Professional Documents

Culture Documents

30 TON TRUCK CRANE

Uploaded by

carlos aquinoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

30 TON TRUCK CRANE

Uploaded by

carlos aquinoCopyright:

Available Formats

STC300S-Y2

STC300S-Y2 TRUCK CRANE

30 TONS LIFTING CAPACITY

Quality Changes the World

STC300S-Y2 TRUCK CRANE STC300S-Y2 TRUCK CRANE

2 COMPANY BRIFE INTRODUCTION COMPANY BRIFE INTRODUCTION 3

SANY Automobile Hoisting Machinery is one of the core business unit of Sany Heavy Industry,

mainly engaged in the research and development of high end, mid to large tonnage crane

series, including mobile crane, crawler crane, tower crane and loader crane. It has two industrial

parks in Ningxiang and Huzhou, since entering the market, the products of Sany Automobile

Hoisting Machinery have received worldwide recognition with advanced technology, lean

manufacturing, high reliability and excellent service.

Quality Changes the World Quality Changes the World

STC300S-Y2 TRUCK CRANE STC300S-Y2 TRUCK CRANE

4 ICON SELLING POINTS 5

SANY TRUCK CRANE

CONTENT

04 Icon

05 Selling Points

06 Introduction

09 Dimension

10 Technical Parameter

11 Operation Condition

12 Load Chart

14 Wheel Crane Family Map

Excellent and stable chassis performance / Ultra long and super strong boom system

chassis system 10.6m basic boom, 40.5m full-extended boom and Max. lifting

Double-axle drive is used, providing good trafficability and height of 49m including jib take the leads in industry in the same

comfortableness under complex road condition with reliable tonnage. Rated lifting capacity is 30T, ensuring super strong lifting

traveling performance. capacity. Jib mounting angles are 0°, 15°, and 30° which ensure

Cab Carrier frame Suspension system fast and convenient change-over between different operating

Engine has the multimode power output function, which reduces

power consumption. conditions so as to improve working efficiency of the machine.

The use of tipping over early-warning technology provides high

stability and safety of the overall operation.

Hydraulic system Outriggers Telescopic boom

Control system Engine Lattice jibs

Telescopic system Transmission system Superlift devices

Luffing system Drive/Steer Luffing lattice jib

Slewing Axles winch mechanism:

Highly efficient, stable, energy-saving and Safe, stable, advanced and intelligent electric

adjustable hydraulic system control system

Hydraulic system load feedback featuring long service life, high The adoption of CAN-bus full-digital network control technology

Counterweight Tyres efficiency and low energy consumption is applied to enhance ensures stable control signal, simple harness, and high reliability.

lifting capacity and micro-mobility. Unique steering buffer design is Timely feedback of data information can achieve the monitoring

applied to ensure stable braking operation. of the overall working status in real time. The load moment limiter

equipping with the comprehensive intelligent protection system

Safety system Brakes system is used with accuracy within 3% to provide a comprehensive

logic and interlock control, thus ensuring more safe and reliable

operation.

Hoist system Electrical system

Quality Changes the World Quality Changes the World

STC300S-Y2 TRUCK CRANE STC300S-Y2 TRUCK CRANE

6 INTRODUCTION INTRODUCTION 7

Superstructure Superstructure

Cab ■ It is made of safety glass and anti-corrosion steel plate with ergonomic design such as full- Hoisting system ■ The winch adopts the high-pressure automatic variable plunger motor, enabling automatic

coverage soften interior, large interior space, panoramic sunroof and adjustable seats etc., switch-over between low load high speed mode and high load low speed mode, and

and humanized design providing more comfortable and relaxing operation experience. ensuring highly efficient operation and stable lifting and lowering of the load.

The display of load moment limiter integrates main console and operation display system, ■ One main hook: 320Kg, one auxiliary hook: 90Kg. Wire rope of main winch: left-handed

which clearly show the data of all operating superstructure conditions for lifting operation. wire rope 16-35W×7-1960USS, with length of 200m. Wire rope of auxiliary winch: left-

handed wire rope 16-35W×7-1960USS, with length of 105m.

