Professional Documents

Culture Documents

Section: Power Factor Correction Square D Varset™ by Schneider Electric

Uploaded by

Gem EscalanteOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section: Power Factor Correction Square D Varset™ by Schneider Electric

Uploaded by

Gem EscalanteCopyright:

Available Formats

SECTION [26 35 33.

16] [16340]

POWER FACTOR CORRECTION

Square D VarSet™ by Schneider Electric

Schneider Electric Editor’s Note:

This guide specification is written in accordance with the Construction Specifications Institute (CSI) Master Format. This

section must be carefully reviewed and edited by the architect or the engineer to meet the requirements of the project.

Coordinate this section with other specification sections within the Contract Documents and Drawings.

To properly use / edit this document, show formatting and hidden text by selecting ¶ on the menu or by typing (Ctrl+*)

simultaneously. Except for these introductory and closing paragraphs, green hidden text will not print. Text in red is optional.

Red text in [brackets] denotes multiple options where one or more should be chosen. All red text should be edited and

changed to black for final project conformation. In addition, these introductory paragraphs should be deleted or changed to

hidden text.

PART 1 - GENERAL

0.1 SUMMARY

A. Scope: Provide labor, material, equipment, related services, and supervision required, including, but not

limited to, manufacturing, fabrication, configuration and installation for power factor correction

equipment (also identified as automatic capacitor banks, PFC equipment) as required for the complete

performance of the Work, as shown on the Drawings, as specified herein.

B. Related Sections: Related sections include, but shall not be limited to, the following:

1. Drawings and general provisions of the Contract, including General and Supplementary

Conditions and Division 01 Specification Sections, apply to this Section.

2. Applicable general requirements for electrical Work specified within Division 26 Specification

Sections apply to this Section.

3. Refer to specification Section 26 13 09 Electrical Power Management System for additional

requirements.

0.2 REFERENCES

A. General, Publications: The publications listed below form a part of this Specification to the extent

referenced. The publications are referred to in the text by the basic designation only. The

edition/revision of the referenced publications shall be the latest date as of the date of the Contract

Documents, unless otherwise specified.

1. American National Standards Institute (ANSI)

2. ANSI C37.51, "Switchgear Metal Enclosed Low Voltage AC Power Circuit Breaker Switchgear

Assemblies Conformance Test Procedures."

3. American Society for Testing and Materials (ASTM)

4. ASTM E 329, "Standard Specification for Agencies Engaged in the Testing and/or Inspection of

Materials Used in Construction."

5. Canadian Standards Association (CSA)

6. C.22.2 No. 190, “Capacitors for Power Factor Correction.”

a. C22.1, “Canadian Electrical Code, Part I” (CEC)

b. Z462, “Workplace Electrical Safety”

7. National Electrical Manufacturers Association (NEMA)

8. NEMA 250, "Enclosures for Electrical Equipment (1000 Volts Maximum)"

Section [26 35 33.16][16340] Page 1 Schneider Electric

Power Factor Correction 09/08/2020

9. National Fire Protection Association (NFPA)

10. NFPA 70, "National Electrical Code" hereinafter referred to as NEC.

11. NFPA 70E, "Standard for Electrical Safety Requirements for Employee Workplaces"

12. Underwriters Laboratories, Inc. (UL)

13. UL 508a, "Industrial Control Panels"

14. UL 810, "Standard for Capacitors."

0.3 DEFINITIONS

A. Unless specifically defined within the Contract Documents, the words or acronyms contained within this

specification shall be as defined within, or by the references listed within this specification, the Contract

Documents, or, if not listed by either, by common industry practice.

B. PFC: Power Factor Correction

0.4 SUBMITTALS

A. General: Submittals shall be in accordance with the requirements of Section [01 33 00][01300]

Submittals and Section [26 00 10][16010] Electrical Requirements, in addition to those specified herein.

1. Submit sufficient information to determine compliance with the Contract Documents. Identify

submittal data with the specific equipment tags and/or service descriptions to which they pertain.

Submittal data shall be clearly marked to identify the specific model numbers, options, and

features of equipment and work proposed.

2. Deviations from the Contract Documents shall be indicated within the submittal. Each deviation

shall reference the corresponding drawing or specification number, show the Contract Document

requirement text and/or illustration, and shall be accompanied by a detailed written justification for

the deviation.

0.5 QUALITY ASSURANCE

A. Manufacturer Qualifications: Manufacturer shall be a firm engaged in the manufacture of specified

products of types and sizes required, and whose products have been in satisfactory use in similar

service for a minimum of 20 years.

1. The manufacturer shall have a valid ISO 9001 certification and an applicable quality assurance

system that is regularly reviewed and audited by a third party registrar. Manufacturing, inspection,

and testing procedures shall be developed and controlled under the guidelines of the quality

assurance system.

2. The manufacturer or their representative shall have service, repair, and technical support

services available 24 hours 7 days a week basis.

