Professional Documents

Culture Documents

Optimization of Catamaran Demihull Form PDF

Uploaded by

gksahaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Optimization of Catamaran Demihull Form PDF

Uploaded by

gksahaCopyright:

Available Formats

OPTIMIZATION OF CATAMARAN DEMIHULL FORM

IN EARLY STAGES OF THE DESIGN PROCESS

Muhammad Iqbal, Andi Trimulyono

Department of Naval Architecture,

Faculty of Engineering, Diponegoro University, Semarang, 50275, Indonesia

Email:m_iqbal@undip.ac.id

Abstrak

The amounts of research about catamaran have generated a practical formula to simplify the

calculations of catamaran resistance. Ship designer will calculate the predictions of catamaran

resistance rapidly. The aim of this research is focused to search the optimal demihull form where the

hull form has the lowest resistance compared to other hull form models with the same displacement.

To generate the different hull form, the initial hull form (parent hull) is transformed so that become

some models by changing the parameter of coefficient block (Cb) in range ±10% with Lwl, T, H,

volume and displacement are constant. The transformed hull form are calculated their total resistance

from Froude number (Fr) 0,2 to 0,65 with spacing hull to length ratio (S/L) 0,2 to 0,4. The results of

calculation show that the optimal demihull form is Model 4 where the initial hull form Cb +5%. The

model has the lowest resistance compared to other models. The comparisons of resistance Model 4

with the configurations of S/L shows that the lowest resistance is S/L 0,4, so that the optimal demihull

form is Model 4 with S/L 0,4.

Keywords : Optimization, Catamaran, Demihull Form

1. INTRODUCTION much to be ignored because for practical purposes.

In reference [3] research, the interference of the

At the present, the developments of catamaran are ship resistance components have been successfully

significant. Enthusiasts of catamaran are also very broken and generating an empirical formula to

much in the world. This is because the catamaran calculate it. This will make it easier for designers

has advantages compared to monohull vessel at to speed up the calculation of catamarans

the same displacement [1]. resistance prediction. Designers only need to

calculate the wave resistance coefficient (Cw) of

The amounts of research about catamarans have demihull catamaran.

generated a practical formula to simplify the

calculations of catamaran resistance. This makes By using reference [3] formula, it will be known

the working time in the early stages of the design total resistance of demihullalong with its

process becomes faster. interference factors. Then, to calculate the

catamarans resistance is by doubling the total

The breakdown of catamaran resistance resistance of demihull.The aim of this research is

component is the same as the monohull, just that focused to search rapidly the optimal demihull

each component is multiplied by a factor of form in early stages of the design process where

interference between the hulls. These topics are the hull form has the lowest resistance compared

studied by many researchers in the world related to other hull form models with the same

to the breakdown of interference components. displacement.

At the time reference [2] research about To generate the different demihull form, the initial

catamaran, the influence of interference is still demihull form (parent hull) is transformed to

KAPAL, Vol. 11, No.3Oktober2014 125

become some models by changing the parameter Table 2. Principal Dimensions of Parent Hull

of coefficient block (Cb) using the Lackenby

method. This method is moving the stations Particular Demihull

forwards and backwards without changing the Lwl 19,963 (m)

B 2,223 (m)

section form until the required Cb are fulfilled [4]. H 2,501 (m)

The hull comparison by changing Cb is also T 1,113 (m)

described in [5] to select the bestRoll on-Roll off Cb 0,394

Truck Carrier Hull Design. WSA 53,386 m2

Volume 19,443 m3

Displacement 19,929 Ton

When the total resistance is low, the fuel L/B 9,0

consumption and the exhaust gases emissions B/T 2,0

produced by the ship will be lower. L/(Vol)1/3 7,42

2. METHODS

This study begins by determining the initial design

of hull form demihull catamarans. The demihull

form is then transformed by changing the

parameters of Cb with parameters L, H, T and

displacement is constant. The reason for not

changing the length of the vessel parameters is to

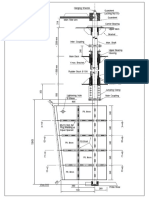

match the value of the Froude number (Fr) Figure 1.Parrent Hull

between transformed demihull forms.

