Professional Documents

Culture Documents

MT Level - I QB 4 PDF

MT Level - I QB 4 PDF

Uploaded by

kingstonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MT Level - I QB 4 PDF

MT Level - I QB 4 PDF

Uploaded by

kingstonCopyright:

Available Formats

Southern Inspection Services

MT LEVEL I QB-4

1. In what way does surface roughness hinder the MPI test on a part?

a. hindrance of particle migration

b. reduction in contrast

c. distortion of the magnetic field

d. all of the above

2. What do the following cleaning methods all have in common? Shot

blasting, sand blasting, wire brushing and scraping

a. none are used for precleaning a part for MPI

b. none require electricity

c. all are mechanical methods

d. all are environmentally friendly

3. Which cleaning method is not likely to be used to remove oil films

prior to an MPI test?

a. vapour degreasing

b. wire brushing

c. steam cleaning

d. ultrasonic cleaning

4. The magnetic field produced by a yoke made of permanent magnets is

_______ between the poles.

a. longitudinal

b. circular

c. both a and b

d. constantly varying

5. The swinging field MPI technique is used with

a. sequenced D.C.

b. combined D.C. and A.C. fields

c. combined A.C. fields

d. all of the above

6. The advantage of the swinging field or multidirectional magnetization

technique is

a. cost of equipment

b. detection of small defects

c. time saving because it is single step test

d. both b and c

www.sisndt.com / www. ndtsis.com Page 1

Southern Inspection Services

7. When permeability of a material is quoted without an additional

qualifying term the permeability referred to is

a. initial permeability

b. incremental permeability

c. maximum permeability

d. osmotic permeability

8. Current for circular magnetization of a part whose maximum

permeability is 500 will be ___________ compared to a part with

maximum permeability of 4000.

a. more

b. less

c. about the same

d. it depends if A.C. or D.C. is used

9. In MPI a handy rule of thumb relating current flow and suspected flaw

orientation is; current flow should be directed _______ major axis.

a. under suspected defects'

b. parallel to suspected defects'

c. perpendicular to suspected defects'

d. diagonally to suspected defects'

10. The strength of a circular magnetic field is not diminished by

________ of a part.

a. Permeability

b. diameter

c. length

d. any of the above

11. A 2cm diameter pipe and a 2cm diameter bar of the same steel alloy

are each circularly magnetized by a 1000 amp D.C. head shot. The

strongest magnetic field will occur on the surface of the __________.

a. bar

b. pipe

c. pipe if its wall is less than 0.5cm

d. none of the above, fields will be equal

www.sisndt.com / www. ndtsis.com Page 2

Southern Inspection Services

12. When a hollow non-magnetic central conductor is used to induce a

circular magnetic field in a ferro-magnetic cylinder maximum field

strength is at the

a. central conductor's outside surface

b. central conductor's inside surface

c. magnetic material's inside surface

d. magnetic material's outside surface

13. When A.C. is used instead of D.C. for a head shot on a steel tube, the

field on the inside surface of the tube is

a. much less

b. much more

c. nearly the same

d. both are exactly zero

14. The best way to determine magnetizing current required for irregularly

shaped pieces is

a. length to diameter ratio equations

b. 40 amps per mm of part thickness

c. empirically (trial and error)

d. finite element analysis

15. When using the prod method of MPI, defects are normally looked for

a. between the prods

b. under the prods

c. in circles about 4" (100mm) radius from the prods

d. in all of the above locations

16. In order to maintain the same field strength at the midpoint of prods

spaced 8 inches apart as was had with a 6 inch spacing you must

a. increase the magnetizing current

b. decrease the magnetizing current

c. use D.C. instead of A.C.

d. use larger diameter prod electrodes

17. Which is not a consideration when choosing current type to use for

prod inspection methods of MPI?

a. particle mobility

b. Safety

c. power consumption

d. heating effects on equipment

www.sisndt.com / www. ndtsis.com Page 3

Southern Inspection Services

18. Capacitive discharge methods of producing a magnetizing current do

so for only a short duration.

