Professional Documents

Culture Documents

7.1. Blowing Wheel, Infeed/Discharge Starwheel: Contiform Mechanical Adjustments

Uploaded by

Joel Coaguila CosiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7.1. Blowing Wheel, Infeed/Discharge Starwheel: Contiform Mechanical Adjustments

Uploaded by

Joel Coaguila CosiCopyright:

Available Formats

Contiform

Mechanical Adjustments

7.1. Blowing Wheel, Infeed/Discharge Starwheel

Clamp Transfer to the Blow Mould

To adjust the blowing wheel at the infeed/discharge

starwheel, remove the clamp from one arm and replace it

using the adjusting device (3).

The mould, to which this arm transferred, and the blowing

nozzle of this station must be removed as well. Instead of the

blowing nozzle, the adjusting tip (2) must be screwed into

the blowing piston. Then, jog the starwheel to the transfer

position.

As a rule, the zero reference arm according to the test record

n

should be used here. Usually, arm number 1 is the zero

reference arm (1).

kap4-09010.eps

o p Marks At the transfer position, the adjusting tip (2) should be set to

allow for an admission at the mark (3) of one graduation

(approx. 1 mm) up to Contiform S 16 and two graduations

(approx. 2 mm) as of Contiform S 20, to compensate for the

belt backlash at maximum machine speed.

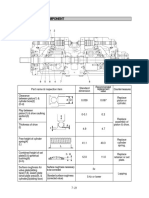

Einstell12-001_1/2.eps

Firstly loosen the 6 hexagon head screws (4) and turn the

starwheel manually in machine operating direction past the

correct position. The starwheel must then be turned back in

the opposite direction until the correct position is reached.

This is necessary to exclude any possible play from the

transfer arm.

If the position is correct, retighten the screws (4) with a

q torque of 45 Nm and check the position again.

DS-e09-0014(07)-1 10/05 KAT/me

kap4-09012.eps

Training Manual 7-1

Contiform

Mechanical Adjustments

Height Adjustment, Infeed/Discharge

Starwheel

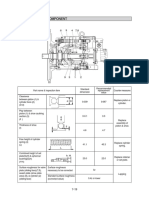

First, loosen the hexagon head screws on the tightener (1).

kap4-09012.eps

Then loosen the hexagon socket screw (2). By turning the

brass disk (3), you can move the complete infeed/discharge

o starwheel up or down, thus enabling the height to be

adjusted precisely.

p Please make sure that, after height adjustment, the brass disk

will be turned back 1/2 revolution, so that it does not closely

fit the starwheel.

09-14050.eps

The topmost mould carrier is the zero reference mould, and

the arm identified with position 1 is the reference arm

(measured in the factory) used for adjustment. Move the

reference arm above the reference mould. Make sure that the

preform is in the clamp. It should be adjusted in such a way

that the distance between the lower edge of the preform

neck ring and the upper edge of the mould shell amounts to

0.3 mm (using a feeler gauge) for the infeed starwheel and

0 mm for the discharge starwheel.

Infeed/discharge starwheel: lowest arm, highest mould

kap4-09013.eps

DS-e09-0014(07)-1 10/05 KAT/me

09-14049.eps

Training Manual 7-2

Contiform

Mechanical Adjustments

7.2. Adjustment of the Heating Chain in Relation to the Infeed

Starwheel of the Blowing Wheel

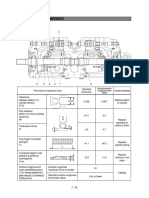

The heating chain must be adjusted at the transfer position

to the infeed starwheel of the blowing wheel as follows.

kap4-09005.eps

Check whether the position of the heating mandrel is centred

to the clamp.

If the heating mandrel is not positioned above the centre of

the clamp, the position of the heating chain must be

readjusted.

kap4-09006.eps

DS-e09-0014(07)-1 10/05 KAT/me

Training Manual 7-3

Contiform

Mechanical Adjustments

kap4-09007.eps

First, remove the cover plate (1) above the belt drive to allow

for access to the oven drive unit.

Then, loosen all inner screws (2) at the pulley. This will

disengage the heating chain from the rest of the machine.

Turn the main drive using the handwheel to exactly centre

the clamp of the infeed starwheel above the heating mandrel

of the oven.