B. Installer Qualifications: Installer shall be a firm that shall have a minimum of five years of successful

installation experience with projects utilizing low voltage automatic capacitor banks similar in type and

scope to that required for this Project.

C. Inspecting and Testing Agency Qualifications: To qualify for acceptance, an independent inspecting and

testing agency hired by the Contractor or manufacturer to test products shall demonstrate to the

Architect/Engineer’s satisfaction that they are qualified according to ASTM E 329 to conduct testing

indicated.

D. All work performed and all materials used shall be in accordance with the National Electrical Code, and

with applicable local regulations and ordinances. Process controllers, assemblies, materials, and

equipment shall be listed and labeled by Underwriter’s Laboratories or by a testing agency acceptable to

authorities having jurisdiction, and marked for intended use.

Section [26 35 33.16][16340] Page 2 Schneider Electric

Power Factor Correction 09/08/2020

0.6 DELIVERY, STORAGE AND HANDLING

A. Prior to delivery to the Project site, ensure that suitable storage space is available to store materials in a

well-ventilated area protected from weather, moisture, soiling, extreme temperatures, humidity, and

corrosive atmospheres. Materials shall be protected during delivery and storage and shall not exceed

the manufacturer stated storage requirements. As a minimum, store indoors in clean, dry space with

uniform temperature to prevent condensation. In addition, protect electronics from all forms of electrical

and magnetic energy that could reasonably cause damage.

B. Deliver materials to the Project site in supplier’s or manufacturer’s original wrappings and containers,

labeled with supplier’s or manufacturer’s name, material or product brand name, and equipment tag

number or service name as identified within the Contract Documents.

C. Inspect and report any concealed damage or violation of delivery storage, and handling requirements to

the Engineer.

0.7 WARRANTY

A. General: Refer to [Section 01 77 00 - Closeout Procedures] [Section 01770 - Closeout Procedures].

B. Additional Owner Rights: The warranty shall not deprive the Owner of other rights the Owner may have

under other provisions of the Contract Documents and shall be in addition to and run concurrent with

other warranties made by the Contractor under requirements of the Contract Documents.

0.8 SPECIAL TOOLS AND SPARE PARTS [NOT USED]

A. The Contractor shall provide a recommended spare parts list with the following information provided as

a minimum:

1. Contact information for the closest parts stocking location to the Owner.

2. Critical spare parts shall be identified as those parts being associated with long lead times and/or

those being critical to the unit's operation.

3. Maintenance spares shall be identified as being those parts required to regularly perform

scheduled maintenance on the furnished equipment. These spares shall include, but shall not be

limited to, consumable spares that are required to be exchanged during scheduled maintenance

periods.

B. Spare parts shall be provided for each type and size of unit furnished. At a minimum, the following shall

be provided:

C. Provide the minimum spare parts recommended by the manufacturer.

D. Provide [1] set of each type of power and control fuse installed within equipment

E. Spare parts shall be properly marked and packaged for long term storage. Printed circuit boards shall

be provided in separate anti-static containers.

PART 2 - PRODUCTS

0.1 MANUFACTURERS

A. [Basis-of-Design Product: Subject to compliance with requirements, provide Square D VarSet, by

Schneider Electric.]

B. Acceptable Products: PFC equipment specified herein shall be the product of a single manufacturer.

Products and manufacturers specified are to establish a standard of quality for design, function,

materials, and appearance. Products shall be modified as necessary by the manufacturer for

Section [26 35 33.16][16340] Page 3 Schneider Electric

Power Factor Correction 09/08/2020

compliance with requirements. Provide the following specified product and manufacturer without

exception, unless approved as a substitute by addendum to the Contract Documents prior to the bid

date:

C. Square D VarSet by Schneider Electric

D. [2nd manufacturer and model]

E. [3rd manufacturer and model]

0.2 GENERAL REQUIREMENTS

A. Capacitor bank shall be able to select a target power factor, adjustable to any value between 0.80

lagging and unity. When the power factor differs from the target setting for more than 1 to 30 seconds,

capacitor bank shall bring the corrected circuit power factor to the closest target setting.

B. Electrical Components, Devices, and Accessories: Electrical components, devices, and accessories

shall be listed and labeled as defined in NEC, Article 100, by an inspecting and testing agency

acceptable to authorities having jurisdiction, and marked for intended use.

