Professional Documents

Culture Documents

Gantt Charts, Took Several Different Forms, Depending On Their

Uploaded by

senior high0 ratings0% found this document useful (0 votes)

48 views5 pagesOriginal Title

Lecture 4

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

48 views5 pagesGantt Charts, Took Several Different Forms, Depending On Their

Uploaded by

senior highCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

CE 23 - Construction Methods and Project Management technique permits start-to-start and finish-to-finish

Lesson 3: Planning and Scheduling relationships.

As you already know, some planning must be done I order

to perform any function with a minimum of wasted time and

effort. This is true whether the function is getting to work on

time or constructing a multi-million dollar building. A schedule

is nothing more than a time-phased plan. Schedules are used

as guides during the performances of an operation at the

desired or required time.

Scheduling is utilized for many different phases of the

construction process, from master planning through facility

construction to facility operation and maintenance. In the

construction phase itself, schedules are useful for a number of

purposes before starting a project and after completion of the

project as well as during the actual conduct of construction

work. Some of the principal uses for schedules during each of

these phases of construction are listed below

Before Starting

1. Provides an estimate of the time required for each portion

5. PERT (Project Evaluation and Review Technique)

of the project as well as for the total project.

The same with CPM that uses network diagram. The major

2. Establishes the planned rate of progress.

difference with PERT and CPM is that PERT utilizes probability

3. Forms the basis for managers to issue instructions to

concepts to deal with uncertainty associated with activity-time

subordinates.

estimates.

4. Establishes the planned sequence for the use of personnel,

materials, machines, and money.

Formula/Parameters:

During Construction

1. Enables the manager to prepare a checklist of key dates,

activities, resources, and so on.

2. Provides a means for evaluating the effect of changes and

delays.

3. Serves as the basis for evaluating progress

4. Aids in the coordination of resources

After Completion of Construction

1. Permits a review and analysis of the project as actually

carried out.

2. Provides historical data for improving future planning and

estimating.

Project Work Scheduling

1. Bar Chart or bar chart schedule is a graphical schedule

relating progress of items of work to a time schedule. The bar

schedule traces its origin to a chart developed by Henry L.

Gantt, a pioneer in the application of scientific management Definition of terms:

methods to industrial production. These charts, referred to as Activity- the performance of a specific task

Gantt charts, took several different forms, depending on their Event- the completion of an activity

application. Because of their origin, all forms of bar graph Arrow- represents an activity included in the project

schedules are sometimes called Gantt charts. Network- the arrow diagram representing the sequential

2. Critical Path Method - Activity-on-Arrow Diagram relationship of activities and events for a project

A major deficiency of the bar graph schedule is its failure to Dummy- an artificial activity, represented by dotted lines, to

show relationships between project activities. Thus there is no indicate that an activity following the dummy cannot be

way to determine from a bar graph schedule whether the started until the activities preceding the dummy are completed.

person preparing the schedule was, in fact, aware of these - has zero duration

relationships. A related weakness of the bar graph schedule is Duration (D) - the estimated time required to perform an

its failure to identify those activities which actually control the activity

project duration. We will refer to such duration-controlling Earliest Start (ES) – the earliest time that an activity can be

activities as critical activities. started

3. Precedence Diagram Method - Activity-on-Node Diagram Earliest Finish (EF) – the earliest time that an activity can be

This technique uses the same general principles of network finished : EF =ES + D

logic and time calculations as does the activity-on-arrow Latest Start (LS) – latest time that an activity can be started

technique. However, the activity-on-node network diagram without delaying the completion of a project : LS = LF – D

looks somewhat different from the AOA diagram. Latest Finish (LF) – the latest time that an activity can be

