Professional Documents

Culture Documents

Supplier:Neel Metal Products Ltd. (Faridabad) : Process Fmea

Uploaded by

rohitOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Supplier:Neel Metal Products Ltd. (Faridabad) : Process Fmea

Uploaded by

rohitCopyright:

Available Formats

SUPPLIER :NEEL METAL PRODUCTS LTD.

(FARIDABAD)

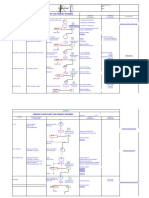

PROCESS FMEA PAGE :

CUSTOMER : AVON TUBE TECH SUPPLIER CODE VEHICLE / MODEL FORM NO.

PART NO./REV. NO. CUSTOMER : -- SUPPLIER : -- PART NAME DATE OF ISSUE/NO.

ASSY. NO./REV.NO. CUSTOMER : -- SUPPLIER : ASSY. NAME DATE (ORIG.)

CORE TEAM : PROCESS RESPONSIBILITY :

OPN. PROCESS POTENTIAL POTENTIAL S CL POTENTIAL O CURRENT D R RECOMMENDED RESP./ ACTION RESULTS

NO. FUNCTION FAILURE EFFECT(S) OF E A CAUSE(S)/ C PROCESS PROCESS E P ACTIONS TARGET S O D R

REQUIREMENTS MODE FAILURE V S MECHANISM(S) C CONTROLS CONTROLS T N COMPL. ACTION TAKEN E C E P

S OF FAILURE PREVENTION DETECTION DATE V C T N

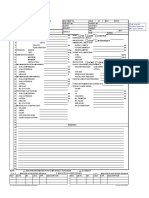

AVOID THICKNESS

1 ERW TUBE SIZE INOPERATIVE HEAT DOWN VARIATION VISUAL

63.5X1.2X5000

FIN CUT

NOISE PRESSURE OF WELDING ROLL

WELDING CRACK AND FINPASS

7 M 2 9 128

LEAKS STRIPES 1. EDGES AVOID UNEVEN STRIPS VISUAL

2. THICKNESS

CUSTOMES DISSATISFECTION VARIATION

MICROMETER/VERNIER

CALIPER/MEASURING

VARIATION IN DIMENSIONS DOES NOT FIT 3 M IMPROPER SIZING 8 PROPER SIZING TAPE 5 120

LOW BOOGI HEIGHT

6 M 3 VISUAL INSPECTION OF 8 144

NON FIN COT/UNDER CUT DIFFERENT PARTS WILL NOT BE BOOGI TWIST CARE MUST BE TAKEN BEAD

PROPERLY INSERTED AT THETIME OF SETTING

ID TOOL BRAKE

RUSTY/DENT/ PICK UP/SLIGHT POOR APPEARANCE 3 Mn LONG TIME STORAGE OF 7 AVOID STORAGE OF VISUAL 4 84

SCRATCH TUBES TUBE

SAFE HANDLING

IMPROPER HANDLING

CARE MUST BE TAKEN

ID SCRATCH DOES NOT FIT 5 M WHEEEL JAM 3 AT THETIME OF SETTING VISUAL 4 60

PREPARED BY : APPROVED BY : ISSUED BY : ISSUE DATE :

LEGEND FOR CLASS : C - CRITICAL ; M - MAJOR ; S - SIGNIFICANT; Mn - MINOR

SEVERITY : C - (8-10) ; M - (7) ; S - (4-6) ; Mn. (1-3)

You might also like

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- Supplier Process FMEA for ERW TubeDocument1 pageSupplier Process FMEA for ERW TuberohitNo ratings yet

- Supplier FMEA for ERW tube processDocument1 pageSupplier FMEA for ERW tube processrohitNo ratings yet

- Slip Type Elevator Cat. IVDocument2 pagesSlip Type Elevator Cat. IVRanjithNo ratings yet

- Checklist of Welding MachineDocument2 pagesChecklist of Welding MachineShahid RazaNo ratings yet

- Safety Clamp Cat. IVDocument6 pagesSafety Clamp Cat. IVRanjithNo ratings yet

- 45 KL Oil Storage Tank V-102: Mechanical Data Sheet For VesselDocument4 pages45 KL Oil Storage Tank V-102: Mechanical Data Sheet For VesselKrunalNo ratings yet

- Assuit Supercritical Power Plant 1X650Mw: Chemical Area To Waste WaterDocument1 pageAssuit Supercritical Power Plant 1X650Mw: Chemical Area To Waste WaterHussein MohamedNo ratings yet

