Professional Documents

Culture Documents

Unconfined Compressive Strength Test: Experiment 1

Uploaded by

Refisa Jiru0 ratings0% found this document useful (0 votes)

10 views5 pagesOriginal Title

EXPERIMENT 1

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views5 pagesUnconfined Compressive Strength Test: Experiment 1

Uploaded by

Refisa JiruCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 5

EXPERIMENT 1 1

Unconfined compressive strength test

Purpose

The primary purpose of this test is to determine the unconfined compressive

Strength, which is then used to calculate the unconsolidated un-drained shear

Strength of the clay under unconfined conditions. According to the ASTM standard,

The unconfined compressive strength (qu) is defined as the compressive stress atwhich an

unconfined cylindrical specimen of soil will fail in a simple compressiontest. In addition, in this test,

the unconfined compressive strength is takenas the maximum load attained per unit area whichever

occurs first during the performance of a test.

ASTM D 2166 -Standard Test Method for Unconfined compressive Strength

Of Cohesive Soil

Significance:

For soils, the un-drained shear strength (SU) is necessary for the determination ofthe bearing

capacity of foundations, dams, etc. The un-drained shear strength (SU)of clays is commonly

determined from an unconfined compression test. TheUn-drained shear strength (SU) of a cohesive

soil is equal to one-half the unconfined

Compressive strength (qu) when the soil is under the ɸ = 0 condition (ɸ = the angle of

internal friction). The most critical condition on the soil usually occursimmediately after

construction, which represents un-drained conditions, when theun-drained shear strength is

basically equal to the cohesion(c). This is expressed as

SU= qu/2

Then, as time passes, the pore water in the soil slowly dissipates, and the inter-granular stress

increases, so that the drained shear strength (τ), given by τ = c’+ σ’ tan ɸ, must be used. Where σ‘=

inter-granular pressure acting perpendicular to the shear plane; c’ and ɸ’ are drained shear strength

parameters.

Equipment:

Compression device, Load and deformation dial gauges, Sample trimming

Equipment, Balance, Moisture can.

Test Procedure:

(1) Extrude the soil sample from Shelby tube sampler. Cut a soil specimen so that the ratio (L/d) is

approximately between 2 and 2.5.where L and d are the length and diameter of soil specimen,

respectively.

(2) Measure the exact diameter of the top of the specimen at three locations

120°apart, and then make the same measurements on the bottom of the specimen. Average the

measurements and record the average as the Diameter onthe data sheet.

(3) Measure the exact length of the specimen at three locations 120°apart, and then average the

measurements and record the average as the length on the data sheet.

(4) Weigh the sample and record the mass on the data sheet.

(5) Calculate the deformation (ΔL) corresponding to 15% strain (e).

Strain (e) = ΔL/Lₒ

AAIT SCHOOL OF CIVIL AND ENVIRONMENTAL ENGINEERING

Where Lₒ= Original specimen length (as measured 1 in step 3) .

(6) Carefully place the specimen in the compression device and centre it on thebottom plate.

Adjust the device so that the upper plate just makes contact with thespecimen and set the load

and deformation dials to zero.

(7) apply the load so that the device produces an axial strain at a rate of 0.5% to

2.0% per minute, and then record the load and deformation dial readings on thedata sheet at

every 20 to 50divisions on deformation the dial.

(8) Keep applying the load until (1) the load (load dial) decreases on the specimensignificantly,

(2) the load holds constant for at least four deformation dial readings or (3) the deformation is

significantly past the 15% strainthat was determined in step 5.

(9) Draw a sketch to depict the sample failure.

(10) Remove the sample from the compression device and obtain a sample forwater content

determination.

Analysis:

(1) Convert the dial readings to the appropriate load and length units, and enter these values on

the data sheet in the deformation and total load columns.

