Professional Documents

Culture Documents

Cement testing and storage requirements

Uploaded by

SABEASNOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cement testing and storage requirements

Uploaded by

SABEASNCopyright:

Available Formats

testing as per BS orSLS.

Any extra test instructed by the Engineer whose result proves the material to be out

ofspecification shall be carried out at no extra cost. If for any reason the period of storage ofconsignment of

cement exceeds three months, a representative sample of the cement shall be retestedto confirm its suitability

before use at no extra cost.

The Contractor shall provide suitable means of storing and protecting the cement against dampness, Cement

which, for any reason has become partially set or which contains lumps of caked cement shall be rejected.

No additives for cement shall be used unless agreed by the Engineer.

1703.1 Cement Grout

Cement grout for grouting dowels shall consist of Ordinary Portland Cement (OPC) and water mixed in the

proportions necessary for the intended purpose.

Cement used for grouting soil nails shall be Type – A, Portland cement complying with (BS196 or

BS197).Grout material should be non-expansive and non-shrinkage material. Therefore, admixture has to be

added to avoid shrinkage effect of cement. The Contractor should be obtained prior approval for the

admixture before use site at site from the Engineer.

The grout shall be mixed until a uniform consistency is obtained and shall normally be used within 45 minutes

of mixing.

1703.2 Cement Mortar

No change

1704 CONCRETE ADMIXTURE (Chapter 1000 and others)

Concrete admixture as retarders, accelerators or as plasticizers shall be used with the prior approval of the

Engineer only and they shall be used strictly in accordance with the manufacturer’s recommendations.

In the use of additives particular attention should be paid to the accurate proportioning of the additive and its

homogeneous introduction in the mix.

1705 NOT USED

1706 NOT USED

1707 NOT USED

1708 SOILS

a. Filling Work

(a) Type IFilling Material and (b) Type IIFilling Material and substitutethe following:

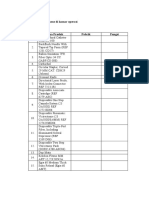

Table1708-1:Material Characteristics for Filling - Type I and Type II

SPECIFICATION LIMIT

PROPERTY TEST METHOD

FILLING TYPE I FILLING TYPE II

Liquid Limit (LL) % AASHTO T89 ≤ 50 ≤ 55

Plasticity Index (PI) % AASHTO T90 ≤ 25 ≤ 25

Maximum Dry Density

AASHTO T180 ≥ 1,600 ≥ 1,500

(MDD) (Modified proctor BS 1377: Part 4

Test) kg/m3

1709 NOT USED

1710 GEOTEXTILES / GEOFABRIC

You might also like

- Bortoft. The Wholeness of Nature - Goethe's Way Toward A Science of Conscious Participation in Nature (1996) PDFDocument1,175 pagesBortoft. The Wholeness of Nature - Goethe's Way Toward A Science of Conscious Participation in Nature (1996) PDFBlaise0986% (7)

- Essential Rubber Formulary: Formulas for PractitionersFrom EverandEssential Rubber Formulary: Formulas for PractitionersRating: 3 out of 5 stars3/5 (1)

- Oem ManualDocument38 pagesOem ManualMohamed Rashed100% (4)

- Jean Epstein - MagnificationDocument18 pagesJean Epstein - MagnificationPhoronidNo ratings yet

- M 295 DesDocument5 pagesM 295 DesJuan Daniel Rojas Palma100% (1)

- M85-17 Cemento PortlandDocument16 pagesM85-17 Cemento PortlandDannyChaconNo ratings yet

- BS 3900 Pull Off TestDocument9 pagesBS 3900 Pull Off TestHassan FekiNo ratings yet

- Sprayed Concrete SpecificationDocument16 pagesSprayed Concrete Specificationtinz_3100% (2)

- M 80-87 (2003) Coarse Aggregate For PCCDocument5 pagesM 80-87 (2003) Coarse Aggregate For PCCWalticoZegarraHerrera100% (1)

- P-304 Cement Treated Base CourseDocument11 pagesP-304 Cement Treated Base CourseSpiros Licoudis100% (1)

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringFrom EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringRating: 4 out of 5 stars4/5 (5)

- Student Exploration: Energy Conversion in A SystemDocument5 pagesStudent Exploration: Energy Conversion in A SystemCassie BNo ratings yet

- CEMENT SPECIFICATIONS AND REQUIREMENTSDocument3 pagesCEMENT SPECIFICATIONS AND REQUIREMENTSSABEASNNo ratings yet

- Semen PDFDocument324 pagesSemen PDFpaimannNo ratings yet

- Technical Guideline Part 1Document6 pagesTechnical Guideline Part 1Mochamad BhadawiNo ratings yet

