Professional Documents

Culture Documents

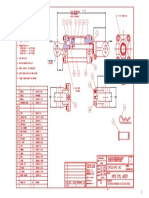

Primary Datum Grid Origin: Freescale Semiconductor

Primary Datum Grid Origin: Freescale Semiconductor

Uploaded by

Vitaliy BespalovOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Primary Datum Grid Origin: Freescale Semiconductor

Primary Datum Grid Origin: Freescale Semiconductor

Uploaded by

Vitaliy BespalovCopyright:

Available Formats

ART FILM - 28719-A-fab.

art

A 07/20/15

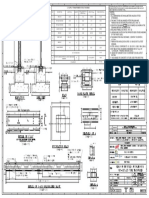

1. THIS DRAWING SPECIFIES THE REQUIREMENTS FOR A PRINTED WIRING BOARD IN ACCORDANCE

WITH SPECIFICATION IPC-A-600 CLASS 2 (LATEST REVISION).

2. THE PWB MUST BE LEAD FREE ASSEMBLY PROCESS COMPATIBLE AND MUST BE ABLE TO HANDLE

A MINIMUM OF 5 CYCLES AT 260 DEGREES CELSIUS FOR 10 SECONDS.

3. BASE MATERIAL - LAMINATE AND PREPREG SHALL MEET IPC-4101B-26, 83 or 98

Tg - MUST BE GREATER THAN OR EQUAL TO 150 DEGREES CELSIUS.

Td - MUST BE GREATER THAN OR EQUAL TO 330 DEGREES CELSIUS.

4. COPPER FOIL WEIGHT - SEE STACKUP DETAIL 'A'

5. CHARACTERISTIC IMPEDANCE - NONE

6. MINIMUM CONDUCTIVE WIDTH/SPACING TO BE .005"/.004"

7. PLATING FINISH - BOTH SIDES ENIG (ELECTROLESS NICKEL IMMERSION GOLD):

.05080 - .232 MICRON (22 - 8 MICROINCH) OF GOLD OVER

2.540 - 6.350 MICRON (100 250 MICROINCH) OF NICKEL.

8. ALL THROUGH HOLE VIAS MAY BE PLATED SHUT.

DRILL CHART: TOP to BOTTOM

9. SOLDERMASK - ORANGE COLOR LPI SOLDERMASK BOTH SIDES. 2.400

MODIFICATION OF SOLDERMASK IS NOT ALLOWED WITHOUT WRITTEN PERMISSION FROM FREESCALE. .063 ALL UNITS ARE IN MILS

THICK +/- 10% FIGURE SIZE TOLERANCE PLATED QTY

10. SILKSCREEN - WHITE EPOXY INK, BOTH SIDES. NO SILK ON PADS.

8 12.0 +2.0/-12.0 PLATED 155

11. ELECTRICAL TEST - 100% IPCD356. 30.0 +3.0/-3.0 PLATED 6

40.0 +2.0/-2.0 PLATED 5

12. PRINTED WIRING BOARD IS TO BE INDIVIDUALLY BAGGED.

17 40.0 +3.0/-3.0 PLATED 5

2.100

13. DRC'S MUST BE RUN ON THE GERBER BEFORE BUILDING BOARDS,

42.0 +3.0/-3.0 PLATED 64

UNLESS PRIOR APPROVAL IS GIVEN IN WRITING BY FREESCALE.

52.0 +3.0/-3.0 PLATED 3

14. TEARDROPS MAYBE ADDED AT THE FAB HOUSE TO ALL SIGNAL LAYERS. 125.0 +3.0/-3.0 NON-PLATED 4

63.0x40.0 +3.0/-3.0 PLATED 2

15. 2 SOLDER SAMPLES TO BE PROVIDED.

63.0x40.0 +3.0/-3.0 PLATED 1

16. BASIC GRID INCREMENT AT 1:1 IS .0001.

17. SUPPLIER MARKINGS - ON SOLDER SIDE ONLY, WHERE SHOWN.

- MUST BE UL RECOGNIZED AND MUST HAVE AN ID THAT CONFORMS TO UL94V-0 16

18. THE PWB WILL BE MARKED AS LEAD FREE BY USE OF AN INK STAMP Pb PRIMARY DATUM

19. THE PWB WILL BE MARKED AS LEAD FREE PROCESS COMPATIBLE BY USE OF AN INK STAMP 260 C

GRID ORIGIN

20. ALL PLATED AND NON-PLATED THROUGH HOLES ARE TO BE DRILLED AT PRIMARY DRILL STEP.

ALL HOLE LOCATION TOLERANCES ARE TO BE +/-.002 IN REFERENCE TO THE PRIMARY DATUM.