(Confirm that the conversion is done correctly, particularly proving dial gagereadings conversion

into load)

(2) Compute the sample cross- sectional area

Aₒ=ᴨ/4*(D) ²

(3) Compute the strain,

/

Ɛ=ΔL Lₒ

(4) computed the corrected area,

Ac=Aₒ/ (1-Ɛ)

(5) Using A’, compute the specimen stress, s

Sc=P/Ac

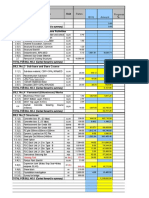

Sample calculation for axial deformation of 2.6 as shown below

Step (1) Calculate the initial AO

AO=3.14.D2/4=3.14×382/4=1134mm2

Step (2) Calculate the axial strain εO

εO=Δz/HO=2.6/76=0.03421

Step (3) Calculate the corrected area AC

AC=AO/ (1-ε1) =1134/ (1-0.03421)=

Step(4) calculate the major principal stress

σ=p/AC=0.284/111

AAIT SCHOOL OF CIVIL AND ENVIRONMENTAL ENGINEERING

displacement(dial displacement corrected 1

) (mm) stain area(mm²) load(dial) load(N) axial stress(KPA) shear stress(KPA)

AAIT SCHOOL OF CIVIL AND ENVIRONMENTAL ENGINEERING

0 0 0 1134 1 0 0 0 0

1136.99208

20 0.2 0.002632 4 53 0.07526 6.61922E-05 3.30961E-05

40 0.4 0.005263 1140 85 0.1207 0.000105877 5.29386E-05

1143.02387

60 0.6 0.007895 3 112 0.15904 0.00013914 6.95699E-05

80 0.8 0.010526 1146.06383 140 0.1988 0.000173463 8.67316E-05

100 1 0.013158 1149.12 161 0.22862 0.000198952 9.94761E-05

1152.19251

120 1.2 0.015789 3 179 0.25418 0.000220605 0.000110303

1155.28150

140 1.4 0.018421 1 195 0.2769 0.000239682 0.000119841

1158.38709

160 1.6 0.021053 7 212 0.30104 0.000259879 0.000129939

1161.50943

180 1.8 0.023684 4 230 0.3266 0.000281186 0.000140593

1164.64864

200 2 0.026316 9 239 0.33938 0.000291401 0.000145701

1167.80487

220 2.2 0.028947 8 241 0.34222 0.000293046 0.000146523

1170.97826

240 2.4 0.031579 1 252 0.35784 0.000305591 0.000152795

1174.16893

260 2.6 0.034211 7 200 0.284 0.000241873 0.000120937

1177.37704

280 2.8 0.036842 9 267 0.37914 0.000322021 0.00016101

300 3 0.039474 1180.60274 271 0.38482 0.000325952 0.000162976

1183.84615

320 3.2 0.042105 4 275 0.3905 0.000329857 0.000164929

1187.10743

340 3.4 0.044737 8 282 0.40044 0.000337324 0.000168662

360 3.6 0.047368 1190.38674 286 0.40612 0.000341166 0.000170583

1193.68421

380 3.8 0.05 1 291 0.41322 0.000346172 0.000173086

400 4 0.052632 1197 294 0.41748 0.000348772 0.000174386

1200.33426

420 4.2 0.055263 2 301 0.42742 0.000356084 0.000178042

1203.68715

440 4.4 0.057895 1 304 0.43168 0.000358631 0.000179316

1207.05882

460 4.6 0.060526 4 306 0.43452 0.000359982 0.000179991

1210.44943

480 4.8 0.063158 8 310 0.4402 0.000363667 0.000181833

1213.85915

500 5 0.065789 5 312 0.44304 0.000364985 0.000182492

520 5.2 0.068421 1217.28813 315 0.4473 0.000367456 0.000183728

AAIT SCHOOL OF CIVIL AND ENVIRONMENTAL ENGINEERING

6 1

1220.73654

540 5.4 0.071053 4 313 0.44446 0.000364092 0.000182046

1224.20454

560 5.6 0.073684 5 310 0.4402 0.00035958 0.00017979

1227.69230

580 5.8 0.076316 8 306 0.43452 0.000353932 0.000176966

AAIT SCHOOL OF CIVIL AND ENVIRONMENTAL ENGINEERING

You might also like

- BOQ BridgeDocument3 pagesBOQ BridgeReffisa JiruNo ratings yet

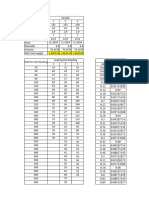

- Compound Interest Factor TablesDocument26 pagesCompound Interest Factor TablesHa Eun KimNo ratings yet

- How To Convert AWG To MM: Wire Diameter CalculationDocument2 pagesHow To Convert AWG To MM: Wire Diameter CalculationYousif_Abdalhalim0% (1)