Hydraulic system ■ High-quality key hydraulic components such as main oil pump, main valve, winch motor,

rotary motor and balancing parts etc. are adopted to achieve stable and reliable operation Safety system ■ Load moment limiter: Load moment limiter calculation system based on lifting load

of the hydraulic system. Superior operation performance is guaranteed by accurate mechanical model is established using an analytical mechanics method, with rated lifting

parameter matching. accuracy up to ±3% through on-line non-load calibration, providing full protection to lifting

■ Main valve has flow compensation, load feedback control function, enabling stable operation. In case of overload operation, system will automatically issue an alarm to provide

and convenient control of single action and combined action under different operation safety protection for manipulation.

conditions. ■ Hydraulic system is configured with the balance valve, overflow valve and two-way

■ Winch adopts the variable motor to ensure high operation efficiency. Max. single line hydraulic lock etc. components, thus achieving the stable and reliable operation of the

speeds of main and auxiliary winches is up to 130r/min which ensures the lifting efficiency hydraulic system.

take the lead in industry. ■ Main winch is equipped with over roll-out limiter to prevent over rolling-out of wire rope.

■ The use of new hydraulic control variable slewing system ensures more stable starting and ■ Boom and jib ends are equipped with height limiters respectively to prevent over-hoisting

control of the slewing operation and excellent micro-mobility. of wire rope.

■ Boom head is equipped with linear transducer, angular transducer and press sensor to

indicate the working condition of whole crane in real-time, giving an alarm and cutting off

Control system ■ CAN-bus instrument: CAN-bus instrument with a combined intelligent control electrical

system is used for easy reading of the traveling parameters at any time. The engine fault the dangerous action automatically.

warning function is applied to ensure convenient and fast troubleshooting.

■ Load moment limiter: The adoption of high intelligent load moment limiter system can Counterweight ■ Counterweight is 5500kg, no flexible counterweight.

■ comprehensively protect lifting operation, ensuring accurate, stable and comfort operation.

Luffing system ■ Dynamic luffing provides more stable luffing operation at low energy loss

■ Luffing angle: -2°~ 80°.

Telescopic system ■ Five-section boom is applied with basic boom length of 10.6m, fully extended boom Chassis

length of 40.5m, jib length of 8 m and lifting height of fully extended boom length of 41m

respectively. Max. lifting height is 49m including jib. It is made of high-strength steel with Driving cab ■ Cab is made of new steel material and sealed rubber structure self-developed by SANY,

U-shaped cross section and with telescopic operation controlled independent by dual- featuring excellent shock absorption and tightness, which is configured with swing-out

cylinder rope. doors at both sides, pneumatically suspended driver’s seat and passenger seat, adjustable

steering wheel, large rearview mirror, comfort driver chair with a headrest, anti-fog fan, air

Slewing system ■ 360° rotation can be achieved with Max. slewing speed of 2.5r/min, providing stable and conditioner, stereo radio, and complete control instruments and meters, providing more

reliable operation of the system. comfortable, safe, and humanized operation experience.

Carrier frame ■ Designed and manufactured by SANY, anti-torsion box structure is welded by fine-grain

high-strength steel plate to provide strong load bearing capacity.

Axles ■ Axles 2 and 3 are drive axles and axle 1 is steering axle, axle and wheel differentials are

installed in axles 2 and 3. The use of welding process for axle housing provides stronger

load bearing capacity.

Engine ■ Type: Inline six-cylinder, water cooled, supercharged and inter-cooling diesel engine

■ Rated power: 213kW/2100( r/min)

■ Environment-protection: Emission complies with EuroⅢ standard

■ Capacity of fuel tank: 300L.

Quality Changes the World Quality Changes the World

STC300S-Y2 TRUCK CRANE STC300S-Y2 TRUCK CRANE

8 INTRODUCTION DIMENSION 9

Chassis

Transmission ■ Gearbox: Manual/automatic gearbox is adopted, with 9-gear and large speed ratio range

system applied, which meets the requirements of low gradeability speed and high traveling speed.

