................ 6700-0640-850

Dutch ............................... 6700-0641-850

Portuguese ....................... 6700-0642-850

10. Rubber Sleeve.......................................0211-0719-500

11. Screws (4)..............................................0140-6124-112

18 6700-0011-000 (Rev. 8.1) 08/19

7/Service - Disassembly and Assembly

11

10

8

12

7

6

5

13

4

3

2

1

1. Snap ring................................................0203-5213-300

2. O-ring.....................................................6700-0131-500

3. O-ring.....................................................6700-0132-500

4. Brass nut................................................0402-1659-500

5. Spring.....................................................0203-3054-300

6. Spring Button.........................................0212-0800-100

7. Spring Case Cover.................................0221-6365-300

8. O-ring.....................................................6700-0100-400

9. Baffle-Guide Plate..................................0212-0804-100

10. Piston.....................................................6700-0099-400

11. O-ring.....................................................0210-0527-300

12. Flapper Valve......................................... 0211-1451-100

13. Control Shaft..........................................0221-6351-500

6700-0011-000 (Rev. 8.1) 08/19 19

7/Service - Disassembly and Assembly

7.3 Assembly ⚠ WARNING: The vacuum relief valve must be

tested to ensure compliance with manufacturer’s

Before reassembling the unit, sparingly lubricate all of the specifications before the unit is placed in service.

O-rings with Dow Corning® No. 111. Remove the unit from service if it fails the test,

excessive suction can cause injury to a patient.

⚠ CAUTIONS: To prevent stripping of the plastic threads,

place the screw in the hole and turn counter-clockwise Ensure that the conductive wire (if present) between the

until it drops into the original threads, then tighten the adapter/probe connector and the patient port fitting is

screw. properly connected.

⚠ Over-tightening of the screws may results in stripped ⚠ WARNING: If the vacuum regulator is repaired or

threads.. disassembled, the service checkout procedure

(Section 8 Service Checkout Procedure) must be

When installing the diaphragm, orient it with its metal section performed before using the equipment on a patient.

towards the metal piston of the regulator assembly. The rim

of the diaphragm should fit over the outside of the diaphragm Important: This entire Service Check-out Procedure MUST

seat for a good seal. Do not lubricate the diaphragm. Tighten be performed in numerical order.

the regulator assembly mounting screws in an “X” pattern to

prevent warpage (do not over tighten the screws).

Before placing the front cover on a reassembled unit connect

it to a functioning vacuum source and adjust the vacuum

relief valve. Refer to Section 8.5 Vacuum Limit Test.

Mode Selector

Switch | (On)

Supply Vacuum Gauge

30 0 to 760 mmHg (0 to 101.3 kPa)

40

3

4 20

High Flow 2

50 Low Vacuum

5

1

10

6

60

a

-kP

O

H2

Vacuum

-cm Supply Vacuum

Regulator 300 mmHg (40.0 kPa)

Open flow of 80 LPM

Suction

Control

Knob

Thoracic

Occluded

Water Manometer or

Calibrated Pressure Gauge

Water Manometer or

70 cmH2O (6.9 kPa)

Calibrated Vacuum Gauge

70 cmH2O (6.9 kPa)

Flowmeter

50 LPM

Positive Pressure Source

Open Flow 10 LPM

20 6700-0011-000 (Rev. 8.1) 08/19

8/Service Checkout Procedure

8.1 Set-Up 8.4 Regulation Test

1. Verify that there is a minimum of 300 mmHg (40.0 kPa) 1. Disconnect the calibration gauge and occlude the patient

vacuum on the supply gauge. port.

2. The supply open flow must be at least 80 LPM. 2. Set the vacuum level on the gauge to 30 cmH2O (2.9

kPa).

3. Connect the supply vacuum to the adapter/probe port of

the regulator. 3. Open and close the patient port several times.

4. With the patient port occluded, the regulator gauge

8.2 Flow Test should return to the setting listed in step 2 within a

1. Connect the regulator’s patient port to the flowmeter tolerance of ± 3 cmH2O (± 0.3 kPa).

with tubing. Use the shortest tubing possible with an

inside diameter of 0.25 in (6 mm) or larger. 8.5 Vacuum Limit Test

2. Rotate the suction control knob fully clockwise (increase). 1. Occlude the patient port of the regulator.

3. Turn the mode selector switch to | (ON) and verify that 2. Turn the suction control knob fully counter-clockwise

the flow rate is at least 40 LPM. (full decrease).