4. Lead Lag Method - Variation of PDM, with lead and lag finished without delaying the completion time of a project

The lead Lag Method is an extension of the AON format that LF = LS + D

provides for incorporation of lag-time factors as well as Total Float (TF) – the amount of time that the start or finish of

permitting additional precedence relationships. The use of lag an activity can be delayed without delaying the completion of a

time is very useful when diagramming construction project project : TF = LF – EF = LS - ES

relationships, where activities can often start as soon as a Free float (FF) – the amount of time that finish of an activity

portion of a preceding activity is completed. In a addition to can be delayed without delaying the earliest start for a

the usual finish-to-start precedence relationship, this following activity FF = ES following activity - EF this activity

Critical Path - the series of interconnected activities through

the network for which each activity has zero float time. It

determines the minimum time required to complete a project

Conducting a Crash Program

Purpose is to reduce the total time to finish a project at the

least possible additional cost.

Means:

1. Increase the rate of providing materials

2. Increase the number of workers which may reduce the

productivity per worker

3. Assign workers to do overtime at premium wage rates

4. Increase the number of units of equipment assigned to

critical activities

Cost slope - additional cost per unit of time of reduction in the

duration of activity

Example 3: Conduct a crash program to reduce the completion

CrashCost NormalCost time of the project by five days.

CostSlope

NormalDura tion CrashDurat ion

Sample Problems:

Example 1: Draw the AOA and AON for the activities below.

Indicate ES, EF, LS, LF. Determine the critical path and tabulate

the float for each activity.

Duration Activities immediately

Activities

(Days) Preceding Following

A - Lay-out 1 None B,C

B - Slab 4 A D

excavation

C - Slab forms 1 A G

D - Place 1 B E,F

blocks

E - Rough 2 D H

plumbing

F - Rough 2 D K

electrical

G - Place 1 C I,J

concrete

H - Place 1 E K

home

I - Remove 2 G L

forms

J - Cure 7 G L

concrete

K - Hook-up 4 F,H L

home

L - Clean-up 2 J,K,I None

Example 2: Given the estimates of duration of activities,

determine:

a. The expected completion time of the project

b. The probability that the project will be finished in less than

or equal to 17 days.

c. The probability that the project will be finished within 17 to

19 days.

Activity Duration Estimates

a m b

A 5 11 11

B 7 7 7

C 3 5 13

D 2 9 10

Figure 1: Bar graph schedule for construction project

Figure 2: Scheduled Cumulative Progress

Figure 3: Bar Graph with Cumulative Progress Curve

Figure 4: Precedence diagram for example project.

Adding logic constraints to figure 4:

a. Erection of the tower and tank cannot begin until 3 days after completion of foundation.

b. Installation of pump cannot be completed until 1 day after completion of pipe installation.

c. The foundation can start 3 days after start of excavation

Figure 5: Revised precedence diagram for the constraints mentioned above (Lead Lag Method)

You might also like

- CISA Exam-Testing Concept-PERT/CPM/Gantt Chart/FPA/EVA/Timebox (Chapter-3)From EverandCISA Exam-Testing Concept-PERT/CPM/Gantt Chart/FPA/EVA/Timebox (Chapter-3)Rating: 1.5 out of 5 stars1.5/5 (3)

- Cba Om-Pm Prepared Lecture ReferenceDocument63 pagesCba Om-Pm Prepared Lecture ReferenceMargz CafifgeNo ratings yet

- CPM and Pert AnalysisDocument30 pagesCPM and Pert AnalysisMichael Laguitan0% (1)

- Project Scheduling: Time-Scaled Network AnalysisDocument30 pagesProject Scheduling: Time-Scaled Network AnalysisEurydice100% (1)

- OR Chapter 5Document21 pagesOR Chapter 5anon_92845981No ratings yet

- PM Methods for Planning & Scheduling ProjectsDocument30 pagesPM Methods for Planning & Scheduling ProjectsJames OwusuNo ratings yet

- Project Management TechniquesDocument53 pagesProject Management Techniquesaditi_apteNo ratings yet

- Scheduling and NetworksDocument70 pagesScheduling and NetworksSanjana SudeepNo ratings yet

