Professional Documents

Culture Documents

ELECTRICAL Charging - Service Information - Ram Pickup

ELECTRICAL Charging - Service Information - Ram Pickup

Uploaded by

charlesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ELECTRICAL Charging - Service Information - Ram Pickup

ELECTRICAL Charging - Service Information - Ram Pickup

Uploaded by

charlesCopyright:

Available Formats

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

2014 ELECTRICAL

Charging - Service Information - Ram Pickup

DESCRIPTION

DESCRIPTION

The charging system consists of:

Generator

Electronic Voltage Regulator (EVR) circuitry within the Powertrain Control Module (PCM).

Ignition switch

Battery (refer to BATTERY SYSTEM - SERVICE INFORMATION - 2500 HD & 3500 HD for

information)

Battery temperature sensor

Check Gauges Lamp (if equipped)

Voltmeter (refer to INSTRUMENT PANEL for information)

Wiring harness and connections (refer to SYSTEM WIRING DIAGRAMS for information)

OPERATION

OPERATION

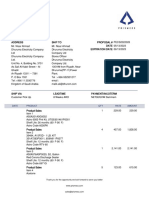

Fig. 1: Charging System

Courtesy of CHRYSLER GROUP, LLC

1 - PCM

2 - PDC

Thursday, November 16, 2017 18:59:23

18:59:20 Page 1

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

3 - Battery

4 - Generator

5 - Feed Back Circuit B+

6 - Control Circuit

7 - Battery Sense

The charging system is turned on and off with the Powertrain Control Module (PCM) and ignition switch with

engine running. The field circuit will not be energized until engine is running and ignition switch on. This

voltage is connected through the PCM and supplied to one of the generator field terminals (Gen. Source B+) at

the back of the generator. The generator is internally grounded. The generator regulates the field using pin-1 of

the field connector (high side driver).

The generator is driven by the engine through a serpentine belt and pulley, or a decoupler pulley arrangement.

The PCM receives a voltage input from the generator (5) and also a battery voltage input (7) from the Power

Distribution Center (PDC), it then compares the voltages to the desired voltage programed in the Electronic

Voltage Regulator (EVR) software, and, if there is a difference it sends a signal to the generator EVR circuit to

increase or decrease output. It uses a Pulse Width Modulation (PWM) to send signals to the generator circuitry

to control the amount of output from the generator. The amount of DC current produced by the generator is

controlled by the EVR circuitry contained within the PCM (1).

All vehicles are equipped with On-Board Diagnostics (OBD). All OBD-sensed systems, including EVR

circuitry, are monitored by the PCM. Each monitored circuit is assigned a Diagnostic Trouble Code (DTC). The

PCM will store a DTC in electronic memory for certain failures it detects.

The Check Gauges Lamp (if equipped) monitors: charging system voltage, engine coolant temperature and

engine oil pressure. If an extreme condition is indicated, the lamp will be illuminated. This is done as reminder

to check the three gauges. The lamp is located on the instrument panel.

Voltage is monitored at the B+ terminal stud to insure it is connected. If the B+ cable is loose, the PCM will

shut down generator field. Because of this new feature, pin-2 of the field connector is internally connected to

the B+ terminal.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - CHARGING SYSTEM

The following procedures may be used to diagnose the charging system if:

the check gauges lamp (if equipped) is illuminated with the engine running

the voltmeter (if equipped) does not register properly

an undercharged or overcharged battery condition occurs.

Remember that an undercharged battery is often caused by:

Thursday, November 16, 2017 18:59:20 Page 2

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

accessories being left on with the engine not running

a faulty or improperly adjusted switch that allows a lamp to stay on for Ignition-Off Draw Test. Refer to

BATTERY, STANDARD PROCEDURE .

INSPECTION

The PCM (Powertrain Control Module) monitors the critical input and output circuits of the charging system,

making sure they are operational. A Diagnostic Trouble Code (DTC) is assigned to each input and output circuit

monitored by the On-Board Diagnostic (OBD) system. Some charging system circuits are checked

continuously, and some are checked only under certain conditions.