- ASME Section VIII Pressure Vessel - Transportation AnalysisDocument4 pagesASME Section VIII Pressure Vessel - Transportation AnalysisChitti Raju DendukuriNo ratings yet

- Fluids Project: Chilled Water System: Mahmood Alaraibi - 201700841Document30 pagesFluids Project: Chilled Water System: Mahmood Alaraibi - 201700841Mahmood Al-OraibiNo ratings yet

- Ex2 21aDocument18 pagesEx2 21aManzah-iddi Abdul-rafik ZangshiniNo ratings yet

- Experiment 2Document7 pagesExperiment 2Refisa JiruNo ratings yet

- Calculo Flujo Tuberia Demostracion VelocidadDocument6 pagesCalculo Flujo Tuberia Demostracion VelocidadAldo Edson Caballero RodriguezNo ratings yet

- Stress Strain 2Document1 pageStress Strain 2Shivam DixitNo ratings yet

- Criterio de Nash: Coordenadas Desnivel Dmin Pendiente X y D KM Sxy No. Línea de MallaDocument9 pagesCriterio de Nash: Coordenadas Desnivel Dmin Pendiente X y D KM Sxy No. Línea de MallaErick De Jesus PalemonNo ratings yet

- Data Triaxial - Kelompok 1Document8 pagesData Triaxial - Kelompok 1Andini ZahrianiNo ratings yet

- STR MechanicsDocument6 pagesSTR Mechanicsmuhammad haroonNo ratings yet

- ECN801 Final - P2018Document26 pagesECN801 Final - P2018Robiul Awal RobinNo ratings yet

- Interest TableDocument31 pagesInterest TableSiddhartha MukherjeeNo ratings yet

- Bai Giang Chuong 2Document30 pagesBai Giang Chuong 2Hồ Tùng DươngNo ratings yet

- Workbook 1Document3 pagesWorkbook 1zniqqhmxNo ratings yet

- Orbital PlotsDocument9 pagesOrbital PlotsJianNo ratings yet

- 28 Days UcsDocument26 pages28 Days Ucslittle kids KingNo ratings yet

- Reporte5 JMMNDocument24 pagesReporte5 JMMNThe YisusNo ratings yet

- Time (S) Conducti Vity (MS) Conc (Gmol/l) C (T) Del T E (T) T E (T) T 2 E (T) F (T) T E (T) DT Tetha E (Tetha) T 2 E (T) DTDocument4 pagesTime (S) Conducti Vity (MS) Conc (Gmol/l) C (T) Del T E (T) T E (T) T 2 E (T) F (T) T E (T) DT Tetha E (Tetha) T 2 E (T) DTPraneethNo ratings yet

- Calculation of Loads On A Straight Wing of The Big Aspect RatioDocument9 pagesCalculation of Loads On A Straight Wing of The Big Aspect RatiogavinNo ratings yet

- Seccion Circular Repaso Vapm 6cbDocument19 pagesSeccion Circular Repaso Vapm 6cbserviciosmbalderasNo ratings yet

- Pruebas de Viscoelasticidad SalchichaDocument34 pagesPruebas de Viscoelasticidad SalchichaCatalina Mazo RivasNo ratings yet

- PROYECTO FIGMM FeldaspatoDocument6 pagesPROYECTO FIGMM FeldaspatoTicona JuanNo ratings yet

- Practica No2 - Material 1 1Document49 pagesPractica No2 - Material 1 1SnikeNo ratings yet

- Perda de CargaDocument20 pagesPerda de Cargalhcnoguera1502No ratings yet

- Water Structure Design Task Group 3Document27 pagesWater Structure Design Task Group 3MUHAMMAD TRIYONO PRATAMA BAHAR -No ratings yet

- CFE SismoDocument29 pagesCFE SismoDaniel RosalesNo ratings yet

- Engineering Tables - Standard Wire Gauge - Wikibooks, Open Books For An Open WorldDocument5 pagesEngineering Tables - Standard Wire Gauge - Wikibooks, Open Books For An Open WorldSuleman KhanNo ratings yet

- Tabel Diskonto Compound Interest PDFDocument26 pagesTabel Diskonto Compound Interest PDFLintangHzNo ratings yet

- Pipe Fittings Surface Area CompressDocument15 pagesPipe Fittings Surface Area CompressFaraz KhalidNo ratings yet

- Sistema Estructural de Tres Capas (Jones)Document4 pagesSistema Estructural de Tres Capas (Jones)Andrés VacaNo ratings yet

