Professional Documents

Culture Documents

Iso-Tc135-Sc3 - Iso - Dis - 2400 - 2011 PDF

Uploaded by

Vuong Tran VanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Iso-Tc135-Sc3 - Iso - Dis - 2400 - 2011 PDF

Uploaded by

Vuong Tran VanCopyright:

Available Formats

DRAFT INTERNATIONAL STANDARD ISO/DIS 2400

ISO/TC 135/SC 3 Secretariat: JISC

Voting begins on Voting terminates on

2011-03-17 2011-08-17

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION • МЕЖДУНАРОДНАЯ ОРГАНИЗАЦИЯ ПО СТАНДАРТИЗАЦИИ • ORGANISATION INTERNATIONALE DE NORMALISATION

Non-destructive testing — Ultrasonic examination —

Specification for calibration block No. 1

Essais non destructifs — Contrôle par ultrasons — Spécifications relatives au bloc d'étalonnage n° 1

[Revision of first edition (ISO 2400:1972)]

ICS 25.160.40

ISO/CEN PARALLEL PROCESSING

This draft has been developed within the European Committee for Standardization (CEN), and

processed under the CEN-lead mode of collaboration as defined in the Vienna Agreement.

This draft is hereby submitted to the ISO member bodies and to the CEN member bodies for a parallel

five-month enquiry.

Should this draft be accepted, a final draft, established on the basis of comments received, will be

submitted to a parallel two-month approval vote in ISO and formal vote in CEN.

To expedite distribution, this document is circulated as received from the committee

secretariat. ISO Central Secretariat work of editing and text composition will be undertaken at

publication stage.

Pour accélérer la distribution, le présent document est distribué tel qu'il est parvenu du

secrétariat du comité. Le travail de rédaction et de composition de texte sera effectué au

Secrétariat central de l'ISO au stade de publication.

THIS DOCUMENT IS A DRAFT CIRCULATED FOR COMMENT AND APPROVAL. IT IS THEREFORE SUBJECT TO CHANGE AND MAY NOT BE

REFERRED TO AS AN INTERNATIONAL STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS BEING ACCEPTABLE FOR INDUSTRIAL, TECHNOLOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON OCCASION HAVE TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL TO BECOME

STANDARDS TO WHICH REFERENCE MAY BE MADE IN NATIONAL REGULATIONS.

RECIPIENTS OF THIS DRAFT ARE INVITED TO SUBMIT, WITH THEIR COMMENTS, NOTIFICATION OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPORTING DOCUMENTATION.

© International Organization for Standardization, 2011

ISO/DIS 2400

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall

not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

Copyright notice

This ISO document is a Draft International Standard and is copyright-protected by ISO. Except as permitted

under the applicable laws of the user’s country, neither this ISO draft nor any extract from it may be

reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic,

photocopying, recording or otherwise, without prior written permission being secured.

Requests for permission to reproduce should be addressed to either ISO at the address below or ISO’s

member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

ii © ISO 2011 – All rights reserved

ISO/DIS 2400

Contents Page

11

Foreword ............................................................................................................................................................iv

1 Scope ......................................................................................................................................................1

2 Normative references............................................................................................................................1

3 Terms and definitions ...........................................................................................................................1

4 Terms and definitions ...........................................................................................................................1

5 Manufacture ...........................................................................................................................................1

20

5.1 Steel ........................................................................................................................................................1

5.2 Dimensions ............................................................................................................................................1

5.3 Machining, heat treatment and surface finish....................................................................................2

5.4 Reference marks....................................................................................................................................2

6 Velocities................................................................................................................................................2

7 Marking ...................................................................................................................................................2

8 Certificate ...............................................................................................................................................2

9 Possible modifications to block no. 1 .................................................................................................3

9.1 General ...................................................................................................................................................3

9.2 Slots at zero point .................................................................................................................................3

9.3 Circular reflector....................................................................................................................................3

FT

9.4 Block thickness .....................................................................................................................................3

10 Existing blocks ......................................................................................................................................3

Annex A (normative) Determination of velocities ..........................................................................................8

A.1 General ...................................................................................................................................................8

A.2 Longitudinal waves ...............................................................................................................................8

A.3 Transverse waves..................................................................................................................................8

A

R

D

© ISO 2010 – All rights reserved iii

ISO/DIS 2400

Foreword

11

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

20

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 2400 was prepared by Technical Committee ISO/TC 135, Non-destructive testing, Subcommittee SC 3,

and by Technical Committee CEN/TC 138, Non-destructive testing in collaboration.