C. The complete equipment shall be manufactured per UL 508, and CSA 22.2 No. 190.

D. Capacitor equipment shall be suitable for the following conditions:

E. Operating ambient temperature range shall be 23 °F ( 5 °C) to 104 °F (40 °C) maximum.

F. Highest mean over any period of 24 hours shall be 104 °F (40 °C).

G. Highest mean over one year shall be 95 °F (35 °C).

H. Maximum Altitude: 6562 feet (2000 m).

I. Humidity: 0 percent to 95 percent, non-condensing.

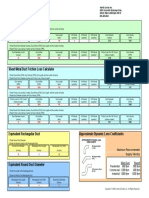

0.3 POWER FACTOR CORRECTION UNITS

A. Equipment Size / Ratings

B. Operating voltage shall be [480 volts] (line to line), three phase, [60] hertz.

C. Rated capacitor cell voltage shall be minimum of [575 volts for 480 Volt networks].

D. Total kVAR rating of the capacitor bank shall be [_____] kVAR at [480V].

PART 3 - Capacitor steps shall be [_____] kVAR for [480V] networks.

PART 4 - If the incomer has terminal lugs, then the same shall be of copper and all copper buswork shall be

braced to withstand fault level at either 25 kA RMS amperes symmetrical plus 10 percent for four cycles per ANSI

C37.51. [If the incomer is a circuit breaker, then the same shall be rated to withstand a fault level of 65 kA at 480

volts. The main circuit breaker shall be rated for a minimum of 135 percent of the capacitor system full load

current at operating voltage.]

A. Enclosure:

1. Enclosure(s) shall be freestanding / wall mounted, and shall be constructed of sheet steel,

including, but not limited to a hinged door, ground lug, and removable lifting eyes, finished with

standard [ANSI/ASA 49 gray][ANSI/ASA 61 gray][ RAL 7035] paint.

2. Enclosure(s) shall meet NEMA 250 Type 1 for indoor application.

3. Enclosure door(s) shall be full height, key lockable with door mounted controller, to comply with

NFPA70E requirements.

B. Capacitors

1. Internal capacitor cells shall be UL and CSA recognized in compliance with UL 810 and CSA22.2,

No. 190.

Section [26 35 33.16][16340] Page 4 Schneider Electric

Power Factor Correction 09/08/2020

2. Liquid filled or impregnated capacitors are not acceptable. Individual capacitor elements shall be

of a self-healing design utilizing a low loss metalized film dielectric system with a pressure

sensitive circuit interrupter. Electrical losses, including, but not limited to, contribution of discharge

resistors, shall average less than 0.5 watts per kVAR.

3. Capacitor shall be able of continuous operation at 135 percent of the rated rms current, including

fundamental and harmonic currents, and be suitable for continuous operation at terminal to

terminal voltage (rms including harmonics) equals to 110% of the rated voltage.

4. Capacitor elements shall be delta connected at rated voltage. Wye connected capacitor elements

shall not be acceptable.

5. Capacitor shall incorporate a 3-phase pressure switch disconnector for protection against internal

faults, over pressure, etc. The pressure switch disconnector must isolate all the three phases

simultaneously in the event of fault.

6. Discharge resistors shall be provided to meet UL/CSA requirement (reduce voltage on the cells to

50 volts or less within one minute after the capacitor has been switched off).

C. Internal Overcurrent Protective Device: Thermal magnetic molded case current limiting circuit breaker

shall be provided on the line side of each contactor. Circuit breaker shall be UL/CSA listed, shall have

inverse time current element for low level overloads, and shall have adequate short circuit current

interrupting rating.

D. Contactors:

1. For applications with gradual load variation, electromagnetic contactors shall be used. The

electromagnetic contactors shall be three poles; rated for the repetitive high inrush switching duty

in the capacitor application. Contactors shall be designed for capacitor switching duty, UL / CSA

listed and rated 600 volts AC with 120 volts AC operating coils.

2. For applications with dynamic load variation or electronic loads that are sensitive to transient over

voltages, transient free switching shall be used. Transient free switching with (solid state

capacitor switching module) shall enable a 1 second response time. The thyristors in the

switching module shall be rated to 200 amperes RMS nominal current per phase up to 600V, and

shall be rated for 2400 PIV. Up to 3 stages can grouped in a single switching module for effective

thermal management. The switching module shall be protected by thermal protection device to

prevent overheating. The air flow through the heat sink shall be external to the capacitor bank.

Losses from the heat sink, shall not add to the temperature rise internal to the capacitor bank.

E. De-Tuning Reactors:

1. Tuning reactors for each capacitive stage shall be selected such that filter tuning of each stage

shall be equal to 4.2 x 60 hertz equivalent to a 252 Hz tuning.

2. Reactor shall be constructed of EI laminated low hysteresis core with a controlled air gap and

three aluminum windings.

3. Reactor insulation shall be rated for 180 °C, class H.

4. Center leg of tuning reactor shall have an embedded thermistor wired to a thermistor relay for the

stage to deenergize the associated contactor in the event of reactor overheating.

F. Control Power Requirements:

1. 120 volt AC control circuit transformer shall be provided within the enclosure.

2. Major components, including, but not limited to, both primary and secondary winding of the

transformer, shall be fused.