The transformed demihull forms are calculated 2.2. Hull Form Transformation

their total resistance from Froude number (Fr) 0,2

to 0,65 as presented in Table 1 with spacing hull Demihull form is transformed by changing the

ratio to length (S/L) 0,2 to 0,4. parameter of coefficient block (Cb) in range ±10%

with Lwl, T, H, volume and displacement are

Table 1. Ship Speed Range constant. The transformed demihulls presented in

Table 3-4 and Figure 2-4.

v

Fr

m/s Knot

0,20 2,83 5,44 Table 3.Demihull Form Transformations

0,25 3,49 6,80

0,30 4,23 8,16

4,89 9,52 Model Transformation Cb

0,35

0,40 5,64 10,88 1 Parent Hull Cb – 10% 0,353

0,45 6,30 12,24 2 Parent Hull Cb – 5% 0,373

0,50 7,04 13,60 3 Parent Hull Cb 0,394

0,55 7,70 14,96 4 Parent Hull Cb + 5% 0,413

0,60 8,44 16,32 5 Parent Hull Cb + 10% 0,428

0,65 9,10 17,68

Table 4. Transformed Demihull Forms

2.1. Parent Hull

Parameter Model Model Model Model Model

1 2 3 4 5

The initial demihull form (parent hull) that used in B (m) 2,479 2,347 2,223 2,119 2,043

this study is The NPL Hull Form Series 4b with WSA (m2) 54,11 54,68 53,39 53,82 54,18

the principal dimensions presented in Table 2 and L/B 8,1 8,5 9,0 9,4 9,8

Figure 1. B/T 2,23 2,11 2,00 1,90 1,84

KAPAL, Vol. 11, No.3Oktober2014 126

Table 4 shows that the result of WSA after

transformations is not linear. It is not as constant

as the changing of Cb. Inversely, the changing of

ship breadth (B) is constant. The HigherCb the

lower B.

Figure 4. Model 4 and Model 5

2.3. Total Resistance Calculation

Calculation of total resistance catamarans begins

by calculating the total resistance coefficient (Ct)

of demihull. Because basically, the total of

resistance coefficient of catamaran obtained

bydoubling the total resistance of demihull along

its interference. To calculate Ct demihull and its

interference can use equation (1).

Ct = (1+ϕk)σCf + τCw (1)

where :

Ct = Coefficient of total resistance

Cf = Coefficient of friction resistance

obtained by skin friction

formula ITTC’57

Cw = Coefficient of wave resistance.

In this study Cw is calculated by

Slender Body Method

Figure 2.Transformed Demihull Forms ϕ = Pressure field change around the

two hulls

σ = Velocity augmentation between

the demihull

τ = Wave resistance interference

factor

For practical purpose, reference [2] combine ϕ and

σ into a viscous resistance interference β presented

in equation (2)

Figure 3. Model 1 and Model 2 Ct = (1+βk)Cf + τCw (2)

(1+βk) also called as Viscous Form Factor.

Reference [3] modify the reference [6] formula by

adding variable of S/L and also generate the

empirical formulas to calculate wave interferences

factor (τ) at the certain Froude Number (Fr). The

empirical formula to calculate (1+βk) presentedin

KAPAL, Vol. 11, No.3Oktober2014 127

equation (3) and the empirical formulas to 0,47 0,990 0,935 0,898

calculate (τ) presented in equation (4-9). To 0,56 0,830 0,732 0,670

0,65 0,669 0,622 0,591

calculate the total resistance demihull is using

equation (10).

(1+βk) = 3,03(L/Vol1/3)-0,40 + 0,016(S/L)-0,65 (3) To obtain the wave interference factor desired, it must

be interpolated from Table 6. In this study, the

τ = 0,068(S/L)-1,38 ,at Fr = 0,19 (4) interpolation used is Cubic Spline Interpolation

τ = 0,359(S/L)-0,87 ,at Fr = 0,28 (5) Method. The results presentedin Table 7 and Figure 5.

τ = 0,574(S/L)-0,33 ,at Fr = 0,37 (6)

τ = 0,790(S/L)-0,14 ,at Fr = 0,47 (7) Table7. Cubic Spline Interpolation of τ

τ = 0,504(S/L)-0,31 ,at Fr = 0,56 (8)

Fr S/L 0,2 S/L 0,3 S/L 0,4

τ = 0,501(S/L)-0,18 ,at Fr = 0,65 (9) 0,20 0,901 0,550 0,387

0,25 1,443 0,966 0,724

where : 0,30 1,365 1,000 0,804

Vol = Ship volume under water (m3) 0,35 1,070 0,885 0,776

0,40 0,926 0,864 0,819

S/L = spacing hull to length ratio

0,45 0,974 0,927 0,893

0,50 0,966 0,893 0,847

0,55 0,858 0,763 0,702

Rt =0,5*ρ*v2*WSA*Ct (kN)(10) 0,60 0,720 0,625 0,564

0,65 0,669 0,622 0,591

where :

Rt = Total resistance (kN)

ρ = Sea water density (1,025 ton/m3)

v Ship velocity (m/s)

WSA = Wetted Surface Area (m2)

Ct = Coefficient of total resistance

3. RESULTS AND DISCUSSION

Table 5 is viscous form factor calculated by using

equation (3). Table 6 shows the result of wave

resistance interference factor (τ) at the certain Froude

Number (Fr) calculated by equation (4-9).