- Project Management2Document68 pagesProject Management2panghal13No ratings yet

- Estimation Engineering Lecture NotesDocument31 pagesEstimation Engineering Lecture NotesAri ZrarNo ratings yet

- Kerzner, CH 6Document46 pagesKerzner, CH 6Fisiha FikiruNo ratings yet

- Chapter 4 PMDocument13 pagesChapter 4 PMPrayerNo ratings yet

- Lec 4 6Document44 pagesLec 4 6waqaryounas28936No ratings yet

- Pert Case StudyDocument4 pagesPert Case Studyolayemi taiwo100% (5)

- CPM & Pert: TechniquesDocument27 pagesCPM & Pert: TechniquesharishankarnadarNo ratings yet

- Chapter 13 SolutionDocument26 pagesChapter 13 SolutionSunil Sharma100% (1)

- Chapter 6Document33 pagesChapter 6Hassan Abib BasalNo ratings yet

- Project Management - CPM&PERTDocument32 pagesProject Management - CPM&PERTADITYA SINGHNo ratings yet

- Project ManagementDocument43 pagesProject Managementalp_ganNo ratings yet

- Project Management Cpm/Pert: Professor AhmadiDocument19 pagesProject Management Cpm/Pert: Professor AhmadiboubkaNo ratings yet

- Chapter PEM CPM PERTDocument75 pagesChapter PEM CPM PERTkalakhetianushaNo ratings yet

- Network Planning MethodsDocument24 pagesNetwork Planning MethodsRahulAdhikariNo ratings yet

- Critical Path Method (CPM) : Project Management For ITDocument23 pagesCritical Path Method (CPM) : Project Management For ITSyed EmadNo ratings yet

- Pert/Cpm: Project Scheduling Project SchedulingDocument51 pagesPert/Cpm: Project Scheduling Project SchedulingSandeep NakireddyNo ratings yet

- IT Project Scheduling TechniquesDocument32 pagesIT Project Scheduling TechniquesHabtie TesfahunNo ratings yet

- Qualitative Planning MethodDocument37 pagesQualitative Planning Methodsasmita nayakNo ratings yet

- Scheduling The Project: CPM & Pert: DR Sandeep K. Gupta (PHD, Mba, M.Tech) Assistant Professor, SnuDocument14 pagesScheduling The Project: CPM & Pert: DR Sandeep K. Gupta (PHD, Mba, M.Tech) Assistant Professor, SnuNilanjana KuthariNo ratings yet

- CH3 Project Time ManagementDocument32 pagesCH3 Project Time ManagementOz GNo ratings yet

- Operations Research Project Management Using Network AnalysisDocument16 pagesOperations Research Project Management Using Network Analysisshivina guptaNo ratings yet

- Lecture HandoutDocument59 pagesLecture HandoutSHITAL SUMANNo ratings yet

- Project Scheduling (Session 14 - 15)Document37 pagesProject Scheduling (Session 14 - 15)GauravNo ratings yet

- Project Planning Techniques: Network Analysis and PERTDocument25 pagesProject Planning Techniques: Network Analysis and PERTDaudi MakelemoNo ratings yet

- Project Planning Using Network TechniqueDocument25 pagesProject Planning Using Network Techniquesailormoon72No ratings yet

- Chapter 5 C M Notes PPDocument64 pagesChapter 5 C M Notes PPzulizwxnNo ratings yet

- Lecture 10 - Project Planning and SchedulingDocument26 pagesLecture 10 - Project Planning and SchedulingjbjuanzonNo ratings yet

- Scheduling and PlanningDocument43 pagesScheduling and PlanningMaricon PadriquezNo ratings yet

- Project ManagementDocument4 pagesProject ManagementJez IlleNo ratings yet

- Lecture 9 - Project Planning and SchedulingDocument27 pagesLecture 9 - Project Planning and SchedulingLouise Luy100% (3)

- Chapter 7 ProjectDocument24 pagesChapter 7 Projectkel GetanehNo ratings yet

- Network Models CPM U9Document13 pagesNetwork Models CPM U9min_feelingsNo ratings yet

