Professional Documents

Culture Documents

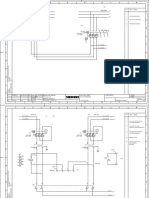

Ek - 200 - K - 1193 - 40ext60tpd KCP - L1 PDF

Uploaded by

awigaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ek - 200 - K - 1193 - 40ext60tpd KCP - L1 PDF

Uploaded by

awigaCopyright:

Available Formats

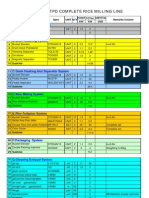

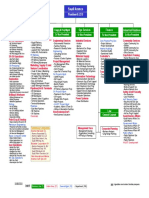

42000

6000 6000 6000 6000 6000 6000 6000

2-7

FUTURE EXTEND

2-8 2-9

C

ELEV

3-9

2-12

3-3

2ND. PRESSING

3-2

PALM KERNEL 1-1 3-11

3-10

2-6

2-10

2-11

INTAKE STATION 3-8 ELEV

A B

ELEV

18000

2-5

2-4

2-13

1ST. PRESSING C

ELEV

3-6 3-5

1-2 3-7 3-4

2-1 2-2 2-3

FUTURE EXTEND

3-12

FINAL CAKE

STORE

2-10 Palm Kernel Meal Conveyor 1 Unit 3-9 Filtered Cake Conveyor - I 1 Unit

2-9 2nd. Pressing Oil Expeller 2 Units 3-8 Pressure Leaf Filter 2 Units

2-8 Palm Kernel Cake Hopper 1 Unit 3-7 Unfiltered Oil Tank c/w Agitator 1 Unit

2-7 Palm Kernel Cake Distribution Conveyor 1 Unit 3-6 Sludge Return Conveyor - i 1 Unit

2-6 Palm Kernel Cake Cross Conveyor 1 Unit 3-5a Vibrating Screen Pump 1 Unit MUAR BAN LEE ENGINEERING S/B.

2-5 Palm Kernel Cake Elevator 1 Unit 3-5 Vibrating Screen 1 Unit NO. JR52, Lot 1818, Kawasan Perindustrian Bukit Pasir

Crude Oil Tank c/w Agitator 84300, Muar, Johor, Malaysia.

2-4 Palm Kernel Cake Conveyor 1 Unit 3-4 1 Unit

Tel. : 606 - 9859998 (H.Line), Fax : 606-9858889

2-3 1st. Pressing Oil Expeller 2 Units 3-3 Oil Cross Conveyor 1 Unit http://www.mbl.com email://mbl@mbl.com

ISO CERTIFIED

2-2 Palm Kernel Hopper 1 Lot 3-2 2nd. Pressing Oil Conveyor 1 Unit

2-1 Palm Kernel Distribution Conveyor 1 Unit 3-1 1st. Pressing Oil Conveyor 1 Unit Proposed Palm Kernel Crushing Plant.

___ ___ Capacity : 40 EXT 60 Mt. Per 24 hours

2-0 PRESSING STATION 3-0 OIL RECOVERY STATION

1-2 Palm Kernel Elevator 1 Unit 2-13 Palm Kernel Meal Conveyor In Store 1 Unit 3-12 Filtered Oil Tank 1 Unit

1-1 Palm Kernel Intake Conveyor 1 Unit 2-12 Palm Kernel Meal Transfer Conveyor 1 Unit 3-11 Vibrating Screen & Filter Press Platform 1 Unit

1-0 INTAKE STATION ___ 2-11 Palm Kernel Meal Elevator 1 Unit 3-10 Filtered Cake Conveyor - II 1 Unit

ITEM NO. DESCRIPTION QTY. ITEM NO. DESCRIPTION QTY. ITEM NO. DESCRIPTION QTY.

You might also like

- Analisa Biaya Pembuatan Pabrik Kelapa SawitDocument14 pagesAnalisa Biaya Pembuatan Pabrik Kelapa SawitHeryy TanujayaNo ratings yet

- Spect Press CB15T & CB4000L For BPK & TS MillDocument3 pagesSpect Press CB15T & CB4000L For BPK & TS Millrendra100% (1)

- Rab Pks 60 Ton Tbs Per JamDocument5 pagesRab Pks 60 Ton Tbs Per JamOptimuz Optimuz75% (4)

- Velocity Diagram Crack Mix Dry Separating SystemDocument1 pageVelocity Diagram Crack Mix Dry Separating SystemHeryy Tanujaya100% (1)

- Diagram Alur Proses PKS TS OKDocument1 pageDiagram Alur Proses PKS TS OKCandra Putra100% (1)