This second edition cancels and replaces the first edition (ISO 12400:1972) which has been technically

revised.

FT

The main changes are the addition of new clauses on :

⎯ manufacture of the block;

⎯ sound “velocities”;

⎯ marking and certification of the blocks;

⎯ possible modifications to block no. 1;

⎯ use of existing blocks;

A

⎯ normative Annex on determination of velocities“.

R

D

iv © ISO 2010 – All rights reserved

DRAFT INTERNATIONAL STANDARD ISO/DIS 2400

Non-destructive testing — Ultrasonic examination —

11

Specification for calibration block No. 1

1 Scope

This International Standard specifies requirements for the dimensions, material and manufacture of a steel

block for calibrating ultrasonic test equipment used in manual testing.

20

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 5577:2000, Non-destructive testing — Ultrasonic inspection — Vocabulary

EN 1330-4:2010, Non-destructive testing — Terminology — Part 4: Terms used in ultrasonic testing.

EN 10025-2:2005, Hot rolled products of structural steels — Part 2: Technical delivery conditions for non-alloy

FT

structural steels

3 Terms and definitions

For this International Standard the definitions given in ISO 5577:2000 and EN 1330-4:2010 apply.

4 Terms and definitions

A

For the purposes of this document, the terms and definitions given in ISO 5577:2000 and EN 1330-4:2010

apply.

5 Manufacture

R

5.1 Steel

Blocks shall be manufactured from steel grade S355JO specified in EN 10025-2:2005.

5.2 Dimensions

D

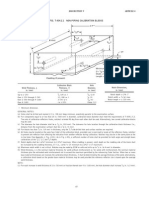

The dimensions of calibration block No. 1 shall be as shown in Figure 1.

NOTE This standard does not include any requirement for a plastics insert.

© ISO 2010 – All rights reserved 1

ISO/DIS 2400

5.3 Machining, heat treatment and surface finish

Blocks shall be rough-machined to a dimension of 320 mm x 120 mm x 30 mm before heat treatment which

shall consist of:

⎯ austenitizing at 920 °C for 30 min ;

11

⎯ rapid cooling (quenching) in water ;

⎯ tempering by heating to 650 °C for 3 h ; and then

⎯ cooling in air.

All external surfaces shall be machined to an Ra value not greater than 0,8 µm.

20

Prior to final machining, the block shall be proved free from internal discontinuities. For this purpose, an

ultrasonic examination shall be carried out after the heat treatment, with a longitudinal wave probe of at least

10 MHz nominal centre frequency and having a transducer size of 10 mm to 15 mm. The block shall be

checked on the basis of all four long faces to cover the complete volume. With the probe positioned on the

largest face of the block, the equipment gain shall be set to achieve a grain scatter noise of 10 % of the

screen height. No echo shall have an amplitude greater than that of the grain scatter noise.

5.4 Reference marks

Reference marks shall be permanently marked as shown in Tigure 1 and in Table 1.

6 Velocities

FT

The velocities of longitudinal and transverse waves shall be determined as described in Annex A. The

velocities shall be determined within a maximum permissible error of ± 0,2 %, i.e. with an uncertainty of

± 6 m/s for transverse waves and ± 12 m/s for longitudinal waves.

The determined longitudinal wave velocity, vl, shall be 5 920 m/s ± 30 m/s and the transverse wave velocity,

vt, shall be 3 255 m/s ± 15 m/s.