21. FINISHED PCB MUST BE PANELIZED FOR ASSEMBLY ACCORDING TO CONTRACT MANUFACTURERS REQUIREMENTS.

THE ADDITION OF RAILS AND .125' NON-PLATED TOOLING HOLES ARE AT THE DISCRETION OF

CONTRACT MANUFACTURER.PANELIZATION MUST BE APPROVED BY CONTRACT MANUFACTURER.

22. DO NOT PROVIDE SOLDERMASK CLEARANCES FOR THE SPECIFIC LOCATIONS

LEAVE SOLDERMASK AS THEY APPEAR ON CAD.

23. INTENTIONAL SHORT AT SH1, SH2, AND SH3 BETWEEN NETS GND AND GNDM.

FINISHED Cu WEIGHT

LAYER 1 COMPONENT SIDE 1 oz.

LAYER 2 SOLDER SIDE 1 oz.

DETAIL A

LAYER STACKUP

SCALE: NONE

170-28719

THIS DOCUMENT CONTAINS INFORMATION

___ PUBI (PUBLIC INFORMATION)

PROPRIETARY TO FREESCALE AND SHALL FREESCALE SEMICONDUCTOR

NOT BE USED FOR ENGINEERING DESIGN

X

___ FIUO (FREESCALE INTERNAL USE ONLY)

PROCUREMENT OR MANUFACTURE IN WHOLE

OR IN PART WITHOUT THE CONSENT OF

___ FCP (FREESCALE CONFIDENTIAL PROPRIETARY) FREESCALE.

6501 WILLIAM CANNON DRIVE WEST AUSTIN, TEXAS 78735 USA

PRINTED WIRING BOARD

AVID TECH. 07/20/15

FRDM-MC-LVBLDC

LAY-28719 FAB-28719 A

1/1 1 1

ART FILM - 28719-A-fab.art

You might also like

- Nial Course On Price Action ForexDocument57 pagesNial Course On Price Action Forexnishitsardhara100% (2)

- Solution Manual Global Strategy 2nd Edition PengDocument12 pagesSolution Manual Global Strategy 2nd Edition PengJessica SuryaNo ratings yet

- Mark Property Tax ReceiptDocument2 pagesMark Property Tax Receiptpeterson greyNo ratings yet

- NCNDADocument5 pagesNCNDAlinkinpaqNo ratings yet

- WI 750 001 Doc NumberingDocument3 pagesWI 750 001 Doc NumberingTamara Johnson-PariagNo ratings yet

- Gmail - Rauias ReceiptDocument2 pagesGmail - Rauias ReceiptRishabh OjhaNo ratings yet

- Fredon FAB-27556 - EDocument1 pageFredon FAB-27556 - Ebruno magalhãesNo ratings yet

- Reinforcement Detail of Berkheda Fore WayDocument1 pageReinforcement Detail of Berkheda Fore WayvishalNo ratings yet

- DU3x8x1.25ASAE-R10Document1 pageDU3x8x1.25ASAE-R10JaimeNo ratings yet

- Romantic Baboy - HFSSDocument1 pageRomantic Baboy - HFSSneilmaniacupNo ratings yet

- City of Industry, California Title,: Dimenss Decimal c4WNYD Oft OnlyDocument1 pageCity of Industry, California Title,: Dimenss Decimal c4WNYD Oft OnlyRenato WatanabeNo ratings yet

- Dell Vostro V13 V13TL 6050A2296601-MB-A02 Schematic PDFDocument49 pagesDell Vostro V13 V13TL 6050A2296601-MB-A02 Schematic PDFAlain Erik González ApaNo ratings yet

- 4100R Series - Thick Film Molded DIPsDocument3 pages4100R Series - Thick Film Molded DIPssiogNo ratings yet

- 2D Customer Drawing PDFDocument1 page2D Customer Drawing PDFJøsh HessNo ratings yet

- Acm TSC VS MF DWG ST 2001Document1 pageAcm TSC VS MF DWG ST 2001Aecom IndiaNo ratings yet