4. Turn the mode selector switch to O (OFF) and disconnect 3. Slowly increase the vacuum and observe the gauge.

the flowmeter.

4. The vacuum relief valve should open at 55 cmH2O ±

5 cmH2O (5.4 kPa ± 0.5 kPa). The gauge needle may

8.3 Gauge Test oscillate, but the vacuum should not increase beyond 60

Note: All Ohio Medical gauges are supplied with an accuracy cmH2O (5.9 kPa) as the suction control knob is turned

of ± 5% of full scale deflection throughout their range. further clockwise.

Note: All gauge needles should come to rest at the stop pin 5. If adjustment is required, grip the vacuum relief valve

when no suction is being supplied. Gauges which do not firmly with pliers and rotate the screw about 1/8 turn with

comply may be out of calibration. a screwdriver. Repeat the previous step and check the

suction level at which the valve opens.

When checking gauge accuracy, be sure that the calibration

gauge has an accuracy of ± 1 cmH2O (± 0.1 kPa) or better. Note: Clockwise rotation will increase the suction level

at which the relief valve opens. Counter-clockwise

1. Connect the regulator’s patient port to the calibration rotation will decrease the suction level at which the relief

gauge with tubing. valve opens.

2. Turn the mode selector switch to | (ON). 6. When the desired limit is reached, lock the screw with a

drop of removable thread locker Loctite® 242.

3. Check that the regulator gauge is in agreement with the

vacuum calibration gauge within the ± 3 cmH2O (± 0.3 ⚠ WARNING: Excess Loctite® may seal the steel ball

kPa) tolerance. Recommended test points are 15, 30, to the seat. This will disable the vacuum relief valve

and 45 cmH2O (1.5, 2.9, and 4.4 kPa). and may allow suction to exceed the pre-set limit.

7. Repeat the steps one through four if the relief valve does

not open within the specified range.

Valve

Body

Steel Loctite® 242

Ball

O-ring

Screw with

Magnet

6700-0011-000 (Rev. 8.1) 08/19 21

8/Service Checkout Procedure

8.6 Positive Pressure Relief Test 8.7 Leak Test

1. Set the mode selector switch to O (OFF). 1. Connect the patient port to port “A” of the bubble leak

tester with tubing (see diagram below).

2. Connect the positive pressure source and calibrated

pressure gauge to the patient port of the regulator with 2. Set the mode selector switch to O (OFF) and check

tubing (see diagram on page 20). that the suction control knob is set approximately in the

middle of its range.

3. Apply a positive pressure (at 10 LPM open flow) and

observe the calibrated pressure gauge. 3. Observe the bubble leak tester. No bubbles should

appear within 10 seconds.

4. The reading on the pressure gauge should not exceed

10 cmH2O (1.0 kPa). 4. Rotate the suction control knob fully counter-clockwise

(decrease) and turn the mode selector switch to | (ON).

5. Observe the bubble leak tester. No bubbles should

appear within 10 seconds.

Mode

Selector

Switch

O (Off)

30 35 40

20

25

_ cmH O

45 Port B

15

2 50

10 55 14” ID Clear

5

60 Tubing with

Port A Knife Edge

Vacuum

Regulator Sealed

C

R E A

S Suction

Control

E

N

I

Knob

1.0 in Water

Thoracic

Bubble Leak Tester

Bubble Leak Test Set-Up

22 6700-0011-000 (Rev. 8.1) 08/19

9/Maintenance

9.1 General Maintenance of Suction 9.2 Recommended Maintenance

Equipment In addition to the pre-use checkout procedure, the following

periodic maintenance should be performed.

⚠ WARNINGS: The pre-use checkout procedure

(Section 4.2.3 Pre-use Checkout Procedure) must Item Comments

be performed before using this equipment on

Perform Service Checkout If the regulator does not

each patient. If the regulator fails any part of the

Procedure pass the service checkout

pre-use checkout procedure, it must be removed

procedure (Section

from service and repaired by qualified service

8 Service Checkout

personnel.

Procedure), refer to Section

⚠ After patient use, regulators may be contaminated. 6 Troubleshooting section of

Handle in accordance with your hospital’s infection this manual. Repair

control policy. as necessary.