■ Transmission shaft: With optimized arrangement of the transmission shaft, the transmission

is stable and reliable.

■ For most optimized transmission, face-tooth coupling transmission shaft is used with large 12850

transmission torque. 10600~40500

Brakes system ■ Air serve brakes are used for all wheels with dual-circuit brake system applied. Engine is

equipped with an exhaust brake.

Suspension system ■ All axles adopt the plate spring suspension systems with plate spring passed 100,000 1345

fatigue tests and with optimization of performance parameters of the front and rear plate

3650

springs applied to ensure strength and also to provide comfort ridding.

2816

2700

Steering system ■ Hydraulic power mechanical steering system is applied for axle 1 with unloading valve

1571

installed in the steering gear.

20°

13°

Outriggers ■ Four-point supporting of the H-shaped outriggers ensures easy operation and strong

1500 2605 4690 1350

stability. They are made of fine-grain high-strength steel sheet. With full hydraulic horizontal

telescoping for flexible outriggers.

Tyres ■ 11 (number of tyres) - type: 11.00-20-18PR; bias tires are used, featuring with large bearing

3100

5300

2200

capacity and durable use.

φ400

Electrical system ■ With 2*12V maintenance-free batteries, the crane power can be cut off manually via a

mechanical master power switch.

6200

2500

R11

R 000

R12 1150

000 0

R10

500

2976.5 2323.5

5300

Quality Changes the World Quality Changes the World

STC300S-Y2 TRUCK CRANE STC300S-Y2 TRUCK CRANE

10 TECHNICAL PARAMETER OPERATION CONDITION 11

STC300S-Y2 Working Ranges

Type Item Parameter

Capacity Max. lifting capacity 30 t 50m

0° 15°

Overall length 12850mm 49

30°

Overall width 2500mm 2.8 48

Dimensions 2.8

47

Overall height 3650mm 2.5 2.7

2.4 2.6 46

Axle distance 4690mm/1350mm

1.9

2.2 45

Overall weight 33000kg 1.75 2

44

2

Weight Front axle load 7100kg 1.7 43

Axle load 1.6

1.7

Rear axle load 25900kg 1.55 42

40.5m

41

Rated power 213kW/2100(r/min) 1.35

Engine 1.45 40

Rated torque 1050N.m/1200~1400rpm 5.8 5.4 1

5 4.65 39

Max.traveling speed 89Km/h 4.3

38

4.1 1 0.9

Turning radius Min.turning radius 10.5m 3.9 37

3.6 0.65

34.89m

Min.ground clearance 220mm 36

3.1

Traveling Approach angle 20º 7.5 7.4 35

2.6 0.7

33.02m

6.8 34

Departure angle 13º 6.35 5.85 0.55

5.8 5.5 5.1 33

Max.gradeability 40% 2.05

Lifting height (m)