a. typically 1 to 2 seconds

b. typically 0.5 to 1 seconds

c. typically 10 to 100ms

d. typically 5 to 55 µs

19. Precracked magnetic steel plates are an effective means of

a. qualitative analysis of MPI bath concentrations

b. quantitative analysis of MPI bath concentrations

c. calibrating ammeters on MPI bench units

d. sizing unknown MPI indications

20. Typical pocket sized magnetic field indicators are used to measure

a. magnetizing force in a coil

b. external residual fields

c. internal residual fields

d. circular field strength during current flow

21. A low cost rugged tool used to measure residual magnetic field

strength of ferromagnetic parts is a

a. residu-meter

b. shunt meter

c. magnetic field indicator

d. Helmholtz coil

22. A good magnetic field indicator (MFI) should have which

characteristic?

a. rugged supports to prevent damage to the pointer needle

b. not be easily demagnetized by strong external fields

c. not induce magnetic poles of the parts they test

d. all of the above

23. Excessive background in wet fluorescent MPI testing results from

a. excessive current density

b. excessive particle density

c. excessive blacklight intensity

d. both a and b

www.sisndt.com / www. ndtsis.com Page 4

Southern Inspection Services

24. The standard steel ring 7/8" thick having a 1 1/4" diameter central hole

and 12 0.007" diameter holes arranged with increasing depth from the

outside edge of the ring is called a(n)

a. annular ring

b. Ketos ring

c. ASME ring

d. DIN ring

25. Probability of seeing a wet fluorescent MPI indication

a. increases with increasing blacklight intensity

b. increases with decreasing white light background

c. increases with decreasing blacklight intensity

d. both a and b

26. Although settling time prior to measuring wet fluorescent magnetic

particle concentration is now increased to 1 hour for most standards,

complete settling usually takes

a. 15 minutes

b. 30 minutes

c. 2 hours

d. 24 hours

27. When viewing the oil carrier of wet fluorescent particles (ie. the liquid

without the particles) under blacklight it usually has a _________ tint.

a. yellowish

b. Bluish

c. yellow/green

d. reddish

28. The purpose of adding an antifoaming agent to wet MPI bath is to

a. reduce suds resulting from agitation

b. eliminate phosphates for environmental protection

c. prevent fluorescent material from disbonding from the oxides

d. all of the above

29. Indications from medium to deep surface breaking seams found using

A.C. MPI

a. are not possible to find

b. usually look alike

c. require extra large particles

d. form double indications

www.sisndt.com / www. ndtsis.com Page 5

Southern Inspection Services

30. Fastest particle settlement in an MPI bath would occur for

a. small dense particles in a low viscosity liquid

b. small dense particles in a high viscosity liquid

c. larger dense particles in a low viscosity liquid

d. all of the above would settle about the same rate due to the Bernoulli

effect

31. MPI indication width tends to increase for increasing

a. defect width

b. defect depth

c. magnetizing current strength

d. all of the above

32. Because in general, there exists a direct relationship between

indication width and seam (defect) depth, a minimum magnetizing

current level can be set to

a. maintain uniform indication widths

b. detect significant flaws

c. both a and b

d. none of the above

33. Very fine MPI particles which fall into a crack opening can cause the

flux lines to remain in the part, this could result in

a. over estimating crack depth

b. over estimating crack length

c. missing the crack altogether

d. missing the crack all together if nonfluorescent particles are used

34. When lighting requirements are specified for a blacklight viewing of

fluorescent MPI, 20 lux white light intensity is

a. a recommended maximum

b. a recommended minimum

c. only a rough estimate

d. must be strictly met to ensure visibility of indications

35. What method is used to ensure proper magnetization levels are used?

a. formulae (rules of thumb)