G. Power Factor Controller:

1. The PF controller shall be a programmable unit with a single current input and single line to line

voltage input. The controller shall be suitable for operation with energy import and energy export

Section [26 35 33.16][16340] Page 5 Schneider Electric

Power Factor Correction 09/08/2020

(4 quadrant operations). The controller shall measure power factor in the distribution system, and

per the programmed control logic, shall connect or disconnect the required amount of capacitor

stages needed to maintain the preset power factor.

2. The controller shall utilize a switching logic that shall optimize the use of capacitor elements and

contactors in the bank. Three switching logics shall be available; Automatic (Best Fit), LIFO &

Progressive.

3. A backlit LCD display shall be provided to view the system condition and gain access to all the

menus. Indication of actual Power Factor, Alarms, stage energization and inductive/capacitive

condition shall be provided.

4. Backlit LCD display shall light up when the controller is being access.

5. The controller shall be equipped with a quick set up menu to allow for simple and quick startup of

the Automatic Capacitor bank.

6. The controller shall also be equipped with an expert setup menu allowing password controlled

access to advanced parameters like: measurement, maintenance, controls, capacitor data,

alarms and Modbus communication.

7. When overriding the automatic mode for maintenance, a ten minutes maximum override time

shall be provided with an automatic return to automatic mode of operation.

8. A common alarm dry contact shall be provided to signal an alarm status.

9. The controller shall automatically select the system frequency (50 hertz or 60 hertz).

10. An automatic step detection and an automatic voltage and current input wiring connection must

be provided to reduce risks of bad connection. CT ratio, position and polarity shall be adjustable

by the controller.

11. The controller shall monitor all connected steps and provide the real-time power in kW, kVAR and

kVA. The controller shall also monitor remaining step kVAR capacity as a percentage of the

original reactive power and the PFC system hours of operation since commissioning.

12. The controller shall permit programming of the switching stage response time, number of stages

(12 maximum), and various adjustment parameters depending on system design.

13. The controller shall be equipped with a Modbus RTU (RS 485, 2 wires) communication port.

Furthermore, communication via Ethernet TCP/IP shall be possible when an Ethernet gateway

(Link 150) is added to the automatic capacitor bank.

14. A digital input shall be provided to activate the Cosphi #2 for application with back-up generator.

15. The controller shall allow the following settings and readings.

16. Automatic initialization and stage rating detection

17. Any step sequence detection (User definable step sequence)

18. Measurement of capacitance per stage

19. Cap bank over load current ratio

20. THD Voltage

21. 4 Quadrant operation

22. Active, reactive and apparent power

23. Record of the Max temp internal of the capacitor bank since reset

24. RS485 interface.

H. The controller shall initiate alarms and warnings in the following events.

I. Temperature limit is exceeded

J. Insufficient capacitor output

K. Overload current ratio limit is exceeded

L. Under voltage, Over voltage

Section [26 35 33.16][16340] Page 6 Schneider Electric

Power Factor Correction 09/08/2020

M. THDU limit is exceeded

0.2 EXTERNAL CURRENT TRANSFORMER (CT):

A. A current transformer to be installed upstream of where the automatic capacitor is attached to the

electrical distribution system, shall be provided with a ratio of [____] amperes to [1][5] amperes. The

field installable CT shall be split core type with an opening large enough to facilitate installation around

the cables or bus.

B. A shorting terminal shall be provided for two incoming current transformer wires.

0.3 ELECTRICAL POWER MANAGEMENT SYSTEM [NOT USED]

A. The Capacitor bank shall provide the necessary communications connectivity and functionality required

to support the functionality of an Electrical Power Management System (EPMS). This shall include, but

not be limited, to the following:

1. Communications connectivity using the specified Ethernet network and protocols of the EPMS

and related EPMS connected equipment necessary to provide functionality. Equipment may be

connected through a communications gateway as shown or specified; otherwise Ethernet and

protocol connectivity shall be provided within the equipment.

2. Compliance with Cyber security requirements.

3. Remote EPMS application functionality for equipment configuration [ and operational control];

electrical power monitoring; power quality monitoring, compliance and correction; and alarm

monitoring with event log.

4. Refer to the Electrical Power Management System specification section for additional

requirements.

B. Native software compatibility shall be fully factory-tested, and shall include the following characteristics.

1. Capability for pre-engineered, interactive graphical display screens to view and analyze real-time

device data. Data displayed shall include the following

2. Power factor (target, measured total, measured displacement)

3. Total Power values (kW, kVAR, and kVA)

4. Average Current

5. Step settings & status of each step (whether closed, faulty, whether step type is automatic or

fixed)

6. Step capacity for each step (initial, present and percentage remaining)

7. Device status information (line-to-line voltage, average current, temperature)

8. Device maintenance warnings & alarms (step broken, step power loss, hunting, over-under

compensation, temperature alarms, operating hours exceeded, switching cycles exceeded etc.)

9. Device diagnostic data (operating hours, ambient temperature, overload current ratio, fan relay

status etc.)

