Professional Documents

Culture Documents

SMA Application Guideline: Lead Free MLCC, Chip-R, MLCI

Uploaded by

Bru MOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SMA Application Guideline: Lead Free MLCC, Chip-R, MLCI

Uploaded by

Bru MCopyright:

Available Formats

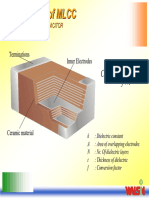

Walsin Technology Corporation

Lead Free MLCC, Chip-R, MLCI

SMA Application Guideline

HTTP://WWW.PASSIVECOMPONENT.COM Version 03 Page-1

Walsin Technology Corporation

Background Sn/Pb Phase Diagram (Engineering version)

Pb free solder material was started in 1995. A An alloy cannot necessarily be soldered at its melting point.

composition of (Sn-4Bi-2Ag-0.5Cu-0.1Ge) was At or slightly above its melting temperature the alloy is still

announced in July 1998, though, since later it was found sluggish, does not flow very easily, and seems to have

that for 42 alloy (most popular material fore lead frame), restraint in its wetting characteristics.

wetting and joint strength was insufficient and further

A good rule of thumb to use a range of approximately by

“Life-off” problem was newly found, the composition was

33~90°C above the melting point for soldering operation, this

reviewed and resulted in the present composition.

range is suitable for most alloys.

According to the test data shown in that meeting, major

components (QFP, Chip-R, MLCC) were tested and For 63/37 solder alloy, recommended alloy temperature

significant difference in mechanical strength was not during wetting around 245~275 °C.

found compared with Sn/Pb solder. Some of Japanese

electronic equipment providers may think technical

problems were to some extent cleared. However, since

the data was just experimental and looked at only one

aspect, different reliability problems might come up from

each device manufacturer. The company also

mentioned the solution as “latest” and “maybe not final”.

Concretely technical standards for some test items were

given by Sony. The standards are to test wetting and

robustness of electrical components quantitatively. For

some tests, use of special test equipment is required,

however some of them can be replaced by other

methods that require none of special equipment.

Particularly for wetting test, “self-alignment method” can

be used, because self-alignment effect seen in reflow

soldering process depends large part on wetting.

Figure 1. Sn/Pb Phase Diagram (Ref. “Solders and Soldering 3rd

edition”, Howard H. Manko)

The proposal of Infineon, Philips and STMicroelectronics contains an upper limit for “lead-free” components of 0.1% related to

the individual material, not to the whole package or component. The “lead-free” products give at least their European clients a

certainty to be “green” in time. Although legislation has not yet been consolidated, a max. level of 1000ppm is mentioned in

the law of some countries.

Note: Shipping materials such as blister tape and paper based boxes are not part of this consideration, since they are usually

part of existing recycling processes.

HTTP://WWW.PASSIVECOMPONENT.COM Version 03 Page-2

Walsin Technology Corporation

Evaluation of Pb Free solder paste

Score=1 means very good, score=6 means very poor. Score=10 means extremely bad (Ref. and rated by Soldertec Ltd.)

*8 *9

Sn-3.5Ag Sn-Ag-Cu Sn-Ag-Cu-Sb Sn-0.7Cu Sn-Bi-Ag Sn-Zn-Bi

Melting/Process temperature 5 3.5 3.5 6 2 1

*1

Peeling off after soldering 2.5 2.5 2.5 2.5 5.5 5.5

*2

Solderability 4 2 3 5 1 10

*3

Profile 3 1.5 1.5 5 4 10

*4

Reliability 3 1.5 1.5 4 5 6

*5

Recycling 2.5 2.5 2.5 2.5 5 6

*6

Cost 4.5 4.5 4.5 1.5 4.5 1.5

*7

Alloy authorization 1.5 3 4 1.5 5 6

Total score 26 21 23 28 32 46

Average score 3.3 2.6 2.9 3.5 4.0 5.6

*1

Bi alloy easy to peel-off or lift-off after soldering, as well as not so environmental friendly. But Bi is helpful in wettability and

solderability and to reduce soldering temperature.

*2

Zn alloy easy to be oxides, powerful flux is required.

*3

The advantage of Sn-Ag-C u (-Sb) and Sn-Bi-Ag is able to apply lower solder joint temperature. However, need to

considerate the soldered peel-off issue by applying Sn-Bi-Ag.