- Revision history and diagramsDocument3 pagesRevision history and diagramsCarl Diaz100% (1)

- Report UT CS From 21Document112 pagesReport UT CS From 21daemsalNo ratings yet

- Repport UT CS - 1Document22 pagesRepport UT CS - 1daemsalNo ratings yet

- WE HEREBY That The Following Tire Products Are Manufactured in Compliance With The Specifications of Norm INEN 2100Document2 pagesWE HEREBY That The Following Tire Products Are Manufactured in Compliance With The Specifications of Norm INEN 2100Daniel BarbaNo ratings yet

- Saudi Aramco instrument specificationDocument1 pageSaudi Aramco instrument specificationgayu87No ratings yet

- 22-DS-R-010 Rev 0 P-2440 Fire Water Feed PumpDocument3 pages22-DS-R-010 Rev 0 P-2440 Fire Water Feed PumpChike NwachukwuNo ratings yet

- Pre-Concrete Inspection Checklist:: 13 Oktober 2023: CCMSPHR/SPK/3700132652Document1 pagePre-Concrete Inspection Checklist:: 13 Oktober 2023: CCMSPHR/SPK/3700132652yazitNo ratings yet

- 22-DS-R-006 Rev 0 P-4110 A-B Firewater PumpDocument3 pages22-DS-R-006 Rev 0 P-4110 A-B Firewater PumpChike NwachukwuNo ratings yet

- 1416 MC MDS V 104 - Rev.0Document5 pages1416 MC MDS V 104 - Rev.0KrunalNo ratings yet

- 3795-210-S10-E99-0002-Rev.3 PLC Io Mapping List Including Time Synchronize SDocument7 pages3795-210-S10-E99-0002-Rev.3 PLC Io Mapping List Including Time Synchronize SFomaa ElsayedNo ratings yet

- U123 DD N EL 73 0016 00 E Panel Arrangement DrawingsDocument6 pagesU123 DD N EL 73 0016 00 E Panel Arrangement DrawingsJovan JovanovićNo ratings yet

- MINI DIP/SIP-2A Flexible Test Handler: On SemiconductorDocument10 pagesMINI DIP/SIP-2A Flexible Test Handler: On Semiconductor김대헌No ratings yet

- Fire and Gas Detection System Cable ScheduleDocument6 pagesFire and Gas Detection System Cable ScheduleAnonymous v6ybIxZFNo ratings yet

- 22-DS-R-008 Rev 0 P 2460 A-B Utility Water PumpDocument3 pages22-DS-R-008 Rev 0 P 2460 A-B Utility Water PumpChike NwachukwuNo ratings yet

- Cs B Final Report Valero SunrayDocument11 pagesCs B Final Report Valero Sunrayjmz mtzNo ratings yet

- Aramco Accumulator Vessel Data SheetDocument3 pagesAramco Accumulator Vessel Data SheetAhmed MusallamNo ratings yet

- Test Sertifikasi: Kiraç Galvaniz Telekom Metal Mak - İnş.El - San.Ve Tic.A.ŞDocument3 pagesTest Sertifikasi: Kiraç Galvaniz Telekom Metal Mak - İnş.El - San.Ve Tic.A.ŞBeytullah KurnalıNo ratings yet

- Front Elevation Escalator Section: General NoteDocument1 pageFront Elevation Escalator Section: General NoteHabibulla BavajiNo ratings yet

- Ac Oqa 2014Document1 pageAc Oqa 2014pm9286vNo ratings yet

- TSR Info Unit Accident PTSBM Site Muara Lawa (1) 230921 144623Document5 pagesTSR Info Unit Accident PTSBM Site Muara Lawa (1) 230921 144623Ifan saputroNo ratings yet

- Pumps Sample Data Sheet (By ICI)Document5 pagesPumps Sample Data Sheet (By ICI)farrukhiqbal05No ratings yet

- Manual Tong Cat. IVDocument8 pagesManual Tong Cat. IVRanjithNo ratings yet

- PQR Pipeline Butt-Weld Through Thickness Repair ProcedureDocument2 pagesPQR Pipeline Butt-Weld Through Thickness Repair ProcedureRicardo NapitupuluNo ratings yet

- 22-DS-R-004 Rev 0 P-2230 Diesel Fuel Transfer Pump ElecDocument48 pages22-DS-R-004 Rev 0 P-2230 Diesel Fuel Transfer Pump ElecChike NwachukwuNo ratings yet