- Customer Job No. Test Standard Astm D 638 Type and Designation Material Specimen Removal Specimen Type Pre-Treatment Tester Note Machine DataDocument25 pagesCustomer Job No. Test Standard Astm D 638 Type and Designation Material Specimen Removal Specimen Type Pre-Treatment Tester Note Machine DataMuhammad HafizNo ratings yet

- Tensile Testing LabDocument4 pagesTensile Testing LabQ_TNo ratings yet

- Chart TitleDocument6 pagesChart TitlezniqqhmxNo ratings yet

- Dectra Molina E-O 20 Sep 2016Document29 pagesDectra Molina E-O 20 Sep 2016REYNER IVAN SANTIAGO MENDOZANo ratings yet

- HydrologyDocument23 pagesHydrologyYang RhiaNo ratings yet

- 21 tb1Document6 pages21 tb1lotannaNo ratings yet

- AWG Specifications TableDocument6 pagesAWG Specifications TablediegojhonathanNo ratings yet

- Kabiling, Amielyn B. Separation Process Take Home Quiz 2: 1 2 1 2 1 2 1A 2A 1A 2A 1B 2B 1 2Document4 pagesKabiling, Amielyn B. Separation Process Take Home Quiz 2: 1 2 1 2 1 2 1A 2A 1A 2A 1B 2B 1 2amielynNo ratings yet

- T (Sec) Conductivity (MS) C (T) C (T) DT E (T) T E (T) F (T) T 2 E (T) Te (T) DT T 2 E (T) DTDocument1 pageT (Sec) Conductivity (MS) C (T) C (T) DT E (T) T E (T) F (T) T 2 E (T) Te (T) DT T 2 E (T) DTPraneethNo ratings yet

- Velocity Distribution at Different Times For Flow of Water: 0.9 1 T 20 Sec T 40 SecDocument13 pagesVelocity Distribution at Different Times For Flow of Water: 0.9 1 T 20 Sec T 40 SecMuhammad Umer RanaNo ratings yet

- Tugas Overpressure Model Casing: Mey Frenty BR Tarigan 12316013Document4 pagesTugas Overpressure Model Casing: Mey Frenty BR Tarigan 12316013Ryzal AdzizNo ratings yet

- Saturation TablesDocument44 pagesSaturation TablesPrathik KaundinyaNo ratings yet

- Wire Gauge and Current Limits PDFDocument3 pagesWire Gauge and Current Limits PDFShahbazNo ratings yet

- Time (S) Velocity (Gyroscope y (Rad/s)Document2 pagesTime (S) Velocity (Gyroscope y (Rad/s)John Alexander GNo ratings yet

- 表5.3 8 9Document7 pages表5.3 8 9高振No ratings yet

- How To Convert AWG To MMDocument3 pagesHow To Convert AWG To MManamulk_1No ratings yet

- Wire Gauge ChartDocument2 pagesWire Gauge Chartkrishna0% (1)

- Tables NewDocument27 pagesTables Newnon31863No ratings yet

- Triaxial Lab ExperimentDocument15 pagesTriaxial Lab ExperimentAdrian Mufc RampersadNo ratings yet

- Factor de DesviaciónDocument15 pagesFactor de Desviaciónfelip7No ratings yet

- Tensión Cold Rolled 3 - 1747068Document24 pagesTensión Cold Rolled 3 - 1747068The YisusNo ratings yet

- Tr = Tmax = G Ѳ J R L: Experiment of Torsion testing machineDocument5 pagesTr = Tmax = G Ѳ J R L: Experiment of Torsion testing machineAyuguNo ratings yet

- External Internal Thread Dimensions For UNF Screw Thread 2016Document1 pageExternal Internal Thread Dimensions For UNF Screw Thread 2016Satnam Rachna FastenersNo ratings yet

- External Internal Thread Dimensions For UNF Screw Thread 2016Document1 pageExternal Internal Thread Dimensions For UNF Screw Thread 2016Ranjeet DongreNo ratings yet

- Arctanhx: Arcsinh Arctanh MsinhDocument3 pagesArctanhx: Arcsinh Arctanh MsinhttNo ratings yet

- American Wire GaugeDocument3 pagesAmerican Wire Gaugeعلي القحطانيNo ratings yet