*4

It is average performance; the ranking might be changed under different application conditions.

*5

Zn and Bi will also created issues/costs, same situation as other alloys.

*6

The approximately of related costs is depended on Ag content. Tin strip is efficient than Solder paste.

*7

Sn-Ag-Cu is secured by some patents; some authorizations and patents secure Sn-Ag-Cu-Sb; Sn-Bi-Ag and Sn-Zn-Bi are

secured in various ways of patents.

*8

The recommended composition : Sn- (3.4~4.1)Ag- (0.5~0.9)Cu

*9

Standard composition : Sn-2.5Ag-0.8Cu-0.55Sb

Pb Free Components from Walsin Technology

New coating technology, then offers advantages beyond the simpler elimination of lead :

l Pure tin termination coating.

l Improved shelf life because of low intermetallic growth.

l Improved solderability because of neglible degradation of the solder surface.

l No whiskers and no lead.

HTTP://WWW.PASSIVECOMPONENT.COM Version 03 Page-3

Walsin Technology Corporation

Recommended IR Reflow Soldering Conditions

Ÿ The following Lead free solderpastes are suitable to be applied with WTC components :

1. Sn-3Ag-0.5Cu series of Lead free solder paste. Recommended by JEITIA on Jun.-2000. Typical ally melting

point at +225~230°C.

2. Sn-(3.7~4.1)Ag-(0.4~0.8)Cu series (e.g. Multicore Sn-3.8Ag-0.7Cu) of Lead free solder paste. Recommended

by NEMI.

3. Sn-2.5Ag-0.5Cu-1Bi series (e.g. Senju #OZ-7085-340F-32-12) of Lead free solderpaste. Typical alloy melting

point at +222°C.

4. Sn-2.2Ag-20In series (e.g. Indium Indalloy #227) Lead free solderpaste.

Ÿ Soldering profile :

Fig 2. Infrared soldering profile for Lead-Free SMD

Others

For more information, please contact with Application Group, R&D Dept., Walsin Technology :

e-Mail : PCDA1@PASSIVECOMPONENT.COM

Fax : +886-7-8136745

Address : 1, West 13 Street, Kaohsiung Export Processing Zone, Kaohsiung, Taiwan, R.o.C.

HTTP://WWW.PASSIVECOMPONENT.COM Version 03 Page-4

You might also like

- Duplex Welding GuidelinesDocument13 pagesDuplex Welding GuidelinesadelNo ratings yet

- Solder PDFDocument4 pagesSolder PDFCompuElectronic IbagueNo ratings yet

- Solids-Free, High-Density Brines For Packer-Fluid ApplicationsDocument8 pagesSolids-Free, High-Density Brines For Packer-Fluid ApplicationsRicardo FernandezNo ratings yet

- Nepcon: Smart GROUPDocument6 pagesNepcon: Smart GROUPanandsharma9No ratings yet

- Zincelectroplating PDFDocument10 pagesZincelectroplating PDFSunil PrasadNo ratings yet

- Lead Free Hand Soldering - Process and Material IssuesDocument3 pagesLead Free Hand Soldering - Process and Material Issuessmtdrkd50% (2)

- Bga Reballing SmtaDocument18 pagesBga Reballing SmtaJose Luis RomeroNo ratings yet

- Bga Reballing SmtaDocument18 pagesBga Reballing SmtaAvs ElectronNo ratings yet

- Soldering Guidelines For Land Grid Array Packages: Application Note 61Document12 pagesSoldering Guidelines For Land Grid Array Packages: Application Note 61Younes Ben TaherNo ratings yet

- Lead-Free SMT Defects How To Prevent ThemDocument9 pagesLead-Free SMT Defects How To Prevent ThemTin NguyenNo ratings yet

- Lead-Free Comparison of AlloysDocument11 pagesLead-Free Comparison of Alloysmuki10No ratings yet

- Fujifilm Finepix s9000 s9500 SM ET 1Document147 pagesFujifilm Finepix s9000 s9500 SM ET 1newionNo ratings yet

- Fastener Design ManualDocument10 pagesFastener Design ManualJohn PaulsyNo ratings yet