- Work Instruction - Texfocus English VDocument3 pagesWork Instruction - Texfocus English Vgguillermo_63No ratings yet

- Pipe Supports: Presented by N S ThatteDocument28 pagesPipe Supports: Presented by N S Thattesatish04No ratings yet

- Construction Check Sheet Instrument Multi-Core Cable Insulation and Continuity Test I-007ADocument1 pageConstruction Check Sheet Instrument Multi-Core Cable Insulation and Continuity Test I-007AKailash PandeyNo ratings yet

- Data Sheet: Quality Flow ChartDocument3 pagesData Sheet: Quality Flow ChartIgor PNo ratings yet

- S010101100[7708]Document1 pageS010101100[7708]agustin laraNo ratings yet

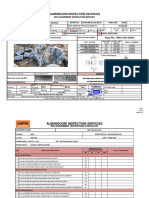

- Fuel Tank Inspection ReportDocument2 pagesFuel Tank Inspection Reportswaran autoqaNo ratings yet

- Field Quality Assurance Plan for ACC PackageDocument2 pagesField Quality Assurance Plan for ACC PackageHema NandhNo ratings yet

- Hiking Superior Industrial Co., Limited: Certificate of Detailed QualityDocument1 pageHiking Superior Industrial Co., Limited: Certificate of Detailed QualityCarlos CordovaNo ratings yet

- Report 1 Paut Sts 409Document12 pagesReport 1 Paut Sts 409DEBJYOTI SENGUPTA100% (2)

- Wac - Test Certificate 7313Document1 pageWac - Test Certificate 7313dian priyantoNo ratings yet

- Process flow chart for primary structural steel fabricationDocument3 pagesProcess flow chart for primary structural steel fabricationmadhu krishnaNo ratings yet

- Installasi fm200Document1 pageInstallasi fm200Calon SultanNo ratings yet

- Submersible Sewage Pumps: Type - I-NsDocument8 pagesSubmersible Sewage Pumps: Type - I-NsNabeel KarvinkarNo ratings yet

- Issue B Exhibit No. 4-6 Dated - 18-11-2011 Cir SeamDocument1 pageIssue B Exhibit No. 4-6 Dated - 18-11-2011 Cir SeamGanesh YadavNo ratings yet

- Tech Spec - Part3 1484197535Document88 pagesTech Spec - Part3 1484197535Instrument CandidatesNo ratings yet

- Spark Holiday Test Report SummaryDocument3 pagesSpark Holiday Test Report SummaryPat Lim100% (1)

- Ultrasonic Examination ReportDocument2 pagesUltrasonic Examination ReportdaemsalNo ratings yet

- End User-Technical Sheet: 7 Units of Air CurtainsDocument41 pagesEnd User-Technical Sheet: 7 Units of Air CurtainsAngelica Sta. MariaNo ratings yet

- Veco Engineering Ltd. Equipment Data Sheet: Expansion JointDocument2 pagesVeco Engineering Ltd. Equipment Data Sheet: Expansion Jointwado11No ratings yet

- A Title: Roof Plan: NotesDocument1 pageA Title: Roof Plan: NotesCHEEKOTI VIVEKNo ratings yet

- General Notes Symbol List Abbreviations: Reference Sheet - SprinklerDocument64 pagesGeneral Notes Symbol List Abbreviations: Reference Sheet - SprinklerAnonymous qOBFvINo ratings yet

- Project Name: Project: Gaonme LeadingDocument6 pagesProject Name: Project: Gaonme LeadingSoyusz PowerNo ratings yet

- The Arctic Shutter - Thermal Window Shutter For Cold ClimatesDocument1 pageThe Arctic Shutter - Thermal Window Shutter For Cold ClimatesKhanh DamNo ratings yet

- Carv Full Report 49525Document2 pagesCarv Full Report 49525gaurav kumar100% (1)

- B.O. 13730 - CHTIS06-12 30DEG V-RIB, 45DEG HPR 72IN LAIDIG RECLAIM DISC (Prelim)Document1 pageB.O. 13730 - CHTIS06-12 30DEG V-RIB, 45DEG HPR 72IN LAIDIG RECLAIM DISC (Prelim)Dario CisnerosNo ratings yet

- Set-Up Approval Report-Brkt - HC CollectorDocument2 pagesSet-Up Approval Report-Brkt - HC Collectorswaran autoqaNo ratings yet

- Painampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PDocument22 pagesPainampuram, Muthukurmandal, S.P.S.R. Nellore District, A.Pkkumar_717405No ratings yet