Refer to DTC INDEX - 2500 HD & 3500 HD in; Powertrain Control Module for more DTC information.

To perform a complete test of the charging system, use a diagnostic scan tool. Perform the following

inspections before attaching the scan tool.

1. Inspect the battery condition. Refer to INSPECTION .

2. Inspect the condition of battery cable terminals, battery posts, connections at engine block, starter

solenoid and relay. They should be clean and tight. Repair as required.

3. Inspect all fuses in both the fuseblock and the Power Distribution Center (PDC) for tightness in

receptacles. They should be properly installed and tight. Repair or replace as required.

4. Inspect the generator mounting bolts for tightness. Replace or tighten the bolts if required for torque

specifications. Refer to SPECIFICATIONS.

5. Inspect the generator drive belt condition and tension. Tighten or replace the belt as required. Refer to

ACCESSORY DRIVE .

6. Inspect the automatic belt tensioner (if equipped).

7. Inspect the generator electrical connections at generator field, battery output, and ground terminal (if

equipped). Also check the generator ground wire connection at the engine (if equipped). They should all

be clean and tight. Repair as required.

SPECIFICATIONS

GENERATOR RATINGS

TYPE RATED SAE AMPS ENGINES

DENSO 160 3.7L / 4.7L / 5.7L

DENSO 160 6.7L Diesel

DENSO 180 6.7L Diesel

TORQUE - GENERATOR / CHARGING SYSTEM

DESCRIPTION N.m Ft. Lbs. In. Lbs.

Generator Mounting Bolts 50 36 -

Thursday, November 16, 2017 18:59:20 Page 3

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

Generator B+ Output Cable 12 9 125

Terminal Nut

Generator B+ Cable Nut 6.7L

15 - 133

Diesel Engine

Generator Bolts 6.7L Diesel

48 35 -

Engine

GENERATOR

DESCRIPTION

DESCRIPTION

The generator is belt-driven by the engine using a serpentine type drive belt. It is serviced only as a complete

assembly. If the generator fails for any reason, the entire assembly must be replaced.

OPERATION

OPERATION

As the energized rotor begins to rotate within the generator, the spinning magnetic field induces a current into

the windings of the stator coil. Once the generator begins producing sufficient current, it also provides the

current needed to energize the rotor.

The stator winding connections deliver the induced alternating current to 3 or 6 positive and 3 or 6 negative

diodes for rectification. From the diodes, rectified direct current is delivered to the vehicle electrical system

through the generator battery terminal.

Although the generators appear the same externally, different generators with different output ratings are used

on this vehicle. Be certain that the replacement generator has the same output rating and part number as the

original unit. Refer to GENERATOR for amperage ratings and part numbers.

Noise emitting from the generator may be caused by: worn, loose or defective bearings; a loose or defective

drive pulley; incorrect, worn, damaged or misadjusted fan drive belt; loose mounting bolts; a misaligned drive

pulley or a defective stator or diode.

REMOVAL

5.7L

Thursday, November 16, 2017 18:59:20 Page 4

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

Fig. 2: Remove/Install Generator

Courtesy of CHRYSLER GROUP, LLC

WARNING: Disconnect the negative cable from the battery before removing the

battery output wire (B+ wire) from the generator. Failure to do so can

result in injury or damage to the electrical system.

1. Disconnect the negative battery cable.

2. Remove the accessory drive belt. Refer to BELT, SERPENTINE, REMOVAL .

3. Unsnap the plastic insulator cap from the B+ output terminal.

4. Remove the B+ terminal mounting nut at the rear of the generator (1). Disconnect the terminal from the

generator.

5. Disconnect the field wire connector at the rear of generator by pushing on the connector tab.

6. Remove the two generator mounting bolts (2).

7. Remove the generator from the vehicle.

6.4L

Thursday, November 16, 2017 18:59:20 Page 5

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

Fig. 3: Generator - 6.4L

Courtesy of CHRYSLER GROUP, LLC

WARNING: Disconnect the negative cable from the battery before removing the

battery output wire (B+ wire) from the generator. Failure to do so can

result in injury or damage to the electrical system.