Then, lock the hexagon socket screws (2) with a torque of

42 Nm and check the optimum state of the oven in relation

to the machine.

To test, jog some preforms through the machine.

kap4-09008.eps

DS-e09-0014(07)-1 10/05 KAT/me

Training Manual 7-4

Contiform

Mechanical Adjustments

7.3. Infeed Starwheel

The infeed starwheel (otherwise known as the starwheel

with chamfered pockets) must be readjusted if the heating

mandrel fails to meet the centre of the preform neck finish.

p q

They are readjusted by means of the clamping set (6)

provided in the centre of the infeed starwheel. To do so, a

preform is jogged through the starwheel as far as the transfer

position. If this position is not correct, this unit will need to

be readjusted.

s

kap4-09001.eps

To do so, loosen all hexagon socket screws (1) and unscrew

them a little. Now, completely remove three of the screws

and screw them into the forcing-off thread (2), until there is a

resistance. Now, turn these screws, one after the other, half a

rotation each and repeat this procedure until the clamping

o n set springs apart. Then return the screws to the position

shown in (1).

kap4-09002.eps

The infeed starwheel can now be turned manually until the

transfer position is correct. It may be better to remove the

centre guide (3). To do so, loosen the clip (4) and lift off the

guide. In this way, the transfer position (5) is better visible.

Slightly tighten the screws of the clamping set, check the

transfer by jogging some preforms through the passage and

readjust if necessary. If the transfer position is correct, evenly

retighten the screws of the clamping set (1) in a diagonal

p order using a torque of 17 Nm. Refit the centre guide (3), if it

has been removed, and lock with the clip (4).

kap4-09003.eps

DS-e09-0014(07)-1 10/05 KAT/me

r

kap4-09004.eps

Training Manual 7-5

Contiform

Mechanical Adjustments

7.4. Pyrometer Adjustment

1 Pyrometer

kap4-09009.eps

As shown on the drawing, the pyrometer should measure

the temperature profile of at least 3 preforms!

Mandrel chain The laser beam should be directed to the central preform of

5 preforms (A) in the heating zone, and should be set at such

A an angle that it meets all of the 3 preforms. If a preform is

missing, it should not detect any gap with this setting.

Laser beam The 3rd layer of the heating tubes is the optimum height

adjustment position for the pyrometer .

pyrometer.dsf

DS-e09-0014(07)-1 10/05 KAT/me

Training Manual 7-6

Contiform

Mechanical Adjustments

7.5. Stretching Module to the Stretching Cam

Adjust the joint head (1) at the piston rod to set a gap (2) of

0.1-0.2 mm between the cam roller and the highest point of

n the stretching cam, which is provided with a mark HP

(highest point). To do so, check with the feeler gauge and

readjust if required.

o

kap4-09016.eps

DS-e09-0014(07)-1 10/05 KAT/me

Training Manual 7-7

Contiform

Mechanical Adjustments

7.6. Blowing Nozzle

The blowing nozzle must be adjusted as follows: there must

be a distance of 0.7 mm between the blowing nozzle (1) and

the blow mould.

kap4-09014.eps

Adjusting the Height of the Blowing Nozzle

First remove the castle nut (1). Raise the blowing nozzle slide

by hand (bottom picture) (2) and place a spacer (approx. 50

n mm) underneath it (3) so that the setscrew (4) can be

accessed. Then loosen the setscrew and, as shown in the

bottom picture on the right, the blowing nozzle piston can be

moved upwards or downwards by turning it using the

spanner (5). When doing so, please make sure that the

wrench stays in position to prevent the sleeve from also

being turned, as can be seen in the picture.

09-14046.eps

p

o

DS-e09-0014(07)-1 10/05 KAT/me

q

09-14047/09-14048.eps

Training Manual 7-8

Contiform

Mechanical Adjustments

7.7. Stretching Rod

kap4-09017.eps

To check or adjust the stretching rod, use the adjustment

device (1) for base moulds.

p At first, the appropriate base mould must be jogged to the

adjustment device. Loosen the two threaded pins with

q hexagon socket at the side of the device (2), it is then

possible to shift toward the inside. Exactly position the base

mould roller (3) above the value (4) indicated on the hori-

zontal part of the adjusting device and insert a feeler gauge

between roller and adjusting device. The mould can now be

n opened and the base mould will remain exactly in the

production position.