7 Marking

A

The block shall be permanently marked in the area shown in Figure 1, as follows :

a) number of this International Standard EN ISO 2400;

b) manufacturer's serial number and trade mark.

R

8 Certificate

A certificate shall be issued by the manufacturer for each block, detailing:

D

a) statement that the block complies with EN ISO 2400;

b) the mean value of the determined longitudinal wave velocities, vl ; see Clause 5;

c) the mean value of the determined transverse wave velocities, vt ; see Clause 5.

2 © ISO 2010 – All rights reserved

ISO/DIS 2400

9 Possible modifications to block no. 1

9.1 General

11

One of the modifications in 8.2 or 8.3 shall be made to the block.

9.2 Slots at zero point

If this modification is chosen, two slots at the zero point shall be machined, see Figure 2, which for angle

beam probes provide calibrating signals at intervals of 100 mm.

9.3 Circular reflector

20

If this modification is chosen, a circular arc reflector accessible from the longer sides of the block shall be

machined, see figure 3. For angle beam probes this provides calibrating signals at beam path lengths of

25 mm, 225 mm, 350 mm, etc.

9.4 Block thickness

Thicker blocks are permitted.

10 Existing blocks

Existing blocks fulfil the requirements of this International Standard provided that they meet the requirements

on velocities (see clause 5) and dimensions (see 4.2) with the exception that the small side drilled hole may

FT

have a diameter of 1,5 mm.

A

R

D

© ISO 2010 – All rights reserved 3

ISO/DIS 2400

dimensions in mm

11

20

FT

A

Tolerances unless otherwise stated ± 0,10 mm. Angle identification and index mark lengths ± 0,4 mm. Angle

indents should be in 5 mm high characters. Surface finish Ra ≤ 0,8 µm all over.

Figure 1 — Block dimensions with tolerances

R

D

4 © ISO 2010 – All rights reserved

ISO/DIS 2400

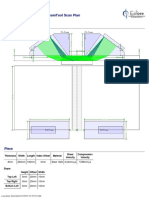

dimensions in mm

11

20

Key

1 Machined slots

Figure 2 — Two zero point slots

FT

A

R

D

© ISO 2010 – All rights reserved 5

ISO/DIS 2400

dimensions in mm

11

20

Figure 3 — Circular reflector

FT

A

R

D

6 © ISO 2010 – All rights reserved

ISO/DIS 2400

Table 1 — Indent distance

Distance b from hole A Distance a from the edge Indent with label Indent without

mm mm label

52,0 87,0 60°

56,4 91,4 62°

11

61,5 96,5 64°

67,4 102,4 66°

74,3 109,3 68°

82,4 117,4 70°

92,3 127,3 72°

104,6 139,6 74°

20

120,3 155,3 76°

Distance b from hole B Distance a from the edge Indent with label Indent without

mm mm label

41,2 76,2 70°

46,2 81,2 72°

52,3 87,3 74o

60,2 95,2 76°

70,6 105,6 78°

85,1 120,1 80°

Distance b from hole A Distance a from the edge Indent with label Indent without

FT

mm mm label

40,4 75,4 30°

49,0 84,0 35°

50,9 85,9 36°

56,7 91,7 39°

58,7 93,7 40°

63,0 98,0 42°

67,6 102,6 44°

A

70,0 105,0 45°

72,5 107,5 46°

77,7 112,7 48°

83,4 118,4 50°

R

89,6 124,6 52°

96,3 131,3 54°

100,0 135,0 55°

103,8 138,8 56°

112,0 147,0 58°

D

121,2 156,2 60°

© ISO 2010 – All rights reserved 7

ISO/DIS 2400

Annex A

(normative)

Determination of velocities

11

A.1 General

This method first measures the physical dimensions of the block to an uncertainty of 0,01 mm. The areas to

be used are checked to ensure that there are no variations in thickness greater than 0,01 mm over the area of

the probe face. An instrument in conjunction with a straight beam probe is then used to measure the time-of-

20

flight (to an accuracy in the measurement of time difference of 0,2 %). Velocities are then calculated

(path/time)1) . The time-of-flight is measured in different directions, i.e. at two well separated positions through

the 25 mm thickness (one at the quadrant and one close to the large hole) and one position through the

100 mm thickness. The measurements shall be carried out within the temperature range of 17 °C to 23 °C.