1. Disconnect and isolate the negative battery cable.

2. Remove the serpentine belt. Refer to BELT, SERPENTINE, REMOVAL .

3. Unsnap the plastic insulator cap (5) from the B+ output terminal.

4. Remove the B+ terminal mounting nut (2) at the rear of the generator. Disconnect the terminal from the

generator.

5. Disconnect the field wire connector (6) at the rear of the generator by pushing on the connector tab.

Thursday, November 16, 2017 18:59:20 Page 6

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

Fig. 4: Generator, Bolts & Connector

Courtesy of CHRYSLER GROUP, LLC

6. Remove the mounting bolts (3).

7. Remove the generator (1) from vehicle.

6.4L - DUAL

WARNING: Disconnect the negative cable from the battery before removing the

battery output wire (B+ wire) from the generator. Failure to do so can

result in injury or damage to the electrical system.

Fig. 5: Removing/Installing Belt

Courtesy of CHRYSLER GROUP, LLC

1. Disconnect and isolate the negative battery cable.

2. Remove the secondary accessory drive belt. Refer to BELT, SERPENTINE, REMOVAL .

Thursday, November 16, 2017 18:59:20 Page 7

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

Fig. 6: Generator - 6.4L

Courtesy of CHRYSLER GROUP, LLC

3. If required, remove the secondary generator wiring harness (3) from the intake manifold.

4. Partially raise the vehicle.

5. Remove the right front wheel.

6. Remove the inner splash shield.

Fig. 7: Generator, Insulator Cap, B+ Output Terminal & Connector

Courtesy of CHRYSLER GROUP, LLC

7. Unsnap the plastic insulator cap (4) from the B+ output terminal (2).

8. Remove the B+ terminal mounting nut (3) at the rear of the generator. Disconnect the terminal from the

generator.

9. Disconnect the field wire connector (1) at the rear of the generator by pushing on the connector tab.

Thursday, November 16, 2017 18:59:20 Page 8

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

Fig. 8: Generator, Insulator Cap, B+ Output Terminal & Connector

Courtesy of CHRYSLER GROUP, LLC

10. Remove the front mounting bolts (2).

11. Remove the side mount bolt (4).

Fig. 9: Generator & Heater Hose

Courtesy of CHRYSLER GROUP, LLC

12. Using care, remove the generator (1) past the heater hose (2).

13. Remove the generator (3) from vehicle.

6.7L DIESEL

Thursday, November 16, 2017 18:59:20 Page 9

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

Fig. 10: Installing Field Wire Connector

Courtesy of CHRYSLER GROUP, LLC

WARNING: Disconnect both negative cables from both batteries before removing

battery output wire (B+ wire) from generator. Failure to do so can result in

injury or damage to electrical system.

1. Disconnect both negative battery cables.

2. Remove the serpentine drive belt. Refer to BELT, SERPENTINE, REMOVAL .

3. Disconnect field wire connector (3) from the generator.

Thursday, November 16, 2017 18:59:20 Page 10

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

Fig. 11: Removing Generator B+ Cable & Nut

Courtesy of CHRYSLER GROUP, LLC

4. Unsnap plastic insulator cap (1) from B+ output terminal.

5. Remove nut (2) and the B+ cable (1) from generator.

Fig. 12: Removing Generator & Bolts

Thursday, November 16, 2017 18:59:20 Page 11

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

Courtesy of CHRYSLER GROUP, LLC

6. Remove bolts (2) and the generator (1) from engine.

6.7L DIESEL-DUAL

WARNING: Disconnect both negative cables from both batteries before removing

battery output wire (B+ wire) from generator. Failure to do so can result in

injury or damage to electrical system.