5.6 5.4 4.8

5 4.45 32

Fuel consumption per 100km 34.5L 4.5 4.2 0.4

31

.28m

4.1 3.8 1.6

Min.rated range 3m 3.8

30

27.41m 29

3.6 3.4

Tail slewing radius of swingtable 3.47m 10.7 10 9.5 3.05 1.25

29

9 8.6 3.2

8.2 3

Boom section 5 28

6.7 2.4

7.4 7.4 7 7.45

27

Boom shape U-shaped 6.3

5.8

6.3 5.75 2.7 0.95

6.65

5.3 5.35 26

Base boom 1029kN.m 4.8 1.9

23.68m

Main 4.85

25

2.4

performance Max.lifting moment Full-extend boom 573kN.m 4.55 4 4.25 0.75

13 12.5 24

parameters

21.81m

3.7 3.7

Full-extend boom+jib 387kN.m 11.5 1.45

23

12 10.5 3.5 2.1

10 11.1 9.4

Base boom 10.6m 8.8 8.7 3.3 2.95 22

9.5 8 7.5 7.85 3.1 0.6

Boom length Full-extend boom 40.5m 8.4 7 7 21

6.5 6.15 1.1

18.07m

Full-extend boom+jib 48.5m 6 1.8 20

2.2

5.5 2.85

19

Outrigger span (Longitudinal×Transversal) 5.3m×6.2m 19 18 16.5 5 4.6

5.3

16.2m

15.5 14.5 18

Max.single rope lifting speed of main winch (no load) 130m/min 12 11.5 13.5 4.8

10.5 17

10 9.5 12.6 11.25 4 0.8

14.33m

Max.single rope lifting speed of auxiliary winch (no load) 130m/min 24 24

4.5 2.45 1.7 1.4

16

23 21 9 8.5 3.4

9.3 4.3

Working speed Full extension/retraction time of boom 100s/100s 20

18.3

8

15

16.5 7.5 7.7

Full lifting/descending time of boom 45s/55s 3.8 14

14.5 13.3 7

6.5

Slewing speed (0~2.5) r/min 11.5 13

10.6m

6.5 3.3 2.5 1.9 1.32

Superstructure Cold and Heating 30 28 9.45 5.5 12

6 1.1

Air conditioner 26 11

Chassis Cold and Heating 23

21 7.85

4.6

19 10

17 5.5

6.65 9

15

13 4

8

5 2.5 7

6

1.9

11.6 5

4

3

2

1

3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33m

Working Radius (m)

Quality Changes the World Quality Changes the World

STC300S-Y2 TRUCK CRANE STC300S-Y2 TRUCK CRANE

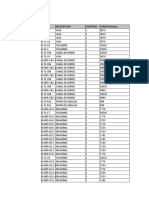

12 LOAD CHART LOAD CHART 13

Unit:Kg Unit:Kg

Prerequisites: Load chart for jib

① Operating condition(fully extended boom +jib)10.6m-40.5m;

② Outrigger length: 6.2m; Boom+jib

③ 360° rotation; Angle of elevation( ° ) 40.5m+8m Angle of elevation( ° )

④ Counterweight: 5.5t. compensation angle0° compensation angle 15° compensation angle 30°

Working Main boom Working 78 2800 2500 1900 78

range(m) 10.6m 14.33m 16.2m 18.07m 21.81m 23.68m 27.41m 29.28m 33.02m 34.89m 40.5m range(m) 75 2800 2400 1750 75

3 30000 24000 3 72 2700 2200 1700 72

70 2600 2000 1600 70

3.5 28000 24000 12000 3.5

65 2000 1700 1350 65

4 26000 23000 11500 19000 10000 4

60 1550 1450 1000 60

4.5 23000 21000 10500 18000 9500 13000 4.5

55 1000 900 700 55

5 21000 20000 10000 16500 8800 12500 7400 10700 5

50 650 550 400 50

5.5 19000 18300 9500 15500 8400 12000 7400 10000 5.5

6 17000 16500 9000 14500 8000 11500 7000 9500 6

Notes:

6.5 15000 14500 8500 13500 7500 11100 6650 9000 5800 7500 6.5 1. Values listed in the table refer to rated lifting capacity measured at flat and solid ground under the lever state of the crane;

7 13000 13300 8000 12600 7000 10500 6300 8600 5600 7400 7 2. Value above heavy line shall be determined by strength of the crane and under this line shall be determined by stability of the crane;

8 11600 11500 7500 11250 6500 9400 5800 8200 5400 6800 8 3. Working radius listed in the load chart is the actual radius with load;

9 9450 7000 9300 6000 8700 5300 7450 5000 6350 5800 9 4. Rated load values determined by stability shall comply with ISO 4305;

10 7850 6500 7700 5500 7850 4800 6700 4500 5850 5400 10 5. Rated lifting capacity listed in the table included weights of lifting hooks (320kg of main hook and 90kg of auxiliary hook)and hangers;

11 6650 6000 6500 5000 7000 4550 6300 4100 5500 5000 11 6. With the 5th outrigger extended, the value listed in the table shall be applicable for 360°operation;

12 5500 5500 4800 6150 4000 5750 3800 5100 4650 12 7. Rated lifting capacity with pulley at boom tip shall not exceed 3500kg. If jib is applied, the rated lifting capacity of the boom shall be

13 5000 4600 4500 5300 3700 5350 3600 4800 4300 13 deducted by 550kg.