A.2 Longitudinal waves

Use a probe with nominal centre frequency of at least 5 MHz, broadband pulse and having a transducer size

of 10 mm to 15 mm diameter. Measure the time difference between the first and second backwall echo.

A.3 Transverse waves

FT

For all directions, use a 0° transverse wave probe of frequency of 4 MHz to 5 MHz, broadband pulse, and

having a transducer size of 10 mm to 15 mm diameter. Measure the time difference between the first and

second backwall echo.

Because transverse waves are polarized, in each location of the probe make two measurements with the

plane of polarization in the second measurement perpendicular to the first measurement and parallel to one

side of the block. Therefore for each calibration block there are at least six values for transverse wave

velocity.

A

R

D

1) 1 mm/µs = 1 x 103 m/s.

8 © ISO 2010 – All rights reserved

You might also like

- BLOQUEDocument1 pageBLOQUEAlvaro Alexis Mendoza PradaNo ratings yet

- Example Report TOFD 2 INT-GP1186-09-70 PDFDocument1 pageExample Report TOFD 2 INT-GP1186-09-70 PDFEMTC EMTCNo ratings yet

- 109428-BS en 583-4-2002Document18 pages109428-BS en 583-4-2002Nensha KagasawaNo ratings yet

- Evaluation of Flaw Acceptance Ratios According to ASME Section VIII CodeDocument3 pagesEvaluation of Flaw Acceptance Ratios According to ASME Section VIII CodeWoodrow FoxNo ratings yet

- Manual Ultrasonic Phased ArrayDocument53 pagesManual Ultrasonic Phased ArrayMilan TonicNo ratings yet

- BeamTool Scan Plan SummaryDocument2 pagesBeamTool Scan Plan Summarywilfran villegasNo ratings yet

- PAUT 22.8mm Scan PlanDocument3 pagesPAUT 22.8mm Scan PlanSai Krishna YellapuNo ratings yet

- PA Caracterization BlockDocument2 pagesPA Caracterization BlockMuallim MursyidNo ratings yet

- Terms Used in Ultrasonic Testing BSEN 1330-4 PDFDocument95 pagesTerms Used in Ultrasonic Testing BSEN 1330-4 PDFThe Normal HeartNo ratings yet

- UT For Duplex Stainless Steel WeldsDocument5 pagesUT For Duplex Stainless Steel WeldsvsnaiduqcNo ratings yet

- Ultrasonic Examination Austenitic and Dissimilar WeldsDocument6 pagesUltrasonic Examination Austenitic and Dissimilar WeldshocimtmNo ratings yet

- Advances in Tube Testing 2008Document39 pagesAdvances in Tube Testing 2008AhmedA.Hassan100% (1)

- DGS CurvesDocument40 pagesDGS CurveshocimtmNo ratings yet

- Astm E-164 (2019)Document24 pagesAstm E-164 (2019)AnaNo ratings yet

- PCN General RulesDocument25 pagesPCN General RulesSangeeth Kavil PNo ratings yet

- UT Chapter 11Document70 pagesUT Chapter 11knizam1971100% (1)

- Weld-Solution en LTR 201712 WebDocument8 pagesWeld-Solution en LTR 201712 WebLương Hồ VũNo ratings yet

- 2018 Doppler CatalogDocument24 pages2018 Doppler CatalogRene ParedeschaconNo ratings yet

- Beamtool Scan Plan: Inspection LayoutDocument4 pagesBeamtool Scan Plan: Inspection LayoutMohan RajNo ratings yet

- Paut Paper PDFDocument7 pagesPaut Paper PDFAyesha GeNo ratings yet

- AGR Field Operations TD Focus-Scan Data SheetDocument2 pagesAGR Field Operations TD Focus-Scan Data SheetJeganeswaranNo ratings yet