- Reinforcement Brs TablesDocument5 pagesReinforcement Brs TablesPhanendra Kumar AttadaNo ratings yet

- EkoTek - Part IVDocument15 pagesEkoTek - Part IVwuri rahardjoNo ratings yet

- VLE CalculationDocument8 pagesVLE CalculationDa SaintNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- EBCS EN 1991 1.7 2014 - Final - Accidental ActionsDocument64 pagesEBCS EN 1991 1.7 2014 - Final - Accidental ActionsGirum Menassie100% (1)

- Chapter 4planing of BuildingsDocument33 pagesChapter 4planing of BuildingsRefisa JiruNo ratings yet

- The Gypsum Association Is A NotDocument17 pagesThe Gypsum Association Is A NotRefisa JiruNo ratings yet

- Building Sustainable University Partnerships:: U.S.-EthiopianDocument44 pagesBuilding Sustainable University Partnerships:: U.S.-EthiopianRefisa JiruNo ratings yet

- Building Sustainable University Partnerships:: U.S.-EthiopianDocument44 pagesBuilding Sustainable University Partnerships:: U.S.-EthiopianRefisa JiruNo ratings yet

- Lecture 3 - 3 RocksDocument45 pagesLecture 3 - 3 RocksRefisa JiruNo ratings yet

- EBCS en 1991 1.6 2014 - VersionFinal - Actions During Executio - SECUREDDocument29 pagesEBCS en 1991 1.6 2014 - VersionFinal - Actions During Executio - SECUREDSitotaw AlemuNo ratings yet

- Lecture 1 - 2 Branch of GeologyDocument26 pagesLecture 1 - 2 Branch of GeologyRefisa JiruNo ratings yet

- Chapter-5.7 Finishing PDFDocument13 pagesChapter-5.7 Finishing PDFRefisa JiruNo ratings yet

- CE 01022 PII Chap12 PDFDocument25 pagesCE 01022 PII Chap12 PDFRefisa JiruNo ratings yet

- BLDG F.P. 2Document2 pagesBLDG F.P. 2Refisa JiruNo ratings yet

- Answer Sheet For Holistic Examination For The Four CodeDocument4 pagesAnswer Sheet For Holistic Examination For The Four CodeRefisa JiruNo ratings yet

- ContentDocument2 pagesContentRefisa JiruNo ratings yet

- AcknowledgementDocument1 pageAcknowledgementRefisa JiruNo ratings yet

- Axially and Eccentrically Loaded ColumnsDocument13 pagesAxially and Eccentrically Loaded ColumnsRefisa JiruNo ratings yet

- Chapter 3 STR 3 Beams Shear BondDocument12 pagesChapter 3 STR 3 Beams Shear BondRefisa JiruNo ratings yet

- Specification Form of Table PDFDocument12 pagesSpecification Form of Table PDFRefisa JiruNo ratings yet

- Chapter II-IIIDocument10 pagesChapter II-IIIRefisa JiruNo ratings yet

- Road Item Engineering EstimatesDocument10 pagesRoad Item Engineering EstimatesRefisa JiruNo ratings yet

- Tutorials For Holistic ExamDocument40 pagesTutorials For Holistic ExamRefisa JiruNo ratings yet

- Answer Sheet For Holistic Examination For The Four CodeDocument4 pagesAnswer Sheet For Holistic Examination For The Four CodeRefisa JiruNo ratings yet

- Chapter IVDocument10 pagesChapter IVRefisa JiruNo ratings yet

- Exampl c1Document18 pagesExampl c1sowhat-01No ratings yet

- Elongation Index: Experiment-1Document2 pagesElongation Index: Experiment-1Refisa JiruNo ratings yet

- Experiment-5 Flakiness Index (FI) Objective Theory: Minimum Mass of Test PortionDocument1 pageExperiment-5 Flakiness Index (FI) Objective Theory: Minimum Mass of Test PortionRefisa Jiru0% (1)

- Building BOQ FinalDocument42 pagesBuilding BOQ FinalRefisa JiruNo ratings yet

- Final For Print PDFDocument21 pagesFinal For Print PDFRefisa JiruNo ratings yet

- HS1..CH1 HydrDocument74 pagesHS1..CH1 HydrRefisa JiruNo ratings yet

- (California Bearing Ratio Value) : ExperimentDocument2 pages(California Bearing Ratio Value) : ExperimentRefisa JiruNo ratings yet