- RDSO Specification of HDPE PipeDocument20 pagesRDSO Specification of HDPE Pipelinus200No ratings yet

- Concrete Block Masonry SpecificationsDocument11 pagesConcrete Block Masonry SpecificationsPreston VargheseNo ratings yet

- AdmixtureDocument4 pagesAdmixturecoorgguy123No ratings yet

- Astm Cal C1707Document3 pagesAstm Cal C1707Ivan GuerreroNo ratings yet

- Annex 4.1 - Technical Specifications - Civil WorksDocument6 pagesAnnex 4.1 - Technical Specifications - Civil WorksMW ALSABRINo ratings yet

- DPWH Approves Epoxy Asphalt Pavement TechnologyDocument5 pagesDPWH Approves Epoxy Asphalt Pavement TechnologyFaustino AbadNo ratings yet

- Astm C1707Document3 pagesAstm C1707Jino LegastoNo ratings yet

- Example of Stress Absorbing Membrane InterlayerDocument7 pagesExample of Stress Absorbing Membrane Interlayershanil3001No ratings yet

- 3CC System Performance SpecificationDocument1 page3CC System Performance SpecificationAnonymous qTP5oq7gNo ratings yet

- Astm C150-2009Document10 pagesAstm C150-2009Nathan Blackburn100% (1)

- IRS Guidelins HPCDocument12 pagesIRS Guidelins HPCsaritasohamNo ratings yet

- Lisqn Iksvzysam Lhesav Fof'Kf"V: HKKJRH EkudDocument13 pagesLisqn Iksvzysam Lhesav Fof'Kf"V: HKKJRH EkudRaghav TiwaryNo ratings yet

- ASTM C1707Document3 pagesASTM C1707adolfo camayoNo ratings yet

- OPSS - PROV 1101 - Nov 2020Document9 pagesOPSS - PROV 1101 - Nov 2020Samantha McLachlinNo ratings yet

- Section R8 Double Bituminous Surface DressingDocument13 pagesSection R8 Double Bituminous Surface DressingBALEN KAKLNo ratings yet

- 3CC System Technical SpecificationDocument3 pages3CC System Technical SpecificationAnonymous qTP5oq7gNo ratings yet

- Section R10Document26 pagesSection R10BALEN KAKLNo ratings yet

- A3 Conc. Classification PDFDocument25 pagesA3 Conc. Classification PDFUsman Afzal50% (2)

- Guidelines for Using Ready Mixed ConcreteDocument10 pagesGuidelines for Using Ready Mixed Concretegangulyranjith6112No ratings yet

- Everdure Caltite System - Technical SpecificationDocument3 pagesEverdure Caltite System - Technical SpecificationAnonymous qTP5oq7gNo ratings yet

- M 157-06 Ready-Mixed ConcreteDocument14 pagesM 157-06 Ready-Mixed ConcreteFRANZ RICHARD SARDINAS MALLCONo ratings yet

- ASTRU - Vulcanising Cement, Cushion GumDocument7 pagesASTRU - Vulcanising Cement, Cushion GumBharat Chatrath50% (2)

- Grout Rev.c PDFDocument6 pagesGrout Rev.c PDFMithun UdayanarayanaNo ratings yet

- Materials Guide for Construction ProjectsDocument52 pagesMaterials Guide for Construction ProjectsRyanNo ratings yet

- 32 Bitumen MasticDocument4 pages32 Bitumen MasticArul Mozhi VarmanNo ratings yet

- Test 2 Build Private Limited: Work InstructionsDocument4 pagesTest 2 Build Private Limited: Work InstructionsVallavarajanNo ratings yet

- Anti Stripping AgentDocument1 pageAnti Stripping Agentdiana aznanNo ratings yet

- MaterialsDocument295 pagesMaterialshthanhbinh166No ratings yet

- Es-2730-Hot Mix Asph Conc PaveDocument7 pagesEs-2730-Hot Mix Asph Conc Paveraghav abudhabiNo ratings yet

- M 6-03 Fine Aggregate For PCC PDFDocument6 pagesM 6-03 Fine Aggregate For PCC PDFWalticoZegarraHerrera100% (1)

- Comprehensive Training For DPWHDocument1 pageComprehensive Training For DPWHkyliegNo ratings yet

- Mastic Asphalt Wearing Course SurfacingDocument18 pagesMastic Asphalt Wearing Course SurfacingSoumitra SengarNo ratings yet

- Portland Cement: Standard Specification ForDocument9 pagesPortland Cement: Standard Specification ForPérez NelsonNo ratings yet

- Portland Cement ConcreteDocument15 pagesPortland Cement ConcreteIm ChinithNo ratings yet

- Civil Guidelines and SpecificationsDocument65 pagesCivil Guidelines and SpecificationshardikNo ratings yet