- OPMA 5364 Part 5Document33 pagesOPMA 5364 Part 5Tran Tuan AnhNo ratings yet

- Week006 PresentationDocument38 pagesWeek006 PresentationMichael Angelo MallariNo ratings yet

- Unit - Nari 6Document24 pagesUnit - Nari 6Naresh GuduruNo ratings yet

- Project Scheduling TechniquesDocument22 pagesProject Scheduling TechniquesKunjal Kumar SinghNo ratings yet

- Project Planning & SchedulingDocument60 pagesProject Planning & Schedulingxandercage100% (1)

- Lecture Notes Chapter 6 CHE620 Project ManagementDocument39 pagesLecture Notes Chapter 6 CHE620 Project ManagementSyah MieNo ratings yet

- Definition of Terms in A Network: ActivityDocument57 pagesDefinition of Terms in A Network: Activityyusha habibNo ratings yet

- PERT CPM Project Scheduling TechniquesDocument24 pagesPERT CPM Project Scheduling TechniquesCminh TrNo ratings yet

- Pragya Arya Asst. Professor Lal Bahadur Shastri Institute of Management New DelhiDocument28 pagesPragya Arya Asst. Professor Lal Bahadur Shastri Institute of Management New DelhiSonika GognaNo ratings yet

- Quantitative Techniques P-1 With AnswersDocument3 pagesQuantitative Techniques P-1 With AnswersshirylNo ratings yet

- Im-5 UnitDocument31 pagesIm-5 UnitVenu NethaNo ratings yet

- Unit - 6 Projet Management (Pert/Cpm) : Net Work Analysis: It Is Refers To A Number of Techniques For The Planning andDocument40 pagesUnit - 6 Projet Management (Pert/Cpm) : Net Work Analysis: It Is Refers To A Number of Techniques For The Planning andSuneelKumarNo ratings yet

- Lecture 10 (Pert CPM)Document37 pagesLecture 10 (Pert CPM)umair aliNo ratings yet

- Project Planning & Scheduling PDFDocument62 pagesProject Planning & Scheduling PDFInshal KhanNo ratings yet

- Characteristics of Project ManagementDocument19 pagesCharacteristics of Project Managementkccrseyer03No ratings yet

- Construction Methods and Project Management ReviewerDocument19 pagesConstruction Methods and Project Management ReviewerShaina Mariz Serrano PanaliganNo ratings yet

- Network AnalysisDocument22 pagesNetwork AnalysisJayasankar NarayananNo ratings yet

- Chapter-4 Sceduling - FinalDocument76 pagesChapter-4 Sceduling - FinalmelakadugnaNo ratings yet

- 4. Project Planning CPM PERTDocument47 pages4. Project Planning CPM PERTShubham HNo ratings yet

- Psychological Testing: An Overview of Tests, Purposes, and EthicsDocument27 pagesPsychological Testing: An Overview of Tests, Purposes, and Ethicssenior highNo ratings yet

- Work and Kinetic Energy LessonDocument5 pagesWork and Kinetic Energy Lessonsenior highNo ratings yet

- Study Journal Lesson 1-12 - LisondraDocument4 pagesStudy Journal Lesson 1-12 - Lisondrasenior highNo ratings yet

- Periodic Table MLZDocument1 pagePeriodic Table MLZsenior highNo ratings yet

- Study Journal Lesson 1-12 - LisondraDocument4 pagesStudy Journal Lesson 1-12 - Lisondrasenior highNo ratings yet

- Lesson 1 PDFDocument4 pagesLesson 1 PDFsenior highNo ratings yet

- Study Journal Lesson 23-32 - LisondraDocument3 pagesStudy Journal Lesson 23-32 - Lisondrasenior highNo ratings yet

- Study Journal Lesson 23-32 - LisondraDocument3 pagesStudy Journal Lesson 23-32 - Lisondrasenior highNo ratings yet

