Professional Documents

Culture Documents

QW 482 Suggested Format For Welding Procedure

Uploaded by

Nisarg Pandya0 ratings0% found this document useful (0 votes)

8 views1 pageOriginal Title

QW 482 SUGGESTED FORMAT FOR WELDING PROCEDURE

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views1 pageQW 482 Suggested Format For Welding Procedure

Uploaded by

Nisarg PandyaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

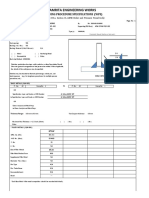

QW-482 2001 SECTION IX

QW-482 SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATIONS (WPS)

(See QW-200.1, Section IX, ASME Boiler and Pressure Vesa,1 Code)

Company Name By:

Welding Procedure Specification No. Date Supporting PQR No.(s)

Revision No. Date

Welding Process(es) Type(s)

JOINTS (QW-402) Detills

Joint Design

Backing (Yas) (No)

Backing Material (Type)

(Ref., to both b.c:&ing ,end retaine,.,)

(] Metal (] Nonfusing Metal

(] Nonmetallic (] Other

Sketches, Production Drawings, Weld Symbols or Written Description

should show the general arrangement ofthe parts to be welded. Where

applicable, the root spacing and the details of weld groove may be

specified.

(At the option of the Mfgr., sketches may be attached to illustrate joint

design, weld layers and bead sequence, e.g., for notch toughness proce-

dures, for multiple process procedures, etc.)

*BASE METALS (QW-403)

P-No. Group No. to P-No.

OR

Specification type and grade

to Specification type and grade

OR

CheiT'. Analysis and Mech. Prop.

to·Chem. Analysis and Mech. Prop.

Thickness Range:

Base Metal: Groove Fillet

Other

*FILLERMETALS (QW-4Q4)

Spec. No. (SFA)

AWS No. (Class)

F-No.

A-No.

Size of Filler Metals

Weld Metal

Thickness. Range:

Groove

Fillet

Electrode-Flux (Class)

Flux Trade Name

Consumable Insert

Other

*Each base metal-filler metal combination should be recorded individually.

(7/00) Thi. form (EOOOO6) may be obtained from tha Order Capt., ASME, 22 Law Drive, Box 2300, Fairfield, NJ 07007·2300

f~

242

You might also like

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Form QW-482 Welding Procedure Specification FormatDocument4 pagesForm QW-482 Welding Procedure Specification FormatJesus Silva HenaoNo ratings yet

- QW-482 WPS FormatDocument2 pagesQW-482 WPS FormatMardeOpamen100% (1)

- QW 406 Asme CodeDocument3 pagesQW 406 Asme CodeMardeOpamenNo ratings yet

- QW-482 201.1Document2 pagesQW-482 201.1Barwin CruzNo ratings yet

- Wps Format (Qw-482)Document2 pagesWps Format (Qw-482)Sebastian RajeshNo ratings yet

- Proposed Welding Procedure Specification FormatDocument2 pagesProposed Welding Procedure Specification FormatAli MoghiNo ratings yet

- Nma App B PDFDocument11 pagesNma App B PDFJesus Gabrielw Blanco GhostbustersIzNo ratings yet

- QW 482Document2 pagesQW 482MuchamadAsyhariNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)MALABAR TIMESNo ratings yet

- Welding Procedure Specification for ASME Section IXDocument4 pagesWelding Procedure Specification for ASME Section IXRahul MoottolikandyNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)pradeep4545No ratings yet

- WPS Format PDFDocument2 pagesWPS Format PDFHimansu Sekhar JenaNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Balkishan DyavanapellyNo ratings yet

- WPS&PQR FormsDocument4 pagesWPS&PQR FormsArab WeldersNo ratings yet

- Wps PQR FormDocument8 pagesWps PQR Formmayank0738No ratings yet

- BPVC Ix QW-482Document2 pagesBPVC Ix QW-482ganesh82No ratings yet

- QW-482 WELDING PROCEDURE SPECIFICATIONS (WPSDocument1 pageQW-482 WELDING PROCEDURE SPECIFICATIONS (WPSlinaNo ratings yet

- QW 482Document2 pagesQW 482Ramu NallathambiNo ratings yet

- QW-482 (WPS) GTAW 4MM FilletDocument4 pagesQW-482 (WPS) GTAW 4MM FilletBalkishan DyavanapellyNo ratings yet

