Professional Documents

Culture Documents

Intercambiadores 1

Intercambiadores 1

Uploaded by

Zule GalvánOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Intercambiadores 1

Intercambiadores 1

Uploaded by

Zule GalvánCopyright:

Available Formats

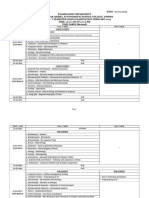

11-1

Chapter 11

HEAT EXCHANGERS

Types of Heat Exchangers

11-1C Heat exchangers are classified according to the flow type as parallel flow, counter flow, and cross-

flow arrangement. In parallel flow, both the hot and cold fluids enter the heat exchanger at the same end

and move in the same direction. In counter-flow, the hot and cold fluids enter the heat exchanger at

opposite ends and flow in opposite direction. In cross-flow, the hot and cold fluid streams move

perpendicular to each other.

11-2C In terms of construction type, heat exchangers are classified as compact, shell and tube and

regenerative heat exchangers. Compact heat exchangers are specifically designed to obtain large heat

transfer surface areas per unit volume. The large surface area in compact heat exchangers is obtained by

attaching closely spaced thin plate or corrugated fins to the walls separating the two fluids. Shell and tube

heat exchangers contain a large number of tubes packed in a shell with their axes parallel to that of the

shell. Regenerative heat exchangers involve the alternate passage of the hot and cold fluid streams through

the same flow area. In compact heat exchangers, the two fluids usually move perpendicular to each other.

11-3C A heat exchanger is classified as being compact if β > 700 m2/m3 or (200 ft2/ft3) where β is the ratio

of the heat transfer surface area to its volume which is called the area density. The area density for double-

pipe heat exchanger can not be in the order of 700. Therefore, it can not be classified as a compact heat

exchanger.

11-4C In counter-flow heat exchangers, the hot and the cold fluids move parallel to each other but both

enter the heat exchanger at opposite ends and flow in opposite direction. In cross-flow heat exchangers, the

two fluids usually move perpendicular to each other. The cross-flow is said to be unmixed when the plate

fins force the fluid to flow through a particular interfin spacing and prevent it from moving in the

transverse direction. When the fluid is free to move in the transverse direction, the cross-flow is said to be

mixed.

11-5C In the shell and tube exchangers, baffles are commonly placed in the shell to force the shell side

fluid to flow across the shell to enhance heat transfer and to maintain uniform spacing between the tubes.

Baffles disrupt the flow of fluid, and an increased pumping power will be needed to maintain flow. On the

other hand, baffles eliminate dead spots and increase heat transfer rate.

11-6C Using six-tube passes in a shell and tube heat exchanger increases the heat transfer surface area, and

the rate of heat transfer increases. But it also increases the manufacturing costs.

11-7C Using so many tubes increases the heat transfer surface area which in turn increases the rate of heat

transfer.

PROPRIETARY MATERIAL. © 2007 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and

educators for course preparation. If you are a student using this Manual, you are using it without permission.

You might also like

- Assignment 2Document28 pagesAssignment 2ahsan aliNo ratings yet

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AFrom EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANo ratings yet

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersFrom EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersRating: 4.5 out of 5 stars4.5/5 (14)

- Double Pipe Heat ExchangersDocument36 pagesDouble Pipe Heat Exchangersshreyasnil50% (2)

- Flow and Heat Transfer in Geothermal Systems: Basic Equations for Describing and Modeling Geothermal Phenomena and TechnologiesFrom EverandFlow and Heat Transfer in Geothermal Systems: Basic Equations for Describing and Modeling Geothermal Phenomena and TechnologiesNo ratings yet

- B's CourseworkDocument10 pagesB's CourseworkEleanor Rajaratnam100% (1)

- Heat Exchanger BasicsDocument59 pagesHeat Exchanger BasicsPassionNo ratings yet

- CH 11Document6 pagesCH 11m_alodat6144No ratings yet

- Heat Exchanger CFDDocument83 pagesHeat Exchanger CFDganeshNo ratings yet

- Heat ExchangerDocument29 pagesHeat Exchangerrodel rentaNo ratings yet

- Parallel - Counter Flow Heat ExchangerDocument12 pagesParallel - Counter Flow Heat Exchangerjr gajelesNo ratings yet