- 14.0grade Wise Scrap Charge Mix.Document8 pages14.0grade Wise Scrap Charge Mix.rohitNo ratings yet

- Facilities and Environmental Conditions (Linked To Vol. III, Sec. 2)Document51 pagesFacilities and Environmental Conditions (Linked To Vol. III, Sec. 2)imran shaukatNo ratings yet

- ISO 9001 Certification for Steel ManufacturingDocument1 pageISO 9001 Certification for Steel ManufacturingrohitNo ratings yet

- Bearing ListDocument1 pageBearing ListPANKAJ JAISWALNo ratings yet

- 16.0 Grade Wise Chemical CompositionDocument29 pages16.0 Grade Wise Chemical CompositionrohitNo ratings yet

- Liquidus Formulae for Molten MetalDocument1 pageLiquidus Formulae for Molten MetalrohitNo ratings yet

- Production risks and mitigation planDocument2 pagesProduction risks and mitigation planrohitNo ratings yet

- As Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-05 Rev No Rev DateDocument1 pageAs Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-05 Rev No Rev DaterohitNo ratings yet

- 13.0 Grade Wise Liquids Temperature & CA-Si Al WireSulphur Wire ChartDocument4 pages13.0 Grade Wise Liquids Temperature & CA-Si Al WireSulphur Wire ChartrohitNo ratings yet

- Test ListDocument3 pagesTest ListrohitNo ratings yet

- 11.0 Raw Material SpecificationDocument6 pages11.0 Raw Material SpecificationrohitNo ratings yet

- As Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-03 Rev No Rev DateDocument1 pageAs Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-03 Rev No Rev DaterohitNo ratings yet

- As Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-04 Rev No Rev DateDocument1 pageAs Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-04 Rev No Rev DaterohitNo ratings yet

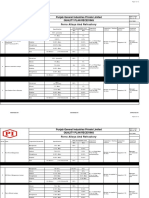

- Punjab General Industries Private Limited Organization ChartDocument1 pagePunjab General Industries Private Limited Organization ChartrohitNo ratings yet

- Break Strength TestingDocument1 pageBreak Strength TestingrohitNo ratings yet

- Pgil Master Ferro Alloy and Refrac ListDocument12 pagesPgil Master Ferro Alloy and Refrac ListrohitNo ratings yet

- Creep Testing: Test Name PrincipleDocument2 pagesCreep Testing: Test Name PrinciplerohitNo ratings yet

- The Lee Company Industrial Microhydraulics Group - Quality ManualDocument65 pagesThe Lee Company Industrial Microhydraulics Group - Quality Manualrohit100% (1)

- Bond Strength Testing Methods & StandardsDocument2 pagesBond Strength Testing Methods & StandardsrohitNo ratings yet

- Compression TestingDocument2 pagesCompression TestingrohitNo ratings yet

- Creep Testing: Test Name PrincipleDocument2 pagesCreep Testing: Test Name PrinciplerohitNo ratings yet

- Co-Efficient of Friction TestingDocument1 pageCo-Efficient of Friction TestingrohitNo ratings yet

- Productivity and Quality Improvement Through Setting Parameters in Hot Rolling Mill Nimish Dhomne PDFDocument4 pagesProductivity and Quality Improvement Through Setting Parameters in Hot Rolling Mill Nimish Dhomne PDFSamir BoseNo ratings yet

- 5 - Mechanical Working and Testing of MaterialsDocument94 pages5 - Mechanical Working and Testing of MaterialsrohitNo ratings yet

- Edx Report and Action PlanDocument1 pageEdx Report and Action PlanrohitNo ratings yet

- Weigh Balance Calibration CertificateDocument1 pageWeigh Balance Calibration Certificaterohit100% (3)

- Bearing ListDocument1 pageBearing ListPANKAJ JAISWALNo ratings yet

- Template 621 Swot AnalysisDocument2 pagesTemplate 621 Swot AnalysisRajendraNo ratings yet

- Quality Manual Pgi-Ml-Qm: As Per IS / ISO / IEC 17025: 2017Document25 pagesQuality Manual Pgi-Ml-Qm: As Per IS / ISO / IEC 17025: 2017rohit100% (6)

- GTGC RID IMS PRC 01 Risk and OpportunitiesDocument11 pagesGTGC RID IMS PRC 01 Risk and OpportunitiesMohamed FlahiNo ratings yet

- Simple Problem On ABC: RequiredDocument3 pagesSimple Problem On ABC: RequiredShreshtha VermaNo ratings yet