Figure 5. Cubic Spline Interpolation of τ

Table 5. Viscous Form Factor

After all the variables are known, then calculate

S/L 1+βk demihullCf and Cw to obtain demihull Ct. Calculation

0,2 1,4047 Cf skin friction is calculated using the formula ITTC

0,3 1,3942

1,3882

'57 and Cw on this study calculated using Slender Body

0,4

Method based on [7].

After getting demihull Ct value, then the value of the

Table6. Wave resistance interference factor (τ)

total resistance (Rt) demihull can be calculated by the

Fr S/L 0,2 S/L 0,3 S/L 0,4 equation (10). To calculate the total resistance of

0,19 0,627 0,358 0,241 catamaran is 2 times the total resistance of demihull.

0,28 1,456 1,023 0,797

0,37 0,976 0,854 0,777 The results of the calculation of the total resistance

KAPAL, Vol. 11, No.3Oktober2014 128

catamaran S/L 0,2 is presented in Table 8 and plot lowestcompared to other models.

graphs of ship resistance presented in Figure 6. From The decreasing ship resistance from Model 1 to

those 5 models that have the lowest total resistance is Model 4 and the increasing ship resistance from

the model 4. model 4 to model 5 is not significant. From those

5 models that have the lowest total resistance is

The ship resistances from Model 1 to Model 4 keep also the model 4.

decreases for each Fr, but at Model 5 the ship resistance

increases. Table9. Total Resistance S/L 0,3 (kN)

Table8. Total Resistance S/L 0,2 (kN) Fr Model Model Model Model Model

1 2 3 4 5

Fr Model Model Model Model Model 0,20 2,969 2,959 2,969 3,086 3,317

1 2 3 4 5 0,25 4,718 4,574 4,588 4,892 5,956

0,30 7,584 7,004 6,786 6,986 8,470

0,20 3,046 3,044 3,070 3,248 3,614

0,35 13,572 11,535 10,139 9,407 11,423

0,25 4,984 4,784 4,816 5,254 6,829

0,40 16,223 14,385 13,075 12,098 13,623

0,30 8,184 7,410 7,124 7,379 9,390

0,45 21,760 20,183 19,033 17,976 19,529

0,35 14,808 12,359 10,680 9,783 12,209

0,50 28,738 27,295 26,213 25,100 26,465

0,40 16,728 14,763 13,362 12,308 13,940

0,55 32,350 31,046 30,049 29,038 30,098

0,45 22,320 20,666 19,461 18,346 19,974

0,60 34,995 33,834 32,941 32,094 32,899

0,50 29,923 28,371 27,207 25,996 27,463

0,65 39,255 38,057 37,128 36,272 37,017

0,55 34,233 32,782 31,673 30,518 31,696

0,60 37,148 35,837 34,826 33,826 34,732

0,65 40,515 39,240 38,250 37,316 38,106

Figure 7. Catamaran Resistance S/L 0,3

Figure 6. Catamaran Resistance S/L 0,2 Table10. Total Resistance S/L 0,4 (kN)

Fr Model Model Model Model Model

1 2 3 4 5

The results of the calculation of the total resistance 0,20 2,931 2,917 2,920 3,009 3,176

catamaran S/L 0,3 is presented in Table 9 and plot 0,25 4,582 4,465 4,470 4,706 5,511

graphs of ship resistance presented in Figure 7. 0,30 7,261 6,786 6,604 6,774 7,975

Over all, the ship resistance at S/L 0,3 is lower 0,35 12,845 11,051 9,821 9,187 10,961

than that S/L 0,2. The ship resistance also keep 0,40 15,869 14,124 12,880 11,957 13,406