Machines of more recent design are adjusted using another

adjusting device (1). It must be removed again after each

checking or adjustment. The principle, however, is the same

as in the illustration shown above.

n

kap4-09032.eps

kap4-09018.eps

Then, insert a preform (5) and manually pull the stretching

rod downwards until the stretching stopper completely butts

against the counterpart (6). (See the picture on the next

page).

The stretching rod height is correctly adjusted if the preform

cannot be moved upwards or downwards but can easily be

rotated. Otherwise, the height of the stretching rod must be

DS-e09-0014(07)-1 10/05 KAT/me

readjusted, as shown in the following illustration.

Training Manual 7-9

Contiform

Mechanical Adjustments

kap4-09019.eps

Adjusting the Height of the Stretching Rod in

Relation to the Base Mould

Loosen the lock nut (8) at the stretching rod and turn the

stretching rod upwards or downwards, by means of an

open-end wrench applied to the wrench side (9) of the

stretching rod. Then, retighten the lock nut (8).

Check this preset adjustment and repeat until the above-

mentioned criteria are met.

u

v

t

kap4-09020.eps

DS-e09-0014(07)-1 10/05 KAT/me

Training Manual 7-10

Contiform

Mechanical Adjustments

7.8. Adjustment of the Opening and Closing Movement at the

Mould Carrier

Checking the Proximity Switch Adjustment

Pressurise the pneumatic cylinder with 8-10 bar of

compressed air. Use a filler gauge to adjust a distance of 2.2-

0.5 mm (1) between the proximity switch and switching

device.

p

2 Bottom cylinder: 9.5 bar pressure

o 3 Moveable cam segment

n

Einstell12-002.eps

0.2 -0.5 mm

Adjusting the Mould Carrier Control Lever

To loosen the tightener (1), turn out the 6 hexagon head

screws (2) and screw in each respective adjacent thread

again. Please note that three of these six screws are screwed

in more deeply than the others. The reason for this is that

this tightener is mounted on 2 rings which must be

separated by force independently from one another.

Please note that the longer screws must be separated first.

p This means that the longer three screws must be repeatedly

n

tightened one after another for approximately half a rotation

until the top clamping mechanism has been released. This

must then be repeated with the shorter screws until the

kap4-09021.eps

bottom clamping mechanism has been released. Now the

o control lever (3) has been released and can be readjusted.

The 7th screw is used for centring between the top and

bottom clamping mechanism.

09-14053/09-14051.eps

Adjust the Main Lever

Move the mould carrier to the start of the locking cam. Press

the mould-carrier side parts together slightly using a screw

clamp, as can be seen in the picture on the left.

Check with a feeler gauge whether the gap between locking

Gap measurement shaft and hammer is 0.1 mm. The edge of the locking shaft

should have plunged approx. 2 – 5 mm into the locking

hammer for checking.

DS-e09-0014(07)-1 10/05 KAT/me

Training Manual 7-11

Contiform

Mechanical Adjustments

Turn the machine in the direction of operation until the

gauge (1) starts jamming at 0.2mm between shaft and

hammer. This is the exact locking moment which should be

used for fixing the tightener.

n

Feeler gauge 0.2 mm

09-14052/09-14054.eps

Firstly remove 8-10 bar from the main cam and leave

0.1 mm between the fixed segment and the cam roller. Then

pressurise the main cam to 8-10 bar again.

09-14055/09-14056.eps

Place a 8 mm spacer (1) underneath and tighten the tighener

to the specified 27 Nm.

DS-e09-0014(07)-1 10/05 KAT/me

n

09-14057.eps

Training Manual 7-12

Contiform

Mechanical Adjustments

Remove the 8-10 bar pressure from the main cam. Remove

the feeler gauge (0.1mm), screw clamp and spacer. Pressurise

the main cam to 8-10 bar again and once again check the

o n 0.1 mm gap between the locking shaft (1) and the locking

hammer (2).

The mould must be able to be locked easily.