- Boring Logs - 2022Document13 pagesBoring Logs - 2022Drawing HacksNo ratings yet

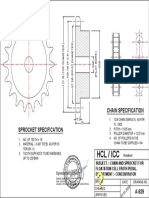

- HCL / Icc: Chain SpecificationDocument1 pageHCL / Icc: Chain Specificationniket0No ratings yet

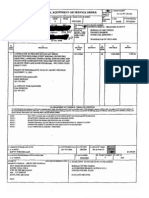

- Factura AuricularesDocument1 pageFactura Auricularesjesska977No ratings yet

- Center Line PDFDocument1 pageCenter Line PDFZayaf AbabNo ratings yet

- 250S15-S28 Solidworks Cad File: Sealed 1/4" Plug Do Not Scale Drawing 1 1Document2 pages250S15-S28 Solidworks Cad File: Sealed 1/4" Plug Do Not Scale Drawing 1 1Marius BudauNo ratings yet

- Bridge Drawings 2019-09-02Document13 pagesBridge Drawings 2019-09-02yasirjurabaNo ratings yet

- File 1326132307Document1 pageFile 1326132307Rodrigo KrammNo ratings yet

- Application Specification: Cable Assembly Instructions FOR 73403-037X SEALED FAKRADocument4 pagesApplication Specification: Cable Assembly Instructions FOR 73403-037X SEALED FAKRAshibu TNo ratings yet

- Revisions Rev. Description Init. Date X1 Initial Release A.P. 11/3/2021 X2 Coil Leads Tinning and Trimming Length Updated. A.P. 11/12/2021Document13 pagesRevisions Rev. Description Init. Date X1 Initial Release A.P. 11/3/2021 X2 Coil Leads Tinning and Trimming Length Updated. A.P. 11/12/2021jhay lagmanNo ratings yet

- The BronteDocument1 pageThe BronteEasyStartHomesNo ratings yet

- DHS, FEMA and Dept. of State: Failure of Hurricane Relief Efforts: 09-02-2003 Order Number 43-YA-BC-381549Document2 pagesDHS, FEMA and Dept. of State: Failure of Hurricane Relief Efforts: 09-02-2003 Order Number 43-YA-BC-381549CREWNo ratings yet

- Full Service Ee1Document1 pageFull Service Ee1Roluna OliverNo ratings yet

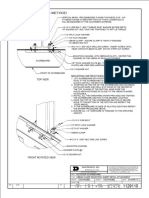

- Detail Deck SilunganDocument2 pagesDetail Deck SilunganoxiNo ratings yet

- 30FB-22 YuanDeanScientificDocument3 pages30FB-22 YuanDeanScientificvictor07No ratings yet

- Eci Telecom LTD.: APOLLO9900Document3 pagesEci Telecom LTD.: APOLLO9900khanhvan nguyenNo ratings yet

- Amar93 03Document1 pageAmar93 03Aniket IndulkarNo ratings yet

- Saudi Arabian Oil Company: Table 1 Minimum Cover RequirementsDocument1 pageSaudi Arabian Oil Company: Table 1 Minimum Cover RequirementsAswin KurupNo ratings yet

- 1516 e (Sheet 1 of 3) 15 Mva 66 - 11.550 KV Aet - 1374Document1 page1516 e (Sheet 1 of 3) 15 Mva 66 - 11.550 KV Aet - 1374shravan Kumar SinghNo ratings yet

- Adobe Scan Dec 21, 2022Document2 pagesAdobe Scan Dec 21, 2022boishal baruahNo ratings yet

- RD 5000 CatalogDocument10 pagesRD 5000 CatalogDOTRAMSA.SRL LA CASA DE LA TOMA DE FUERZA.No ratings yet

- DB-100-SA OpIn DM-BDB-100-SA Rev 1003A 20151125 PDFDocument21 pagesDB-100-SA OpIn DM-BDB-100-SA Rev 1003A 20151125 PDFSeamen 777No ratings yet

- 100DP1T4B1M1QEHDocument1 page100DP1T4B1M1QEHHisham MehremNo ratings yet

- 172 Bbls (6000 IG) VAC SEMI TR OBM (40 Psi ASME) : NeededDocument3 pages172 Bbls (6000 IG) VAC SEMI TR OBM (40 Psi ASME) : Neededmesut ekşiNo ratings yet