1. Disconnect both negative battery cables.

2. Remove engine oil dipstick.

3. Remove fasteners and the engine cover.

4. Remove the serpentine drive belt. Refer to BELT, SERPENTINE, REMOVAL .

5. Partially drain the cooling system. Refer to STANDARD PROCEDURE .

6. Disconnect the upper radiator hose at the radiator.

7. Remove bolt and the upper radiator hose support bracket.

8. Disconnect field wire connector (3) from the generator.

9. Unsnap plastic insulator cap (1) from B+ output terminal.

10. Remove nut (2) and the B+ cable (1) from generator.

Fig. 13: Removing Generator & Bolt

Courtesy of CHRYSLER GROUP, LLC

11. Remove bolts (2) and the generator (1) from engine.

Thursday, November 16, 2017 18:59:20 Page 12

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

Fig. 14: Removing Lower Generator Mounting Bracket Bolts

Courtesy of CHRYSLER GROUP, LLC

12. If necessary, remove the lower generator mounting bracket bolts (1).

Fig. 15: Removing Generator Mounting Bracket & Bolt

Courtesy of CHRYSLER GROUP, LLC

Thursday, November 16, 2017 18:59:20 Page 13

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

13. If necessary, remove bolts (1) and the generator mounting bracket (2).

INSTALLATION

5.7L

Fig. 16: Remove/Install Generator

Courtesy of CHRYSLER GROUP, LLC

1. Position the generator (2) to the engine and install the two mounting bolts (2). Tighten to 50 N.m (36 ft.

lbs.).

2. Snap the field wire connector into the rear of the generator.

3. Install the B+ terminal eyelet to the generator output stud. Tighten mounting nut to 12 N.m (8.8 ft. lbs.).

CAUTION: Never force a belt over a pulley rim using a screwdriver. The

synthetic fiber of the belt can be damaged.

CAUTION: When installing a serpentine accessory drive belt, the belt must be

routed correctly. The water pump may be rotating in the wrong

direction if the belt is installed incorrectly, causing the engine to

overheat. Refer to belt routing label in engine compartment, or refer

to ACCESSORY DRIVE .

4. Install the accessory drive belt. Refer to BELT, SERPENTINE, INSTALLATION .

5. Connect the negative battery cable.

6.4L

Thursday, November 16, 2017 18:59:20 Page 14

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

Fig. 17: Generator, Bolts & Connector

Courtesy of CHRYSLER GROUP, LLC

1. Position the generator (1) to the engine.

2. Install the mounting bolts (3). Torque the bolts to 50 N.m (37 ft. lbs.).

Fig. 18: Generator - 6.4L

Courtesy of CHRYSLER GROUP, LLC

3. Snap the field wire connector (6) into the rear of the generator.

4. Install the B+ terminal eyelet (1) to the generator output stud.

Tighten the mounting nut (2) to 12 N.m (106 in. lbs.).

CAUTION: Never force a belt over a pulley rim using a screwdriver. The

Thursday, November 16, 2017 18:59:20 Page 15

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

synthetic fiber of the belt can be damaged.

CAUTION: When installing a serpentine accessory drive belt, the belt must be

routed correctly. The water pump may be rotating in the wrong

direction if the belt is installed incorrectly, causing the engine to

overheat. Refer to belt routing label in engine compartment, or refer

to ACCESSORY DRIVE .

5. Install the serpentine belt. Refer to BELT, SERPENTINE, INSTALLATION .

6. Install the negative battery cable.

6.4L - DUAL

Fig. 19: Generator, Insulator Cap, B+ Output Terminal & Connector

Courtesy of CHRYSLER GROUP, LLC

1. Position the generator (3) to the engine.

2. Hand start the upper side bolt (4).

3. Install the mounting bolts (3). Torque the bolts to 50 N.m (37 ft. lbs.).

4. Torque the upper side bolt to 50 N.m (37 ft. lbs.).

Thursday, November 16, 2017 18:59:20 Page 16

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

Fig. 20: Generator, Insulator Cap, B+ Output Terminal & Connector

Courtesy of CHRYSLER GROUP, LLC

5. Snap the field wire connector (1) into the rear of the generator.

6. Install the B+ terminal eyelet (2) to the generator output stud.

Tighten the mounting nut (3) to 12 N.m (106 in. lbs.).

Fig. 21: Removing/Installing Belt

Courtesy of CHRYSLER GROUP, LLC

7. Install the secondary generator accessory drive belt (3). Refer to BELT, SERPENTINE,

INSTALLATION .