- 2.0 SDPA - Palm Oil Mill ProjectDocument19 pages2.0 SDPA - Palm Oil Mill ProjectAmeen Zenn100% (1)

- Sterilizer TiltingDocument23 pagesSterilizer Tiltingofchis50% (2)

- PT. Serumpun Indah LestariDocument1 pagePT. Serumpun Indah Lestariandirahmantanjung100% (2)

- Palm Oil Factory Process Handbook: Part 1 #Document1 pagePalm Oil Factory Process Handbook: Part 1 #John HastingNo ratings yet

- Palm Oil Mill - FFB Conveyor Sizing BDocument4 pagesPalm Oil Mill - FFB Conveyor Sizing BAmin Buhari Md Zain100% (5)

- Energy BalanceDocument6 pagesEnergy BalanceAnissa MuniraNo ratings yet

- Catalog Amp Ruang Teknik GroupDocument23 pagesCatalog Amp Ruang Teknik Groupawiga100% (1)

- Kakap PSCDocument2 pagesKakap PSCAulia FadhinaNo ratings yet

- Palm Oil Quotation RabDocument49 pagesPalm Oil Quotation RabEmel Mangkuraja WanitaNo ratings yet

- List Drawing, The NEWDocument92 pagesList Drawing, The NEWRabindranath Hendy TagoreNo ratings yet

- Refinery Process FlowchartDocument13 pagesRefinery Process FlowchartYanly Pattrick Fehilly100% (1)

- Close HouseDocument1 pageClose Houseirfan erikaNo ratings yet

- Material Balance Pabrik Kelapa Sawit 30 Ton PDFDocument27 pagesMaterial Balance Pabrik Kelapa Sawit 30 Ton PDFRamdani Machinetwo100% (1)

- 1.5TPH Wood Pellet Production LineDocument8 pages1.5TPH Wood Pellet Production LineddtyuriNo ratings yet

- Palm Oil Effluent Treatment SchemeDocument11 pagesPalm Oil Effluent Treatment SchemebathalapalliNo ratings yet

- Hot Mix Plant Model DM-45 Capacity 40-60 TPH UniversalDocument3 pagesHot Mix Plant Model DM-45 Capacity 40-60 TPH UniversalShreyansh TiwariNo ratings yet

- KatalogDocument32 pagesKatalogokaresta100% (1)

- SINGLE SCREW EMPTY BUNCH PRESS, Sri SinacoDocument7 pagesSINGLE SCREW EMPTY BUNCH PRESS, Sri Sinacokurniawan_zyreqart100% (2)

- EH - Topic 1 Reception - Final Draft 300413Document5 pagesEH - Topic 1 Reception - Final Draft 300413Amin Buhari Md Zain100% (1)

- Rekapitulasi Estimasi Penawaran Harga Pembangunan Pks Kap. 45 Ton Tbs / Jam Dengan Vertical SterilizerDocument6 pagesRekapitulasi Estimasi Penawaran Harga Pembangunan Pks Kap. 45 Ton Tbs / Jam Dengan Vertical SterilizerTfk BajaNo ratings yet

- BOQ 10 Ton Brondolan. 20 MAR - 2023Document6 pagesBOQ 10 Ton Brondolan. 20 MAR - 20234xjf5yqmvtNo ratings yet

- PErkiraan Investasi 500 TPDDocument3 pagesPErkiraan Investasi 500 TPDAde SatriaNo ratings yet

- Form - Survey Fans & Heater KosongDocument6 pagesForm - Survey Fans & Heater KosongsetiawanjodiNo ratings yet

- CB MODIPALM - Screw PressDocument2 pagesCB MODIPALM - Screw PressawigaNo ratings yet

- Machinery List For Dashboard Conditions Report WIP 2021 Maret Week 2Document4,262 pagesMachinery List For Dashboard Conditions Report WIP 2021 Maret Week 2slamet supriyadiNo ratings yet

- The Quotation of 30TPD Palm Oil Refinery Fractionation PlantDocument16 pagesThe Quotation of 30TPD Palm Oil Refinery Fractionation PlantKen MbayiNo ratings yet

- Ref List of Boiler - PT. Grand Kartech TBKDocument6 pagesRef List of Boiler - PT. Grand Kartech TBKMirwan PrasetiyoNo ratings yet

- Wom201 - Job Description - Mill EngineerDocument1 pageWom201 - Job Description - Mill EngineerJapheth Areso100% (1)

- BQ Pengadaan Pertashop 3 KL Gen3 - Rev.1-DikonversiDocument4 pagesBQ Pengadaan Pertashop 3 KL Gen3 - Rev.1-DikonversiArie WigunaNo ratings yet