10. Device configuration settings (control sensitivity, step switch interval, discharge time etc.)

11. Pre-mapping of registers to standard measurement names without the need for additional

configuration or internal device registers.

12. Automatic collection and logging of device data by EPMS software without additional

configuration. Historical data logged shall include the following.

13. Average current

14. Ambient Temperature

15. Power Factor (total, apparent, reactive, real).

Section [26 35 33.16][16340] Page 7 Schneider Electric

Power Factor Correction 09/08/2020

0.4 MARKINGS AND LABELING

A. All identification and warning labels and nameplates exterior to the AHF shall be resistant to weather,

UV, and their intended installation environment.

B. Each AHF shall be provided with an engraved nameplate identifying the project specific equipment tag

and service description.

C. Warning labels and nameplates shall be present at access locations to advise personnel of possible

hazards. The AHF shall be marked in accordance with UL, NFPA 70 NEC, NFPA 70E, and other

applicable standards.

PART 5 - EXECUTION

0.1 GENERAL

A. In addition to the requirements specified herein, execution shall be in accordance with the requirements

of Specification Section [26 00 10][16010] and Drawings.

B. Examine equipment exterior and interior prior to installation. Report any damage and do not install any

equipment that is structurally, moisture, or mildew damaged.

C. Verification of Conditions: Examine areas and conditions under which the work is to be installed, and

notify the Contractor in writing, with a copy to the Owner and the Engineer, of any conditions detrimental

to the proper and timely completion of the work. Do not proceed with the work until unsatisfactory

conditions have been corrected.

D. Beginning of the work shall indicate acceptance of the areas and conditions as satisfactory by the

Installer.

E. Install equipment in accordance with reviewed product data, final shop drawings, manufacturer’s written

instructions and recommendations, and as indicated on the Drawings.

F. Functional testing, commissioning, and first parameter adjusting shall be carried out by a factory trained

manufacturer’s representative field service engineer. Test and adjust controls and safeties. Replace

damaged or malfunctioning controls and equipment. Report to the Engineer any discrepancies or issues

with the installation.

G. Provide final protection and maintain conditions in a manner acceptable to the manufacturer that shall

help ensure that the equipment is without damage at time of Substantial Completion.

0.2 FACTORY ACCEPTANCE TESTING [NOT USED]

A. Standard tests shall be performed in the factory to confirm proper operation of the capacitor bank,

including, but not limited to, operation of control circuits, functioning of the PF controller, confirming of

kVAR rating at rated voltage and high pot testing per UL / CSA requirements.

0.3 FUNCTIONAL DEMONSTRATION TESTING

A. The contractor shall certify in writing prior to scheduling functional demonstration testing that the

equipment has been installed, adjusted, and tested in accordance with the manufacturer’s

recommendations and is ready for operation.

B. The contractor shall demonstrate the functional and operational features of the capacitor bank along

with the PF Controller.

Section [26 35 33.16][16340] Page 8 Schneider Electric

Power Factor Correction 09/08/2020

END OF SECTION [26 35 33.16][16340]

©2018 Schneider Electric. Authorization is hereby provided to specifier or design professionals, other than competitors of

Schneider Electric, to copy all or part of this document to prepare a specification or bid for a construction project subject to the

Disclaimer Statement provided herein. Schneider Electric, Square D, VarSet, Modbus and EcoStruxure are trademarks and

the property of Schneider Electric SE, its subsidiaries, and affiliated companies. All other trademarks are the property of their

respective owners.

DISCLAIMER STATEMENT

This guide specification has been written and is intended to be used by a professionally qualified specifier and/or design

professional. The use of this guide specification requires the professional judgment and expertise of the qualified specifier

and/or design professional to adapt or revise the information to the specific needs for the Project and is not intended to be

used verbatim as a project specification section without appropriate modifications for the specific use intended. The guide

specification must be used and coordinated in accordance with the procedures of each design firm, and the requirements of

the specific project. This guide specification is subject to change without written notice by the manufacturer and the

manufacturer expressly disclaims any warranty, expressed or implied.

Section [26 35 33.16][16340] Page 9 Schneider Electric

Power Factor Correction 09/08/2020

You might also like

- 26 24 16.13 Isolated Power Systems For HeathcareDocument17 pages26 24 16.13 Isolated Power Systems For Heathcareرضا میرزانیاNo ratings yet

- Switchboards SECTION 16441Document12 pagesSwitchboards SECTION 16441NATHANNo ratings yet

- Medium Voltage, 27KV and 38KV, Metal-Clad Switchgear Spec SDocument14 pagesMedium Voltage, 27KV and 38KV, Metal-Clad Switchgear Spec SJuvencio MolinaNo ratings yet

- Especificaciones Llamado de EnfermeriaDocument14 pagesEspecificaciones Llamado de EnfermeriaGuillermo Jesus Avila ArrietaNo ratings yet