- Cable Termincal Brass Lugs Brass Sheet Terminal Jumper Cables CatalogueDocument79 pagesCable Termincal Brass Lugs Brass Sheet Terminal Jumper Cables Catalogueomarmendozaespacio10No ratings yet

- LTnew 10 KVA-Details of StructureDocument1 pageLTnew 10 KVA-Details of StructureTarun SaiNo ratings yet

- Floor Plan - 00.batch 3Document1 pageFloor Plan - 00.batch 3Fakhere AlamNo ratings yet

- Pe 65612Document2 pagesPe 65612FEKIK AREZKI FEKIK AREZKINo ratings yet

- SD969-2 With BCM (ETACS) - Display (2/4) A/V & NavigationDocument1 pageSD969-2 With BCM (ETACS) - Display (2/4) A/V & NavigationDhashana MoorthyNo ratings yet

- Crystal Report Viewer 1Document8 pagesCrystal Report Viewer 1antitajvirNo ratings yet

- DHS, FEMA and Dept. of State: Failure of Hurricane Relief Efforts: 03-30-2001 Order Number 43-YA-BC-147394Document2 pagesDHS, FEMA and Dept. of State: Failure of Hurricane Relief Efforts: 03-30-2001 Order Number 43-YA-BC-147394CREWNo ratings yet

- Catch Basin Plan: General Plumbing NotesDocument1 pageCatch Basin Plan: General Plumbing NotesCasmir TayagNo ratings yet

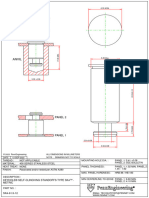

- SK4 61.5 12 PennEngineering 2DSalesDrawing 09 13 2023Document1 pageSK4 61.5 12 PennEngineering 2DSalesDrawing 09 13 2023Herbert LowNo ratings yet

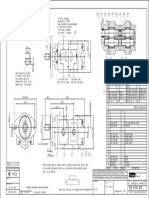

- Toshiba: Totally Enclosed Fan Cooled Round Body C-Faced 3 Phase Induction Motor 324TC-326TC F1 AssemblyDocument4 pagesToshiba: Totally Enclosed Fan Cooled Round Body C-Faced 3 Phase Induction Motor 324TC-326TC F1 Assemblyivan chirinosNo ratings yet

- Especificación de Sistema de Anclaje en EstructuraDocument1 pageEspecificación de Sistema de Anclaje en EstructuraEnmanuel BrachoNo ratings yet

- LAEIS BUCHER GMBHDocument273 pagesLAEIS BUCHER GMBHJunior Martinez100% (1)

- Backup of 04-3973-0100-00, PIG-SIG NI-Xt, Standard 3V Battery or 24VDCDocument1 pageBackup of 04-3973-0100-00, PIG-SIG NI-Xt, Standard 3V Battery or 24VDCalicoonNo ratings yet

- CBR - Av4 PADocument1 pageCBR - Av4 PACésar Matamoros ArayaNo ratings yet

- Revision '00' Engineering BulletinDocument2 pagesRevision '00' Engineering BulletinjordiNo ratings yet

- Cross Section: Scale 1:1000 MTSDocument1 pageCross Section: Scale 1:1000 MTSKristine OgalescoNo ratings yet

- 6RRU Swann 5307 AssemblyDocument1 page6RRU Swann 5307 AssemblyOndra CizekNo ratings yet

- 7029120023Document1 page7029120023Roderick Pinto100% (1)

- Perhitungan Untuk Standar Proporsi: Dinas Pekerjaan Umum Kabupaten SukabumiDocument1 pagePerhitungan Untuk Standar Proporsi: Dinas Pekerjaan Umum Kabupaten SukabumiOloyNo ratings yet

- 21-601-000 46kV, 250kV BIL, 150ADocument1 page21-601-000 46kV, 250kV BIL, 150AAngel StragliatiNo ratings yet

- Daily Pouring ScheduleDocument1 pageDaily Pouring SchedulebgcclarkmarcdelacruzNo ratings yet

- 0412 Wireline Bridge PlugsDocument1 page0412 Wireline Bridge PlugsDigger Downhole ToolsNo ratings yet

- Standing Valve Ball TypeDocument2 pagesStanding Valve Ball TypeNattakorn sangmarkNo ratings yet