b. testpieces

c. gauss/tesla meter

d. all of the above

www.sisndt.com / www. ndtsis.com Page 6

Southern Inspection Services

36. An advantage of MPI over LPI (Liquid Penetrant Inspection) is that

___________ using MPI.

a. ceramics can be tested

b. ferromagnetic materials can be tested

c. coated surfaces can be tested

d. it is always more environmentally friendly

37. The difference between magnetic particle testing and magnetic flux

leakage testing is

a. the type of sensor used to detect fields

b. the type of magnetizing current used

c. the thickness of part that can be tested

d. none, they are exactly the same

38. The "standard depth of penetration" resulting from the skin effect is

caused by

a. hysteresis

b. alternating current

c. direct current

d. Hall detectors

39. To understand magnetic particle indication formation you should

consider

a. discontinuity parameters

b. magnetic field parameters affecting the external flux leakage

c. how the magnetic particles react to passing through the leakage fields

d. all of the above

40. The main purpose of a ferrite core in the coil type flux sensitive

devices for magnetic field testing is

a. reduction of electrical noise

b. to amplify the flux density

c. enhancement of the Hall effect

d. all of the above

www.sisndt.com / www. ndtsis.com Page 7

Southern Inspection Services

MT LEVEL I QB-4 ANSWERS

QUESTION NO ANS REFERENCE PAGE

Question 1: D 48-GP-11M 23

Question 2: C 48-GP-11M 24

Question 3: B 48-GP-11M 24

Question 4: A NDT Handbook 160

Question 5: D NDT Handbook 162

Question 6: D NDTHandbook 163

Question 7: C Betz 181

Question 8: A Betz 183

Question 9: B Betz 186

Question 10: C Betz 186

Question 11: D Betz 189

Question 12: C Betz 192

Question 13: D Betz 194

Question 14: C Betz 202

Question 15: A Betz 203

Question 16: A Betz 206

Question 17: B Betz 207

Question 18: C ME 44 #6 617

Question 19: A ME 45 #9 1014

Question 20: B ME 46 #6 749

Question 21: C ME 46 #6 754

Question 22: D ME 46 #6 754

Question 23: D ME 46 #6 781

Question 24: B ME 46 #6 781

Question 25: D ME 46 #6 782

Question 26: D ME 48 #8 970

Question 27: B ME 48 #8 970

Question 28: A ME 46 #12 1548

Question 29: B ME 46 #12 1548

Question 30: C ME 46 #12 1550

Question 31: D ME 46 #12 1551

Question 32: B ME 46 #12 1557

Question 33: D ME 46 #12 1558

Question 34: A ME 48 #3 332

Question 35: D ME 48 #3 333

Question 36: C ME 48 #3 334

Question 37: A NDT Handbook 180

Question38: B NDT Handbook 181

Question 39: D NDT Handbook 181

Question 40: B NDT Handbook 187

www.sisndt.com / www. ndtsis.com Page 8

You might also like

- Multi Choice Tech 1 AnswerDocument20 pagesMulti Choice Tech 1 AnswerquyennqNo ratings yet

- Rad Multi ChoiceDocument2 pagesRad Multi Choicesabba_420No ratings yet

- MT Level - I QB 5Document8 pagesMT Level - I QB 5kingstonNo ratings yet

- Practice 2 - Questions - CSWIPDocument10 pagesPractice 2 - Questions - CSWIPravichandran0506No ratings yet

- CBIP Examination MPL2 General Sample Exam PaperDocument3 pagesCBIP Examination MPL2 General Sample Exam PaperRohit JosephNo ratings yet

- Ut TwiDocument266 pagesUt TwiADAMJSRAONo ratings yet

- Appendix 1 2017Document34 pagesAppendix 1 2017Sohrab FarmanNo ratings yet

- Section 10 QuestionsDocument6 pagesSection 10 QuestionsSameer MohammadNo ratings yet

- Test No 4ccDocument4 pagesTest No 4ccSalman GhaffarNo ratings yet

- IIW-India Project Format - DocDocument13 pagesIIW-India Project Format - DocRameshBaskaranNo ratings yet