- Test 1Document1 pageTest 1senior highNo ratings yet

- Proper handling and toxicity of butanol, glacial acetic acid, glycine, lysine, tyrosine and leucine solutionsDocument3 pagesProper handling and toxicity of butanol, glacial acetic acid, glycine, lysine, tyrosine and leucine solutionssenior highNo ratings yet

- Physical Properties of Organic Compounds: Review of Intermolecular Forces of Attraction (Ifas)Document13 pagesPhysical Properties of Organic Compounds: Review of Intermolecular Forces of Attraction (Ifas)Darielle JovenNo ratings yet

- ChiralityDocument17 pagesChiralitysenior highNo ratings yet

- Maximum Deflection. Recall Your Lessons in Determining The Deflection of Determinate Beams From Structural Theory Subject) (Document2 pagesMaximum Deflection. Recall Your Lessons in Determining The Deflection of Determinate Beams From Structural Theory Subject) (senior highNo ratings yet

- I MC S M F: Timber Advantages and Disadvantages of Wood Bending Stress in BeamsDocument4 pagesI MC S M F: Timber Advantages and Disadvantages of Wood Bending Stress in Beamssenior highNo ratings yet

- Aristotle's Nicomachean Ethics: Happiness as the Supreme Human GoodDocument4 pagesAristotle's Nicomachean Ethics: Happiness as the Supreme Human Goodsenior highNo ratings yet

- Research EnvironmentDocument2 pagesResearch Environmentsenior highNo ratings yet

- BENEDICT - Anthropology and The AbnormalDocument4 pagesBENEDICT - Anthropology and The Abnormalanon_137579236No ratings yet

- DatusDocument3 pagesDatussenior highNo ratings yet

- Literary Devices Elements TechniquesDocument38 pagesLiterary Devices Elements Techniquessenior high100% (2)

- DocumentDocument1 pageDocumentsenior highNo ratings yet

- Mga IeeditDocument1 pageMga Ieeditsenior highNo ratings yet

- Running Head: DATA ANALYSIS 1Document4 pagesRunning Head: DATA ANALYSIS 1senior highNo ratings yet

- A Reflection On Genesis Chapters One To ThreeDocument1 pageA Reflection On Genesis Chapters One To Threesenior highNo ratings yet

- This Is A DocumentDocument1 pageThis Is A Documentsenior highNo ratings yet

- ADocument5 pagesAsenior highNo ratings yet

- A Summary of The Theology of The BodyDocument2 pagesA Summary of The Theology of The Bodysenior highNo ratings yet

- Quiz 2Document1 pageQuiz 2senior highNo ratings yet

- Soil 1: γ, φ 3 3: K = 0.3 γ = 19.49 kN/mDocument1 pageSoil 1: γ, φ 3 3: K = 0.3 γ = 19.49 kN/msenior highNo ratings yet

- The Hundred Foot JourneyDocument2 pagesThe Hundred Foot Journeysenior high0% (2)

- B - M Assignment: EARTHWORKS: MeasurementDocument6 pagesB - M Assignment: EARTHWORKS: MeasurementRNo ratings yet

- JJG-1999 May-Chord Construction Part 1 by Rick StoneDocument2 pagesJJG-1999 May-Chord Construction Part 1 by Rick StonekousayamadaNo ratings yet

- Naksha - Pesh - Garda - Khyal - Garnu - Parne - KuraaharuDocument10 pagesNaksha - Pesh - Garda - Khyal - Garnu - Parne - Kuraaharurajishv9148No ratings yet

- A Ruler Is A me-WPS OfficeDocument3 pagesA Ruler Is A me-WPS OfficeAde Aisyah Shinta BalkisNo ratings yet

- Method Statement For Concrete Slab CuttingDocument13 pagesMethod Statement For Concrete Slab CuttingACCURATE BUILDING DEMOLITION L.L.C.No ratings yet