14 4000 4300 4600 3500 4850 3400 4450 4100 14 8. If actual boom length and range are between two values specified in the table, larger value will determine the lifting capacity.

15 3800 4000 3300 4250 3200 4200 3900 15

16 3300 3400 3100 3700 3000 3800 3600 16

18 2500 2500 2850 2950 2700 3050 3100 18

20 1900 2450 2200 2400 2400 2600 20

22 1900 1700 2100 1900 2050 22

24 1320 1800 1450 1600 24

26 1400 1100 1250 26

28 1100 800 950 28

30 750 30

32 600 32

Number Number

8 8 6 6 4 4 4 4 4 4 3

of lines of lines

Telescoping

Ⅱ 0 50% 0 100% 0 100% 0 100% 0 100% 100% Ⅱ

Ⅲ 0 0 25% 0 50% 25% 75% 50% 100% 75% 100% Ⅲ

Ⅳ 0 0 25% 0 505 25% 75% 50% 100% 75% 100% Ⅳ

Ⅴ 0 0 25% 0 50% 25% 75% 50% 100% 75% 100% Ⅴ

Quality Changes the World Quality Changes the World

STC300S-Y2 TRUCK CRANE

14 WHEEL CRANE FAMILY MAP

Quality Changes the World

You might also like

- DiabloSport Predator User Manual U7146-1998-2004 Ford VehiclesDocument32 pagesDiabloSport Predator User Manual U7146-1998-2004 Ford Vehicleslazorrazor100% (3)

- Compare Excavators by Specs and CostDocument1 pageCompare Excavators by Specs and Costadityalh67% (3)

- DC G240 eDocument14 pagesDC G240 eHany Mohamed100% (11)

- TD-25M Extra: Engine CoolingDocument7 pagesTD-25M Extra: Engine CoolingJoshwa SimamoraNo ratings yet

- SY35 Vs Competition - V2Document4 pagesSY35 Vs Competition - V2Raj Kumar V RNo ratings yet

- Komatsu - Services WarrantyDocument2 pagesKomatsu - Services WarrantyOZON ccNo ratings yet

- Master Mf6400 WSM 01 enDocument72 pagesMaster Mf6400 WSM 01 enSelmirije2100% (1)

- Power Train Components and SystemsDocument44 pagesPower Train Components and Systemsrayendra100% (4)

- Operation & Maintenance Manual: Delta 8.0m SX Work Boat For Saipem Delta 3Document50 pagesOperation & Maintenance Manual: Delta 8.0m SX Work Boat For Saipem Delta 3Tom Barbedor100% (1)

- New Holland 100hp - 115hp - 135hp - 160hp Section 55 Electrical System - Chapter 9 Part4Document46 pagesNew Holland 100hp - 115hp - 135hp - 160hp Section 55 Electrical System - Chapter 9 Part4DraganMihajlovNo ratings yet

- RS8140 Single Drum CompactorDocument4 pagesRS8140 Single Drum CompactorMartin Lee100% (2)

- Lockup 777Document2 pagesLockup 777Husi Niha100% (1)

- 12H Frein TestDocument13 pages12H Frein TestaniriNo ratings yet

- R220LC-9S (B137) Jeticoconstruction McuadditionaltroubleshootingDocument10 pagesR220LC-9S (B137) Jeticoconstruction McuadditionaltroubleshootingJet acostaNo ratings yet

- Daily Service: Komatsu Small ExcavatorDocument9 pagesDaily Service: Komatsu Small ExcavatorHebert SozinyuNo ratings yet

- Sunward Intelligent Equipment Co.,LtdDocument16 pagesSunward Intelligent Equipment Co.,Ltdconcrete engineeringNo ratings yet

- Komatsu Excavator Pc200 6Document3 pagesKomatsu Excavator Pc200 6rameshjakarta100% (5)

- Komatsu Undercarriage Inspection: PC200LC-8Document1 pageKomatsu Undercarriage Inspection: PC200LC-8automotriz2010No ratings yet