- Floor PlanDocument1 pageFloor PlanmsitchonNo ratings yet

- Structural Drawings PDFDocument8 pagesStructural Drawings PDFWhitepearlNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Shweta Ved PG-17-117: International Business in IndiaDocument8 pagesShweta Ved PG-17-117: International Business in IndiaShivam KapoorNo ratings yet

- The 2010 Global Guide To TaxDocument32 pagesThe 2010 Global Guide To TaxHasmukh1985No ratings yet

- Week 3 Slide HandoutDocument16 pagesWeek 3 Slide HandoutNai MotoNo ratings yet

- 1B-Systems Development ToolsDocument17 pages1B-Systems Development Toolsjane100% (1)

- Management: Richard L. DaftDocument24 pagesManagement: Richard L. DaftOdonchimeg MyagmarsurenNo ratings yet

- Arthur Lewis and Industrial Development in The Caribbean: An AssessmentDocument32 pagesArthur Lewis and Industrial Development in The Caribbean: An AssessmentRichardson HolderNo ratings yet

- 7 Steps To IPO SuccessDocument7 pages7 Steps To IPO Successprabhu sivaNo ratings yet

- Blocker, Flint, Myers, Slater - Proactive Customer Orientation and Its Role For Creating Customer Value in Global MarketsDocument18 pagesBlocker, Flint, Myers, Slater - Proactive Customer Orientation and Its Role For Creating Customer Value in Global MarketsEllaMuNo ratings yet

- House Hearing, 106TH Congress - H.R. 1827, The Government Waste Corrections Act of 1999Document277 pagesHouse Hearing, 106TH Congress - H.R. 1827, The Government Waste Corrections Act of 1999Scribd Government DocsNo ratings yet

- Environment Analysis & DiagnosisDocument75 pagesEnvironment Analysis & Diagnosissamu5614100% (3)

- Fidility ReportDocument24 pagesFidility Reportaloktiwari23No ratings yet

- It Supportnow Supportnow Phone Numbers: It Support Quick Reference GuideDocument2 pagesIt Supportnow Supportnow Phone Numbers: It Support Quick Reference GuideAnonymous u8bpZ58No ratings yet

- Government Grants: Use The Following Information For The Next Three QuestionsDocument2 pagesGovernment Grants: Use The Following Information For The Next Three QuestionsXienaNo ratings yet

- Designing The Business Portfolio: Strategic PlanningDocument2 pagesDesigning The Business Portfolio: Strategic PlanningPetar N NeychevNo ratings yet

- Registration For FieldAssist Recruitment Drive-2022 Graduating BatchDocument2 pagesRegistration For FieldAssist Recruitment Drive-2022 Graduating Batchapoorv sharmaNo ratings yet

- Intermediate Accounting QuizDocument3 pagesIntermediate Accounting QuizJoseNo ratings yet

- Construction Materials Retail Price Index PrimerDocument2 pagesConstruction Materials Retail Price Index PrimerShai DelfinNo ratings yet

- August MAYNILAD BILLDocument1 pageAugust MAYNILAD BILLJIRA JINN GONZALESNo ratings yet

- OM in Finance, Brief and ExpandedDocument41 pagesOM in Finance, Brief and ExpandedJayanth ReddyNo ratings yet

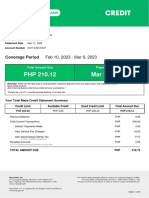

- MayaCredit SoA 2023MARDocument2 pagesMayaCredit SoA 2023MARJan SaysonNo ratings yet

- Oracle ADF DeveloperDocument8 pagesOracle ADF DeveloperSharif MohammedNo ratings yet

- Fenglerk@rider - Edu: Karina Fengler 1361 Deerfield Road Water Mill, NY 11976 (631) - 655-6569Document2 pagesFenglerk@rider - Edu: Karina Fengler 1361 Deerfield Road Water Mill, NY 11976 (631) - 655-6569api-241447058No ratings yet

- PAS 55 2008 BrochureDocument2 pagesPAS 55 2008 BrochureArnulfo Grandas RNo ratings yet

- Chapter 07: Conflict & NegotiationDocument9 pagesChapter 07: Conflict & NegotiationSAQIBNo ratings yet

- A. The Importance of Capital BudgetingDocument16 pagesA. The Importance of Capital BudgetingManish ChaturvediNo ratings yet