- FL - TRANSFER SWITCHES-GUIDE SPECIFICATION-Rev3Document19 pagesFL - TRANSFER SWITCHES-GUIDE SPECIFICATION-Rev3Gem EscalanteNo ratings yet

- Section 26 08 00 - Electrical Systems Commissioning GeneralDocument6 pagesSection 26 08 00 - Electrical Systems Commissioning GeneralRenan Verolli Dal'AvaNo ratings yet

- GET6600G Section 10 Guide Form Spec Rev 2Document14 pagesGET6600G Section 10 Guide Form Spec Rev 2NestorNateraNo ratings yet

- Fiberglass Density Current Baffles - MSTDocument10 pagesFiberglass Density Current Baffles - MSTwafikmh4No ratings yet

- SECTION 26 05 11 Requirements For Electrical InstallationsDocument11 pagesSECTION 26 05 11 Requirements For Electrical InstallationsEzana EzanaNo ratings yet

- Computer-Room Air ConditionersDocument19 pagesComputer-Room Air ConditionersAbdullah.N FAAliNo ratings yet

- BASIC ELECTRICAL MATERIALS AND METHODS - Specs - AllDocument202 pagesBASIC ELECTRICAL MATERIALS AND METHODS - Specs - AllAdnan NajemNo ratings yet

- V07 (Architectural FOH Lighting)Document231 pagesV07 (Architectural FOH Lighting)Parth WankhedeNo ratings yet

- 23 81 26Document8 pages23 81 26KHMHNNo ratings yet

- SECTION 26 05 11 Requirements For Electrical InstallationsDocument11 pagesSECTION 26 05 11 Requirements For Electrical Installationsdaygo21No ratings yet

- A Guid To HVACDocument11 pagesA Guid To HVACHamad GulNo ratings yet

- Electrical AuxiliaryDocument121 pagesElectrical AuxiliaryGove Mojemer RedNo ratings yet

- Crac Specification For CUCDocument12 pagesCrac Specification For CUCLi LiuNo ratings yet

- City Mall and Hotel Electrical Technical SpecificationsDocument149 pagesCity Mall and Hotel Electrical Technical SpecificationsGulbahar SubstationNo ratings yet

- Waste Treatment Machine Ventilation SystemsDocument4 pagesWaste Treatment Machine Ventilation SystemsJay-Mart Dela CruzNo ratings yet

- Westpoint Bath MDocument68 pagesWestpoint Bath MNitin SeeburrunNo ratings yet

- Packaged Outdoor Central StationDocument14 pagesPackaged Outdoor Central StationAbdullah.N FAAliNo ratings yet

- SECTION 26 3213 Engine Generators Part 1 General 1.01 Section IncludesDocument31 pagesSECTION 26 3213 Engine Generators Part 1 General 1.01 Section IncludesMarcos FernandezNo ratings yet

- 12 15 14newDocument27 pages12 15 14newMario Roberto Rodríguez RangelNo ratings yet

- 15785-Pca Air Handling UnitsDocument10 pages15785-Pca Air Handling Unitsadel rihanaNo ratings yet

- GeneratorDocument19 pagesGeneratoruddinnadeemNo ratings yet

- Packaged Small-Capacity Rooftop Air Conditioning UnitsDocument15 pagesPackaged Small-Capacity Rooftop Air Conditioning UnitsChase GietterNo ratings yet

- Chlorination Equipment - MSTDocument20 pagesChlorination Equipment - MSTwafikmh4No ratings yet

- Chlorination Equipment - MSTDocument24 pagesChlorination Equipment - MSTwafikmh4No ratings yet

- Hint210501 Fire Protection General ProvisionsDocument16 pagesHint210501 Fire Protection General Provisionsabdullah sahibNo ratings yet

- HANGERS SUPPORT ROYAL ATLANTIS HVAC PIPING EQUIPMENTDocument8 pagesHANGERS SUPPORT ROYAL ATLANTIS HVAC PIPING EQUIPMENTMY PCNo ratings yet

- Air CurtainsDocument5 pagesAir Curtainsadel rihanaNo ratings yet

- FL - Switchboards-Guide Specification2Document23 pagesFL - Switchboards-Guide Specification2Shafeek GhreebNo ratings yet

- Complinace CBD Towers Scope (SM6)Document26 pagesComplinace CBD Towers Scope (SM6)Li LiuNo ratings yet

- IP Clock System Engineering SpecDocument10 pagesIP Clock System Engineering SpecFaim HasanNo ratings yet

- 03 Fire Protection Spec-Uptown21Document20 pages03 Fire Protection Spec-Uptown21laurenjiaNo ratings yet

- ICT SpecificationDocument99 pagesICT SpecificationZaid HijjawiNo ratings yet

- Section 23 72 00Document7 pagesSection 23 72 00Ismail MohammadNo ratings yet

- Project Standard Specification: Computer-Room Air-Conditioning Units 15783 - Page 1/11Document11 pagesProject Standard Specification: Computer-Room Air-Conditioning Units 15783 - Page 1/11adel rihanaNo ratings yet