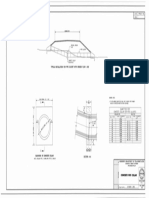

- Concrete pipe collar installation detailsDocument1 pageConcrete pipe collar installation detailsTumulak IanNo ratings yet

- Group 1 PresentationDocument26 pagesGroup 1 PresentationNomanNo ratings yet

- Cfa Pile ProductivityDocument13 pagesCfa Pile ProductivitymNo ratings yet

- Concrete: The GCCA 2050 Cement and Concrete Industry Roadmap For Net Zero ConcreteDocument48 pagesConcrete: The GCCA 2050 Cement and Concrete Industry Roadmap For Net Zero ConcreteLeicel John BelmesNo ratings yet

- Stegbar Windows Doors Standard Sizes Brochure PDFDocument19 pagesStegbar Windows Doors Standard Sizes Brochure PDFsurbhi aggarwalNo ratings yet

- Literature review on non-destructive testing methods for concreteDocument12 pagesLiterature review on non-destructive testing methods for concreteHaiqal RafiqNo ratings yet

- Front Elevation A 1 Rear Elevation A 1: Total Floor Area: 525 SQMDocument2 pagesFront Elevation A 1 Rear Elevation A 1: Total Floor Area: 525 SQMLarry Jay Enaga ConstantinoNo ratings yet

- Annex-A (4 5%)Document3 pagesAnnex-A (4 5%)Naveed KhanNo ratings yet

- Ms Working PlatformDocument4 pagesMs Working Platformmohd solihin bin mohd hasan100% (1)

- Master CableDocument13 pagesMaster CableJoe_AverageNo ratings yet

- Technical Specification For Fire ProtectionDocument3 pagesTechnical Specification For Fire ProtectionJoeven JagocoyNo ratings yet

- Godrej Meadows Mahalunge - 07666027159Document47 pagesGodrej Meadows Mahalunge - 07666027159Meadows MahalungeNo ratings yet

- Astm D8 - 13Document4 pagesAstm D8 - 13Neeraj KumarNo ratings yet

- Wall Formwork Design LCDDocument8 pagesWall Formwork Design LCDRezky KurniawanNo ratings yet

- Indira Paryavaran Bhawan - India's First Net Zero Energy Green BuildingDocument16 pagesIndira Paryavaran Bhawan - India's First Net Zero Energy Green BuildingAshwin RamadesikanNo ratings yet

- Gin Pole MANUALDocument13 pagesGin Pole MANUALHarish BhattNo ratings yet

- Earthquake Resistant Structure - NOTES 3rd YR V SEMDocument12 pagesEarthquake Resistant Structure - NOTES 3rd YR V SEMrutuja100% (1)

- Utility Service: Vicinity Map Service Entrance PoleDocument1 pageUtility Service: Vicinity Map Service Entrance Polejay vasquezNo ratings yet

- Specialized Construction Techniques - FinalDocument102 pagesSpecialized Construction Techniques - FinalSabella JimenezNo ratings yet

- Bituminous Macadam: Property T ST Code R Quirem NTDocument4 pagesBituminous Macadam: Property T ST Code R Quirem NTSOORAJ CHANDRA R SNo ratings yet

- Concrete Mixing and Testing Lab ReportDocument8 pagesConcrete Mixing and Testing Lab ReportSoundMan56100% (4)

- Wiley - Architectural Graphic Standards, 12th Edition - 978-1-118-90950-8Document2 pagesWiley - Architectural Graphic Standards, 12th Edition - 978-1-118-90950-8riyad HamzaNo ratings yet

- Mad World by Ulli BoegershausenDocument3 pagesMad World by Ulli BoegershausenjeomaopestoksjeNo ratings yet

- Cfca-034 Registro Inspeccion de Apriete PernosDocument17 pagesCfca-034 Registro Inspeccion de Apriete PernosespluisjavierNo ratings yet

- Engineer's Blue - WikipediaDocument2 pagesEngineer's Blue - WikipediaTahafanMaggedonNo ratings yet