09-14058/09-14053.eps

DS-e09-0014(07)-1 10/05 KAT/me

Training Manual 7-13

Contiform

Mechanical Adjustments

7.9. Adjusting the Mould Shells

Check the height difference with a dial gauge. When doing

so, place the dial gauge on the left (moveable) and right

(fixed) mould-carrier side part.

The left mould-carrier side part must be lower than the right

so that the pressure pad does not experience any friction.

Tolerance: -0.05 mm.

If necessary, place an adjustment plate (1) underneath.

kap4-09028.eps

Left Side of the Mould Carrier Right Side of the Mould Carrier

kap4-09027.eps

The right side of the mould carrier is the fixed side.

The left side is the side which can be moved. It should be 0-

0.5 mm lower than the right side. You must be able to close

the mould gap once the blowing nozzles have been sealed

DS-e09-0014(07)-1 10/05 KAT/me

against the preform neck finish.

kap4-09026.eps

Training Manual 7-14

Contiform

Mechanical Adjustments

7.10. Adjusting the Mould Carriers

Adjusting the Mould Gap

n 1 Tighten the hexagon socket screws using a torque wrench

with 20 Nm.

2 Tighten the hexagon socket screws using a torque wrench

{ with 25 Nm.

o

{

n kap4-09024.eps

If repairs or other tasks must be performed at the mould

carrier, please make sure that the mould gap (3) is correctly

adjusted to 0.25-0.35 mm. It is very important to always

check this gap width at four points.

For small cavity machines, this mould gap should range

between 0.25 and 0.30 mm, in heatset machines, 0.15 mm.

p In "H" machines, measurements are always performed on hot

moulds.

The hexagonal socket screws (1, 2) are used to fix the

pressure pad (4). This so-called component will close the

q mould gap as soon as the blowing pressure is provided.

kap4-09029.eps

This mould gap can be changed and/or adjusted, when (5)

presses on (1). Afterwards, it is necessary to secure the

r s adjustment screw (5). To do so, lock (6) on (5).

kap4-09030.eps

DS-e09-0014(07)-1 10/05 KAT/me

Training Manual 7-15

Contiform

Mechanical Adjustments

At the interior of the mobile mould-carrier side part, the

gasket must be tightly pressed into the recess during

assembly. To do so, apply some silicone grease to the gasket.

Afterwards, make sure that the pressure compensation

remains mobile at a pressure of 0.5 bar, and the pressure is

allowed escape. This is to make sure that the pressure

compensation device does not jam and remains mobile.

Afterwards, apply a pressure of 2 bar to the pad. Now the

pressure must no longer escape (listen to check).

kap4-09031.eps

Set the shock absorber (7) to 6 mm with the mould-carrier

6 mm side parts being closed.

The mould-carrier side parts should also be closed for

adjusting the distance between the pressure component (8)

and the mould carrier stop to 0.15 mm using a feeler gauge.

t

u kap4-09025.eps

DS-e09-0014(07)-1 10/05 KAT/me

Training Manual 7-16

Contiform

Mechanical Adjustments

7.11. Replacement of the Mandrel

The mandrel should be replaced at the rear of the oven.

kap4-09033.eps

This is the best possible assembly position. When doing so,

you must make sure that the two cylinders (1) which keep

the oven chain tight, are always held without pressure during

assembly.

n

09-14060/09-14059.eps

Remove the plastic bearings (1).

n

kap4-09035.eps

Loosen the screw (1) using a hexagon socket screw key.

o

Remove the lock washer (2) and pull off the pin.

DS-e09-0014(07)-1 10/05 KAT/me

n

kap4-09036.eps

Training Manual 7-17

Contiform

Mechanical Adjustments

7.12. Belt Tension Frequencies

The belt tension frequencies must always be set at the side of

the belt without the tension roller. When a belt is

disassembled, it must be assembled again in the same

running direction! If the original direction of operation is not

known, a new belt must be used! If a used belt is fitted, the

belt must be adjusted according to the tension frequency

indicated in the "used" column (see below). Belts must not

be retightened! A 20% loss of tension is normal!