- Psychrometrics Drying Problems SEODocument5 pagesPsychrometrics Drying Problems SEOStephanie Torrecampo Delima100% (2)

- Fin4010 Assignment 3Document3 pagesFin4010 Assignment 3Grace AtteNo ratings yet

- D20 Q12Document7 pagesD20 Q12Luca PitocchiNo ratings yet

- Anand FDocument76 pagesAnand FSunil BharadwajNo ratings yet

- 737 Flow and ChecklistDocument7 pages737 Flow and ChecklistarelundhansenNo ratings yet

- Hydrogen Plant For The New MillenniumDocument21 pagesHydrogen Plant For The New Millenniumapi-3799861100% (2)

- Application Form For Business Permit: Amendment: AmendmentDocument2 pagesApplication Form For Business Permit: Amendment: AmendmentJdavidNo ratings yet

- Market Profiling, Targeting and PositioningDocument16 pagesMarket Profiling, Targeting and PositioningMichelle RotairoNo ratings yet

- 3 Manacsa&Tan 2012 Strong Republic SidetrackedDocument41 pages3 Manacsa&Tan 2012 Strong Republic SidetrackedGil Osila JaradalNo ratings yet

- Metsec Purlin Technical ManualDocument88 pagesMetsec Purlin Technical ManualAnbalaganV100% (2)

- r6 - SCV - PV - 2012 June MarkB PDFDocument32 pagesr6 - SCV - PV - 2012 June MarkB PDFsanjiivNo ratings yet

- 20-Sdms-02 (Overhead Line Accessories) Rev01Document15 pages20-Sdms-02 (Overhead Line Accessories) Rev01Haytham BafoNo ratings yet

- Rolling ResistanceDocument12 pagesRolling Resistancemu_rajesh3415No ratings yet

- Order 824218 470773 PDFDocument4 pagesOrder 824218 470773 PDFMadalina JariiNo ratings yet

- Excerpt: "Railroaded" by Richard WhiteDocument38 pagesExcerpt: "Railroaded" by Richard Whitewamu885No ratings yet

- Storytelling Tips from Salesforce CEO Marc BenioffDocument2 pagesStorytelling Tips from Salesforce CEO Marc BenioffvsrajkumarNo ratings yet

- Welcome To All: Fundamental Analysis Economic AnalysisDocument11 pagesWelcome To All: Fundamental Analysis Economic AnalysisMD.RUMON BAKSHINo ratings yet

- DataSheet ULCAB300Document2 pagesDataSheet ULCAB300Yuri OliveiraNo ratings yet

- Oatey2021 CommercialCat LCS1146B 022421 WEB LR 1Document204 pagesOatey2021 CommercialCat LCS1146B 022421 WEB LR 1Pablo CINo ratings yet

- MP Process Flow - MBA - MM - MHRMDocument2 pagesMP Process Flow - MBA - MM - MHRMKAVITHA A/P PARIMAL MoeNo ratings yet

- Switches - Cisco Nexus 9000 - ArtDocument96 pagesSwitches - Cisco Nexus 9000 - ArtYasser OmarNo ratings yet

- Ch06 Allocating Resources To The ProjectDocument55 pagesCh06 Allocating Resources To The ProjectJosh ChamaNo ratings yet

- MB1 - The Australian Economy PA 7092016Document8 pagesMB1 - The Australian Economy PA 7092016ninja980117No ratings yet

- Set 1Document4 pagesSet 1insan biasaNo ratings yet

- Bloodborne Pathogens Program: Western Oklahoma State College Employee Training HandbookDocument35 pagesBloodborne Pathogens Program: Western Oklahoma State College Employee Training HandbookKashaNo ratings yet

- Lb-Xp12-350-Pd-En-V1.3-201912 - EquivalenteDocument2 pagesLb-Xp12-350-Pd-En-V1.3-201912 - EquivalenteDaniel Oliveira Freitas RochaNo ratings yet

- 2X16-24 Monorail Hoist-04 - 2Document1 page2X16-24 Monorail Hoist-04 - 2RafifNo ratings yet

- Feasibility ReportDocument10 pagesFeasibility ReportAdityaNo ratings yet

- SDSU PhD Research on Soil HealthDocument2 pagesSDSU PhD Research on Soil HealthTiruneh GA25% (4)

![S010101100[7708]](https://imgv2-1-f.scribdassets.com/img/document/720099059/149x198/fe5bf73c79/1712257964?v=1)