0,45 21,372 19,850 18,740 17,725 19,223

decreases for each Fr from Model 1 to Model 4, 0,50 27,989 26,615 25,585 24,536 25,835

but increases at Model 5. From those 5 models 0,55 31,165 29,953 29,028 28,108 29,093

that has the lowest total resistance is also the 0,60 33,619 32,555 31,738 30,990 31,730

model 4. 0,65 38,433 37,287 36,398 35,595 36,310

The results of the calculation of the total resistance

catamaran S/L 0,4 is presented in Table 10 and

plot graphs of ship resistance presented in Figure

8. All ship resistance at this S/L is the

KAPAL, Vol. 11, No.3Oktober2014 129

5. REFERENCES

[1] Moraes, H.B., Vasconsellos, J.M., Latrre,

R.G, (2004). “Wave Resistance for High-

Speed catamarans”, Ocean Engineering,Vol

31, pp 2253-2282

[2] Insel, M., Molland, A.F. (1991). An

investigation into the resistance components

of high speed displacement catamaran, Royal

Institution of Naval Architects, Spring

Figure 8. Catamaran Resistance S/L 0,4 Meeting, paper No. 11.

[3] Jamaluddin, A., (2012), Experimental And

Numerical Investigation Into The Viscous

The results of the calculation show that for each And Wave Resistance Interferences of

S/L, model 4 has the lowest resistance compared Catamarans (in Indonesian), Ph.D Thesis,

to other models. The resistance comparison of Faculty of Marine Technology, Institute

Model 4 with the configurations of S/L shows that Technology of SepuluhNopember, Indonesia.

the lowest resistance is S/L 0,4 as presented in [4] Scamardella, A., Piscopo, V. (2014).

Figure 9. From the figure it is seen that the value “Passenger ship seakeeping optimization by

of the S/L 0,4 has the lowest total resistance. the Overall Motion Sickness Incidence”,

Ocean Engineering, Vol 76, pp 86-97.

[5] Prabowo, A. R., Zakki, A. F. (2014). “The

Investigation of Roll on-Roll off Truck

Carrier Hull Design for Route TanjungPriok

(Jakarta) - Tanjung Perak (Surabaya)”. The

9th International Conference on Marine

Technology, 24-26 October, Surabaya,

Indonesia.

[6] Molland, A.F., Wellicome, J.F., Couser,

P.R.(1996), “Resistance Experiments on a

Systematic Series of High-Speed

Displacement Catamaran Forms: Variations

Figure 9. Catamaran Resistance Model 4 of Length-Displacement Ratio and Breadth-

Draugh Ratio”, Transaction RINA, 138A

[7] Jamaluddin, A. Utama, I.K.A.P., Hamdani,

4. CONCLUSIONS M.A., 2010. “Investigation of Interferences of

Resistance Coefficient on Catamaran with

The results of calculation show that the optimal

Slender Body Method Computation (in

demihull form is Model 4 where the initial hull

Indonesian)”, KAPAL, Vol 7. No 2.

form Cb +5%. The model has the lowest

resistance compared to other models. The

comparisons of resistance Model 4 with the

configurations of S/L shows that the lowest

resistance is S/L 0,4, so that the optimal demihull

form is Model 4 with S/L 0,4.

KAPAL, Vol. 11, No.3Oktober2014 130

You might also like

- Molecular Modeling of Geochemical Reactions: An IntroductionFrom EverandMolecular Modeling of Geochemical Reactions: An IntroductionJames D. KubickiNo ratings yet

- 7735 16925 1 PB - 2Document7 pages7735 16925 1 PB - 2Athul DileepNo ratings yet

- Optimization of Catamaran Demihull Form in Early Stages of The Design ProcessDocument7 pagesOptimization of Catamaran Demihull Form in Early Stages of The Design ProcessshejtemaeiNo ratings yet

- Optimization of Catamaran Demihull FormDocument7 pagesOptimization of Catamaran Demihull FormwongyuliongNo ratings yet

- 773optimization of Catamaran Demihull Form in Early Stages of The Design Process5-16925-1-Pb - 2Document6 pages773optimization of Catamaran Demihull Form in Early Stages of The Design Process5-16925-1-Pb - 2Muhammad IqbalNo ratings yet

- Analisa Pengaruh Bulbous Bow Terhadap Tahanan Kapal Dan Konsumsi Bahan Bakar Pada Kapal Perintis 2000 GTDocument4 pagesAnalisa Pengaruh Bulbous Bow Terhadap Tahanan Kapal Dan Konsumsi Bahan Bakar Pada Kapal Perintis 2000 GTUntuk KegiatanNo ratings yet

- Optimization Approach For A Catamaran Hull Using CAESES and STAR-CCM+Document5 pagesOptimization Approach For A Catamaran Hull Using CAESES and STAR-CCM+Jennifer JonesNo ratings yet