- Chapter 1Document10 pagesChapter 1kingstonNo ratings yet

- Test No 5Document3 pagesTest No 5Muhammad AsimNo ratings yet

- Technology 1Document10 pagesTechnology 1Tahar Dabbar100% (1)

- General Level-II QuestionsDocument4 pagesGeneral Level-II QuestionsGomathi SankarNo ratings yet

- Magnetic Particle TestingDocument3 pagesMagnetic Particle TestingAnu AnoopNo ratings yet

- MPT-Test PresentationDocument38 pagesMPT-Test PresentationIrfan KhanNo ratings yet

- Magnetic Particle Testing Level II - Specific Examination: Industrial Support Services Co., LTDDocument3 pagesMagnetic Particle Testing Level II - Specific Examination: Industrial Support Services Co., LTDfasffsafsaafasfNo ratings yet

- As Spec Ri 002 AnswerDocument6 pagesAs Spec Ri 002 AnswerKarthikeyan GanesanNo ratings yet

- NDT - Magnetic ParticleDocument73 pagesNDT - Magnetic ParticleUmaibalanNo ratings yet

- CSWIP 3.1 Training FeedbackDocument4 pagesCSWIP 3.1 Training FeedbackGlederson Luiz CostaNo ratings yet

- CSWIP WIS 5 General Quiz: TWI Training & Examination ServicesDocument62 pagesCSWIP WIS 5 General Quiz: TWI Training & Examination Serviceshaoues23No ratings yet

- PW Fs CMT Cycle Step enDocument1 pagePW Fs CMT Cycle Step enBruno DogančićNo ratings yet

- VT Level IIIDocument4 pagesVT Level IIIHuy IpNo ratings yet

- General Multi Choice Paper - 3Document4 pagesGeneral Multi Choice Paper - 3Chinni KrishnaNo ratings yet

- Lavender International NDT LTD: Page 1 of 4 Lavender International: Magnetic Particle Assessments: Module 6-1Document20 pagesLavender International NDT LTD: Page 1 of 4 Lavender International: Magnetic Particle Assessments: Module 6-1Arun Senthil Nathan ViswanathanNo ratings yet

- Magnetic Particles Testing Eng РаздаткаDocument10 pagesMagnetic Particles Testing Eng Раздаткаoluwatobi ajayiNo ratings yet

- NDT MT nds1Document41 pagesNDT MT nds1sathi11189No ratings yet

- Q&A RT I, II and III 10 07 06Document72 pagesQ&A RT I, II and III 10 07 06wefew0% (1)

- PTDocument217 pagesPTkhaled saadnehNo ratings yet

- Twi Training & Certification (S.E. Asia) SDN - BHDDocument1 pageTwi Training & Certification (S.E. Asia) SDN - BHDjasminneeNo ratings yet

- ANSWER: Dye Penetrant Test Explanation:: No Explanation Is Available For This Question!Document4 pagesANSWER: Dye Penetrant Test Explanation:: No Explanation Is Available For This Question!shyamkumar rakoti0% (1)

- FCAW Unit TestDocument4 pagesFCAW Unit TestSatish KeskarNo ratings yet

- Multiple Choice 7 Mechanical TestingDocument5 pagesMultiple Choice 7 Mechanical TestingChandra MohanNo ratings yet

- Cswip Questions and AnswerDocument4 pagesCswip Questions and Answerenels770% (2)

- Magnetic Particle Inspection Day 1Document6 pagesMagnetic Particle Inspection Day 1Muhammad Hannan0% (1)

- RT - Question and AnswerDocument4 pagesRT - Question and Answerdanish.khan80206040No ratings yet

