Professional Documents

Culture Documents

Emulsion and Application

Uploaded by

Samay SharmaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Emulsion and Application

Uploaded by

Samay SharmaCopyright:

Available Formats

E-Notes Physical Pharmacy B.

Pharmacy 4th Semester

COARSE DISPERSION

EMULSIONS

Emulsions are defined as thermodynamically unstable systems

consisting of at least two immiscible liquid phases, one of which is

dispersed as globules in the other liquid phase.

Emulsions are two-phase systems in which the dispersed phase is also

a liquid.

These are coarse dispersions having the globule diameter in the range

from about 0.1 to 100 um.

Emulsions are also called heterogeneous systems or more precisely

biphasic systems.

A large number of emulsions are available in nature. Examples are

milk, rubber latex, crude oil etc. On an industrial scale, the commonly

encountered emulsions are foods, (ice-cream, cake-butter), cosmetics

(creams and lotions), and house-hold items (paints, polishes and

insecticides). Some emulsions themselves have medicinal properties.

For example, liquid paraffin is used as purgative and laxative. Most of

the cases, emulsions are used as vehicles for administering drugs.

Thermodynamic instability indicates that the preparation of emulsion

is difficult, whereas the separation into two liquid phases is a

spontaneous process. Therefore, they should be made stable, at least

for a reasonable period of storage.

ADVANTAGES

1. Mask the unpleasant taste: Drugs having unpleasant taste are

not acceptable orally. Such drugs can be incorporated in the dispersed

phase (internal phase) so that the taste can be masked. Examples are

laxatives, phenolphthalein and vitamin A.

2. Economical: Expensive solvents (vehicles) are required to

dissolve the lipids (oil soluble drugs). Such substances can be easily

dispersed in a less expensive vehicle such as water. Hence emulsions

can be made available at cheaper cost.

3. Improved bioavailability: Absorption of drugs has been found to

be faster and better when formulated as emulsions. For example,

absorption of griseofulvin is erratic from tablets, whereas if it is given

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 1 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

in corn oil-in-water emulsion, its absorption is better. Other examples

are insulin and heparin.

4. Sustained release medication: Water soluble antigenic

materials are dispersed in mineral oil and are given as intramuscular

injections. These preparations act as depots in the muscle and release

antigen from the oil slowly, over a long period. Now-a days, multiple

emulsions (emulsionin-emulsion) are also suggested to provide

sustained release of drugs.

5. Nutritional supplement: Terminally ill-patients are given

nutrients parenterally. Fats are dissolved in the oil phase and water

soluble nutrients are incorporated in the aqueous phase. An emulsion

prepared in this manner represents the balanced nutrients in a single

dosage form.

6. Diagnostic purposes: Radio-opaque emulsions are used as

diagnostic materials in X-ray examination.

7. Topical use: Concentrated emulsions are used in topical delivery

as semisolid vehicles. These have emollient applications. Examples are

cold cream, vanishing cream, benzyl benzoate etc.

Thus, emulsions are administered orally, rectally, parenterally and

topically for various reasons. Parenteral emulsion is used in blood

replacement therapy. Emulsions are widely used in many areas,

petroleum industry, agriculture, food technology, cosmetics etc.

DISADVANTAGES

Emulsions possess certain disadvantages, though these can be handled

by the pharmacist to a certain extent.

1. Emulsions have a short shelf life. They are unstable and the

insoluble phase separates slowly.

2. Being liquid dosage forms, these are packed in glass or plastic

containers. Thus, care should be taken in handling and storage.

The advantages outweigh the disadvantages and emulsions are being

prepared on an industrial scale in certain cases. The use of emulsions

as pharmaceuticals is declining due to stability problems.

CLASSIFICATION OF EMULSIONS

Based on the nature of dispersed phase, emulsions are classified as:

1. Oil-in-water (o/w)

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 2 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

2. Water-in-oil (w/o)

Water-In-Oil Emulsion

An emulsion is referred to as water-in-oil, if the dispersed phase

(internal phase) is water and the continuous phase (dispersion medium)

is oil.

Examples are butter, salad dressings. w/o emulsions are generally

meant for external use, though a few examples of internal use are also

available.

Oil-in-Water Emulsion

An emulsion is referred to as oil-in-water, if the dispersed phase

(internal phase) is oil and the continuous phase (dispersion medium) is

aqueous base. This type of emulsions are meant for both internal and

external use.

External: Benzyl benzoate emulsion (Trade name: Ascabiol) Gamma

benzene hexachloride emulsion (Trade name: Scaboma)

Internal: Vitamin A in corn oil in water, Liquid paraffin in water (Agarol),

Griseofulvin in corn oil in water.

Depending on the globule size, emulsions are empirically classified.

These are as follows:

Microemulsions

Microemulsion is defined as a system of water, oil and amphiphiles,

which is a single optically isotropic and thermodynamically stable

liquid solution.