- Wps FormatDocument2 pagesWps FormatMeghan GhoneNo ratings yet

- WPS Format GuideDocument2 pagesWPS Format GuideKhaled bouhlelNo ratings yet

- 2010 SECTION IX WPS FORMATDocument5 pages2010 SECTION IX WPS FORMATAjay ChodankarNo ratings yet

- Smaw Manual See Permitted Figures (Right) or Per Constr. DWG Butt JointDocument3 pagesSmaw Manual See Permitted Figures (Right) or Per Constr. DWG Butt JointNirmala DeshaNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- WPS-PQR Pengelasan (AA)Document12 pagesWPS-PQR Pengelasan (AA)Abrianto AkuanNo ratings yet

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS)Document2 pagesQw-482 Suggested Format For Welding Procedure Specifications (WPS)Ravelo Jeisson100% (2)

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadNo ratings yet

- Formas Soldadura ASME IX 2017Document7 pagesFormas Soldadura ASME IX 2017Ulises GómezNo ratings yet

- 3 BodyPart Edcb3a5f Eede 445f A423 Ea2f5809c15eDocument6 pages3 BodyPart Edcb3a5f Eede 445f A423 Ea2f5809c15emayank0738No ratings yet

- FORM QW-482 WELDING PROCEDURE SPECIFICATION FORMATDocument6 pagesFORM QW-482 WELDING PROCEDURE SPECIFICATION FORMATStan HonNo ratings yet

- Welding Procedure Specification for 904L Stainless SteelDocument1 pageWelding Procedure Specification for 904L Stainless SteelOmar TocmoNo ratings yet

- Standard Welding Procedure Specification Demonstration FormDocument1 pageStandard Welding Procedure Specification Demonstration FormEmma DNo ratings yet

- Valero Aruba Refinery Welding Procedure Specification: For Insert PatchesDocument3 pagesValero Aruba Refinery Welding Procedure Specification: For Insert PatchesRaymond de WeeverNo ratings yet

- Wps Gmaw SawDocument2 pagesWps Gmaw Sawupedro26No ratings yet

- WELDING PROCEDURE AND QUALIFICATION RECORDSDocument4 pagesWELDING PROCEDURE AND QUALIFICATION RECORDSETSNo ratings yet

- QW-482 SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATIONSDocument2 pagesQW-482 SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATIONSVaibhav GuptaNo ratings yet

- FORM QW-482 WELDING PROCEDURE SPECIFICATIONDocument2 pagesFORM QW-482 WELDING PROCEDURE SPECIFICATIONsbmmlaNo ratings yet

- Rev .No: Rev. Date: Page 1 of 2Document2 pagesRev .No: Rev. Date: Page 1 of 2dsyashankaNo ratings yet

- New Microsoft Excel WorksheetDocument6 pagesNew Microsoft Excel Worksheetravi00098No ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad MunadiNo ratings yet

- Format For Manufacturer Record of Welding Operator QualificationDocument1 pageFormat For Manufacturer Record of Welding Operator QualificationRajeev KumarNo ratings yet

- Welding ProceduresDocument29 pagesWelding ProceduresLaith Salman100% (1)

- Ejemplo Prueba 991003Document2 pagesEjemplo Prueba 991003MARIO ALBANo ratings yet

- (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code) Record of The Actual Conditions Used To Weld Test CouponDocument3 pages(See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code) Record of The Actual Conditions Used To Weld Test CouponRaul Fernando GalarzaNo ratings yet

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysFrom EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Metallurgy and Corrosion Control in Oil and Gas ProductionFrom EverandMetallurgy and Corrosion Control in Oil and Gas ProductionNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Metal Tanks (Heavy Gauge) World Summary: Market Values & Financials by CountryFrom EverandMetal Tanks (Heavy Gauge) World Summary: Market Values & Financials by CountryNo ratings yet

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985From EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985No ratings yet

- Bevel Effect & Adj HoleDocument1 pageBevel Effect & Adj HoleNisarg PandyaNo ratings yet

- Blind Thickness Calculation: Refer Section 304.5.3 ASME B31.3 Diam, NB Class Diam, DGDocument1 pageBlind Thickness Calculation: Refer Section 304.5.3 ASME B31.3 Diam, NB Class Diam, DGVarun MalhotraNo ratings yet