- Section 16200 Electrical, GeneralDocument6 pagesSection 16200 Electrical, GeneralctoujagueNo ratings yet

- Medium Voltage Switchgear InstallationDocument7 pagesMedium Voltage Switchgear InstallationWaleed Abd El-HamiedNo ratings yet

- Motor-Control Centers Project Specification for HVACDocument15 pagesMotor-Control Centers Project Specification for HVACSoumojit SamantaNo ratings yet

- 26 5200 Safety LightingDocument12 pages26 5200 Safety LightingAnuroop SivadasNo ratings yet

- Technical Specifications for Jet Fan InstallationDocument16 pagesTechnical Specifications for Jet Fan InstallationDewanggaNo ratings yet

- Low voltage panel board installationDocument7 pagesLow voltage panel board installationuddinnadeemNo ratings yet

- Enclosed Switches and Circuit Breakers-Rev05Document7 pagesEnclosed Switches and Circuit Breakers-Rev05Mohamed HamedNo ratings yet

- 26 05 00 Common Work Results On ElectricalDocument7 pages26 05 00 Common Work Results On ElectricalkaichosanNo ratings yet

- 26 2413 Main Distribution Board PDFDocument18 pages26 2413 Main Distribution Board PDFMena Amir KhairyNo ratings yet

- SpecificationsDocument7 pagesSpecificationsvenkat0236No ratings yet

- 16441Document7 pages16441uddinnadeemNo ratings yet

- Attachment 1 - Section 15620 Centrifugal ChillersDocument21 pagesAttachment 1 - Section 15620 Centrifugal ChillersMohammad Ali DiabNo ratings yet

- Electrical SpecificationDocument48 pagesElectrical SpecificationAhmad SaadeldinNo ratings yet

- Overcurrent Protective Device Coordination StudyDocument3 pagesOvercurrent Protective Device Coordination StudySankalp TiwariNo ratings yet

- Ges A 03Document15 pagesGes A 03Chokri HmeidiNo ratings yet

- Light Fittings - SpecificationDocument6 pagesLight Fittings - SpecificationduleepabowatteNo ratings yet

- Technicalspecificationforcpsystem 151216044929 PDFDocument62 pagesTechnicalspecificationforcpsystem 151216044929 PDFsouheil boussaidNo ratings yet

- 262416-Panelboards Rev 2Document7 pages262416-Panelboards Rev 2Hany NassimNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Bellbrook Centre Project PlansDocument39 pagesBellbrook Centre Project PlansGem EscalanteNo ratings yet

- Request For Quotation MCKDocument1 pageRequest For Quotation MCKGem EscalanteNo ratings yet

- Fire Stop Sealant - Hilti PDFDocument1 pageFire Stop Sealant - Hilti PDFREGINALD DUMALANTA DE GUZMANNo ratings yet

- Don's Cheat Sheet for Cylinder CalculationsDocument2 pagesDon's Cheat Sheet for Cylinder Calculationsrobyn100No ratings yet

- Replacement of Ducting at E-Coat Area: Toyota Motors Phils., CorporationDocument4 pagesReplacement of Ducting at E-Coat Area: Toyota Motors Phils., CorporationGem EscalanteNo ratings yet

- NDFR Dine-In and Takeout Menu Final - 04.22.2021Document2 pagesNDFR Dine-In and Takeout Menu Final - 04.22.2021Gem EscalanteNo ratings yet

- Perk ComboDocument1 pagePerk ComboGem EscalanteNo ratings yet

- SEISMIC RESTRAINT CALCULATIONSDocument3 pagesSEISMIC RESTRAINT CALCULATIONSGem EscalanteNo ratings yet

- Relocation of Fire Hose Cabinet: Toyota Motor Phils. CorpDocument4 pagesRelocation of Fire Hose Cabinet: Toyota Motor Phils. CorpGem EscalanteNo ratings yet

- Construction Personnel Request FormDocument1 pageConstruction Personnel Request FormAl-kenzar TahirNo ratings yet

- Flexible Duct Friction Loss CalculatorDocument1 pageFlexible Duct Friction Loss CalculatorThinh TranNo ratings yet

- FL - Transfer Switches DATA SHEETDocument1 pageFL - Transfer Switches DATA SHEETGem EscalanteNo ratings yet

- Fire Sprinklers PDFDocument28 pagesFire Sprinklers PDFChristopher BrownNo ratings yet

- T64 CRE500 T70D: Quick Reference CFM Chart For Standard GrillesDocument1 pageT64 CRE500 T70D: Quick Reference CFM Chart For Standard GrillesGem EscalanteNo ratings yet

- PlumbingDocument62 pagesPlumbingAnonymous iTzCnMNo ratings yet

- E-Ductulator (EDocFind - Com)Document8 pagesE-Ductulator (EDocFind - Com)sahil1969No ratings yet