8. Install the inner splash shield.

9. Install the right front wheel.

Thursday, November 16, 2017 18:59:20 Page 17

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

10. Lower the vehicle.

Fig. 22: Generator - 6.4L

Courtesy of CHRYSLER GROUP, LLC

11. If removed, install the secondary generator wiring harness (3) to the intake manifold.

CAUTION: Never force a belt over a pulley rim using a screwdriver. The

synthetic fiber of the belt can be damaged.

CAUTION: When installing a serpentine accessory drive belt, the belt must be

routed correctly. The water pump may be rotating in the wrong

direction if the belt is installed incorrectly, causing the engine to

overheat. Refer to belt routing label in engine compartment, or refer

to ACCESSORY DRIVE .

12. Install the negative battery cable.

6.7L DIESEL

Thursday, November 16, 2017 18:59:20 Page 18

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

Fig. 23: Removing Generator & Bolts

Courtesy of CHRYSLER GROUP, LLC

1. Install the generator (1). Tighten bolts (2) to 48 N.m (35 ft. lbs.).

Fig. 24: Removing Generator B+ Cable & Nut

Courtesy of CHRYSLER GROUP, LLC

Thursday, November 16, 2017 18:59:20 Page 19

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

2. Install B+ terminal eyelet to generator output stud. Tighten nut to 15 N.m (133 in. lbs.).

3. Snap the plastic insulator cap (1) onto B+ output terminal.

Fig. 25: Installing Field Wire Connector

Courtesy of CHRYSLER GROUP, LLC

CAUTION: Never force a belt over a pulley rim using a screwdriver. The

synthetic fiber of the belt can be damaged.

CAUTION: When installing a serpentine accessory drive belt, the belt must be

routed correctly. The water pump may be rotating in the wrong

direction if the belt is installed incorrectly, causing the engine to

overheat. Refer to belt routing label in engine compartment, or refer

to ACCESSORY DRIVE .

4. Connect the field wire connector (1) into the generator.

5. Install the serpentine drive belt. Refer to BELT, SERPENTINE, INSTALLATION .

Install both negative battery cables.

6.7L DIESEL-DUAL

Thursday, November 16, 2017 18:59:20 Page 20

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

Fig. 26: Removing Generator Mounting Bracket & Bolt

Courtesy of CHRYSLER GROUP, LLC

1. If removed, install the generator mounting bracket (2). Tighten bolts (1) 60 N.m (44 ft. lbs.).

Fig. 27: Removing Lower Generator Mounting Bracket Bolts

Courtesy of CHRYSLER GROUP, LLC

Thursday, November 16, 2017 18:59:20 Page 21

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

2. If removed, install the lower generator mounting bracket bolts (1) and tighten to 33 N.m (24 ft. lbs.).

Fig. 28: Removing Generator & Bolt

Courtesy of CHRYSLER GROUP, LLC

3. Install the generator (1). Tighten bolts (2) to 65 N.m (48 ft. lbs.).

4. Install B+ terminal eyelet to generator output stud. Tighten nut to 15 N.m (133 in. lbs.).

5. Snap the plastic insulator cap (1) onto B+ output terminal.

6. Connect the field wire connector (1) into the generator.

7. Install the upper radiator hose support bracket. Tighten bolt to 15 N.m (133 in. lbs.).

8. Connect the upper radiator hose at the radiator.

9. Fill the cooling system. Refer to STANDARD PROCEDURE .

CAUTION: Never force a belt over a pulley rim using a screwdriver. The

synthetic fiber of the belt can be damaged.

CAUTION: When installing a serpentine accessory drive belt, the belt must be

routed correctly. The water pump may be rotating in the wrong

direction if the belt is installed incorrectly, causing the engine to

overheat. Refer to belt routing label in engine compartment, or refer

to ACCESSORY DRIVE .