- FFB & SFB Conveyor-SizingDocument14 pagesFFB & SFB Conveyor-SizingAzaharimahadiNo ratings yet

- PMT YO EFB Press - 1Document20 pagesPMT YO EFB Press - 1eko cienkNo ratings yet

- Calcul Conveioare SurubDocument2 pagesCalcul Conveioare SurubgvisanNo ratings yet

- MSB P15 Screw Press Manual (2022) PDFDocument25 pagesMSB P15 Screw Press Manual (2022) PDFajialiidris97100% (1)

- RAB PKS 45 TonperjamDocument9 pagesRAB PKS 45 TonperjamBoedak ThekingNo ratings yet

- Poeb118 PDFDocument56 pagesPoeb118 PDFDeny Handoko100% (1)

- Elevator Calculations Bechtel PDFDocument2 pagesElevator Calculations Bechtel PDFMarlonNo ratings yet

- 1.0tph palm fruite crushing mill-印尼 PDFDocument5 pages1.0tph palm fruite crushing mill-印尼 PDFAgus AriyantoNo ratings yet

- Tulsa Gas Technologies India Pvt. LTD: Data Sheet For 37 KW CNG Booster CompressorDocument6 pagesTulsa Gas Technologies India Pvt. LTD: Data Sheet For 37 KW CNG Booster Compressorsumit kumarNo ratings yet

- Bill of Quantity Pertashop 3Kl Model Roof Listplang/AcpDocument8 pagesBill of Quantity Pertashop 3Kl Model Roof Listplang/AcpTeguh IS100% (1)

- Mechanical Maintenance Palm Mill OilDocument38 pagesMechanical Maintenance Palm Mill Oilvicky alviolandNo ratings yet

- Synopsis PDFDocument670 pagesSynopsis PDFZulfan Al Hajj Harahap100% (2)

- Crude Palm Oil Mill Process IntroductionDocument2 pagesCrude Palm Oil Mill Process IntroductionMarcel MrcNo ratings yet

- 200tpd Rice MillDocument5 pages200tpd Rice MillAzim KowshikNo ratings yet

- Screw ConveyorDocument1 pageScrew ConveyorBalaji NatarajanNo ratings yet

- Pks 30 Ton Horizontal Sterilizer Pt. AfrDocument6 pagesPks 30 Ton Horizontal Sterilizer Pt. AfrDominique Mendoza80% (5)

- Alur ProsesDocument4 pagesAlur Prosesdwi anggraeniNo ratings yet

- Kernel Crushing Plant Process PresentationDocument18 pagesKernel Crushing Plant Process PresentationSuryadi Putra SiregarNo ratings yet

- SF06 Plan ParaclisDocument1 pageSF06 Plan ParaclisDia SavaNo ratings yet

- South 2: Engr. Emadudden M. Macadato Proposed 2-Storey Split Type House Sorainah G. Tamay - MacadatoDocument1 pageSouth 2: Engr. Emadudden M. Macadato Proposed 2-Storey Split Type House Sorainah G. Tamay - MacadatoEmad MacadatoNo ratings yet

- Folio 1Document1 pageFolio 1Mo JlalNo ratings yet

- Partial Roof Plan 2: Mechanical Design Position: Mechanical Engineer PRC No.: 2195 PTR No.: 3399286 TIN No.: 145-553-983Document1 pagePartial Roof Plan 2: Mechanical Design Position: Mechanical Engineer PRC No.: 2195 PTR No.: 3399286 TIN No.: 145-553-983Nathaniel Gutierez MangubatNo ratings yet

- (8CL) WP 1Document1 page(8CL) WP 1nonantonio7No ratings yet

- 10 - +GB03 2de01 Bustie BreakerDocument4 pages10 - +GB03 2de01 Bustie BreakerhamzehNo ratings yet

- LMC Air Receiver M-2Document1 pageLMC Air Receiver M-2hilarionsayson5No ratings yet

- Vellore Mahal - SF Electrical LayoutDocument1 pageVellore Mahal - SF Electrical LayoutVinoth KumarNo ratings yet

- Hisense Rsag7.820.1933 Psu SCHDocument10 pagesHisense Rsag7.820.1933 Psu SCHJuan Carlos CortesNo ratings yet

- HDL 61cuDocument1 pageHDL 61curiza jakaNo ratings yet

- CB MODIPALM - Screw PressDocument2 pagesCB MODIPALM - Screw PressawigaNo ratings yet

- Aspuc System Tap Series: Asphalt Plant SystemsDocument6 pagesAspuc System Tap Series: Asphalt Plant SystemsawigaNo ratings yet