- Blind Thickness Calculation: Refer Section 304.5.3 ASME B31.3 Diam, NB Class Diam, DGDocument1 pageBlind Thickness Calculation: Refer Section 304.5.3 ASME B31.3 Diam, NB Class Diam, DGVarun MalhotraNo ratings yet

- Buoyancy Per Unit LengthDocument4 pagesBuoyancy Per Unit LengthNisarg PandyaNo ratings yet

- FlangesDocument5 pagesFlangesNisarg PandyaNo ratings yet

- Heat Exchanger Design - ProcessDocument42 pagesHeat Exchanger Design - Processalokbdas100% (1)

- BS137991974 PDFDocument1 pageBS137991974 PDFNisarg PandyaNo ratings yet

- BS137991974 PDFDocument1 pageBS137991974 PDFNisarg PandyaNo ratings yet

- Buoyancy Per Unit LengthDocument4 pagesBuoyancy Per Unit LengthNisarg PandyaNo ratings yet

- Asme ptc2 8 PDFDocument1 pageAsme ptc2 8 PDFNisarg PandyaNo ratings yet

- Asme ptc2 6Document1 pageAsme ptc2 6Nisarg PandyaNo ratings yet

- WIC Role of InspectorDocument19 pagesWIC Role of InspectorNisarg PandyaNo ratings yet

- ASME Copyright Info Handling Services 1999Document1 pageASME Copyright Info Handling Services 1999Nisarg PandyaNo ratings yet

- ASME B46.1-2009 Surface RoughnessDocument8 pagesASME B46.1-2009 Surface RoughnessIqbal Muhammad22% (9)

- Asme ptc2 4Document1 pageAsme ptc2 4Nisarg PandyaNo ratings yet

- Fastner Testing Part 4Document6 pagesFastner Testing Part 4Nisarg PandyaNo ratings yet

- Asme mfc-1m PDFDocument37 pagesAsme mfc-1m PDFNisarg PandyaNo ratings yet

- Asme ptc2 7Document1 pageAsme ptc2 7Nisarg PandyaNo ratings yet

- Nuclear Inservice InspectionDocument2 pagesNuclear Inservice InspectionNisarg PandyaNo ratings yet

- Liquid Displacement SystemDocument1 pageLiquid Displacement SystemNisarg PandyaNo ratings yet

- Qar For CS For Nuclear FacilityDocument5 pagesQar For CS For Nuclear FacilityNisarg PandyaNo ratings yet

- 6 Designation: Parallel Pipe Thread ISO 7/1-Rp 1 Taper Pipe Thread ISO 711-Rc 1 Always Taper Pipe Thread ISO 7/ L-R 1Document1 page6 Designation: Parallel Pipe Thread ISO 7/1-Rp 1 Taper Pipe Thread ISO 711-Rc 1 Always Taper Pipe Thread ISO 7/ L-R 1Nisarg PandyaNo ratings yet

- Asme n626-1 PDFDocument11 pagesAsme n626-1 PDFNisarg PandyaNo ratings yet

- Asme Fap-1 PDFDocument34 pagesAsme Fap-1 PDFNisarg PandyaNo ratings yet

- QW 482 Suggested Format For Welding ProcedureDocument1 pageQW 482 Suggested Format For Welding ProcedureNisarg PandyaNo ratings yet

- Asme Nqa Tech ReptDocument17 pagesAsme Nqa Tech ReptNisarg PandyaNo ratings yet

- Asme Nqa1a PDFDocument12 pagesAsme Nqa1a PDFNisarg PandyaNo ratings yet

- IS0 Base Material Used For Welder QualificationDocument1 pageIS0 Base Material Used For Welder QualificationNisarg PandyaNo ratings yet

- Is 554Document3 pagesIs 554Nisarg PandyaNo ratings yet

- The Material For Fittings IS0Document1 pageThe Material For Fittings IS0Nisarg PandyaNo ratings yet

- Determine The Cauchy ConstantDocument2 pagesDetermine The Cauchy ConstantBS Physics100% (2)

- 03 Structural Analysis PresentationDocument30 pages03 Structural Analysis PresentationMohammed AnwhazNo ratings yet