10. Install the serpentine drive belt. Refer to BELT, SERPENTINE, INSTALLATION .

11. Install the engine cover and fasteners.

Thursday, November 16, 2017 18:59:20 Page 22

2014 RAM 3500 HD Laramie

2014 ELECTRICAL Charging - Service Information - Ram Pickup

12. Install the engine oil dipstick.

13. Install both negative battery cables.

REGULATOR, VOLTAGE

DESCRIPTION

DESCRIPTION

The Electronic Voltage Regulator (EVR) is not a separate component. It is actually a voltage regulating circuit

located within the PCM (Powertrain Control Module). The EVR is not serviced separately. If replacement is

necessary, the PCM must be replaced.

OPERATION

OPERATION

The amount of direct current produced by the generator is controlled by EVR circuitry contained within the

PCM. This circuitry is connected in series with the generators second rotor field terminal and its ground.

Voltage is regulated by cycling the battery positive path to control the strength of the rotor magnetic field. The

EVR circuitry monitors system line voltage (B+) and battery temperature (refer to SENSOR, INTELLIGENT

BATTERY (IBS) for more information). It then determines a target charging voltage. If sensed battery voltage

is 0.5 volts or lower than the target voltage, the PCM grounds the field winding until sensed battery voltage is

0.5 volts above target voltage. A circuit in the PCM cycles the battery positive (high side) of the generator field

up to 400 times per second (400Hz), but has the capability to ground the field control wire 100% of the time

(full field) to achieve the target voltage. If the charging rate cannot be monitored (limp-in), a duty cycle of 25%

is used by the PCM in order to have some generator output for additional information. Refer to OPERATION.

Thursday, November 16, 2017 18:59:20 Page 23

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Bjooks Pedalcrush SampleDocument20 pagesBjooks Pedalcrush Sampleaaronice178% (9)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- TRANSFER CASE BW44-46 - Service Information - Ram Pickup PDFDocument42 pagesTRANSFER CASE BW44-46 - Service Information - Ram Pickup PDFcharles100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- TRANSFER CASE BW44-47 - Service Information - Ram Pickup PDFDocument60 pagesTRANSFER CASE BW44-47 - Service Information - Ram Pickup PDFcharles100% (1)

- System Wiring Diagrams Ram - 3500 HD 1 of 2Document167 pagesSystem Wiring Diagrams Ram - 3500 HD 1 of 2charlesNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- MANUAL TRANSMISSION G56 - Service Information - Ram Pickup PDFDocument101 pagesMANUAL TRANSMISSION G56 - Service Information - Ram Pickup PDFcharlesNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- TRANSFER CASE Final Drive Control Module (FDCM) - Electrical Diagnostics - Ram Pickup PDFDocument139 pagesTRANSFER CASE Final Drive Control Module (FDCM) - Electrical Diagnostics - Ram Pickup PDFcharlesNo ratings yet

- SYSTEM WIRING DIAGRAMS RAM - 3500 HD 2 of 2 PDFDocument97 pagesSYSTEM WIRING DIAGRAMS RAM - 3500 HD 2 of 2 PDFcharlesNo ratings yet

- STEERING Steering Control Module (SCM) - Electrical Diagnostics - Ram Pickup PDFDocument59 pagesSTEERING Steering Control Module (SCM) - Electrical Diagnostics - Ram Pickup PDFcharlesNo ratings yet

- Winchester Model 1885 2Document13 pagesWinchester Model 1885 2carlosfanjul1No ratings yet

- Approach May June12Document36 pagesApproach May June12charlesNo ratings yet

- Azure Transit Vnet Deployment GuideDocument178 pagesAzure Transit Vnet Deployment GuidecharlesNo ratings yet

- SUSPENSION Rear Suspension - Ram Pickup PDFDocument67 pagesSUSPENSION Rear Suspension - Ram Pickup PDFcharlesNo ratings yet

- GENERAL INFORMATION Vehicle Quick Reference - Ram Pickup PDFDocument57 pagesGENERAL INFORMATION Vehicle Quick Reference - Ram Pickup PDFcharlesNo ratings yet

- SUSPENSION Front Air Suspension Control Module (ASCM) - Electrical Diagnostics - Ram Pickup PDFDocument236 pagesSUSPENSION Front Air Suspension Control Module (ASCM) - Electrical Diagnostics - Ram Pickup PDFcharles100% (1)