- Circ-it configured Environmental SpecificationsDocument2 pagesCirc-it configured Environmental SpecificationsMarcos Kaian Moraes RodriguesNo ratings yet

- I S Eniso16811-2014Document14 pagesI S Eniso16811-2014Nicko Arya DharmaNo ratings yet

- Mandatory Appendix V Phased Array Linear ScanningDocument2 pagesMandatory Appendix V Phased Array Linear ScanningAngelTinoco100% (1)

- PAUT for Heavy Wall Austenitic SS WeldsDocument10 pagesPAUT for Heavy Wall Austenitic SS WeldsrupamNo ratings yet

- NDT Procedure BS EN 10160:1999 (Full Version Available From N-D-T.com)Document6 pagesNDT Procedure BS EN 10160:1999 (Full Version Available From N-D-T.com)Mark BrailsfordNo ratings yet

- Calibration BlocksDocument3 pagesCalibration BlocksvenkatNo ratings yet

- Dac & DGSDocument14 pagesDac & DGSAhmad Daniel100% (1)

- Successful Ultrasonic Inspection of Austenitic WeldsDocument6 pagesSuccessful Ultrasonic Inspection of Austenitic WeldsAnonymous 5qPKvmuTWCNo ratings yet

- 2008 Development of A Procedure For The Ultrasonic Examination of Nickel LNG Storage Tank Welds Using Phased Array TechnologyDocument5 pages2008 Development of A Procedure For The Ultrasonic Examination of Nickel LNG Storage Tank Welds Using Phased Array Technologyநந்த குமார் சம்பத் நாகராஜன்No ratings yet

- PA Probe Catalog en 201304Document24 pagesPA Probe Catalog en 201304Durgamadhaba Mishra100% (2)

- Basic Principles of Ultrasonic TestingDocument101 pagesBasic Principles of Ultrasonic TestingJohn Eric OliverNo ratings yet

- MX2 Training Program 14D Phased Array Analysis-Depth Height SizingDocument15 pagesMX2 Training Program 14D Phased Array Analysis-Depth Height SizingANH TAI MAINo ratings yet

- EN 15317 AnglaisDocument25 pagesEN 15317 Anglaisbarbier100% (1)

- MX2 Training Program 02 Intro To MX2Document25 pagesMX2 Training Program 02 Intro To MX2Victor Antonio Diaz FaundezNo ratings yet

- UT TEST PROCEDURE LAMINATIONSDocument8 pagesUT TEST PROCEDURE LAMINATIONSperogami100% (1)

- Use of Dgs Method For Ultrasonic TestiingDocument3 pagesUse of Dgs Method For Ultrasonic Testiingarunpawar_cet9462No ratings yet

- AWS D1.1 Phased Array GuidelineDocument40 pagesAWS D1.1 Phased Array GuidelineMario Perez100% (1)

- Eddy Current Tubing DentingDocument54 pagesEddy Current Tubing Dentingaldeanucu100% (3)

- 8.5 Curved Surface Correction (CSC) - Olympus IMSDocument4 pages8.5 Curved Surface Correction (CSC) - Olympus IMSTHIRU.SNo ratings yet

- Iqi'sDocument6 pagesIqi's24inspector100% (1)

- PAUT of ''CRA WELDSDocument7 pagesPAUT of ''CRA WELDSDurgamadhaba Mishra100% (1)

- 2011 PipeWizard Training Part 01Document62 pages2011 PipeWizard Training Part 01rajeev jegadeesan100% (1)

- ISO Standards On NDT of WeldingDocument2 pagesISO Standards On NDT of WeldingDavid Alejandro Vega Alfonso100% (1)

- 14.0 Specific ExaminationDocument18 pages14.0 Specific ExaminationPDDELUCANo ratings yet

- DUAL MATRIX ARRAY OverviewDocument37 pagesDUAL MATRIX ARRAY OverviewLe Anh Duy100% (1)

- Inspection Report Bifab Ut On Duplex Stainless Steel Piping PDFDocument11 pagesInspection Report Bifab Ut On Duplex Stainless Steel Piping PDFquiron2014No ratings yet