⚠ If the unit has been contaminated, clean and Check Elastometric Replace, lubricate and

disinfect all suction equipment before disassembly. Components repair as necessary to

• Positive pressure minimize in-use failures.

Protection of the vacuum piping system is as important as safety relief (flapper)

maintenance of the suction equipment. The use of collection valve

canisters with reliable shut-off valves, overflow safety trap • Switch O-ring

assemblies and disposable suction filters will protect the • Low vacuum relief

regulator, wall outlet, and piping system. valve sleeve

Routine maintenance and inspection are important to • Control shaft O-rings

the performance of suction equipment. The following is a • Patient port O-ring

recommended list for care of suction equipment after each • Adapter/probe

patient use. connector O-ring

1. Perform a thorough cleaning by washing all bottles,

tubing, metal connectors, etc, and removing all residue.

2. Wipe all exterior surfaces with a solution of water and

mild detergent.

3. Perform a careful visual inspection.

4. Check that the high flow disposable suction filter is clean

and in good condition.

5. Check that all tubing is in good condition and connected

securely to the correct ports.

6. Check the floats in the overflow safety trap and collection

bottle for correct operation.

7. Perform the pre-use checkout procedure.

6700-0011-000 (Rev. 8.1) 08/19 23

9/Maintenance

9.3 Repair Policy For Warranty and non-warranty repairs, mail the

package to

⚠ WARNING: To reduce transportation personnel

and/or service personnel exposure to hazardous Ohio Medical LLC

contamination, clean and disinfect all suction 1111 Lakeside Drive

equipment before shipping for service. Gurnee, IL 60031 USA

RMA #___________________

⚠ CAUTIONS: Do not steam autoclave or liquid sterilize

the regulator. Severe impairment of the operation of In other locations contact your nearest Ohio Medical

the regulator will result. The only acceptable method office or authorized Ohio Medical distributor.

of sterilization is with gas (ethylene oxide).

9.6 Installation Procedure for

⚠ Only competent individuals trained in the repair of this

equipment should attempt to service it. Adapters/Probes

Do not use malfunctioning equipment. Make all necessary All adapters/probes should be sealed and installed properly

repairs. Have the equipment repaired by qualified service to prevent leaks and to support the equipment when

personnel or by Ohio Medical. Parts listed in this service mounted. The adapter/probe port is a 1/8-27 NPTF tapered

manual may be repaired or replaced by a competent, pipe thread. It is important to note that adapters/probes seal

trained person who has experience in repairing devices on the thread and may have threads exposed after they

of this nature. After repair, perform the service checkout have been tightened properly.

procedure (Section 8 Service Checkout Procedure) to

Prior to installing the adapter/probe, seal the thread with

ensure that the equipment is functioning properly, and

Teflon® (PTFE) tape or one of the following lubricants:

complies with the published specifications.

Dow Corning® 111 (6700-0074-200)

9.4 Technical Assistance

⚠ CAUTION: Do not use any Loctite® products, or

If technical assistance is required, contact Ohio Medical products which contain methacrylate ester as an active

technical support or field operations listed on the back cover. ingredient, to seal the adapter/probe threads.

9.5 Return Instructions The torque range for installing adapters/probes is 4.0 ft-lb

(5.4 N-m) minimum to 10.0 ft-lb (13.6 N-m) maximum.

1. Call for a Return Material Authorization (RMA)

Adapters/probes which are not keyed for specific orientation,

number before sending any items for warranty and/

should be torqued to approximately 6.0 ft-lb (8.1 N-m).

or non-warranty repair. (1-866-549-6446)

Adapters/probes that are keyed to specific orientation, must

2. Clean and disinfect the vacuum regulator.

be torqued initially to 4.0 ft-lbs. Additional torque is applied

3. Package the vacuum regulator securely for protection, only until orientation is correct.

preferably in the original container.

9.7 Disposal Instructions

4. Include a letter describing in detail any difficulties

experienced with the vacuum regulator. Include the Dispose of vacuum regulator in accordance with local

person, title, and telephone number to contact for regulations.

questions.

5. If the vacuum regulator is covered under warranty,

include the warranty information that came with the

device and a copy of the invoice.

6. Include a purchase order to cover repair of a regulator

not under warranty.