- 6996 TB 0102 Ground Granulated Blast Furnace Slag Its Chemistry and Use Chemical Admixtures Technical enDocument4 pages6996 TB 0102 Ground Granulated Blast Furnace Slag Its Chemistry and Use Chemical Admixtures Technical ensreeraj77No ratings yet

- 331 Flux-Cored Wire Data SheetDocument2 pages331 Flux-Cored Wire Data Sheetanon_985163484No ratings yet

- Creation of Control PlanDocument4 pagesCreation of Control PlanAnthonyNo ratings yet

- Artigo Aplicacao Die&PryDocument2 pagesArtigo Aplicacao Die&PryrcacertiNo ratings yet

- 2205 DB Us enDocument8 pages2205 DB Us enPhasin ChitutsahaNo ratings yet

- Case Study On The Validation of SAC305 and SnCu Based Solders in SMT Wave and Hand Soldering at The Contract Assembler LevelDocument8 pagesCase Study On The Validation of SAC305 and SnCu Based Solders in SMT Wave and Hand Soldering at The Contract Assembler LevelJoel JacoboNo ratings yet

- An Engineer S Guide To Component Re-Conditioning Using The RHSD ProcessDocument6 pagesAn Engineer S Guide To Component Re-Conditioning Using The RHSD ProcessAdair NettoNo ratings yet

- S 5800Document114 pagesS 5800elenoremailNo ratings yet

- Fujifilm Finepix s8000fdDocument134 pagesFujifilm Finepix s8000fdzilikonNo ratings yet

- Solder Paste SC Blf03: Lead-FreeDocument2 pagesSolder Paste SC Blf03: Lead-FreeluismcmcNo ratings yet

- Manufacturing Technology for Aerospace Structural MaterialsFrom EverandManufacturing Technology for Aerospace Structural MaterialsRating: 5 out of 5 stars5/5 (2)

- AN5963Document7 pagesAN5963Smriti SNo ratings yet

- Brazing Operation InstructionDocument9 pagesBrazing Operation InstructionRicardoNo ratings yet

- Silicon Carbide - Wikipedia, The Free EncyclopediaDocument11 pagesSilicon Carbide - Wikipedia, The Free EncyclopediaRtyu IuytNo ratings yet

- Cladding & Overlay - Ni InstituteDocument24 pagesCladding & Overlay - Ni Institutesajid aslamNo ratings yet

- Expt 5,6,7Document15 pagesExpt 5,6,7wocison461No ratings yet

- Case Study On Blistering Issue in Resin Impregnated Carbon Seal Face During Test in Viscous OilDocument3 pagesCase Study On Blistering Issue in Resin Impregnated Carbon Seal Face During Test in Viscous OilimtiyazNo ratings yet

- DS Gas Sensors Rosemount 71550Document4 pagesDS Gas Sensors Rosemount 71550Yamil Alberto Mena NogueraNo ratings yet

- Indium5.1 Pbfree Solder Paste 97901 r8Document2 pagesIndium5.1 Pbfree Solder Paste 97901 r8Gustavo Kubo LacerdaNo ratings yet

- Piping NotesDocument17 pagesPiping Notesravindra_jivaniNo ratings yet

- DSM-0318.0 AM 625 Ni AlloyDocument3 pagesDSM-0318.0 AM 625 Ni AlloyApichitNo ratings yet

- Fuji Finepix s5200 s5600Document121 pagesFuji Finepix s5200 s5600zilikonNo ratings yet

- 1 - Solderjoints IPC610EDocument36 pages1 - Solderjoints IPC610EboogamiNo ratings yet

- Implementation of Lead-Free Wave Soldering ProcessDocument15 pagesImplementation of Lead-Free Wave Soldering ProcessXuan HoangNo ratings yet

- Lead-Free SolderingDocument15 pagesLead-Free SolderingChandra KusmayaNo ratings yet

- Glass Recycling in Cement Production AnDocument7 pagesGlass Recycling in Cement Production AnKiran KiranaNo ratings yet

- Surface FinishesDocument8 pagesSurface FinishesasritaipNo ratings yet

- Implementation Reliability Lead Free SoldersDocument13 pagesImplementation Reliability Lead Free SoldersArvind KumarNo ratings yet

- Standard Practice For Preparation of Zinc-Coated and Zinc-Alloy-Coated Steel Panels For Testing Paint and Related Coating ProductsDocument3 pagesStandard Practice For Preparation of Zinc-Coated and Zinc-Alloy-Coated Steel Panels For Testing Paint and Related Coating ProductsAhmad TfailyNo ratings yet