- CAT 777G FiltersDocument3 pagesCAT 777G FiltersettoscarNo ratings yet

- SK28SR-6/SK30SR-6/SK35SR-6 lifting capacitiesDocument12 pagesSK28SR-6/SK30SR-6/SK35SR-6 lifting capacitiesPHÁT NGUYỄN THẾNo ratings yet

- Create PDFs with pdfFactory Pro trial softwareDocument6 pagesCreate PDFs with pdfFactory Pro trial softwareCamilo Andrés Perdomo Velasco100% (1)

- Sany Wheel-Loader SpecSheet 6-10-19Document2 pagesSany Wheel-Loader SpecSheet 6-10-19Akhmad SebehNo ratings yet

- Liebherr 942 Oil FlowDocument10 pagesLiebherr 942 Oil FlowLiebherr100% (2)

- 345 GC Hydraulic Excavator - Technical Specifications (Electronic Only) (LAXB) AEXQ2380Document13 pages345 GC Hydraulic Excavator - Technical Specifications (Electronic Only) (LAXB) AEXQ2380souleymane aboudramane SOOBANo ratings yet

- User Manual 88830539Document8 pagesUser Manual 88830539David GonzalezNo ratings yet

- Improved Doosan DX225LCA ExcavatorDocument11 pagesImproved Doosan DX225LCA ExcavatorRichard Thodé JrNo ratings yet

- Series TF350 180Document2 pagesSeries TF350 180Eka Sugiantoro0% (1)

- Sem 636DDocument2 pagesSem 636DVinoth KumarNo ratings yet

- Brosur Sany SY750-HDocument2 pagesBrosur Sany SY750-Hmbah petrukNo ratings yet

- Ex450lc 5Document7 pagesEx450lc 5anon_485665212100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document7 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768X'mix Dreamer100% (1)

- Diagrama Sistema Hidráulico CAT 777FDocument4 pagesDiagrama Sistema Hidráulico CAT 777FJorge MendozaNo ratings yet

- Mobil: Crane Training Type ArticulatedDocument87 pagesMobil: Crane Training Type ArticulatedRidwanAlwiNo ratings yet

- Inspeccion Visual Ta1 Tractor d6r II (B)Document7 pagesInspeccion Visual Ta1 Tractor d6r II (B)RAMON CALDERONNo ratings yet

- D275a 5R - Cen00228 05Document16 pagesD275a 5R - Cen00228 05Nacer NacerNo ratings yet

- PC1250Document106 pagesPC1250yonathan yonathan100% (1)

- Self Learning Handbook SupportDocument262 pagesSelf Learning Handbook SupportRicky Pradana100% (1)

- 15 Adaptable Komatsu MonoblockDocument4 pages15 Adaptable Komatsu MonoblockJoshua DaltonNo ratings yet

- Sany ForkliftDocument14 pagesSany ForkliftMuhammad IqbalNo ratings yet

- HD465 7E0 (English)Document12 pagesHD465 7E0 (English)Ed OrtizNo ratings yet

- Cat Dcs Sis ControllerDocument2 pagesCat Dcs Sis ControllerIGNACIO GARCIA100% (1)

- PC200 6Document2 pagesPC200 6Naughty VongNo ratings yet

- PC130 8Document20 pagesPC130 8anggieNo ratings yet

- Sany Scc1500e 150 Ton Crawler CranesDocument56 pagesSany Scc1500e 150 Ton Crawler CranesJSP Sudipta SekhNo ratings yet

- Daily inspection report for PC1250-7 excavatorDocument2 pagesDaily inspection report for PC1250-7 excavatorAfrizal Bee Mei AeNo ratings yet

- Dimensi & Terminal Board Saimo Feeder Controller 6105-s5p - 2Document3 pagesDimensi & Terminal Board Saimo Feeder Controller 6105-s5p - 2DangolNo ratings yet

- Caterpillar 390F L Hydraulic Excavator (2017)Document36 pagesCaterpillar 390F L Hydraulic Excavator (2017)Alexis Bustios100% (1)