- Experimental and CFD Study of Wave Resistance of High-Speed Round Bilge Catamaran Hull FormsDocument13 pagesExperimental and CFD Study of Wave Resistance of High-Speed Round Bilge Catamaran Hull FormsWai Yan Thet PaingNo ratings yet

- Hiper04 Paper ADocument13 pagesHiper04 Paper AaspoisdNo ratings yet

- 19 TR DBDanisman-Paper Rev1Document13 pages19 TR DBDanisman-Paper Rev1dimzikNo ratings yet

- Lec Notes 2Document33 pagesLec Notes 2yetNo ratings yet

- Finding The Hull Form For Given Seakeeping Characteristics PDFDocument8 pagesFinding The Hull Form For Given Seakeeping Characteristics PDFy_596688032No ratings yet

- Design of Berm BreakwatersDocument32 pagesDesign of Berm BreakwatersAnonymous VkzquW39No ratings yet

- Humpback Whale Inspired Design For Tidal Turbine Blades: Weichao Shi, Mehmet Atlar, Rosemary NormanDocument9 pagesHumpback Whale Inspired Design For Tidal Turbine Blades: Weichao Shi, Mehmet Atlar, Rosemary NormanVikram HegdeNo ratings yet

- Structural Modifications For The Longitudinal StreDocument10 pagesStructural Modifications For The Longitudinal StreTea JevtićNo ratings yet

- Stab 012Document15 pagesStab 012Kenneth TanNo ratings yet

- Hydraulic Head Losses in An Unlined Pressure Tunnel of A High Head Power Plant PDFDocument18 pagesHydraulic Head Losses in An Unlined Pressure Tunnel of A High Head Power Plant PDFRoberto FErnandesNo ratings yet

- Distribution TransformerDocument57 pagesDistribution TransformerarnabNo ratings yet

- Hydrodynamic Studies On A Trimaran Hull FormDocument10 pagesHydrodynamic Studies On A Trimaran Hull FormPereowei OmborNo ratings yet

- Ikeda RevisitedDocument11 pagesIkeda RevisitedZawadul IslamNo ratings yet

- Ship Design ProjectProject Report On DesDocument40 pagesShip Design ProjectProject Report On DesFederico Babich100% (1)

- The Aerodynamics Performance of BlendedDocument5 pagesThe Aerodynamics Performance of Blendeddarshan gowdaNo ratings yet

- Reinforced Concrete Continuous Beam Analysis and Design (CSA A23.3-14)Document44 pagesReinforced Concrete Continuous Beam Analysis and Design (CSA A23.3-14)Kriselle Jane Ang-angan GaerlanNo ratings yet

- Project1 2004Document3 pagesProject1 2004first.class.baby.boyNo ratings yet

- Torque and Drag-Two Factors in Extended-Reach Drilling: W, Has A Horizontal Force at LeftDocument4 pagesTorque and Drag-Two Factors in Extended-Reach Drilling: W, Has A Horizontal Force at LeftTariq SaihoodNo ratings yet

- Strut and Tie ModelDocument11 pagesStrut and Tie Modelshahriar_938521054No ratings yet

- Sun, J. 2012. Hull Form DesignDocument10 pagesSun, J. 2012. Hull Form DesignManuel Esteban MercadoNo ratings yet

- Investigation On The Optimum Distance Between The Hulls of A Danube Delta Passenger CatamaranDocument8 pagesInvestigation On The Optimum Distance Between The Hulls of A Danube Delta Passenger CatamaranSathish VidyutNo ratings yet

- CFDLV14 N8 P71 80Document10 pagesCFDLV14 N8 P71 80mabm89No ratings yet

- Time Zones 1 & 2: Answer Each Section in Separate BookletsDocument12 pagesTime Zones 1 & 2: Answer Each Section in Separate BookletsIdlan IzharNo ratings yet

- Chesap - Symp. Hull Shape DragDocument10 pagesChesap - Symp. Hull Shape DragИван ИвановNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universitydevang majithiyaNo ratings yet

- CH 13 PoweringDocument12 pagesCH 13 PoweringABeNo ratings yet

- Lines PlanDocument23 pagesLines PlanhaeiriNo ratings yet

- Ose 0502003Document17 pagesOse 0502003MjNo ratings yet

- CFDLV15 N6 P54 64Document11 pagesCFDLV15 N6 P54 64mabm89No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityyicef37689No ratings yet