Micro-emulsions contain globules of the size about 0.01 um. Droplets

of such dimensions cannot refract light, and as a result, globules are

invisible to the naked eye. Therefore, micro-emulsions are transparent

systems. They may also be unstable as Brownian movement of the

colloidal particles and subsequent collisions may lead to coalescence

and the formation of large globules of reduced mobility. In fact, they

consist of large swollen micelles. Unlike micellar solubilized systems,

these are not thermodynamically stable. Microemulsions have shown

enhanced bioavailability of drug, which are poorly soluble in water.

Examples are etoposide and methotrexate.

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 3 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

Fine Emulsions

Normally these have a milky appearance and the globule size ranges

from 0.25 to 25 um.

Special Type Multiple emulsions

These are 'emulsion-within-emulsion', and designated as w/o/w or

o/w/o. For example, w/o/w emulsion is prepared by incorporating the

emulsion w/o in an aqueous phase. The drug that is incorporated in

the innermost phase must cross two phase boundaries before getting

absorbed. Multiple emulsion systems have been proposed in oral

sustained release or intramuscular therapy. Multiple emulsions reduce

drug loss into an aqueous phase and improve the encapsulation

efficiency.

APPEARANCE AND IDENTIFICATION

Usually, emulsions may appear as opaque or milky, however, their

appearance may range from a grey translucence to sparkling clarity.

Transparency may be due to smaller globule size and/or same

refractive indices of external and internal phases. Milky white emulsion

may have a greyish cast indicating larger globule size) or bluish cast

(indicating relatively smaller globule size).

Since the performance of an emulsion depends on its type, it is

important for us to know the type of emulsion with which we are

dealing.

Dye Solubility Test

This test is based on the principle that the dye can be dispersed

uniformly throughout the phase in which it is more soluble. For

example, amaranth and methylene blue, water soluble dyes readily tint

the water phase of o/w emulsion, while sudan III and scarlet red, oil

soluble dyes readily colour the oil phase of the w/o emulsion.

Normally, the dye powder is dusted on the emulsion for better results.

It is better to sprinkle water- and oil-soluble dyes on two samples of

the same emulsion.

For example, in case of o/w type, the water soluble dye is miscible

indicating the o/w, whereas oil soluble dye shows immiscibility. Thus,

both the tests confirm the o/w type emulsion.

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 4 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

Dilution Test

This test depends on the fact that when a dispersion medium is added

to an emulsion, no phase separation is possible. For example, when

water is added to o/w emulsion, it is freely miscible with the emulsion

and no phase separation occurs. Similarly addition of oil to w/o

emulsion shows miscibility.

Conductivity Test

This test is based on the ability of water to conduct electricity. If water

is the continuous phase, then the emulsion conducts electricity. This

can be confirmed by the deflection of indicator in voltmeter. If oil is the

continuous phase, the emulsion fails to conduct.

Creaming Test

The direction of creaming precisely identifies the emulsion type, if the

densities of aqueous and oil phases are known. Water-in-oil emulsions

normally cream downward as oil is usually less dense than water. Oil-

in water emulsion normally cream upwards.

Other tests for identification of the type of emulsion are cobalt chloride

test, filter-paper test and fluorescence test. They have some limitations.

Consult the British Pharmaceutical Codex, 1994, for details about

these tests.

These methods are simple, but may give incorrect results. It is

necessary that the results obtained by one method should always be

confirmed by means of other methods, mentioned above.

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 5 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

Cobalt Chloride Test

When a filter paper soaked in cobalt chloride solution is dipped in to an

emulsion and dried, it turns from blue to pink, indicating that the

emulsion is o/w type.

Fluorescence Test

If an emulsion on exposure to ultra-violet radiations shows continuous

fluorescence under microscope, then it is w/o type and if it shows only

spotty fluorescence, then it is o/w type.

THERMODYNAMIC CAUSES FOR INSTABILITY

According to the definition, emulsification is not a spontaneous process

and hence emulsions have minimal stability. Reasons for instability

can be understood from the nature of immiscible phases and their

interfacial properties.

Emulsions are thermodynamically unstable. Why?

When polar (aqueous) and nonpolar (oil) liquids are mixed together, one

of the liquids forms small droplets and gets dispersed in the other

liquid, forming an emulsion. When left aside, droplets fuse themselves

and finally separate as two layers. This is an indication of instability of

an emulsion. This state of instability may be described by the fact that

the cohesive forces between the molecules of the same type are

stronger than the adhesive forces between unlike molecules. Any

attempt to increase the adhesive forces between these phases can

produce a stable emulsion.

The instability of emulsions can also be explained as follows (Figure 1).

A system is said to be thermodynamically stable, if it possesses low

surface free energy. The higher the interfacial area, the greater is the

interfacial free energy, and hence lower the stability. When two

immiscible liquids are mixed, one of the liquids is broken into small

globules (droplets) and gets dispersed. As a result, globules possess an

enormously enhanced surface area compared to its original surface

area.

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 6 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

Fig.1 Principles illustrating the instability and stability of emulsions.