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product Identificationmohamed AdelNo ratings yet

- ncsmq92 SolderDocument2 pagesncsmq92 SolderSergio MoyaNo ratings yet

- Solder Joint Reliability Theory and Applications PDFDocument650 pagesSolder Joint Reliability Theory and Applications PDFanbarasuval84100% (2)

- EN - 33 CuRophos - 2 5 15 18Document3 pagesEN - 33 CuRophos - 2 5 15 18kmNo ratings yet

- Reliability of PB Free Solder Alloys inDocument6 pagesReliability of PB Free Solder Alloys inAbhijit KarNo ratings yet

- Soldering To Gold 97743 r4Document2 pagesSoldering To Gold 97743 r4stephaneNo ratings yet

- Ni Inco 4421 Weldingofflakeandspheroidalgraphiteni ResistcastingsDocument6 pagesNi Inco 4421 Weldingofflakeandspheroidalgraphiteni ResistcastingsLeandro Dilkin ConsulNo ratings yet

- Gbfs SlagDocument2 pagesGbfs SlagchandramohanNo ratings yet

- CLCDocument14 pagesCLCSagar SagarNo ratings yet

- Solder Paste Specification: No-Clean Xjs-638Document6 pagesSolder Paste Specification: No-Clean Xjs-638Guilherme Dos Santos MoreiraNo ratings yet

- Diffusion Coatings: Abbreviations 4.05.1Document24 pagesDiffusion Coatings: Abbreviations 4.05.1Raza AliNo ratings yet

- Upd GM F 003 cw85 207 - Old - Street enDocument13 pagesUpd GM F 003 cw85 207 - Old - Street enreza ebadiNo ratings yet

- Wall Colmonoy - Properties of Hard Surfacing Alloy Colmonoy 88 - July 2019Document8 pagesWall Colmonoy - Properties of Hard Surfacing Alloy Colmonoy 88 - July 2019joseocsilvaNo ratings yet

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesFrom EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Metal Powders: A Global Survey of Production, Applications and MarketsFrom EverandMetal Powders: A Global Survey of Production, Applications and MarketsNo ratings yet

- The Art of Lead Burning: A practical treatise explaining the apparatus and processesFrom EverandThe Art of Lead Burning: A practical treatise explaining the apparatus and processesNo ratings yet

- Concrete Materials: Properties, Specifications, and TestingFrom EverandConcrete Materials: Properties, Specifications, and TestingRating: 4.5 out of 5 stars4.5/5 (5)

- Sm51625El Lan 10/100/1000 Base-T (Poe+) Transformer: Features ApplicationsDocument2 pagesSm51625El Lan 10/100/1000 Base-T (Poe+) Transformer: Features ApplicationsBru MNo ratings yet

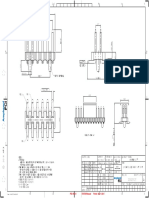

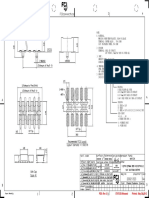

- 1.27mm Header SM PDFDocument2 pages1.27mm Header SM PDFBru MNo ratings yet

- Notes:: Amphenol Canada CorpDocument2 pagesNotes:: Amphenol Canada CorpBru MNo ratings yet

- Serial Digital Interface (SDI) Release NotesDocument2 pagesSerial Digital Interface (SDI) Release NotesBru MNo ratings yet

- 1.27mm F HDR ThruDocument1 page1.27mm F HDR ThruBru MNo ratings yet

- XXX - Cyclone V Product TableDocument2 pagesXXX - Cyclone V Product TableBru MNo ratings yet

- Ulti Ayer Eramic ApacitorDocument4 pagesUlti Ayer Eramic ApacitorBru MNo ratings yet

- Open Lvds Display Interface (Openldi) SpecificationDocument45 pagesOpen Lvds Display Interface (Openldi) SpecificationBru MNo ratings yet

- XU9M18MB9AQW DATASHEET US en-USDocument1 pageXU9M18MB9AQW DATASHEET US en-USحمزة صباحNo ratings yet