- Salient Features:: Crawler DozerDocument4 pagesSalient Features:: Crawler DozerSAFE EARTHMOVERSNo ratings yet

- PM Clinic benefits of preventative maintenanceDocument3 pagesPM Clinic benefits of preventative maintenancePurnama AbhieNo ratings yet

- XCMG Wheel Loader LW300KNDocument4 pagesXCMG Wheel Loader LW300KNMeliw WuNo ratings yet

- Sany 250Document9 pagesSany 250arifNo ratings yet

- Cummins Engine Hydraulic Crawler CraneDocument21 pagesCummins Engine Hydraulic Crawler CraneDrajat Darmawan0% (1)

- Cat 320 GCDocument10 pagesCat 320 GCli longNo ratings yet

- Zaxis 50uDocument7 pagesZaxis 50uashokrawat010% (1)

- Western Resume ExampleDocument5 pagesWestern Resume ExampleGage Floyd Bitayo0% (1)

- PC350 350LC-7Document7 pagesPC350 350LC-7bellatobingNo ratings yet

- Bus, Truck Braking Performance Study Reveals Maximum CapabilitiesDocument56 pagesBus, Truck Braking Performance Study Reveals Maximum CapabilitiesdeshpandeamolNo ratings yet

- D8R ComplianceDocument17 pagesD8R ComplianceagegnehutamiratNo ratings yet

- Sany Excavators SY75C Tier 3Document8 pagesSany Excavators SY75C Tier 3csbersama0% (1)

- Komatsu PC 200 VgyDocument4 pagesKomatsu PC 200 VgyPrihandikaAristiasPutra100% (1)

- Crawler Crane-Hitachi Sumitomo SCX550E 55t SpecificationsDocument28 pagesCrawler Crane-Hitachi Sumitomo SCX550E 55t SpecificationsAnonymous hRWwL7pZnCNo ratings yet

- R800 MCV NavigationDocument42 pagesR800 MCV NavigationJorge Rojas100% (1)

- 330 GC ExcavadoraDocument13 pages330 GC ExcavadoraAndres Felipe Marquez GiraldoNo ratings yet

- STC300H Truck Crane 30 Ton Lifting CapacityDocument9 pagesSTC300H Truck Crane 30 Ton Lifting CapacityGermán CampoyNo ratings yet

- Stc300S Truck Crane 30 Tons Lifting CapacityDocument9 pagesStc300S Truck Crane 30 Tons Lifting CapacityKhayra MadinaNo ratings yet

- Truck Crane Stc250 Ir2Document9 pagesTruck Crane Stc250 Ir2ahmadfarrizNo ratings yet

- 8572451Document130 pages8572451carlos aquinoNo ratings yet

- Alloy Steel Astm A 335 t12 PipbesDocument15 pagesAlloy Steel Astm A 335 t12 PipbesBoby SaputraNo ratings yet

- Laser Material Removal Cutting Drilling and Marking 2008 CORD PDFDocument36 pagesLaser Material Removal Cutting Drilling and Marking 2008 CORD PDFcarlos aquinoNo ratings yet

- Boltingwelding January 2014Document84 pagesBoltingwelding January 2014amine bouizarNo ratings yet

- Fatigue Performance of Thermally Cut Bolt Holes in Structural Steel S460MDocument13 pagesFatigue Performance of Thermally Cut Bolt Holes in Structural Steel S460Mcarlos aquinoNo ratings yet

- Daito Crii Aisc Approved Plasma Cut Bolt HolesDocument4 pagesDaito Crii Aisc Approved Plasma Cut Bolt Holescarlos aquinoNo ratings yet

- Torre 1Document90 pagesTorre 1carlos aquinoNo ratings yet

- Minas-A5-2 Manu e PDFDocument512 pagesMinas-A5-2 Manu e PDFRoland von KurnatowskiNo ratings yet

- Daito Crii Aisc Approved Plasma Cut Bolt HolesDocument4 pagesDaito Crii Aisc Approved Plasma Cut Bolt Holescarlos aquinoNo ratings yet