09-14061.eps

Belt tensioning frequencies, 8-10 mould

positions

New Used

Belt 1 17.3 -18.1Hz 14.5 -15.5Hz

Belt 2 30.1 -31.6Hz 25.2 -26.9Hz

Belt 3 42.1 -44.2Hz 35.2 -37.7Hz

Belt 4 19.3 -20.3Hz 16.2 -17.3Hz

2

09-14062/63.eps

3 1

DS-e09-0014(07)-1 10/05 KAT/me

Training Manual 7-18

Contiform

Mechanical Adjustments

Belt tensioning frequencies, 12-14 mould

positions

New used

Belt 1 15.8 -16.6Hz 13.2 -14.1Hz

Belt 2 49.3 -51.7Hz 41.3 -44.1Hz

Belt 3 37.7 -39.1Hz 31.2 -33.4Hz

Belt 4 20.3 -21.2Hz 17.0 -18.1Hz

4 3 09-14064/65.eps

1

2

Belt tensioning frequencies, 16-18 mould

positions

New used

Belt 1 14.4 -15.1Hz 12.0 -12.8Hz

Belt 2 35.6 -37.3Hz 29.8 -31.8Hz

Belt 3 30.6 -32.1Hz 25.6 -27.4Hz

Belt 4 20.7 -21.7Hz 17.3 -18.5Hz

1

09-14066/67.eps

DS-e09-0014(07)-1 10/05 KAT/me

Training Manual 7-19

Contiform

Mechanical Adjustments

Belt tensioning frequencies, 20-24 mould

positions

new used

Belt 1 13.8 -14.5 Hz 11.5 -12.3 Hz

Belt 2* 35.3 -37.0 Hz 29.5 -31.6 Hz

Belt 2** 37.4 -39.2 Hz 31.3 -33.4 Hz

Belt 3 23.2 -24.4 Hz 19.4 -20.8 Hz

3

2**

09-14068/69.eps

2* 1

DS-e09-0014(07)-1 10/05 KAT/me

Training Manual 7-20

Contiform

Mechanical Adjustments

7.13. Overview of the Torques

Oven Infeed Starwheel, Cone Tightener

17 Nm

Blowing Wheel Infeed/Discharge Starwheels

45 Nm: M10 hexagon head

41 Nm: tightener

Control Lever for Opening/Closing

27 Nm

Blowing Slide and Stretching Slide

30 Nm

Blowing Nozzle Block

50 Nm

n Mould Compensation in the Mould Carrier

1 4x20 Nm

2 8x25 Nm

o

DS-e09-0014(07)-1 10/05 KAT/me

Flange for Stretching Rod

30 Nm

Training Manual 7-21

Contiform

Mechanical Adjustments

n Securing the Base Mould

1 M6 = 7 Nm

Securing the Mould and Mould Holder

1 Mould secured at: M8 = 12 Nm

2 Mould holder secured at: M6 = 10 Nm

n

o

DS-e09-0014(07)-1 10/05 KAT/me

Training Manual 7-22

You might also like

- Blowing Wheel, Infeed/Discharge Starwheel: Contiform MaintenanceDocument22 pagesBlowing Wheel, Infeed/Discharge Starwheel: Contiform Maintenancedavidwang8512No ratings yet

- Description: Steering Steering Column - Inspection & Adjustment - HR-VDocument4 pagesDescription: Steering Steering Column - Inspection & Adjustment - HR-VpaniyaNo ratings yet

- 012 - Work EquipmentDocument12 pages012 - Work EquipmentАнатолийNo ratings yet

- DELTA-P-VALVE MEP-4802-DPV - DatasheetDocument4 pagesDELTA-P-VALVE MEP-4802-DPV - Datasheetboukhalfa.oman.muscatNo ratings yet

- Geometrical ConstraintDocument37 pagesGeometrical ConstraintSanjoGsingh RajPutNo ratings yet

- A2H Actuator CatalogDocument6 pagesA2H Actuator CatalogahnafNo ratings yet

- Cople Jse1-0237aea-03-16Document15 pagesCople Jse1-0237aea-03-16Jorge GascaNo ratings yet

- Actuator R431004010Document6 pagesActuator R431004010dianNo ratings yet

- Basic Shaft Alignment Workbook PDFDocument63 pagesBasic Shaft Alignment Workbook PDFjos100% (5)