- MVS25N3MW6L: Product DatasheetDocument7 pagesMVS25N3MW6L: Product DatasheetNavneet SinghNo ratings yet

- RTD2122LDocument52 pagesRTD2122LadriantxeNo ratings yet

- NORTEL BSC3000 V15 - Rel3.13Document176 pagesNORTEL BSC3000 V15 - Rel3.13Santos GarciaNo ratings yet

- DMTA 10072 01EN Vanta User International PDFDocument160 pagesDMTA 10072 01EN Vanta User International PDFTechnical A-Star Testing & Inspection Malaysia100% (1)

- TLP5771H: 1. ApplicationsDocument19 pagesTLP5771H: 1. Applicationscarol2No ratings yet

- 1SDA066813R1-xt1b-160-tmd-32-450-4p-f-fDocument4 pages1SDA066813R1-xt1b-160-tmd-32-450-4p-f-fjuan diego vega cacchaNo ratings yet

- Datasheet+HBXX 6516DS VTMDocument3 pagesDatasheet+HBXX 6516DS VTMArturo CadenaNo ratings yet

- E54 PDFDocument9 pagesE54 PDFmanish.sharma- hitechNo ratings yet

- ZCMD21: Product Data SheetDocument3 pagesZCMD21: Product Data SheetDaniel rodriguezNo ratings yet

- Technical Requisition FMSDocument33 pagesTechnical Requisition FMSgiribabuNo ratings yet

- Philips+Q552 2E+LA-4 PDFDocument331 pagesPhilips+Q552 2E+LA-4 PDFWade Dyer100% (1)

- Soft Start - Altistart 48 - VX4G481Document2 pagesSoft Start - Altistart 48 - VX4G481the hawakNo ratings yet

- RC1602B Biw CSXDocument28 pagesRC1602B Biw CSXAndrei MocanuNo ratings yet

- 2.5-V Integrated Reference Circuit: FeaturesDocument24 pages2.5-V Integrated Reference Circuit: FeaturesAnderson BorgesNo ratings yet

- D6F PHDocument6 pagesD6F PHUtkarsh BansalNo ratings yet

- 7M43MS12 0300FFPDocument1 page7M43MS12 0300FFPhgfhfg6 kgkghjkNo ratings yet

- P613SS - B156SS 60cm Multifunction Built in Oven. BaumaticDocument26 pagesP613SS - B156SS 60cm Multifunction Built in Oven. BaumaticBob UNcleNo ratings yet

- 2016 Corpdoc 21 UkDocument24 pages2016 Corpdoc 21 UkAriel YehezkelNo ratings yet

- PowerLogic™ P5 - P5U20Document4 pagesPowerLogic™ P5 - P5U20MOHAN KRISHNANNo ratings yet

- homeLYnk LSS100100 PDFDocument2 pageshomeLYnk LSS100100 PDFaaaNo ratings yet

- lm567c 4Document27 pageslm567c 4Adin BagindutNo ratings yet

- Luminus CFT 90 W Datasheet 1511710Document14 pagesLuminus CFT 90 W Datasheet 1511710Opa2No ratings yet

- Zelio Control Relays - RM35JA32MTDocument7 pagesZelio Control Relays - RM35JA32MTN_LocusNo ratings yet

- Leica ST5010 Boyama CihazıDocument52 pagesLeica ST5010 Boyama Cihazıhüseyin vururNo ratings yet

- MMU 0102, MMA 0204, MMB 0207 - Professional: Vishay BeyschlagDocument13 pagesMMU 0102, MMA 0204, MMB 0207 - Professional: Vishay BeyschlagJan KowalskiNo ratings yet

- Ck106a DatasheetDocument4 pagesCk106a DatasheetSvetlin IvanovNo ratings yet

- ZXSS10 SS1b (V2.0.1.07) - Service Provisioning Guide Multi-Line Selected Group - ENDocument31 pagesZXSS10 SS1b (V2.0.1.07) - Service Provisioning Guide Multi-Line Selected Group - ENabera teshomeNo ratings yet

- Regulatory Compliance Statement RRU3936: Huawei Technologies Co., LTDDocument14 pagesRegulatory Compliance Statement RRU3936: Huawei Technologies Co., LTDParco Camasca VidalNo ratings yet

- Diod e A0017917119 1Document349 pagesDiod e A0017917119 1jim bervelingNo ratings yet