- Ans. Cswip555 Q&ADocument8 pagesAns. Cswip555 Q&AMyak OkuokuNo ratings yet

- Name: . Date: .. Each Question Has Only One Correct Answer! Please Enter Your Answers On The Answer SheetDocument9 pagesName: . Date: .. Each Question Has Only One Correct Answer! Please Enter Your Answers On The Answer SheetKarthikeyan GanesanNo ratings yet

- WISS CSWIP Technology Multiple Choice Exam 2 Version A 18 August 2014Document8 pagesWISS CSWIP Technology Multiple Choice Exam 2 Version A 18 August 2014rinhycraNo ratings yet

- Tutorial IIIDocument21 pagesTutorial IIIravindra_jivaniNo ratings yet

- NDT Magnetic Particle (Home Study) PDFDocument411 pagesNDT Magnetic Particle (Home Study) PDFdonciriusNo ratings yet

- Cswip 3.1Document8 pagesCswip 3.1AnandNo ratings yet

- 80005168enDocument44 pages80005168enFidel Toldrá ReigNo ratings yet

- Norsok M101 Structural Steel FabricationDocument67 pagesNorsok M101 Structural Steel FabricationbreeeeezzzzzeNo ratings yet

- Radiography Part 2 - TWIDocument8 pagesRadiography Part 2 - TWIKolusu SivakumarNo ratings yet

- Ut-Twi - 6Document14 pagesUt-Twi - 6pratap biswasNo ratings yet

- VT 4Document18 pagesVT 4demoknight tf2No ratings yet

- Rusayl Institute Ultrasonic Testing - Level Ii Ut Q Bank - 4Document9 pagesRusayl Institute Ultrasonic Testing - Level Ii Ut Q Bank - 4kingstonNo ratings yet

- Minicoder: Speed and Position Sensor With Amplitude Control OptionDocument12 pagesMinicoder: Speed and Position Sensor With Amplitude Control OptionAlex CarmonaNo ratings yet

- A General Review of Geometric Shape ImperfectionsDocument12 pagesA General Review of Geometric Shape Imperfectionsbipete69No ratings yet

- Welding Inspection: Multi-Choice Questions Paper 1 Please Return This Paper UnmarkedDocument4 pagesWelding Inspection: Multi-Choice Questions Paper 1 Please Return This Paper UnmarkedSurendra KamalNo ratings yet

- Lecture 3, Eddy Current NDEDocument49 pagesLecture 3, Eddy Current NDEMirza Safeer AhmadNo ratings yet

- Ut-Day 3Document21 pagesUt-Day 3DIBYENDU BERANo ratings yet

- Ultrasonic Testing Ut Q Bank A-2Document7 pagesUltrasonic Testing Ut Q Bank A-2kingstonNo ratings yet

- NDE Examination Question PaperDocument6 pagesNDE Examination Question PaperMOhammed PatelNo ratings yet

- Eddy Current Testing Exam Questions Assignment2Document1 pageEddy Current Testing Exam Questions Assignment2Narotam Kumar GupteshwarNo ratings yet

- Experimental Methods: Treatise on Materials Science and Technology, Vol. 19From EverandExperimental Methods: Treatise on Materials Science and Technology, Vol. 19Herbert HermanNo ratings yet

- MT Level - I QB 3Document8 pagesMT Level - I QB 3kingstonNo ratings yet

- Model Test Magnetic Particle TestingDocument24 pagesModel Test Magnetic Particle TestingAnu AnoopNo ratings yet

- Astm A194Document3 pagesAstm A194kingstonNo ratings yet

- The Effect of CarbonDocument4 pagesThe Effect of CarbonkingstonNo ratings yet

- Solid Mechanics Plane Stress and Plane StrainsDocument8 pagesSolid Mechanics Plane Stress and Plane StrainskingstonNo ratings yet

- Asnt Recer RT QB Level IDocument9 pagesAsnt Recer RT QB Level Ikingston100% (1)

- Elastic Stress Analysis For Heat Exchanger Channel Head For Protection Against Plastic Collapse and Protection Against Local Failure (FEA)Document8 pagesElastic Stress Analysis For Heat Exchanger Channel Head For Protection Against Plastic Collapse and Protection Against Local Failure (FEA)kingstonNo ratings yet