7. Ship the vacuum regulator prepaid. Write your return

address and billing address information on the package

or letter that comes with the package.

24 6700-0011-000 (Rev. 8.1) 08/19

Notes

6700-0011-000 (Rev. 8.1) 08/19 25

®

North America

United States

Customer Service, Distribution Center

Technical Support, Sales and Service

Equipment Service Center

Ohio Medical LLC

1111 Lakeside Drive

Gurnee, IL 60031 USA

+1 (866) 549 6446

2797

EMERGO EUROPE

Prinsessegracht 20 2514 AP

The Hague The Netherlands

EMERGO AUSTRALIA

Level 20, Tower II Darling Park 201 Sussex

Street Sydney, NSW 2000 Australia

© 2019 Ohio Medical LLC.

This document contains information that is proprietary and confidential to Ohio Medical LLC.

Use of this information is under license from Ohio Medical LLC.

Any use other than that authorized by Ohio Medical LLC is prohibited.

Ohio Medical and the Ohio Medical Logo are registered trademarks Push-to-Set is a trademark of Ohio Medical LLC.

ISO is a registered trademark of International Organization for Standardization.

NFPA is a registered trademark of National Fire Protection Association, Inc.

Loctite is a registered trademark of Henkel Corporation.

Teflon is a registered trademark of E.I. duPont de Demurs and Company.

Cavicide is a registered trademark of Metrex Research Corporation.

Virex is a registered trademark of S.C. Johnson & Son, Inc.

Kleenaseptic is a registered trademark of Metrex Research Corporation.

Betco is a registered trademark of Betco Corporation.

6700-0011-000 (Rev. 8.1) 08/19

You might also like

- Practical Process Control for Engineers and TechniciansFrom EverandPractical Process Control for Engineers and TechniciansRating: 5 out of 5 stars5/5 (3)

- Whirlpool Cabrio Washer With 6th Sense TechnologyDocument84 pagesWhirlpool Cabrio Washer With 6th Sense TechnologyJohn SmithNo ratings yet

- Atlas Copco Xams496 1050 Cd6 Instruction ManualDocument10 pagesAtlas Copco Xams496 1050 Cd6 Instruction Manualjimmie100% (32)

- Instruction Manual: Automatic TLC Sampler 4Document33 pagesInstruction Manual: Automatic TLC Sampler 4amoricz1No ratings yet

- DHA SeriesDocument68 pagesDHA SeriescathylorrainegalusNo ratings yet

- 2067MANG003010 Training ManualsDocument146 pages2067MANG003010 Training ManualsMaristelle Montaño Longakit100% (1)

- Berthoud Speedair Manual PDFDocument56 pagesBerthoud Speedair Manual PDFjwdNo ratings yet

- wtw6200s Lavadora CabrioDocument84 pageswtw6200s Lavadora Cabrioerle guevaraNo ratings yet

- Gvs 16aDocument76 pagesGvs 16aFati ZoraNo ratings yet

- Neptune 7000Z IOM EnglishDocument44 pagesNeptune 7000Z IOM Englisharisqi wahyuNo ratings yet

- RF1510EN00Document56 pagesRF1510EN00Vijay Kumar NandagiriNo ratings yet

- 35-3001A-05-02 Carbon Dioxide Sample-Draw Detector Operator's ManualDocument25 pages35-3001A-05-02 Carbon Dioxide Sample-Draw Detector Operator's ManualpcatruongNo ratings yet

- L-81 Whirlpool Cabrio WasherDocument84 pagesL-81 Whirlpool Cabrio WasherJose Lorenzo Beltran Real100% (1)

- Durapore Hydrophilic Filter Cartridges User Guide L PDFDocument52 pagesDurapore Hydrophilic Filter Cartridges User Guide L PDFxerxeshakaNo ratings yet

- Instruction Manual: Colin Drive Holbrook. FaxDocument27 pagesInstruction Manual: Colin Drive Holbrook. FaxHendy Dwi WarmikoNo ratings yet

- Instruction Manual - Advance Series 480 Vacuum RegulatorDocument24 pagesInstruction Manual - Advance Series 480 Vacuum RegulatorĐình Sơn HoàngNo ratings yet

- Aestiva User Manual Part2Document140 pagesAestiva User Manual Part2leonkasiaNo ratings yet