- Installation and Arrangement of Universal DrivelinesDocument6 pagesInstallation and Arrangement of Universal DrivelinesPrateek KesarwaniNo ratings yet

- Mechanisms Chap 10 - Determining The Cam Profile - Graphical Method212Document27 pagesMechanisms Chap 10 - Determining The Cam Profile - Graphical Method212劉德信No ratings yet

- W211 Gearbox Shift Rod Remove InstallDocument2 pagesW211 Gearbox Shift Rod Remove InstallNatalia StratulatNo ratings yet

- Free Space Optical Communication Tip-Tilt-Mirror BrochureDocument15 pagesFree Space Optical Communication Tip-Tilt-Mirror Brochuresandeep kumar100% (1)

- Clutch Pedal Sub-Assy (MTM) : AdjustmentDocument2 pagesClutch Pedal Sub-Assy (MTM) : Adjustmentjeremih alhegnNo ratings yet

- Group 2 Major Component: 1. Main PumpDocument11 pagesGroup 2 Major Component: 1. Main PumpMustofa TofaNo ratings yet

- 1962-1963 Supplement - Chevrolet Corvair Shop Manual - Section 6e - Automatic Transmission PDFDocument3 pages1962-1963 Supplement - Chevrolet Corvair Shop Manual - Section 6e - Automatic Transmission PDFbelchior alvaroNo ratings yet

- Siemens Service Instructions Isco C BrakesDocument10 pagesSiemens Service Instructions Isco C BrakesFrancisco DiazNo ratings yet

- Demag Eindschakelaar Dgs - 3en4Document4 pagesDemag Eindschakelaar Dgs - 3en4bsb.edhoeNo ratings yet

- Group 2 Major ComponentDocument9 pagesGroup 2 Major ComponentTaha RdmanNo ratings yet

- Installation and Arrangement of Universal DrivelinesDocument4 pagesInstallation and Arrangement of Universal DrivelinesSrecko PantovicNo ratings yet

- TI 07 006 DF AdjustmentDocument12 pagesTI 07 006 DF Adjustmenteko sunaryoNo ratings yet

- Remove - Install Crankshaft Position Sensor m271 PDFDocument1 pageRemove - Install Crankshaft Position Sensor m271 PDFAlex AndreiNo ratings yet

- L5 Crankshaft Position Sensor: Remove/install Risk of Death Danger!Document1 pageL5 Crankshaft Position Sensor: Remove/install Risk of Death Danger!Ludmila CroitoruNo ratings yet

- ISO 3952-1 Kinematic Diagrams - Graphical Symbols, Part 1Document13 pagesISO 3952-1 Kinematic Diagrams - Graphical Symbols, Part 1Phạm Hữu PhướcNo ratings yet

- Calibration: Dlc3 TsDocument2 pagesCalibration: Dlc3 TsDannyDDannyDNo ratings yet

- Angular Measurement Angular MeasurementDocument5 pagesAngular Measurement Angular Measurementhnmm03No ratings yet

- Group 2 Major Component: 1. Main PumpDocument7 pagesGroup 2 Major Component: 1. Main PumpHậu MinhNo ratings yet

- KukaDocument13 pagesKukaadamczykbMDSNo ratings yet

- 40 - Automatic TransmissionDocument50 pages40 - Automatic TransmissionDevo UvtNo ratings yet

- RepairDocument2 pagesRepairClever Raul Mamani CcajmaNo ratings yet

- Inclined Plane With Roller 11301.00 11301.88: Operating InstructionsDocument4 pagesInclined Plane With Roller 11301.00 11301.88: Operating InstructionsBarthélemy HoubenNo ratings yet

- 1.8m Dual Separate (English)Document8 pages1.8m Dual Separate (English)roger23007No ratings yet

- Adjustment: 1. Inspect Park/Neutral Position Switch AssyDocument1 pageAdjustment: 1. Inspect Park/Neutral Position Switch AssyluisNo ratings yet

- NB Man 00 032Document51 pagesNB Man 00 032Danang Duwii SaputroNo ratings yet

- 40-03 Park Neutral Position Switch Assy (Atm) ReplacementDocument1 page40-03 Park Neutral Position Switch Assy (Atm) ReplacementCelso BidinotiNo ratings yet