- Heat ExchangersDocument3 pagesHeat Exchangersdanena88No ratings yet

- Double Pipe Heat ExchangersDocument27 pagesDouble Pipe Heat ExchangersDURGA KASTURINo ratings yet

- Heat ExchangerDocument39 pagesHeat ExchangerAdithya ShripathiNo ratings yet

- COMSATS Institute of Information Technology, SahiwalDocument11 pagesCOMSATS Institute of Information Technology, SahiwalAsad AliNo ratings yet

- Heat ExchangersDocument23 pagesHeat Exchangersirewen de laraNo ratings yet

- Introduction To Heat Exchangers BBDocument19 pagesIntroduction To Heat Exchangers BBgks5kc8bhdNo ratings yet

- Heat Exchangers: Fundamentals of Thermal-Fluid Sciences, 3rd EditionDocument64 pagesHeat Exchangers: Fundamentals of Thermal-Fluid Sciences, 3rd EditionJhoan Fernando Acevedo EspinosaNo ratings yet

- WWW HeatDocument2 pagesWWW HeatshersoyNo ratings yet

- Example:: Active TechniquesDocument65 pagesExample:: Active TechniquesAnilkumar CENo ratings yet

- New 1Document43 pagesNew 1pandy1604No ratings yet

- Lecture 6Document17 pagesLecture 6ahmed el-sayedNo ratings yet

- 5 5-HeatexchangerDocument10 pages5 5-HeatexchangerMohamed Rafeek GhaniNo ratings yet

- What Is Cross Flow Heat Exchangers and Its Working PrinciplesDocument6 pagesWhat Is Cross Flow Heat Exchangers and Its Working Principlesbouka7000No ratings yet

- Heat Transfer EquipmentDocument46 pagesHeat Transfer EquipmentJoy PalitNo ratings yet

- Heat Exchanger and Its Classification: Dr. Liaquat Ali KhanDocument34 pagesHeat Exchanger and Its Classification: Dr. Liaquat Ali KhanKhalil AhmadNo ratings yet

- Heat ExchangerDocument16 pagesHeat ExchangerNikhil Garg100% (1)

- Heat ExchangersDocument25 pagesHeat ExchangersMohammed Kabiruddin100% (7)

- Concept of CoDocument3 pagesConcept of CoAmol JadhavNo ratings yet

- Suez University Faculty of Petroleum & Mining Engineering: Prepared ByDocument17 pagesSuez University Faculty of Petroleum & Mining Engineering: Prepared ByitezazahsanNo ratings yet

- Heat ExchangerDocument2 pagesHeat ExchangerAfreen MerchantNo ratings yet

- Part.a.classification of Heat ExchangersDocument11 pagesPart.a.classification of Heat ExchangersAhmed GadNo ratings yet

- Heat Exchangers Simple OverviewDocument20 pagesHeat Exchangers Simple OverviewAdhrith JhaNo ratings yet

- Design of Double Pipe Heat Exchanger: Mrs. Kirti B.Zare, Ms. Dipika Kanchan, Ms. Nupur PatelDocument14 pagesDesign of Double Pipe Heat Exchanger: Mrs. Kirti B.Zare, Ms. Dipika Kanchan, Ms. Nupur PatelFranceNo ratings yet

- Course M-2007 Heat Exchanger Fundamentals: 5870 Highway 6 North, Suite 310 Houston, TX 77084 Toll Free: 877 500-7145Document21 pagesCourse M-2007 Heat Exchanger Fundamentals: 5870 Highway 6 North, Suite 310 Houston, TX 77084 Toll Free: 877 500-7145Amr Mohamed Ali HassanNo ratings yet

- Lectures 12Document12 pagesLectures 12verify nameNo ratings yet

- Heatexchanger 141105110809 Conversion Gate01Document9 pagesHeatexchanger 141105110809 Conversion Gate01L ́ RadiCallyNo ratings yet

- Perancangan Proses: Heat ExchangerDocument42 pagesPerancangan Proses: Heat ExchangerIiZz SangPemimpi SpNo ratings yet