- Conf Driver ImpreDocument2 pagesConf Driver Imprecarlos aquinoNo ratings yet

- Distribution Model ESM_20321_PMMDocument1 pageDistribution Model ESM_20321_PMMcarlos aquinoNo ratings yet

- Conf Driver ImpreDocument2 pagesConf Driver Imprecarlos aquinoNo ratings yet

- DC Disc Brake Details and Specs from ISO Certified ManufacturerDocument5 pagesDC Disc Brake Details and Specs from ISO Certified ManufacturerRitesh AnandNo ratings yet

- Coiler: Type No.890 00 29-34 / 890 00 35-40Document84 pagesCoiler: Type No.890 00 29-34 / 890 00 35-40Khaled RabeaNo ratings yet

- Pyro Critical Interlock ListDocument10 pagesPyro Critical Interlock ListValipireddy NagarjunNo ratings yet

- 2002 MERCEDES-BENZ E 320 (211.065) : General DataDocument2 pages2002 MERCEDES-BENZ E 320 (211.065) : General DataArthur MatoyanNo ratings yet

- Jefferies - Federal Mogul Fairness OpinionDocument65 pagesJefferies - Federal Mogul Fairness Opinionchuff6675No ratings yet

- Torsional Vibration Analysis and Measurement TechniquesDocument14 pagesTorsional Vibration Analysis and Measurement TechniquesCrystal FrazierNo ratings yet

- Vnx.su Дачия СуперноваDocument933 pagesVnx.su Дачия Суперноваcvn2100% (1)

- Service Manual Trucks: Disassembly Instructions, Complete VehicleDocument32 pagesService Manual Trucks: Disassembly Instructions, Complete VehicleKenki HuemuraNo ratings yet

- VW 5-Speed Manual Gearbox 0A4 - ErWin Workshop Manual 2010-04Document210 pagesVW 5-Speed Manual Gearbox 0A4 - ErWin Workshop Manual 2010-04gheorghe2No ratings yet

- Designing Gear RatiosDocument34 pagesDesigning Gear RatiosGODNo ratings yet

- Motor CyclesDocument102 pagesMotor CyclesClariziTa Rakel AraSán100% (1)

- Serie VF, W: Installation, Operation and Maintenance ManualDocument68 pagesSerie VF, W: Installation, Operation and Maintenance ManualWilliam N. CalfaNo ratings yet

- Case IH Magnum 235 – 340 and New Holland T8 Fault Code ListsDocument33 pagesCase IH Magnum 235 – 340 and New Holland T8 Fault Code ListsАндрей МельниченкоNo ratings yet

- ZF 325 Series: Product DetailsDocument4 pagesZF 325 Series: Product DetailsSebastian FagoagaNo ratings yet

- New Insignia Prices FRDocument24 pagesNew Insignia Prices FRNikos Anta TagalhsNo ratings yet

- PublicationDocument94 pagesPublicationMilan Slagalica100% (1)

- Power Assisted Gear Shifting Mechanism For AutomobilesDocument12 pagesPower Assisted Gear Shifting Mechanism For AutomobilesSurendra Chaudhary0% (1)

- Vehicle Identification: Technical Bulletin # 1259Document11 pagesVehicle Identification: Technical Bulletin # 1259Jovan MitrevskiNo ratings yet

- Scania Sops RedaktorDocument7 pagesScania Sops Redaktorscania100% (2)

- Unit - I Dynamics of Electric Drives: Electrical Power Transmission SystemsDocument4 pagesUnit - I Dynamics of Electric Drives: Electrical Power Transmission Systemsyemane gebremichalNo ratings yet

- Faresindustries Catalogue Handlers enDocument28 pagesFaresindustries Catalogue Handlers endan PaulNo ratings yet

- Testing And Adjusting IT28F TransmissionDocument20 pagesTesting And Adjusting IT28F TransmissionEdwin MelendezNo ratings yet

- Camion Minero 979. Parte 2Document35 pagesCamion Minero 979. Parte 2Hules FrankNo ratings yet