- jspd170034 rp1Document29 pagesjspd170034 rp1Maciej ReichelNo ratings yet

- Numerical Simulations of A Surface Piercing A-Class Catamaran Hydrofoil and Comparison Against Model TestsDocument10 pagesNumerical Simulations of A Surface Piercing A-Class Catamaran Hydrofoil and Comparison Against Model TestsBillyNo ratings yet

- 72C1FDocument5 pages72C1FManuel Ayala0% (1)

- ShipHydroLN 4Document7 pagesShipHydroLN 4yetNo ratings yet

- SteppedHullReport - 5 13 2009Document22 pagesSteppedHullReport - 5 13 2009dzul effendiNo ratings yet

- Lean Blow Out Limits of A Gas Turbine CombustorDocument10 pagesLean Blow Out Limits of A Gas Turbine CombustorFayçal MahieddineNo ratings yet

- Methods For Designing ShipDocument60 pagesMethods For Designing Shipbahrul100% (1)

- ShipHydroLN 6Document19 pagesShipHydroLN 6SeyfullahYıldızNo ratings yet

- Ship Design For Efficiency and Economy-7-226-25-32Document8 pagesShip Design For Efficiency and Economy-7-226-25-32galin8575No ratings yet

- The Analysis of Motion Dynamics and Resistance of The Multipurpose Boat Operating in Shallow WaterDocument5 pagesThe Analysis of Motion Dynamics and Resistance of The Multipurpose Boat Operating in Shallow WaterxeyranNo ratings yet

- CFD Assessment of Ropax Hull Resistance With Various Initial Drafts and Trim AnglesDocument8 pagesCFD Assessment of Ropax Hull Resistance With Various Initial Drafts and Trim AnglesRahul SunilNo ratings yet

- Ujian 1 1314 Sem 1 With SKEMA PDFDocument15 pagesUjian 1 1314 Sem 1 With SKEMA PDFYap Jin YeeNo ratings yet

- Ujian 1 1314 Sem 1 (With SKEMA)Document15 pagesUjian 1 1314 Sem 1 (With SKEMA)Lew IceNo ratings yet

- Theoretical and Experimental Prediction of Ship Model Resistance With Semi Elliptical Section, Nozzle-Like Side StripsDocument6 pagesTheoretical and Experimental Prediction of Ship Model Resistance With Semi Elliptical Section, Nozzle-Like Side StripsmanrezaNo ratings yet

- Winter 17Document2 pagesWinter 17Bala DuttNo ratings yet

- The Computerized Design Program For Tunnel BlastingDocument10 pagesThe Computerized Design Program For Tunnel BlastingWei WangNo ratings yet

- ch11 AllProblem KeyDocument56 pagesch11 AllProblem Keyladyinred90No ratings yet

- (Catamaran) Effect of Hull Form and Its Associated Parameters On The Resistance of A Catamaran - MaxsurfDocument11 pages(Catamaran) Effect of Hull Form and Its Associated Parameters On The Resistance of A Catamaran - MaxsurfWm Erick Cr100% (1)

- Estudio Estabilidad Barcaza Con Grua PDFDocument9 pagesEstudio Estabilidad Barcaza Con Grua PDFfredy2212No ratings yet

- Weight PredictionDocument9 pagesWeight PredictionEmreNo ratings yet

- OTC-26559-MS Infinite Conductivity Horizontal Borehole Assumption: Applicability & Quantification of ErrorDocument13 pagesOTC-26559-MS Infinite Conductivity Horizontal Borehole Assumption: Applicability & Quantification of ErrorAbbas AlkhudafiNo ratings yet

- Continuous Beam Design With Moment Redistribution (CSA A23.3-14) PDFDocument35 pagesContinuous Beam Design With Moment Redistribution (CSA A23.3-14) PDFtimNo ratings yet

- JSAE Review - Development of Light Weight Cylinder BlockDocument3 pagesJSAE Review - Development of Light Weight Cylinder BlockDarel DalmassoNo ratings yet

- Body PlanDocument1 pageBody PlangksahaNo ratings yet

- Offshore Structure TestingDocument5 pagesOffshore Structure TestinggksahaNo ratings yet

- Ship Framing SystemDocument10 pagesShip Framing SystemgksahaNo ratings yet

- Final Scantling CalculationDocument15 pagesFinal Scantling CalculationAnonymous SiA1p78SUNo ratings yet

- Midship LectureDocument7 pagesMidship LecturegksahaNo ratings yet

- Framing ConstructionDocument12 pagesFraming ConstructionTruculent TrinoyNo ratings yet

- Catalogue Card Catalogue Card Catalogue Card Catalogue Card: HydrosterDocument10 pagesCatalogue Card Catalogue Card Catalogue Card Catalogue Card: HydrosterTasmiaH.ShoilyNo ratings yet