- APP ICF SpecificationDocument71 pagesAPP ICF SpecificationSudheep DuraiNo ratings yet

- Asphalt Additives and Modifiers: Standard Practice ForDocument7 pagesAsphalt Additives and Modifiers: Standard Practice ForXarmdNo ratings yet

- CTS Grout Standard Non Shrink Master Specification Rev 11 2015Document6 pagesCTS Grout Standard Non Shrink Master Specification Rev 11 2015Wilfredo GarciaNo ratings yet

- Astm C618 19Document2 pagesAstm C618 19maniharimeenaNo ratings yet

- Specs-Pavement MarkingsDocument4 pagesSpecs-Pavement MarkingsAnsar Bedharudeen100% (1)

- M&C-PCN-100-2013 DraftDocument31 pagesM&C-PCN-100-2013 DraftManoj KumarNo ratings yet

- Material Specification For Thermoplastic Pavement Marking MaterialsDocument10 pagesMaterial Specification For Thermoplastic Pavement Marking MaterialsTony ParkNo ratings yet

- AdmixturesDocument9 pagesAdmixturesIm ChinithNo ratings yet

- PCN 100 2018Document33 pagesPCN 100 2018NITIN GUPTANo ratings yet

- Astm C150Document9 pagesAstm C150npwal0% (1)

- Bidding Document-Rio-21-01-008Document58 pagesBidding Document-Rio-21-01-008Sen LinNo ratings yet

- (JD - II1'1I": Department of Public Works and Highways .U.Document6 pages(JD - II1'1I": Department of Public Works and Highways .U.jonathanNo ratings yet

- Mechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingFrom EverandMechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingNo ratings yet

- Geo-textile Material SpecificationDocument2 pagesGeo-textile Material SpecificationSABEASNNo ratings yet

- Project Name Engineer Ref Dwg. No. Approver: Dia (MM) Spacing (MM) Bar No. Bar Shape A (M) B (M) C (M)Document3 pagesProject Name Engineer Ref Dwg. No. Approver: Dia (MM) Spacing (MM) Bar No. Bar Shape A (M) B (M) C (M)SABEASNNo ratings yet

- Checklist For Plastering: Project: Doc. No. Client: Project LocationDocument4 pagesChecklist For Plastering: Project: Doc. No. Client: Project LocationNoorul Mufas MnNo ratings yet

- RLL-MWPTPJYDocument27 pagesRLL-MWPTPJYSABEASNNo ratings yet

- Daily Entery PDFDocument1 pageDaily Entery PDFSABEASNNo ratings yet

- ASTM StandardsDocument1 pageASTM StandardsSABEASNNo ratings yet

- 4 Back-Filling of Holes and Depression Caused by Removal of StumpsDocument1 page4 Back-Filling of Holes and Depression Caused by Removal of StumpsSABEASNNo ratings yet

- Checklist For ConcretingDocument4 pagesChecklist For ConcretingManish KapadneNo ratings yet

- Cement testing and storage requirementsDocument3 pagesCement testing and storage requirementsSABEASNNo ratings yet

- Material Sodium Chloride Soluble SulphatesDocument2 pagesMaterial Sodium Chloride Soluble SulphatesSABEASNNo ratings yet

- Portland CementDocument1 pagePortland CementSABEASNNo ratings yet

- Sampling and TestingDocument1 pageSampling and TestingSABEASNNo ratings yet

- CLDocument1 pageCLSABEASNNo ratings yet

- SubmittalsDocument2 pagesSubmittalsSABEASNNo ratings yet

- DrillingDocument2 pagesDrillingSABEASNNo ratings yet

- Hot-dip galvanized connection clipsDocument2 pagesHot-dip galvanized connection clipsSABEASNNo ratings yet

- Soil Nailing and Horizontal Drains 2101 Soil Nailing 2101.1 DescriptionDocument2 pagesSoil Nailing and Horizontal Drains 2101 Soil Nailing 2101.1 DescriptionSABEASNNo ratings yet

- 802.2 Materials A. Grass SeedsDocument2 pages802.2 Materials A. Grass SeedsSABEASNNo ratings yet

- De WateringDocument2 pagesDe WateringSABEASNNo ratings yet

- Payment PDFDocument2 pagesPayment PDFSABEASNNo ratings yet

- QC Plan Ensures High Construction QualityDocument2 pagesQC Plan Ensures High Construction QualitySABEASNNo ratings yet

- No Mesh/Net: RequirementsDocument3 pagesNo Mesh/Net: RequirementsSABEASNNo ratings yet

- Earthworks excavation and slope trimmingDocument3 pagesEarthworks excavation and slope trimmingSABEASNNo ratings yet

- CwmfprojectdefinitionDocument14 pagesCwmfprojectdefinitionmohammad rizwanNo ratings yet