- WWW - Schneider-Electric - Us: 11/13/2015 - Page 1 of 2Document2 pagesWWW - Schneider-Electric - Us: 11/13/2015 - Page 1 of 2Gem EscalanteNo ratings yet

- KSB Know-How, Volume 0 - Selecting-Centrifugal-Pumps-data PDFDocument92 pagesKSB Know-How, Volume 0 - Selecting-Centrifugal-Pumps-data PDFRodrigo Astudillo AedoNo ratings yet

- Scania 5-Series Engine Inspection ManualDocument275 pagesScania 5-Series Engine Inspection Manualgiovani martinsNo ratings yet

- Synchrometer STEDocument6 pagesSynchrometer STErcmNo ratings yet

- What is a 50/50 in minesweeperDocument7 pagesWhat is a 50/50 in minesweeperGannon GageNo ratings yet

- Lufthansa Technical Training Troubleshooting Fundamentals CourseDocument160 pagesLufthansa Technical Training Troubleshooting Fundamentals CourseBELISARIONo ratings yet

- Level 11 Pin Relays Catalog PageDocument12 pagesLevel 11 Pin Relays Catalog PageRicardo RosárioNo ratings yet

- Jadenlimkaijie w1Document4 pagesJadenlimkaijie w1api-518329636No ratings yet

- Risk Assessment of Consumables SuppliesDocument9 pagesRisk Assessment of Consumables SuppliesanfiboleNo ratings yet

- S&T Achievements from Marcos to PresentDocument9 pagesS&T Achievements from Marcos to PresentNICOLE IRISH CABUNILASNo ratings yet

- Prediction of Stock Price Based On Hidden Markov Model and Nearest Neighbour AlgorithmDocument31 pagesPrediction of Stock Price Based On Hidden Markov Model and Nearest Neighbour AlgorithmFirman AkbarNo ratings yet

- IJSRED V2I5P1520190928 129446 F04isc Libre PDFDocument5 pagesIJSRED V2I5P1520190928 129446 F04isc Libre PDFHồ Mỹ DuyênNo ratings yet

- UN Women Branding GuidelinesDocument37 pagesUN Women Branding GuidelinesDenis Shepherd KimathiNo ratings yet

- Tugas CDocument3 pagesTugas CFatiaNo ratings yet

- Job Aplication LetterDocument4 pagesJob Aplication LetterFebiola PurnamasariNo ratings yet

- Plantilla Powerpoint QuimicaDocument22 pagesPlantilla Powerpoint QuimicaMayra HernandezNo ratings yet

- VFD module specification guideDocument17 pagesVFD module specification guideMikhailNo ratings yet

- Civil/Structural Calculation SheetDocument19 pagesCivil/Structural Calculation Sheetfbaxter22No ratings yet

- Unit 25 Sound RecordingDocument21 pagesUnit 25 Sound Recordingapi-480389176No ratings yet

- Standard Operating Procedure For Customer CreationDocument3 pagesStandard Operating Procedure For Customer CreationMRL AccountsNo ratings yet

- Jobs-In-Webduniaweb-Portal/ Telugu Translation Jobs in Webdunia (Web Portal)Document3 pagesJobs-In-Webduniaweb-Portal/ Telugu Translation Jobs in Webdunia (Web Portal)Rangothri Sreenivasa SubramanyamNo ratings yet

- Construction Management LecturesDocument8 pagesConstruction Management LecturesJosua MenisNo ratings yet

- Megahertz Internet Network Pvt. LTD.: Retail InvoiceDocument1 pageMegahertz Internet Network Pvt. LTD.: Retail InvoiceAyush ThapliyalNo ratings yet

- Users Manual 3 994639Document140 pagesUsers Manual 3 994639Parul MehtaNo ratings yet

- Java Basics - Key Elements of a Java ProgramDocument21 pagesJava Basics - Key Elements of a Java ProgramAsh LeeNo ratings yet

- SpecificationsDocument4 pagesSpecificationsBawantha Prasad MihirangaNo ratings yet

- UntitledDocument880 pagesUntitledmahdi beheshti100% (1)

- Unit1 DBMSDocument64 pagesUnit1 DBMSRaj SuraseNo ratings yet

- Novent Microfluidics: Installation GuideDocument24 pagesNovent Microfluidics: Installation GuidetalebNo ratings yet

- All Motor, &electrical Equipment in StorDocument8 pagesAll Motor, &electrical Equipment in StorMd. Saddam HossainNo ratings yet

- 6H000200 PDFDocument2 pages6H000200 PDFSachin RamadasanNo ratings yet

- Lubricated Plug Valves: Price List #3119 - Effective: 3/1/19Document16 pagesLubricated Plug Valves: Price List #3119 - Effective: 3/1/19nurhadiNo ratings yet