- Sonatest PAUTDocument6 pagesSonatest PAUTpokeboy19No ratings yet

- Angle DACDocument1 pageAngle DACJeevanandam ShanmugasundaramNo ratings yet

- Tofd Development: TechniqueDocument32 pagesTofd Development: TechniqueLương Hồ VũNo ratings yet

- DAC Block Details PDFDocument2 pagesDAC Block Details PDFShrikant UtekarNo ratings yet

- OmniScan MX2 PDFDocument12 pagesOmniScan MX2 PDFpokeboy19100% (1)

- Tangential RadiographyDocument9 pagesTangential Radiographykirubha_karan2000No ratings yet

- Iso Dis 13272 e 2Document24 pagesIso Dis 13272 e 2webhareggebru06No ratings yet

- Dis - 26203-2 - 2009Document21 pagesDis - 26203-2 - 2009Institute of Marketing & Training ALGERIANo ratings yet

- Earth-Moving Machinery - Laboratory Tests and Performance Requirements For Roll-Over Protective Structures - Metallic StructuresDocument69 pagesEarth-Moving Machinery - Laboratory Tests and Performance Requirements For Roll-Over Protective Structures - Metallic StructuresMontineriNo ratings yet

- Iso Dis 20283-4 2011Document27 pagesIso Dis 20283-4 2011Ricardo RamirezNo ratings yet

- Asset Management - Overview, Principles and Terminology: Draft International Standard Iso/Dis 55000Document25 pagesAsset Management - Overview, Principles and Terminology: Draft International Standard Iso/Dis 55000Peter Guerrero BacaNo ratings yet

- JurnalDocument29 pagesJurnalIlham MaulanaNo ratings yet

- Certification Scheme: Chương Trình Chứng NhậnDocument13 pagesCertification Scheme: Chương Trình Chứng NhậnVuong Tran VanNo ratings yet

- ISO 17024 2012 Compliance MatrixDocument3 pagesISO 17024 2012 Compliance MatrixVuong Tran Van0% (1)

- Requirements for NDT personnel certificationDocument40 pagesRequirements for NDT personnel certificationKewell LimNo ratings yet

- PCS 003Document22 pagesPCS 003Vuong Tran VanNo ratings yet

- CB Certification RequirementsDocument16 pagesCB Certification RequirementsVuong Tran VanNo ratings yet

- General Requirements For Qualification and PCN Certification of NDT PersonnelDocument26 pagesGeneral Requirements For Qualification and PCN Certification of NDT PersonnelPedro OliveiraNo ratings yet

- AWS D1.1:2020 - Changes To Structural Welding Code - SteelDocument1 pageAWS D1.1:2020 - Changes To Structural Welding Code - SteelVuong Tran VanNo ratings yet

- Bridge Welding Code: 7th EditionDocument29 pagesBridge Welding Code: 7th EditionVuong Tran VanNo ratings yet

- 00.ISO 9712 Scheme SGNDTDocument41 pages00.ISO 9712 Scheme SGNDTVuong Tran VanNo ratings yet

- Mechanical Completion & ComissioningDocument56 pagesMechanical Completion & ComissioningRustam Riyadi100% (1)

- Policy and Procedures Manual: Please Direct Communications ToDocument43 pagesPolicy and Procedures Manual: Please Direct Communications ToVuong Tran VanNo ratings yet

- Gen - 010 - 6 - 4 - NORDNDT - ISO 9712 PersonnelDocument10 pagesGen - 010 - 6 - 4 - NORDNDT - ISO 9712 PersonnelKewell LimNo ratings yet

- E2929 13 Standard Practice For Guided PDFDocument11 pagesE2929 13 Standard Practice For Guided PDFVuong Tran VanNo ratings yet

- AWS D1.5 Code Changes - 2020 Edition: Nesmea Mr. Allen W. Sindel - TRC Presented By: Mr. Robert Horwhat - TRCDocument26 pagesAWS D1.5 Code Changes - 2020 Edition: Nesmea Mr. Allen W. Sindel - TRC Presented By: Mr. Robert Horwhat - TRCVuong Tran VanNo ratings yet