- Asphalt Mixing Plants Overview Ppb-1003-00-Es PDFDocument72 pagesAsphalt Mixing Plants Overview Ppb-1003-00-Es PDFawigaNo ratings yet

- CPK Pump CatalogeDocument16 pagesCPK Pump CatalogeawigaNo ratings yet

- Melter SpecDocument1 pageMelter SpecawigaNo ratings yet

- 670 1222 1 SM PDFDocument14 pages670 1222 1 SM PDFawigaNo ratings yet

- Biblioteca Ingenieria Petrolera 2015Document54 pagesBiblioteca Ingenieria Petrolera 2015margaritaNo ratings yet

- Crude Oil Mktwire July 2011Document13 pagesCrude Oil Mktwire July 2011Al QadiryNo ratings yet

- Discflo Bomba de Carga Curva 804-20-2HHDH Api 10 IngDocument1 pageDiscflo Bomba de Carga Curva 804-20-2HHDH Api 10 IngFrancisco RivasNo ratings yet

- Jaso MA MB Oil ListDocument112 pagesJaso MA MB Oil ListROBINSON FERNEYNo ratings yet

- Q8 Formula Special D1 FE 0W-20: DescriptionDocument1 pageQ8 Formula Special D1 FE 0W-20: DescriptionEzraKitrieGunawanNo ratings yet

- Akpo Field: For The Sheffield Wednesday Striker SeeDocument2 pagesAkpo Field: For The Sheffield Wednesday Striker SeeMasomese Henry KikileNo ratings yet

- Industry in LibyaDocument4 pagesIndustry in LibyaSalem GarrabNo ratings yet

- GO-J Plus Gear Oil, Listing of Approved Oils March 03Document2 pagesGO-J Plus Gear Oil, Listing of Approved Oils March 03Luis Carlos Garcia UmañaNo ratings yet

- Tanabe Air Compressor ManualDocument103 pagesTanabe Air Compressor Manualjin shodanNo ratings yet

- CV Fiber Deki JuandaDocument20 pagesCV Fiber Deki JuandahbusakiNo ratings yet

- Oil Data ComparisonsDocument45 pagesOil Data ComparisonsKevins Small Engine and Tractor ServiceNo ratings yet

- Bentu and Korinci PSCDocument1 pageBentu and Korinci PSCSuhendraNo ratings yet

- OPEC MOMR November 2023Document94 pagesOPEC MOMR November 2023ifaloresimeonNo ratings yet

- 07 Rig List July 2016Document17 pages07 Rig List July 2016ifebrianNo ratings yet

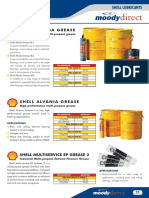

- Shell Lubricants Albida Alvania Multiservice GreasesDocument1 pageShell Lubricants Albida Alvania Multiservice GreasesvinothNo ratings yet

- British Petroleum LimitedDocument593 pagesBritish Petroleum Limitedjk kumarNo ratings yet

- Country Analysis Brief: Venezuela: Last Updated: November 25, 2015Document12 pagesCountry Analysis Brief: Venezuela: Last Updated: November 25, 2015Anonymous HJZffHvTNo ratings yet

- XxxscribdDocument5 pagesXxxscribdXavier ChimaemeNo ratings yet

- HPCL Vizag - Price 01-05-2022Document1 pageHPCL Vizag - Price 01-05-2022rishi1122No ratings yet

- History of Onshore Oil Drilling PDFDocument3 pagesHistory of Onshore Oil Drilling PDFHELPPPPPNo ratings yet

- Halal CertificationDocument3 pagesHalal Certificationfauzan pratama adityaNo ratings yet

- 3780 1st. Edition Oct.2013 3780 +, - 1392: Islamic Republic of IranDocument56 pages3780 1st. Edition Oct.2013 3780 +, - 1392: Islamic Republic of Iranamin32No ratings yet

- ARAMCO Org ChartDocument1 pageARAMCO Org Chartyusuf alamerNo ratings yet

- Mobil Polyrex EMDocument2 pagesMobil Polyrex EMthe anhNo ratings yet

- Aspeltenes in Crude OilDocument4 pagesAspeltenes in Crude OilRavishankarNo ratings yet

- Equivalant For Marine ProductsDocument2 pagesEquivalant For Marine Productsparag7676No ratings yet

- Crude API Location Sulphur: ABO 35,6 Nigeria 0,15Document1 pageCrude API Location Sulphur: ABO 35,6 Nigeria 0,15Eng AlfNo ratings yet

- Refinery Master Apr20A - FinalDocument54 pagesRefinery Master Apr20A - Finaljack fernNo ratings yet

- Edible Oils FDocument15 pagesEdible Oils FPallavi OakNo ratings yet