- Maytag BravosDocument84 pagesMaytag BravosJose AriasNo ratings yet

- Hydac FAMH ManualDocument28 pagesHydac FAMH ManualDavid A. LópezNo ratings yet

- 35-3001-03 Hydrogen Sulfide Sample-Draw Detector Operator's ManualDocument24 pages35-3001-03 Hydrogen Sulfide Sample-Draw Detector Operator's ManualpcatruongNo ratings yet

- 35-3010A-09 Sample-Draw Detector: Part Number: 71-0351 Revision: P1 Released: 1/9/15Document27 pages35-3010A-09 Sample-Draw Detector: Part Number: 71-0351 Revision: P1 Released: 1/9/15pcatruongNo ratings yet

- Whirlpool WFW94 & 95HEX Direct Drive FL (SM)Document86 pagesWhirlpool WFW94 & 95HEX Direct Drive FL (SM)nutznboltz100% (1)

- API 610 (BB5), MultistageDocument56 pagesAPI 610 (BB5), MultistageEleno RibeiroNo ratings yet

- Washing Machine Repair ManualDocument96 pagesWashing Machine Repair ManualMichael SimonelloNo ratings yet

- Pump Division: Type MPTDocument41 pagesPump Division: Type MPTMohamed ZaidNo ratings yet

- Transmission Allison TipsDocument52 pagesTransmission Allison TipsMendez Francisco88% (8)

- Bombas BuschDocument20 pagesBombas BuschJorge Agustin González SaraibaNo ratings yet

- Maytag Bravos 6300Document84 pagesMaytag Bravos 6300Isidro Mendoza100% (1)

- Allison AT500 Service Manual PDFDocument52 pagesAllison AT500 Service Manual PDFedgar tmNo ratings yet

- Franz F Operatormanual V 3 0 ENDocument54 pagesFranz F Operatormanual V 3 0 ENMarkus VäliviitaNo ratings yet

- Ruhrpumpen Vertical Turbine Pumps - Operation and Maintenance ManualsDocument44 pagesRuhrpumpen Vertical Turbine Pumps - Operation and Maintenance ManualsvamcodongNo ratings yet

- Manual Bomag BVP 18-45Document76 pagesManual Bomag BVP 18-45ELIZABETH DIAZ100% (1)

- FW Generator Alfa LavalDocument81 pagesFW Generator Alfa LavalRusuVasileCristian100% (3)

- Whirlpool Duet HTDocument96 pagesWhirlpool Duet HTdanny85901100% (2)

- Busch Instruction Manual RA 0025-0100 F ATEX en 0870155907Document52 pagesBusch Instruction Manual RA 0025-0100 F ATEX en 0870155907phucdc095041No ratings yet

- Flowserve ANSI-Pumps PDFDocument68 pagesFlowserve ANSI-Pumps PDFArup MahantaNo ratings yet

- Vulcan VC4G VC6G Series Gas Convection Oven Service Manual enDocument68 pagesVulcan VC4G VC6G Series Gas Convection Oven Service Manual enRichard RoperNo ratings yet

- Datex-Ohmeda Tec7 - Service ManualDocument48 pagesDatex-Ohmeda Tec7 - Service ManualCarlos Alberto SacsaNo ratings yet

- AKO - Air Operated Pinch Valves - Operating Manual - ENDocument20 pagesAKO - Air Operated Pinch Valves - Operating Manual - ENshivakr89No ratings yet

- Livarno LAH 55 A2 69010 PL HU SL CS SKDocument92 pagesLivarno LAH 55 A2 69010 PL HU SL CS SKpanmihNo ratings yet

- Dokumen - Tips Hydrovane Hv010204Document29 pagesDokumen - Tips Hydrovane Hv010204Melvic BinosNo ratings yet

- WFC 7500 VW 0Document90 pagesWFC 7500 VW 0CSU Andrews LibraryNo ratings yet

- Hydrovane HV01!02!04Document29 pagesHydrovane HV01!02!04Mark Carter100% (4)

- Stephan Artec-Portec - Service Manual 2009Document62 pagesStephan Artec-Portec - Service Manual 2009PrzemekNo ratings yet