- Hot Cell Specialized Support Equipment and Tools: Standard Guide ForDocument15 pagesHot Cell Specialized Support Equipment and Tools: Standard Guide ForVuong Tran VanNo ratings yet

- Bridge Welding Code: 7th EditionDocument29 pagesBridge Welding Code: 7th EditionVuong Tran VanNo ratings yet

- Creep-Fatigue Testing: Standard Test Method ForDocument15 pagesCreep-Fatigue Testing: Standard Test Method ForNilton Santillan100% (1)

- Fully Automated Ut Weld Inspection: WeldroverDocument3 pagesFully Automated Ut Weld Inspection: WeldroverBiju_PottayilNo ratings yet

- Astm F2620-13 PDFDocument25 pagesAstm F2620-13 PDFJORGENo ratings yet

- Scanner CHAIN EN 201204 PDFDocument2 pagesScanner CHAIN EN 201204 PDFVuong Tran VanNo ratings yet

- Non-Destructive Testing - Guided Wave Testing: BSI Standards PublicationDocument22 pagesNon-Destructive Testing - Guided Wave Testing: BSI Standards Publicationcesarrichardo100% (2)

- BS en Iso 16148-2016 PDFDocument38 pagesBS en Iso 16148-2016 PDFVuong Tran Van100% (1)

- Non-Destructive Testing - Guided Wave Testing: BSI Standards PublicationDocument26 pagesNon-Destructive Testing - Guided Wave Testing: BSI Standards PublicationVuong Tran Van100% (3)

- E3023-15 Standard Practice For Probability of Detection Analysis For  Versus A DataDocument12 pagesE3023-15 Standard Practice For Probability of Detection Analysis For  Versus A DataAhmed Shaban KotbNo ratings yet

- BS EN ISO 23278-2009 MT AcceptanceDocument10 pagesBS EN ISO 23278-2009 MT AcceptanceVuong Tran Van100% (1)

- BS EN 499 - Welding Consumables - Covered Electrodes For Man PDFDocument12 pagesBS EN 499 - Welding Consumables - Covered Electrodes For Man PDFVuong Tran VanNo ratings yet

- Determination of Metal Purity Based On Elastic Constant Measurements Derived From Resonant Ultrasound SpectrosDocument4 pagesDetermination of Metal Purity Based On Elastic Constant Measurements Derived From Resonant Ultrasound SpectrosVuong Tran VanNo ratings yet

- E3022-15 Standard Practice For Measurement of Emission Characteristics and Requirements For LED UV-A Lamps Used in Fluorescent Penetrant and Magnetic Particle TestingDocument8 pagesE3022-15 Standard Practice For Measurement of Emission Characteristics and Requirements For LED UV-A Lamps Used in Fluorescent Penetrant and Magnetic Particle TestingAhmed Shaban KotbNo ratings yet

- Acoustic Emission Examination of High Pressure, Low Carbon, Forged Piping Using Controlled Hydrostatic PressurizationDocument6 pagesAcoustic Emission Examination of High Pressure, Low Carbon, Forged Piping Using Controlled Hydrostatic PressurizationVuong Tran VanNo ratings yet

- Concrete TestingDocument34 pagesConcrete TestingKamarajanNo ratings yet

- NASA Composite Materials DevelopmentDocument58 pagesNASA Composite Materials DevelopmentWoodrow FoxNo ratings yet

- Fabrication and Testing Requirements Class: FTR 1 of 2 - 2016-01-12 MC H. Pelders S M. Ummelen ME R.J. Lammers/hpeDocument2 pagesFabrication and Testing Requirements Class: FTR 1 of 2 - 2016-01-12 MC H. Pelders S M. Ummelen ME R.J. Lammers/hpemokie305No ratings yet