- Basic Approach: 111equation Chapter 1 Section 1 Weight EstimationDocument16 pagesBasic Approach: 111equation Chapter 1 Section 1 Weight EstimationgksahaNo ratings yet

- Outfit WeightDocument10 pagesOutfit WeightgksahaNo ratings yet

- Estimating Principal DimensionsDocument26 pagesEstimating Principal DimensionsgksahaNo ratings yet

- Freeboard CalculationDocument45 pagesFreeboard CalculationgksahaNo ratings yet

- Design of Ship RuddersDocument82 pagesDesign of Ship RuddersGerard Sarg100% (1)

- Machinery WeightDocument13 pagesMachinery WeightgksahaNo ratings yet

- Resistance and Power CalculationDocument23 pagesResistance and Power CalculationgksahaNo ratings yet

- Directional Wavemaker Theory With Sidewall ReflectionDocument13 pagesDirectional Wavemaker Theory With Sidewall ReflectiongksahaNo ratings yet

- Rudder DesignDocument18 pagesRudder DesigngksahaNo ratings yet

- Rudder Sample DrawingDocument6 pagesRudder Sample DrawinggksahaNo ratings yet

- Something About The Mechanical Moment of InertiaDocument6 pagesSomething About The Mechanical Moment of InertiagksahaNo ratings yet

- 2780 11979 1 PB PDFDocument18 pages2780 11979 1 PB PDFShaiful IslamNo ratings yet

- Waves Generated by A Piston-Type Wavemaker: Coastal Engineering Proceedings January 1970Document21 pagesWaves Generated by A Piston-Type Wavemaker: Coastal Engineering Proceedings January 1970gksahaNo ratings yet

- Ship Displacement SheetDocument13 pagesShip Displacement SheetgksahaNo ratings yet

- Stability Calculations by Barnes MethodDocument6 pagesStability Calculations by Barnes MethodgksahaNo ratings yet

- Lines and Offset of Series 60Document10 pagesLines and Offset of Series 60gksahaNo ratings yet

- Plunger-Type Wavemaker TheoryDocument10 pagesPlunger-Type Wavemaker TheorygksahaNo ratings yet

- New Approach To Flap-Type Wavemaker Equation With Wave Breaking LimitDocument11 pagesNew Approach To Flap-Type Wavemaker Equation With Wave Breaking LimitgksahaNo ratings yet

- Unsymmetrical BendingDocument2 pagesUnsymmetrical BendinggksahaNo ratings yet

- Simulating Narrow Channel Effect On Surge MotionDocument5 pagesSimulating Narrow Channel Effect On Surge MotiongksahaNo ratings yet

- Ship Motions in Shallow Water PDFDocument10 pagesShip Motions in Shallow Water PDFgksahaNo ratings yet

- Damage Stability Assessment of ContainershipDocument18 pagesDamage Stability Assessment of ContainershipgksahaNo ratings yet

- Resis Sinkage Trim Wake Test PDFDocument30 pagesResis Sinkage Trim Wake Test PDFSea Man MktNo ratings yet

- F (X) X 5 G (X) X: I. ExercisesDocument2 pagesF (X) X 5 G (X) X: I. ExercisesJaafar SorianoNo ratings yet

- EDH Engineering GuideDocument3 pagesEDH Engineering GuidelakshminarayananNo ratings yet

- Medication Calculation - Commonly Used FormulasDocument1 pageMedication Calculation - Commonly Used FormulasAaron AntonioNo ratings yet

- GRE Practice Questions - QuantitativeDocument12 pagesGRE Practice Questions - QuantitativeGigglyJewel_20100% (1)

- Topic by TopicDocument287 pagesTopic by TopicA.Benson0% (1)

- CFMDocument16 pagesCFMShoaibIqbalNo ratings yet

- Investigation On Volume and Surface Area of CylinderDocument4 pagesInvestigation On Volume and Surface Area of CylinderMuhammad Asad AliNo ratings yet

- Physics Measurement WorksheetDocument3 pagesPhysics Measurement WorksheetTahir SaeedNo ratings yet

- TSM Strapping (Tank Calibration)Document2 pagesTSM Strapping (Tank Calibration)skthen72No ratings yet

- Cargo Handling & Stowage Full SyllabusDocument73 pagesCargo Handling & Stowage Full Syllabusalfa89pNo ratings yet

- G9 Elite Science Lab Assessment DensityDocument4 pagesG9 Elite Science Lab Assessment DensitymaryamNo ratings yet