- M VACDocument98 pagesM VACLuis Alberto Perez ParedesNo ratings yet

- 750-183 OM Boiler Mate June10Document51 pages750-183 OM Boiler Mate June10Bülent KabadayiNo ratings yet

- 27 BeamerDocument226 pages27 BeamerashufriendluckyNo ratings yet

- Drager Fabius - Technical Documentation PDFDocument205 pagesDrager Fabius - Technical Documentation PDFDronNo ratings yet

- Jobaid-W10329932-L-84 2Document84 pagesJobaid-W10329932-L-84 2Ashton TyreeNo ratings yet

- 35-3001-04-01 Carbon Monoxide Sample-Draw Detector Operator's ManualDocument27 pages35-3001-04-01 Carbon Monoxide Sample-Draw Detector Operator's ManualpcatruongNo ratings yet

- ELGA PURELAB Option R7 Operator ManualDocument45 pagesELGA PURELAB Option R7 Operator ManualDaniel VargasNo ratings yet

- Series 92 93 Pneumatic Actuators Operations Maintenance ManualDocument14 pagesSeries 92 93 Pneumatic Actuators Operations Maintenance ManualEdison RiosNo ratings yet

- Instruction Manual: Precision AC Current Shunt SetDocument44 pagesInstruction Manual: Precision AC Current Shunt SetLabotech MetrologiaNo ratings yet

- Milroyal B HPD Low FlowDocument40 pagesMilroyal B HPD Low Flowmarshiel_rasNo ratings yet

- Variable Speed Pumping: A Guide to Successful ApplicationsFrom EverandVariable Speed Pumping: A Guide to Successful ApplicationsRating: 3 out of 5 stars3/5 (2)

- Evaluation and Optimization of Laboratory Methods and Analytical ProceduresFrom EverandEvaluation and Optimization of Laboratory Methods and Analytical ProceduresNo ratings yet

- Microprocessor Programming and Applications for Scientists and EngineersFrom EverandMicroprocessor Programming and Applications for Scientists and EngineersNo ratings yet

- Guidelines For Use of Bubble-CPAP ConcentratorsDocument10 pagesGuidelines For Use of Bubble-CPAP ConcentratorsevanNo ratings yet

- 4008S Service ManualDocument595 pages4008S Service ManualRamanjaneya goud84% (25)

- Guidance HG 2013Document34 pagesGuidance HG 2013ROSSINo ratings yet

- GE Lullaby Phototherapy System - User ManualDocument42 pagesGE Lullaby Phototherapy System - User Manualiberman PereNo ratings yet

- E-Cart Service ManualDocument7 pagesE-Cart Service ManualevanNo ratings yet

- Mindray PM-60 Inglish Manual PDFDocument52 pagesMindray PM-60 Inglish Manual PDFMiguel FigueroaNo ratings yet

- Service Manual: 5. Trouble ShootingDocument2 pagesService Manual: 5. Trouble ShootingevanNo ratings yet

- Wheel ChairDocument28 pagesWheel ChairevanNo ratings yet

- Stryker X8000 Xenon Light Source Service ManualDocument71 pagesStryker X8000 Xenon Light Source Service Manualrafael gonzalez75% (4)

- Wheel ChairDocument28 pagesWheel ChairevanNo ratings yet

- Bubble Cpap PDFDocument43 pagesBubble Cpap PDFevanNo ratings yet

- Edan F9 F9Express Service ManualDocument86 pagesEdan F9 F9Express Service ManualBryan VasquezNo ratings yet

- E-Cart Service ManualDocument7 pagesE-Cart Service ManualevanNo ratings yet

- Infant Incubator Service ManualDocument62 pagesInfant Incubator Service ManualevanNo ratings yet

- Abpm-05.. Service ManualDocument37 pagesAbpm-05.. Service ManualevanNo ratings yet

- 101 FormatDocument3 pages101 FormatevanNo ratings yet

- GINC TRM v103Document206 pagesGINC TRM v103Pablo Millaquén GNo ratings yet

- Mindray PM-60 Inglish Manual PDFDocument52 pagesMindray PM-60 Inglish Manual PDFMiguel FigueroaNo ratings yet

- Sunstrand Hydro Service ManualDocument69 pagesSunstrand Hydro Service ManualKevins Small Engine and Tractor Service100% (8)