- Inserting of Rebar RecordsDocument3 pagesInserting of Rebar RecordsSABEASNNo ratings yet

- App 05Document1 pageApp 05SABEASNNo ratings yet

- Aftershocks and The Whole-Life Seismic Performance of Granular SlopesDocument42 pagesAftershocks and The Whole-Life Seismic Performance of Granular SlopeskrainajackaNo ratings yet

- 004 Page 58 87 PDFDocument30 pages004 Page 58 87 PDFSABEASNNo ratings yet

- Understanding the Properties and Applications of Cemented CarbideDocument20 pagesUnderstanding the Properties and Applications of Cemented Carbidemp87_ingNo ratings yet

- Course Name ME 2materials Science Hande Öztürk Room 318: Hande - Ozturk@ozyegin - Edu.trDocument3 pagesCourse Name ME 2materials Science Hande Öztürk Room 318: Hande - Ozturk@ozyegin - Edu.trlopezclaNo ratings yet

- Sample Problems For KinematicsDocument43 pagesSample Problems For Kinematicsdavid jenil nabuaNo ratings yet

- Jouf University: Department of Information Systems Dr. Abd El-Aziz Ahmed Java Programming Fall 2018 Practice Lab 1Document2 pagesJouf University: Department of Information Systems Dr. Abd El-Aziz Ahmed Java Programming Fall 2018 Practice Lab 1wiemNo ratings yet

- FMEM MCQsDocument162 pagesFMEM MCQsjawaliyaabhishek1312No ratings yet

- Projectile MotionDocument9 pagesProjectile MotionPaulo John RubioNo ratings yet

- Special Magic Squares of Order Six and EightDocument13 pagesSpecial Magic Squares of Order Six and EightIJDIWCNo ratings yet

- 26 PDFDocument280 pages26 PDFHumberto Medina100% (1)

- Hydraulic Seals-SKF PDFDocument0 pagesHydraulic Seals-SKF PDFSharath ThimmegowdaNo ratings yet

- Nepal Aviation Authority 8Document5 pagesNepal Aviation Authority 8Janup PokharelNo ratings yet

- Medical Ultrasound ImagingDocument9 pagesMedical Ultrasound Imagingsakata_abera4No ratings yet

- MM321 Lab N# 4: Bypass Factor of A Heating CoilDocument7 pagesMM321 Lab N# 4: Bypass Factor of A Heating CoilSiddhant Vishal ChandNo ratings yet

- Physics: Tata Institute of Fundamental Research GS-2020 Screening TestDocument57 pagesPhysics: Tata Institute of Fundamental Research GS-2020 Screening TestAryA JackNo ratings yet

- IFIA Test Question Book With Answers - Americas Version Spanish - July 2013 Mecánica de SuelosDocument91 pagesIFIA Test Question Book With Answers - Americas Version Spanish - July 2013 Mecánica de Suelosjruiz_813786No ratings yet

- Polymer Bound CatalystsDocument12 pagesPolymer Bound CatalystsStefan GherghinaNo ratings yet

- Rbalance Rotor Balancing ProcedureDocument2 pagesRbalance Rotor Balancing ProcedureBradley NelsonNo ratings yet

- Dry-Out and Heat-Up Procedures - 2015 WorkshopDocument30 pagesDry-Out and Heat-Up Procedures - 2015 WorkshopyuriNo ratings yet

- 1x5x5 Design ReportDocument47 pages1x5x5 Design ReportGajendra BishtNo ratings yet

- Engineering Material QuestionsDocument82 pagesEngineering Material QuestionsRakesh Inani67% (3)

- Assignment 6 SolutionsDocument4 pagesAssignment 6 SolutionsClerry SamuelNo ratings yet

- Troubleshoot 4-20 mA loopsDocument14 pagesTroubleshoot 4-20 mA loopsrozzillaNo ratings yet

- NLC23 - Grade 7 Enhancement Mathematics Student Workbook - FinalDocument58 pagesNLC23 - Grade 7 Enhancement Mathematics Student Workbook - FinalJohn Christopher Romero100% (1)

- Indian Night Vision TechDocument10 pagesIndian Night Vision Techshashank_shrNo ratings yet

- Alat kesehatan khusus kamar operasiDocument4 pagesAlat kesehatan khusus kamar operasinitaNo ratings yet

- Laying of All Asphalt Courses in One Step: SciencedirectDocument10 pagesLaying of All Asphalt Courses in One Step: SciencedirectRehan BaxiNo ratings yet

- Summer: Worldwide Paragliding and Paramotoring Magazine. For FreeDocument62 pagesSummer: Worldwide Paragliding and Paramotoring Magazine. For Freevgdlpc74No ratings yet