- B1-5-5 Turning - Effects - of ForcesDocument172 pagesB1-5-5 Turning - Effects - of ForcesMuhammad QasimNo ratings yet

- Pneumatic Positioner Type 3766 Electropneumatic Positioner Type 3767Document12 pagesPneumatic Positioner Type 3766 Electropneumatic Positioner Type 3767Garix LanuzixNo ratings yet

- Group 2 Major ComponentDocument11 pagesGroup 2 Major ComponentSergey MovchanNo ratings yet

- 2. المكونات الرئيسيهDocument8 pages2. المكونات الرئيسيهالمهندسوليدالطويلNo ratings yet

- Assig.6 1.CuevaS - Mechanicalvibrations2023Document16 pagesAssig.6 1.CuevaS - Mechanicalvibrations2023SamuelAndresNo ratings yet

- Deckel FP1 Active Operator ManualDocument10 pagesDeckel FP1 Active Operator ManualBasil HwangNo ratings yet

- FP 1Document5 pagesFP 1PatrickKisulaNo ratings yet

- Technicky Manual 1 enDocument66 pagesTechnicky Manual 1 enSherif AdelNo ratings yet

- Group 2 Major ComponentDocument8 pagesGroup 2 Major ComponentDavidNo ratings yet

- E-COMPACT Installation Manual: A Table of ContentsDocument10 pagesE-COMPACT Installation Manual: A Table of ContentsCaptvik VikNo ratings yet

- MIL8013 InstructionmanualDocument11 pagesMIL8013 InstructionmanualMasud Alam67% (3)

- Manual BEKA PICODocument3 pagesManual BEKA PICOBody Lift Big MachineNo ratings yet

- APP2008-047 Polar InterpolationDocument9 pagesAPP2008-047 Polar InterpolationIvan Dario SantiestebanNo ratings yet

- Camshaft (1Nz Fe/2Nz Fe) : ReplacementDocument8 pagesCamshaft (1Nz Fe/2Nz Fe) : ReplacementMaung KyawNo ratings yet

- LEP 1.3.12 Ballistic Pendulum: Related Topics EquipmentDocument3 pagesLEP 1.3.12 Ballistic Pendulum: Related Topics EquipmentHeriNo ratings yet

- Toyota C250 Manual Transmission Repair Manual RM1020EDocument91 pagesToyota C250 Manual Transmission Repair Manual RM1020EMatheus BorelliNo ratings yet

- Manual For Wheel Adjustment of Eight-Wheel TrolleyDocument3 pagesManual For Wheel Adjustment of Eight-Wheel Trolleytest testtNo ratings yet

- Balancing Procedure: PT - Armindo Jaya Mandiri Electro Mechanical WorkshopDocument8 pagesBalancing Procedure: PT - Armindo Jaya Mandiri Electro Mechanical Workshopgst ajahNo ratings yet

- Balancing Procedure: PT - Armindo Jaya Mandiri Electro Mechanical WorkshopDocument8 pagesBalancing Procedure: PT - Armindo Jaya Mandiri Electro Mechanical Workshopgst ajahNo ratings yet

- 40-09 Park Neutral Position Switch Assy (Atm) AdjustmentDocument6 pages40-09 Park Neutral Position Switch Assy (Atm) AdjustmentCelso BidinotiNo ratings yet

- Balancing Tail RotorsDocument14 pagesBalancing Tail Rotorsjmam1992No ratings yet

- Refurbishing Upper Tension Mechanism Singer Vintage MachinesDocument13 pagesRefurbishing Upper Tension Mechanism Singer Vintage Machinesfmaria64100% (6)

- NE700 Valve PositionerDocument9 pagesNE700 Valve Positionersteve@air-innovations.co.zaNo ratings yet

- ROUP 2 MAJOR COMPONENT HyundaiDocument9 pagesROUP 2 MAJOR COMPONENT Hyundaiعمروصالح كليسNo ratings yet

- BMW M54-M52tu Cam Replacement DIY: Important! Read This Before Using These Instructions!Document13 pagesBMW M54-M52tu Cam Replacement DIY: Important! Read This Before Using These Instructions!Azwar anasNo ratings yet