- Tap Out™ Stik: Features SpecificationsDocument2 pagesTap Out™ Stik: Features SpecificationsMatthew AusterNo ratings yet

- Separation Processes Lecture 1 IntroductionDocument14 pagesSeparation Processes Lecture 1 Introductionabood assrfndyNo ratings yet

- KTM50S1 50Hz SS304 MergedDocument7 pagesKTM50S1 50Hz SS304 MergedEdbaac BANo ratings yet

- Centrifugal CompressorsDocument52 pagesCentrifugal CompressorsFadoooll75% (4)

- Biological Techniques HecDocument2 pagesBiological Techniques HecHaroon yaseen100% (2)

- Jurnal Rekayasa Proses: Dew Point Control UnitDocument22 pagesJurnal Rekayasa Proses: Dew Point Control UnitMelvin FelixanderNo ratings yet

- Product Specification Sheet BELZONA 5891: General InformationDocument4 pagesProduct Specification Sheet BELZONA 5891: General InformationMohamed NouzerNo ratings yet

- Geotechnical Engineering - Ii (Foundation Engineering) : Settlement of PilesDocument11 pagesGeotechnical Engineering - Ii (Foundation Engineering) : Settlement of PilesPascasio PascasioNo ratings yet

- Jason Weiss-Elastic Properties, Creep, and Relaxation PDFDocument13 pagesJason Weiss-Elastic Properties, Creep, and Relaxation PDFFaiz SulthanNo ratings yet

- Gtaw 03Document40 pagesGtaw 03பத்மநாபன் ஶ்ரீநிவாஸன்No ratings yet

- 2019 - Super Moisture-Absorbent Gels For All-Weather PDFDocument7 pages2019 - Super Moisture-Absorbent Gels For All-Weather PDFDanh TruongNo ratings yet

- Mechanical Engineering Stress Analysis VisualizedDocument7 pagesMechanical Engineering Stress Analysis VisualizedHamood Al-bahraniNo ratings yet

- Indian Geotech Conference - Analysis of Delhi Metro Cross Passage ConstructionDocument4 pagesIndian Geotech Conference - Analysis of Delhi Metro Cross Passage ConstructionDEBASIS BARMANNo ratings yet

- Noise MonitoringDocument7 pagesNoise Monitoringshahrul rollNo ratings yet

- 3 Unit EMDocument5 pages3 Unit EMS.Sampath Chemistry Ghss GurubarapalliNo ratings yet

- SindxbDocument51 pagesSindxbImad-eddine. GuiraNo ratings yet

- AnnexureDocument3 pagesAnnexureqamarNo ratings yet

- Solution 2.2: CHAPTER 2. The First Law and Other Basic ConceptsDocument8 pagesSolution 2.2: CHAPTER 2. The First Law and Other Basic ConceptsFelix LauwentoNo ratings yet

- CE 8601 Internal 2 Answerkey 2021Document10 pagesCE 8601 Internal 2 Answerkey 2021ci_balaNo ratings yet

- Ipex PVC Pipe Design GuideDocument110 pagesIpex PVC Pipe Design GuideMike Gogollygook100% (1)

- Breaking Down AC Corrosion of PipelinesDocument7 pagesBreaking Down AC Corrosion of PipelinesHenryNo ratings yet

- Refractive Index and Thickness Determination of Thin-Films Using Lloydõs InterferometerDocument8 pagesRefractive Index and Thickness Determination of Thin-Films Using Lloydõs InterferometerLuis MestaNo ratings yet

- Lecture 1 Semiconductor TheoryDocument31 pagesLecture 1 Semiconductor TheorySibisi SinethembaNo ratings yet

- bc10wbch11 Sec2Document7 pagesbc10wbch11 Sec2api-283427523No ratings yet

- Regents PhysicsDocument2 pagesRegents PhysicsSusmita GhoshNo ratings yet

- Plane FramesDocument52 pagesPlane Framesshaheen juttNo ratings yet

- Total Hydransafe HFDU 46Document1 pageTotal Hydransafe HFDU 46AdnanNo ratings yet

- What Is A Cooling Tower - SPX Cooling TechnologiesDocument6 pagesWhat Is A Cooling Tower - SPX Cooling Technologiesprabhanshu241991No ratings yet