- Active Techniques: in This Active Techniques, For Enhancement of Heat Transfer SomeDocument67 pagesActive Techniques: in This Active Techniques, For Enhancement of Heat Transfer SomeAnilkumar CENo ratings yet

- Heat Exchanger IntroductionDocument8 pagesHeat Exchanger Introductionalan_yaobin8409No ratings yet

- Introduction Heat ExchangerDocument11 pagesIntroduction Heat ExchangerLorna AhlaamiNo ratings yet

- Efficient Industrial Heat Exchangers - Seminar ReportDocument67 pagesEfficient Industrial Heat Exchangers - Seminar ReportdaemonohNo ratings yet

- Shell and Tube Heat ExchangerDocument30 pagesShell and Tube Heat ExchangerMurphy MofeNo ratings yet

- Heat Exchanger Design and SelectionDocument44 pagesHeat Exchanger Design and Selectiondenizkund100% (1)

- Heat ExchangerDocument11 pagesHeat ExchangerHuda ShahNo ratings yet

- Klasifikasi Heat ExchangerDocument77 pagesKlasifikasi Heat ExchangerGeovany FakhriNo ratings yet

- Chapter 10. Heat Exchanger DevicesDocument36 pagesChapter 10. Heat Exchanger DevicesDayanidiNo ratings yet

- Heat Exchangers and Heat Pipes: Figs. 1 2Document6 pagesHeat Exchangers and Heat Pipes: Figs. 1 2Ricardo Rincon VegaNo ratings yet

- Main Project DocumentationDocument62 pagesMain Project Documentationnitin_micNo ratings yet

- AME 365 Heat Transfer & Combustion (UNIT 5)Document73 pagesAME 365 Heat Transfer & Combustion (UNIT 5)somenewguyonthewebNo ratings yet

- Types of Heat Exchangers - Classification of Heat ExchangersDocument3 pagesTypes of Heat Exchangers - Classification of Heat ExchangersMuhammet Ahmet SarıkayaNo ratings yet

- Double Pipe Heat ExchangerDocument88 pagesDouble Pipe Heat ExchangerirfanNo ratings yet

- Heat Transfer Coefficient U That Accounts For The Contribution of All These Effects On Heat TransferDocument4 pagesHeat Transfer Coefficient U That Accounts For The Contribution of All These Effects On Heat TransferIvon MaulanaNo ratings yet

- Heat Exchanger: Abbas wehbe reson مسلاا: Heat transfer (II) ةداملا: 3 /HVAC عرفلا / ةلحرملا: D.Sattar aljabair فرشملاDocument10 pagesHeat Exchanger: Abbas wehbe reson مسلاا: Heat transfer (II) ةداملا: 3 /HVAC عرفلا / ةلحرملا: D.Sattar aljabair فرشملاgggggggNo ratings yet

- Heat Transfer Terms HandoutDocument4 pagesHeat Transfer Terms HandoutFLORA,GISELLE H.No ratings yet

- Multiphase Flow Metering: Principles and ApplicationsFrom EverandMultiphase Flow Metering: Principles and ApplicationsRating: 2.5 out of 5 stars2.5/5 (2)

- Problems of Heat Transfer and Hydraulics of Two-Phase MediaFrom EverandProblems of Heat Transfer and Hydraulics of Two-Phase MediaRating: 5 out of 5 stars5/5 (2)

- How it Works: Dealing in simple language with steam, electricity, light, heat, sound, hydraulics, optics, etc., and with their applications to apparatus in common useFrom EverandHow it Works: Dealing in simple language with steam, electricity, light, heat, sound, hydraulics, optics, etc., and with their applications to apparatus in common useNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- The Water Supply of the El Paso and Southwestern Railway from Carrizozo to Santa Rosa, N. Mex. American Society of Civil Engineers: Transactions, No. 1170From EverandThe Water Supply of the El Paso and Southwestern Railway from Carrizozo to Santa Rosa, N. Mex. American Society of Civil Engineers: Transactions, No. 1170No ratings yet

- AMTE113 - Theory of FlightDocument210 pagesAMTE113 - Theory of FlightJc LoepzNo ratings yet