- Usama Tamboli CV QDocument3 pagesUsama Tamboli CV QUsamah TNo ratings yet

- DNV ST E271 Offshore ContainersDocument107 pagesDNV ST E271 Offshore ContainersWantana RattaneeNo ratings yet

- Astm E1417 - E1417m - 13Document11 pagesAstm E1417 - E1417m - 13Teddy HariyantoNo ratings yet

- Radiography SpecificationDocument46 pagesRadiography SpecificationPaul BainesNo ratings yet

- GP 32-20Document366 pagesGP 32-20Diego100% (1)

- Bs en 729-4-1995-Quality Requirements For Welding PDFDocument10 pagesBs en 729-4-1995-Quality Requirements For Welding PDFscofiel1No ratings yet

- Catalogue PDF'S - CompressedDocument576 pagesCatalogue PDF'S - Compressedjunyang liNo ratings yet

- API Meeting 4 - 2007Document47 pagesAPI Meeting 4 - 2007Mahmoud GamalNo ratings yet

- Exotic Materials Product Bulletin - 1774Document2 pagesExotic Materials Product Bulletin - 1774Govindharj RNo ratings yet

- Advanced Ultrasonic Techniques For Nondestructive Testing of Austenitic and Dissimilar Welds in Nuclear FacilitiesDocument10 pagesAdvanced Ultrasonic Techniques For Nondestructive Testing of Austenitic and Dissimilar Welds in Nuclear FacilitiesAnonymous 5qPKvmuTWCNo ratings yet

- An Introduction To Failure Analysis For Metallurgical EngineersDocument21 pagesAn Introduction To Failure Analysis For Metallurgical Engineersrpadhra8803No ratings yet

- NG22 282 CST PSL 100011 - Revc0Document9 pagesNG22 282 CST PSL 100011 - Revc0Theophilus OrupaboNo ratings yet

- APPEA Guidlines For Lifting EquipmentDocument103 pagesAPPEA Guidlines For Lifting Equipmentt1tacalNo ratings yet

- Inspection and Test Plan For Pressure Vessel Repair, Modification, AlterationDocument5 pagesInspection and Test Plan For Pressure Vessel Repair, Modification, AlterationMuhammed Abo-Fandood50% (2)

- Engineer CV Material Specialists Mechanical Piping NDT Coating Inspection Oil Gas AlgeriaDocument3 pagesEngineer CV Material Specialists Mechanical Piping NDT Coating Inspection Oil Gas Algeriaait.koufiNo ratings yet

- PHD ThesisDocument200 pagesPHD ThesisdoolyiiNo ratings yet

- Weld Testing Methods GuideDocument4 pagesWeld Testing Methods GuidejoaoNo ratings yet

- Standard Procedure For Acoustic Emission TestDocument10 pagesStandard Procedure For Acoustic Emission TestprendoascroccoNo ratings yet

- Décret 21-261.englilsh VersionDocument14 pagesDécret 21-261.englilsh Versionqa/qcNo ratings yet

- Robotic Tank Inspection & Cleaning BrouchreDocument16 pagesRobotic Tank Inspection & Cleaning BrouchreJayson PintoNo ratings yet

- CP16 Adrian Viorel Jica UTDocument19 pagesCP16 Adrian Viorel Jica UTadrianvjicaNo ratings yet

- Annexure To SOW 3 STD Specification For Welding and NDT PipingDocument15 pagesAnnexure To SOW 3 STD Specification For Welding and NDT PipingASHISH GORDENo ratings yet

- NDT ISO IEC 17025 Application DocumentDocument41 pagesNDT ISO IEC 17025 Application DocumentVicky SinghNo ratings yet

- A Pi 653 Tank Inspection FormDocument5 pagesA Pi 653 Tank Inspection FormErenBaşaraNo ratings yet

- Practice Points For MasonryDocument8 pagesPractice Points For MasonryJatinder Bhatia100% (1)

- Aws D14.6.-2005Document186 pagesAws D14.6.-2005ardfall17No ratings yet

- Pim Agenda PalngDocument14 pagesPim Agenda Palngbaris121919No ratings yet