- SUSPENSION Tires & Wheels - Service Information - Ram Pickup PDFDocument49 pagesSUSPENSION Tires & Wheels - Service Information - Ram Pickup PDFcharlesNo ratings yet

- SUSPENSION Front Suspension & Wheel Alignment - Ram Pickup PDFDocument86 pagesSUSPENSION Front Suspension & Wheel Alignment - Ram Pickup PDFcharlesNo ratings yet

- Suspension Ram Wheel Alignment Specifications PDFDocument22 pagesSuspension Ram Wheel Alignment Specifications PDFcharlesNo ratings yet

- REMINDER INDICATOR RESET PROCEDURES Chrysler Dodge Plymouth RAM - 1978-14 PDFDocument22 pagesREMINDER INDICATOR RESET PROCEDURES Chrysler Dodge Plymouth RAM - 1978-14 PDFcharlesNo ratings yet

- STEERING Steering System - Ram Pickup PDFDocument96 pagesSTEERING Steering System - Ram Pickup PDFcharlesNo ratings yet

- HVAC Heating & Air Conditioning - Service Information - Ram Pickup PDFDocument200 pagesHVAC Heating & Air Conditioning - Service Information - Ram Pickup PDFcharlesNo ratings yet

- RESTRAINTS Service Information - Ram Pickup PDFDocument146 pagesRESTRAINTS Service Information - Ram Pickup PDFcharlesNo ratings yet

- GENERAL INFORMATION Circuit Testing Procedures - Non-DTC-Based Diagnostics - Ram Pickup PDFDocument51 pagesGENERAL INFORMATION Circuit Testing Procedures - Non-DTC-Based Diagnostics - Ram Pickup PDFcharlesNo ratings yet

- GENERAL INFORMATION Vehicle Data - Ram Pickup PDFDocument14 pagesGENERAL INFORMATION Vehicle Data - Ram Pickup PDFcharlesNo ratings yet

- HVAC Heating & Air Conditioning - Electrical Diagnostics - Ram Pickup PDFDocument213 pagesHVAC Heating & Air Conditioning - Electrical Diagnostics - Ram Pickup PDFcharlesNo ratings yet

- ENGINE PERFORMANCE Emissions Control - Ram Pickup PDFDocument138 pagesENGINE PERFORMANCE Emissions Control - Ram Pickup PDFcharlesNo ratings yet

- ENGINE 6.4L - Service Information - Ram Pickup PDFDocument294 pagesENGINE 6.4L - Service Information - Ram Pickup PDFcharlesNo ratings yet

- ENGINE Starting - Service Information - Ram Pickup PDFDocument27 pagesENGINE Starting - Service Information - Ram Pickup PDFcharlesNo ratings yet

- ENGINE Fuel System - Ram Pickup PDFDocument391 pagesENGINE Fuel System - Ram Pickup PDFcharlesNo ratings yet

- ENGINE PERFORMANCE Driveability - Diesel - Non-DTC Based Diagnostics, 6.7L Diesel - Ram Pickup PDFDocument73 pagesENGINE PERFORMANCE Driveability - Diesel - Non-DTC Based Diagnostics, 6.7L Diesel - Ram Pickup PDFcharlesNo ratings yet

- ENGINE Ignition System - Service Information - Ram Pickup PDFDocument20 pagesENGINE Ignition System - Service Information - Ram Pickup PDFcharlesNo ratings yet

- ENGINE 6.7L Diesel - Service Information - Ram Pickup PDFDocument317 pagesENGINE 6.7L Diesel - Service Information - Ram Pickup PDFcharles100% (2)

- ENGINE Cooling System - Ram Pickup PDFDocument213 pagesENGINE Cooling System - Ram Pickup PDFcharlesNo ratings yet

- JOSE FERNANDEZ, Emilio Macias, Eddy Rivero AUTOPSY REPORTSDocument23 pagesJOSE FERNANDEZ, Emilio Macias, Eddy Rivero AUTOPSY REPORTSSyndicated NewsNo ratings yet