- Aerody Lesson 3Document29 pagesAerody Lesson 3Kyle MedranoNo ratings yet

- Performance Sensitivities of Rotating Detonation Engines Installed Onto Waverider Forebodies - 1604804741521434Document14 pagesPerformance Sensitivities of Rotating Detonation Engines Installed Onto Waverider Forebodies - 1604804741521434RCUNo ratings yet

- Latheesh 2018 IOP Conf. Ser.: Mater. Sci. Eng. 310 012122Document11 pagesLatheesh 2018 IOP Conf. Ser.: Mater. Sci. Eng. 310 012122luiggi19970530No ratings yet

- Astm g3Document5 pagesAstm g3Shivam PurohitNo ratings yet

- Ga Drawing Gas Scrubber Package 230822Document1 pageGa Drawing Gas Scrubber Package 230822CIRCLE CHANNELNo ratings yet

- EMS507 Lecture 5 - Simple Linear SystemsDocument22 pagesEMS507 Lecture 5 - Simple Linear Systems124ll124No ratings yet

- Overseas Family School Physics Ia Temperature and Resistance of Nichrome Wire Experiment Shixiao Physics SLDocument13 pagesOverseas Family School Physics Ia Temperature and Resistance of Nichrome Wire Experiment Shixiao Physics SLxiao shiNo ratings yet

- Rock Mechanics ModellingDocument17 pagesRock Mechanics ModellingXedice QasimovaNo ratings yet

- Luminac Flexi-Mag Series PDFDocument16 pagesLuminac Flexi-Mag Series PDFSangeeta SikariaNo ratings yet

- A Focus On HedgingDocument14 pagesA Focus On Hedginghussein aloklaNo ratings yet

- Sample Sci Lab CalendarDocument1 pageSample Sci Lab CalendarclayivanNo ratings yet

- Bu 3 Mod 3 Lecture 4 Lighting DesignDocument17 pagesBu 3 Mod 3 Lecture 4 Lighting DesignSebastian CincoNo ratings yet

- Oil WhirlDocument10 pagesOil WhirlAftabNo ratings yet

- 1 s2.0 S0141635922000319 MainDocument23 pages1 s2.0 S0141635922000319 MainCarina PeixotoNo ratings yet

- 292902revised Time Table-B.sc.-Bca-V Semester (Main) Examination February 2024Document3 pages292902revised Time Table-B.sc.-Bca-V Semester (Main) Examination February 2024nawojeh586No ratings yet

- Curricula BE EE 3-8 SemDocument77 pagesCurricula BE EE 3-8 SemMarfatNo ratings yet

- Calibration of Anemometer and BalometerDocument7 pagesCalibration of Anemometer and BalometerManivasagan Vasu0% (1)

- Mechanical Material Properties For Structural Simulation of SRMDocument7 pagesMechanical Material Properties For Structural Simulation of SRMSidharth MaheshNo ratings yet

- RegularizationDocument4 pagesRegularizationMasaNo ratings yet

- Sast3884 01Document1 pageSast3884 01Jan JanNo ratings yet

- Lesson Notes Lecture 14Document5 pagesLesson Notes Lecture 14Quantum SaudiNo ratings yet

- Time of Setting of Hydraulic Cement by Vicat NeedleDocument6 pagesTime of Setting of Hydraulic Cement by Vicat NeedleAbdullah TrwanshyNo ratings yet

- 2017 - Janjuhah Et Al., - Carbonates and Evaporites1Document19 pages2017 - Janjuhah Et Al., - Carbonates and Evaporites1Waleed HassanNo ratings yet

- Scientific Machine Learning Through Physics-Informed Neural Networks: Where We Are and What's NextDocument67 pagesScientific Machine Learning Through Physics-Informed Neural Networks: Where We Are and What's NextprfdjkdkvcssdNo ratings yet

- BS 8666Document23 pagesBS 8666Joshua David RomeroNo ratings yet

- College Physics 9th Edition Serway Test BankDocument35 pagesCollege Physics 9th Edition Serway Test Bankshannonsellersdfrjxwiabt100% (34)

- Section3 - Pipeline StoppersDocument22 pagesSection3 - Pipeline StoppersMelele MuNo ratings yet

- Elektronik 1 Sunum 5 9736Document210 pagesElektronik 1 Sunum 5 9736inamullahNo ratings yet