- E-Series Hyd Pressure Setting Proc B40E and B50E (Pre Prod) Rev.CDocument31 pagesE-Series Hyd Pressure Setting Proc B40E and B50E (Pre Prod) Rev.CJUAN MANUEL RUIZ BERMEJONo ratings yet

- Festo Pneumatics BasicDocument122 pagesFesto Pneumatics BasicabrfinNo ratings yet

- ATT 101HeavyLine - Hammermaster - Range - Update PDFDocument5 pagesATT 101HeavyLine - Hammermaster - Range - Update PDFArturo Muñoz RamosNo ratings yet

- BVA J Series Manual Toe JackDocument12 pagesBVA J Series Manual Toe JackTitanplyNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©murillo_rodriguez8382No ratings yet

- VW - DSG Component AgungDocument4 pagesVW - DSG Component AgungAgung PurnamaNo ratings yet

- Ferti JetDocument19 pagesFerti JetCèsar Daniel Linares QuirozNo ratings yet

- NPR280-JockeyPump Rev.A PDFDocument9 pagesNPR280-JockeyPump Rev.A PDFSaw MyintaungNo ratings yet

- Fittings - K ValueDocument2 pagesFittings - K ValueKarthikeyan SankarrajanNo ratings yet

- 205M Parr 1108 Oxygen Bomb InstDocument16 pages205M Parr 1108 Oxygen Bomb InstmarzinusNo ratings yet

- Pressurisation, Flexfiller 225D, Operation & Maintenance - PressurisationDocument37 pagesPressurisation, Flexfiller 225D, Operation & Maintenance - PressurisationachusanachuNo ratings yet

- A05 0939Document2 pagesA05 0939Argile-assholeNo ratings yet

- 01 Bdp2-Manual enDocument16 pages01 Bdp2-Manual enSalaheddine CherkaouiNo ratings yet

- Midmark 319 Examination Table - Service ManualDocument108 pagesMidmark 319 Examination Table - Service ManualРинат ЖахинNo ratings yet

- Catalogue Fittings and Valves: Juli 2012Document86 pagesCatalogue Fittings and Valves: Juli 2012amr al yacoubNo ratings yet

- PIUSI Brochure Agricoltura Web enDocument32 pagesPIUSI Brochure Agricoltura Web enManuel.suarezgmail ComNo ratings yet

- Reciprocating Compressors-HIT Dryers - ENGDocument16 pagesReciprocating Compressors-HIT Dryers - ENGJavier Moctezuma MNo ratings yet

- MN Valve Sizing Handbook GEA19540A English PDFDocument30 pagesMN Valve Sizing Handbook GEA19540A English PDFGuillaume MontarnalNo ratings yet

- Labotronic 10 30 RTXDocument33 pagesLabotronic 10 30 RTXAbdullah Al-OtaibiNo ratings yet

- Layout: Rear View Front ViewDocument14 pagesLayout: Rear View Front ViewRms AutomotrizNo ratings yet

- As-3814 Industrial and Commercial Gas-Fired AppliancesDocument124 pagesAs-3814 Industrial and Commercial Gas-Fired Applianceshk168100% (1)

- MSDS - Co2Document7 pagesMSDS - Co2JackNo ratings yet

- SCX550E SM 1-2-1 For TNDocument35 pagesSCX550E SM 1-2-1 For TNilonk antonieNo ratings yet

- Fairbanks Nijhuis Fire Pumps Brochure, GeneralDocument8 pagesFairbanks Nijhuis Fire Pumps Brochure, GeneralFerdinan Tulus Yones Tobing100% (1)

- APT14, APT14HC and APT14SHC Automatic Pump Traps: Design Compliance StandardsDocument9 pagesAPT14, APT14HC and APT14SHC Automatic Pump Traps: Design Compliance StandardsmodulofrikiNo ratings yet

- Santech Technition Series CatalogDocument276 pagesSantech Technition Series Catalogimgtx100% (2)

- VM 0113 en EditDocument4 pagesVM 0113 en EditCristianNo ratings yet

- Dynamx: ™ Variable Flow-Control Valves, Series DXU - CDocument12 pagesDynamx: ™ Variable Flow-Control Valves, Series DXU - CClaudio ScacciatelliNo ratings yet

- Ashiq Mechatronics Case StudyDocument10 pagesAshiq Mechatronics Case StudyagsbbNo ratings yet