- Filters in RadiographyDocument1 pageFilters in RadiographykingstonNo ratings yet

- Nig VT Spec QB S2 - Level IiDocument12 pagesNig VT Spec QB S2 - Level Iikingston100% (1)

- Geometric Unsharpness: RadiographyDocument3 pagesGeometric Unsharpness: RadiographykingstonNo ratings yet

- Girth Flange Load Calculation Using by FEA TechniquesDocument12 pagesGirth Flange Load Calculation Using by FEA TechniqueskingstonNo ratings yet

- VT QB S4 Pro Wiyh KeyDocument12 pagesVT QB S4 Pro Wiyh KeykingstonNo ratings yet

- Secondary (Scatter) Radiation and Undercut ControlDocument2 pagesSecondary (Scatter) Radiation and Undercut ControlkingstonNo ratings yet

- ASNT RECER RT QB (Aligned) MAIN FOILDERDocument26 pagesASNT RECER RT QB (Aligned) MAIN FOILDERkingston100% (2)

- RT 11Document4 pagesRT 11kingstonNo ratings yet

- X-Ray Generators: WWW - Xraylamp.webd - PLDocument3 pagesX-Ray Generators: WWW - Xraylamp.webd - PLkingstonNo ratings yet

- RT 19Document3 pagesRT 19kingstonNo ratings yet

- Exposure Vaults & Cabinets: RadiographyDocument1 pageExposure Vaults & Cabinets: RadiographykingstonNo ratings yet

- Activity (Of Radionuclides) : Home Education Resources NDT Course Material RadiographyDocument1 pageActivity (Of Radionuclides) : Home Education Resources NDT Course Material RadiographykingstonNo ratings yet

- MT Level - I QB 2Document8 pagesMT Level - I QB 2kingstonNo ratings yet

- More Information On Radiation SafetyDocument2 pagesMore Information On Radiation SafetykingstonNo ratings yet

- MT Level - I QB 3Document8 pagesMT Level - I QB 3kingstonNo ratings yet

- MT Level - I QB 1Document8 pagesMT Level - I QB 1kingstonNo ratings yet

- LPT Kavi Cha QBDocument47 pagesLPT Kavi Cha QBkingstonNo ratings yet

- Indian Society For Non-Destructive Testing: Model Examination - PT Level IIIDocument8 pagesIndian Society For Non-Destructive Testing: Model Examination - PT Level IIIkingstonNo ratings yet

- Liquid Penetrant Testing (PT)Document6 pagesLiquid Penetrant Testing (PT)kingston100% (1)

- Contact Thermometers: With Remote IndicationDocument1 pageContact Thermometers: With Remote IndicationJOSE DANIEL PEREZNo ratings yet

- Chapter 4 Frequency ModulationDocument88 pagesChapter 4 Frequency ModulationtestNo ratings yet

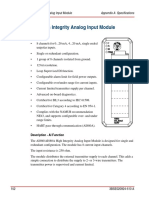

- AI880/AI880A High Integrity Analog Input Module: FeaturesDocument13 pagesAI880/AI880A High Integrity Analog Input Module: FeaturesqaedNo ratings yet

- f0Document41 pagesf0arattupuzhaNo ratings yet

- Power Break® II Circuit Breakers: Stationary and Drawout Breaker AccessoriesDocument2 pagesPower Break® II Circuit Breakers: Stationary and Drawout Breaker AccessoriesAlex RamirezNo ratings yet

- Auma Sqrex 05-2Document48 pagesAuma Sqrex 05-2Valentin AndreiNo ratings yet

- Instek GPT GPI Electrical Saftey Tester ManualDocument14 pagesInstek GPT GPI Electrical Saftey Tester ManualMido AzNo ratings yet