- Major Axis Bending Minor Axis BendingDocument26 pagesMajor Axis Bending Minor Axis Bendingarunkumar.mgsNo ratings yet

- Flat SlabsDocument12 pagesFlat SlabsNani Tirumalasetti100% (2)

- 7 2 A HolesholenotesDocument11 pages7 2 A Holesholenotesapi-234212327No ratings yet

- 3.boiler Documentation, Air & Flue Gas Path, Ducts, EJ, Gates & Dampers (1.5 HRS) PDFDocument90 pages3.boiler Documentation, Air & Flue Gas Path, Ducts, EJ, Gates & Dampers (1.5 HRS) PDFmaneesh_0375% (4)

- Válvula 3 Vías Sauter (Actuador) 593582Document8 pagesVálvula 3 Vías Sauter (Actuador) 5935824toTurno HRTNo ratings yet

- Api 53a PDFDocument1 pageApi 53a PDFGaurang SolankiNo ratings yet

- Hoover VH-W854D-80 Washer Dryer Service ManualDocument23 pagesHoover VH-W854D-80 Washer Dryer Service ManualZMNo ratings yet

- Prajwal PundeDocument2 pagesPrajwal PundeRohan KuldharNo ratings yet

- Tub GrindersDocument12 pagesTub GrindersCoordinador InterjuiceNo ratings yet

- DODGE 46RE Transmission TeardownDocument23 pagesDODGE 46RE Transmission TeardownChristopher Kasian100% (4)

- Parts List m330 2Document21 pagesParts List m330 2DNo ratings yet

- Table-Saw-Workbench-Building-Plan Remodelaholic 24sept19Document9 pagesTable-Saw-Workbench-Building-Plan Remodelaholic 24sept19Joseph VEGANo ratings yet

- Material Specification Sheet Saarstahl - 27Mncrb5-2Document1 pageMaterial Specification Sheet Saarstahl - 27Mncrb5-2rakeshNo ratings yet

- Single Line Diagram ES TKDDocument1 pageSingle Line Diagram ES TKDkseb thrikkalangodeNo ratings yet

- Mini Clamp PKS 16.1: Spare Parts ListDocument2 pagesMini Clamp PKS 16.1: Spare Parts ListSuhas KODRENo ratings yet

- Kwik-Lock: Parts ListsDocument12 pagesKwik-Lock: Parts ListsJonah RagleNo ratings yet

- Manual de Partes Cat 3507Document4 pagesManual de Partes Cat 3507Julito Santa CruzNo ratings yet

- ROVEMA - Bag StylesDocument1 pageROVEMA - Bag StylesHelder Rafael Da SilvaNo ratings yet

- FX Series Hammer Hydraulic BreakerDocument7 pagesFX Series Hammer Hydraulic Breakerrho myoung chullNo ratings yet

- Capacity Regulator CpceDocument8 pagesCapacity Regulator CpceElect Yan LumosoNo ratings yet

- ZX200-3 Signal Control ValveDocument20 pagesZX200-3 Signal Control ValveKevine Khaled100% (2)

- Aircraft Engineering Drawing With CadDocument10 pagesAircraft Engineering Drawing With CadShareef KhanNo ratings yet

- Altec A Class: Overcenter Material Handling Aerial DevicesDocument2 pagesAltec A Class: Overcenter Material Handling Aerial DevicesRony MedinaNo ratings yet

- Hydraulic Systems - Hydraulic Schema - Pilot Circuit: Suction, Delivery and Return CircuitDocument28 pagesHydraulic Systems - Hydraulic Schema - Pilot Circuit: Suction, Delivery and Return Circuitroparts clujNo ratings yet

- Getjobid 369734Document17 pagesGetjobid 369734Muhammad azeemNo ratings yet

- Pressure Switch: Fire Pump PanelDocument1 pagePressure Switch: Fire Pump Panelravi KumarNo ratings yet

- DYNEXQuick ReferenceDocument15 pagesDYNEXQuick ReferenceDJGGNo ratings yet

- Quick Reference Guide For Repair KitsDocument1 pageQuick Reference Guide For Repair KitsEjaz Ahmed RanaNo ratings yet

- Aircraft Control SystemsDocument14 pagesAircraft Control SystemsSubhash pragatheeswaranNo ratings yet