- Important MathsDocument161 pagesImportant MathsAnubhav SwaroopNo ratings yet

- Manual Dispenser v2Document6 pagesManual Dispenser v2Humberto Aranda HernandezNo ratings yet

- SBA #14 - Air Content of SoilDocument3 pagesSBA #14 - Air Content of Soillucy100% (1)

- Question Bank 1 2012-2013Document12 pagesQuestion Bank 1 2012-2013Hany ElGezawy0% (1)

- Dimensional AnalysisDocument13 pagesDimensional AnalysisArdette De JesusNo ratings yet

- CEASIOM XML File Definition: Andrés Puelles Et AlDocument29 pagesCEASIOM XML File Definition: Andrés Puelles Et Alsharath_87No ratings yet

- Experiment Report 1 - Group 2 - Chemistry 40Document12 pagesExperiment Report 1 - Group 2 - Chemistry 40Daniella ChandraNo ratings yet

- HS Discrete Math FInalDocument38 pagesHS Discrete Math FInalEdfinity100% (3)

- Engine Performance ParametersDocument8 pagesEngine Performance ParametersJaphet Charles Japhet MunnahNo ratings yet

- 22503-2019-Winter-Model-Answer-Paper Msbte Study ResourcesDocument16 pages22503-2019-Winter-Model-Answer-Paper Msbte Study ResourcesToufiq Bhati100% (2)

- Physics Notes .ImprovedDocument72 pagesPhysics Notes .Improvedogenrwot albertNo ratings yet

- 10 IGCSE Science Mock Exam Paper 6 2014Document21 pages10 IGCSE Science Mock Exam Paper 6 2014pixelhoboNo ratings yet

- Ge Dresser HPC Meter IomDocument20 pagesGe Dresser HPC Meter IomfharishputraNo ratings yet

- Cylindrical Horizontal Tank Volume CalculationDocument21 pagesCylindrical Horizontal Tank Volume CalculationashrafNo ratings yet

- Chapter-1 of F.mensurationDocument8 pagesChapter-1 of F.mensurationpradeeppoddarNo ratings yet

- Mass Density Volume PixiPPtDocument29 pagesMass Density Volume PixiPPtSharolNo ratings yet

- Yearly Lesson Plan Mathematics Form3 2015Document3 pagesYearly Lesson Plan Mathematics Form3 2015why-edaNo ratings yet

- Conversion TableDocument2 pagesConversion TablemnjnasirNo ratings yet

- Storage Methods and Control EngDocument14 pagesStorage Methods and Control Engapi-313509942No ratings yet

- Summary of Neil Postman's Amusing Ourselves to DeathFrom EverandSummary of Neil Postman's Amusing Ourselves to DeathRating: 4 out of 5 stars4/5 (2)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetFrom EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetRating: 4.5 out of 5 stars4.5/5 (10)

- Troubleshooting and Repair of Diesel EnginesFrom EverandTroubleshooting and Repair of Diesel EnginesRating: 1.5 out of 5 stars1.5/5 (2)

- The Finite Element Method: Linear Static and Dynamic Finite Element AnalysisFrom EverandThe Finite Element Method: Linear Static and Dynamic Finite Element AnalysisRating: 5 out of 5 stars5/5 (3)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansRating: 4.5 out of 5 stars4.5/5 (21)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeFrom EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeRating: 4.5 out of 5 stars4.5/5 (59)

- CAREC Road Safety Engineering Manual 3: Roadside Hazard ManagementFrom EverandCAREC Road Safety Engineering Manual 3: Roadside Hazard ManagementNo ratings yet

- Structural Cross Sections: Analysis and DesignFrom EverandStructural Cross Sections: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (19)

- Pile Design and Construction Rules of ThumbFrom EverandPile Design and Construction Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (15)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Construction Innovation and Process ImprovementFrom EverandConstruction Innovation and Process ImprovementAkintola AkintoyeNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesFrom EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesNo ratings yet

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyFrom EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyRating: 4.5 out of 5 stars4.5/5 (5)

- Engineering Rock Mass Classification: Tunnelling, Foundations and LandslidesFrom EverandEngineering Rock Mass Classification: Tunnelling, Foundations and LandslidesRating: 4 out of 5 stars4/5 (5)

- Skyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownFrom EverandSkyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownNo ratings yet

- Transportation Decision Making: Principles of Project Evaluation and ProgrammingFrom EverandTransportation Decision Making: Principles of Project Evaluation and ProgrammingNo ratings yet