- Covidien ForceTriad ESU - Service Manual PDFDocument212 pagesCovidien ForceTriad ESU - Service Manual PDFsergio ribeiroNo ratings yet

- Working at Maintenance Shop-Sheet metal-JOB PROCEDURE - 2Document2 pagesWorking at Maintenance Shop-Sheet metal-JOB PROCEDURE - 2ananthu.uNo ratings yet

- NewItem 158 MSIHC-REPORTDocument77 pagesNewItem 158 MSIHC-REPORTANKUSHNo ratings yet

- FAQs - Regulation On Safety, Equity, and Quality of Health Goods and ServicesDocument2 pagesFAQs - Regulation On Safety, Equity, and Quality of Health Goods and ServicesPhilippe Ceasar C. BascoNo ratings yet

- Micro Shelter Product Description V5aDocument11 pagesMicro Shelter Product Description V5aIan JaredNo ratings yet

- Check User's Sign-In Activity Logs Log On AAD Portal Active Directory Activity Sing inDocument3 pagesCheck User's Sign-In Activity Logs Log On AAD Portal Active Directory Activity Sing inGauriNo ratings yet

- Question Bank of Managerial Economics - 4 MarkDocument23 pagesQuestion Bank of Managerial Economics - 4 MarklakkuMS100% (4)

- Estimate PECS2022028Document2 pagesEstimate PECS2022028Baqar RazaNo ratings yet

- RIT Housing ConditionsDocument64 pagesRIT Housing ConditionsAhmed AlnabhanNo ratings yet

- Heat (1995 Film) - Wikipedia PDFDocument45 pagesHeat (1995 Film) - Wikipedia PDFRahul RameshNo ratings yet

- Pesticide Spraying Agricultural RobotDocument5 pagesPesticide Spraying Agricultural RobotPremier Publishers100% (1)

- Daniels Criteria - EKG in PEDocument10 pagesDaniels Criteria - EKG in PEbrookswalsh100% (2)

- What Is Investment - Investment Meaning, Types, ObjectivesDocument9 pagesWhat Is Investment - Investment Meaning, Types, Objectiveshavo lavoNo ratings yet

- Cape Communication Studies-Wk 1-2 PDFDocument50 pagesCape Communication Studies-Wk 1-2 PDFSchannelNo ratings yet

- Guía Cátedra GH 2021-2Document8 pagesGuía Cátedra GH 2021-2Juan Diego VergelNo ratings yet

- Petroleum - HTML: International Petroleum Agreements-1: Politics, Oil Prices Steer Evolution of Deal FormsDocument6 pagesPetroleum - HTML: International Petroleum Agreements-1: Politics, Oil Prices Steer Evolution of Deal FormsEmil İsmayilovNo ratings yet

- 0150511191-A-MH2VYHAS - 150506 Standard Ambinent Outdoor 380-3-50&60 PDFDocument52 pages0150511191-A-MH2VYHAS - 150506 Standard Ambinent Outdoor 380-3-50&60 PDFArshad Mahmood100% (1)

- Practice Questions 1Document5 pagesPractice Questions 1Div_nNo ratings yet

- Htadd3w enDocument25 pagesHtadd3w enkivijakolaNo ratings yet

- Knowledge Attitudes and Practices of Medical StudeDocument6 pagesKnowledge Attitudes and Practices of Medical StudeDinie BidiNo ratings yet

- Famous Architect Antoni GaudiDocument4 pagesFamous Architect Antoni GaudiChicken NoodlesNo ratings yet

- Astrological Tables of Houses Part-3Document38 pagesAstrological Tables of Houses Part-3Karanam.Ramakumar67% (3)

- Interview With Agriclture & Industry SurveyDocument2 pagesInterview With Agriclture & Industry SurveyAshok JainNo ratings yet

- Module 6Document3 pagesModule 6Jenn AmaroNo ratings yet

- 77 PubDocument6 pages77 PubMojtaba JabbariNo ratings yet

- Two Mallet Technique KeysDocument1 pageTwo Mallet Technique KeysBrian MoralesNo ratings yet

- Summary OracleDocument39 pagesSummary OracleRoel DonkerNo ratings yet