- LP28013 DatasheetDocument7 pagesLP28013 DatasheetGeorge KamberogiannisNo ratings yet

- Light Shadow Reflection WorksheetDocument6 pagesLight Shadow Reflection WorksheetSHAYAN ABDULLANo ratings yet

- L 11 - Light, Shadows and ReflectionsDocument15 pagesL 11 - Light, Shadows and ReflectionsChaitra KamuriNo ratings yet

- Dry Vs Oil Type Transformer - 1250KVA PDFDocument1 pageDry Vs Oil Type Transformer - 1250KVA PDFAhmed ShoaibNo ratings yet

- Comparison of 6/4 and 12/8 Switched Reluctance Motor Models Using Direct Torque Control With Torque Lookup TableDocument9 pagesComparison of 6/4 and 12/8 Switched Reluctance Motor Models Using Direct Torque Control With Torque Lookup TableSuman SahaNo ratings yet

- ABB Solar Inverters: PVS800 Technical FeaturesDocument44 pagesABB Solar Inverters: PVS800 Technical FeaturesmillarsambasivamNo ratings yet

- Brochure Victron Energy Quattro IIDocument2 pagesBrochure Victron Energy Quattro IISINES FranceNo ratings yet

- 750 00032 18V 10W Solar Panel DatasheetDocument2 pages750 00032 18V 10W Solar Panel DatasheetArun GopinathNo ratings yet

- Data Sheet: HEDS-9730, HEDS-9731Document6 pagesData Sheet: HEDS-9730, HEDS-9731Shohag MiaNo ratings yet

- Catálogo Sensores T MMPP NorisDocument5 pagesCatálogo Sensores T MMPP NorisCalandrasReyCalandrasreyNo ratings yet

- Adamson University College of Engineering Computer Engineering Department Microelectronics LaboratoryDocument9 pagesAdamson University College of Engineering Computer Engineering Department Microelectronics Laboratoryroxy8marie8chanNo ratings yet

- OL3Cap Three-Phase Overload Protection For Shunt Capacitor BanksDocument22 pagesOL3Cap Three-Phase Overload Protection For Shunt Capacitor BanksrajeshNo ratings yet

- "Hybrid Power Generation Using Solar and Wind Energy": Project Reference No.: 37S0987Document7 pages"Hybrid Power Generation Using Solar and Wind Energy": Project Reference No.: 37S0987Richa SharmaNo ratings yet

- Spec - LA 11,22,33 KV LA R1 Sep10Document14 pagesSpec - LA 11,22,33 KV LA R1 Sep10Amarjit KulkarniNo ratings yet

- BEE Module 1 - MergedDocument84 pagesBEE Module 1 - MergedVishnu VaishnaniNo ratings yet

- Bldutl2 - Building Utilities 2 Electrical, Electronic and Mechanical SystemsDocument10 pagesBldutl2 - Building Utilities 2 Electrical, Electronic and Mechanical Systemsgimel tenorioNo ratings yet

- DN027B Led15-Cw D175 RDDocument2 pagesDN027B Led15-Cw D175 RDMin Min AungNo ratings yet

- Driver Door Module PinoutsDocument5 pagesDriver Door Module Pinoutslamping_apNo ratings yet

- ARC 256x ARC Flash Initiator: User ManualDocument17 pagesARC 256x ARC Flash Initiator: User ManualSenta ClausNo ratings yet

- 1MRK511313-BEN A en Product Guide Bay Control REC670 2.0Document106 pages1MRK511313-BEN A en Product Guide Bay Control REC670 2.0PhuongThao NguyenNo ratings yet

- The International Journal of Science & TechnoledgeDocument6 pagesThe International Journal of Science & TechnoledgehakikNo ratings yet

- Datasheet 33Document5 pagesDatasheet 33deivison sobrinhoNo ratings yet

- Power Supply: ABB I-Bus® KNXDocument1 pagePower Supply: ABB I-Bus® KNXJulián HernándezNo ratings yet