- Iraq University College: Name StageDocument24 pagesIraq University College: Name Stageأحمد جاسم محمدNo ratings yet

- Heat of Neutralization LabDocument2 pagesHeat of Neutralization Labmunira9450% (2)

- States of Matter - Answer KeyDocument4 pagesStates of Matter - Answer KeyLisa TrustyNo ratings yet

- Refrigeration & Liquefaction: J. G. Weisend IIDocument36 pagesRefrigeration & Liquefaction: J. G. Weisend IIsyafiqNo ratings yet

- Lectures On Computational Fluid Dynamics PDFDocument205 pagesLectures On Computational Fluid Dynamics PDFfsnexussNo ratings yet

- Al DbosseaDocument20 pagesAl DbosseaMussa ElbarraniNo ratings yet

- Seismic Performance of Circular Elevated Water Tank: Rupachandra J. Aware, Dr. Vageesha S. MathadaDocument6 pagesSeismic Performance of Circular Elevated Water Tank: Rupachandra J. Aware, Dr. Vageesha S. Mathadazikzak2011No ratings yet

- Standard Step Method PDFDocument8 pagesStandard Step Method PDFtonka1406No ratings yet

- Q4 Science 10 Week1Document4 pagesQ4 Science 10 Week1maribel losloso50% (2)

- 151 361 1 PBDocument7 pages151 361 1 PBElafanNo ratings yet

- Bioclimatic ChartDocument15 pagesBioclimatic ChartCarolina MacielNo ratings yet

- General Conduction Equation - Cartesian CoordinatesDocument17 pagesGeneral Conduction Equation - Cartesian Coordinatesnimish_nirmaNo ratings yet

- Back2Basic v1 PDFDocument20 pagesBack2Basic v1 PDFBerry101No ratings yet

- Artemis E-Dyn® 96 Digital Displacement® Hydraulic Pump: EfficiencyDocument3 pagesArtemis E-Dyn® 96 Digital Displacement® Hydraulic Pump: EfficiencyAshish NegiNo ratings yet

- On The Prediction of Long-Term Creep-Failure of GRP PipesDocument35 pagesOn The Prediction of Long-Term Creep-Failure of GRP PipesMuhammad EhtshamNo ratings yet

- Reducing Valve/Reducing Valve With Check Valve: FeaturesDocument6 pagesReducing Valve/Reducing Valve With Check Valve: Featuresworkshop Ega SbyNo ratings yet

- Chapter 3.0Document3 pagesChapter 3.0Jhon Barzola PalominoNo ratings yet

- Hemispherical EndsDocument3 pagesHemispherical EndsEng-CalculationsNo ratings yet

- Reservoir Oil Recovery Via Water InjectionDocument14 pagesReservoir Oil Recovery Via Water InjectionDieudonne MekumbaNo ratings yet

- B747C HP FogJet HP MultiPoint FogJet NozzlesDocument4 pagesB747C HP FogJet HP MultiPoint FogJet NozzlesRidho SprayNo ratings yet

- Economizer Design CalculationsDocument4 pagesEconomizer Design CalculationsDaniyal HashmiNo ratings yet

- Fenomenos 1Document5 pagesFenomenos 1Alejandro Castillo VélezNo ratings yet

- Waterfront - Design Calculation - Railings - Rev.00Document54 pagesWaterfront - Design Calculation - Railings - Rev.00Rhem Aldrin CordovaNo ratings yet

- 01 Fluid MechanicsDocument5 pages01 Fluid MechanicsThali MagalhãesNo ratings yet

- AIChE CEE Bird ExtendedDocument8 pagesAIChE CEE Bird ExtendedMary KeoghNo ratings yet

- Applied Thermal Engineering: Xiaodong Zhang, Dapeng HuDocument7 pagesApplied Thermal Engineering: Xiaodong Zhang, Dapeng HuАли АлжирNo ratings yet

- Master Thesis InterfaceDocument71 pagesMaster Thesis InterfaceHaroon ImtiazNo ratings yet

- Base Plate Andf Anchor Bolt Design For Minor Axis MomentDocument2 pagesBase Plate Andf Anchor Bolt Design For Minor Axis MomentSunil Pulikkal100% (1)

- 01 - Pneumatic Vs HydraulicDocument17 pages01 - Pneumatic Vs HydraulicRizkia MunajatNo ratings yet