Consequently, the interfacial energy increases. The relationship is:

ΔG = γolw .ΔA ……………… (1)

where

ΔG increase in surface free energy, Nm or Jm γ olw

= interfacial tension of oil-water interface, N/m

ΔA = increase in surface area of the interface due to droplet formation,

m2

(A) The system spontaneously tries to change back to its original

state by decreasing ΔA, so that ΔG will be zero. The result is the

coalescence of globules and separation of phases. Therefore, emulsions

are described as thermodynamically unstable. From the physical

stability point of view, the process of coalescence is undesirable.

Regrouping of globules can be prevented to a great extent by adding a

third component called emulsifying agents in emulsion.

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 7 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

(B) In equation (1), the interfacial tension, γ olw may be reduced, so

that the system can be stable. But it cannot be-made zero, because the

dispersed phases have certain positive interfacial tension. Hence, the

term 'ΔG' in equation (1) cannot be made zero. However, the

manufacturing pharmacist adds surface active agents to reduce γ olw

value to a minimum. Thus, the system can be stabilized to a certain

extent.

Certain emulsifying agents can reduce the surface tension thereby

prevent coalescence. Such substances are best suited for the

preparation of a stable emulsion. In spite of the best efforts, emulsions

are still thermodynamically unstable and exhibit shorter shelf life.

EMULSIFYING AGENTS

Emulsifying agents stabilize emulsions by preventing/reducing the

coalescence of dispersed globules. These possess certain degree of

affinity to polar and nonpolar liquids. They act as a bridge between the

polar and nonpolar phases and reduce the interfacial tension.

Consequently, the emulsion is stabilized. A few examples of emulsifying

agents are: Spans, Gelatin, Acacia, Tweens, Soaps.

Bancroft's rule describes the relationship between the nature of

emulsifying agent and type of emulsion formed. Though emulsifying

agents have affinity towards polar and nonpolar liquids, they have a

preferential solubility in one of the liquids. According to Bancroft's rule,

if the surfactant is more soluble in water, then the aqueous phase

becomes continuous phase, i.e., o/w emulsion will be obtained. For

example- Tweens, acacia, bentonite are useful emulsifying agents to

form o/w emulsions. The reverse situation is true; the oil soluble

emulsifier, Spans, are employed in the preparation of w/o type of

emulsions.

The relative solubility of an emulsifying agent in one of the phases is

expressed by HLB scale, i.e., hydrophilic-lipophilic balance. In general,

emulsifiers with a high HLB value (9-16) are preferentially soluble in

water and produce o/w emulsions. Examples are Tween 80 (HLB 15)

and sodium oleate (HLB 18). Similarly, emulsifiers having low HLB

value (38) are more oil soluble and favour the formation of w/o

emulsions. Examples are Span 80 (HLB 4.3) and glyceryl monostearate

(HLB 3.8).

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 8 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

Combinations of emulsifying agents, i.e., oil soluble and the water

soluble, impart better stability than a single agent. For example, a

blend of Tween 20 and Span 20 will be a suitable emulsifier for an o/w

emulsion. The calculation is as follows:

HLB values: Tween 20-16.7; Span 20-8.6

HLB value of blend (50:50) = [(16.72) + (8.62)] = 12.65

Since HLB value is high, o/w emulsion will be formed. On the other

hand, Span 60 (HLB-4.7) and Tween 40 in 80:20 favour w/o emulsion.

Though HLB system and Bancroft's rule provide the guiding principles

regarding the selection of a emulsifier blend, it is not necessarily true

in all situations. For example, it has been reported that liquid paraffin-

in water emulsions are prepared with surfactant combinations having

the HLB value of as low as 3.9. In such situations, viscosity factor

overrides the influence of the interfacial barrier, owing to decreased

collisions of globules.

HLB calculations do not take into account the total concentration of

surfactant to be used. As a guide, 2% is considered optimum and 5% is

maximum. It is essential to prepare a series of samples and study their

stability. Then, the optimum concentration of emulsifying agent (or

blend) should be selected.

In general, ionic type of emulsifying agents (sodium lauryl sulfate,

triethanolamine stearate) are not recommended for internal use,

because they interact with the bio-membranes and adversely affect the

cell functions. Most of the emulsions intended for internal use are o/w

type.

So, they require water soluble, non-ionic emulsifying agents (Tweens).

Both o/w and w/o type of emulsions are employed for external

applications.

It is better to avoid emulsifying agents obtained from natural origin,

because they show considerable batch-to-batch variation. In addition,

they also support the microbial growth. The general description about

individual emulsifying agents, their relative advantages and

disadvantages are discussed in the British Pharmaceutical Codex,

1994.

In summary, emulsifiers stabilize the emulsion. Its stability depends-

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 9 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

* Chemical stability of the emulsifier

* Concentration of the emulsifier

* Incompatibilities due to use of oppositely charged emulsifiers

Auxiliary emulsifying agents: These agents themselves cannot form

stable emulsion, but act as thickening agents and help to stabilize the

emulsion. Examples are: Glyceryl monostearate, CMC sodium, Stearyl

alcohol, Stearic acid Methylcellulose.

EMULSIFYING AGENTS - MECHANISMS OF ACTION (Theories)

Causes for instability of emulsions have been discussed earlier. A

variety of emulsifying agents are used, each probably act by different

mechanisms. Irrespective of their chemical nature, they tend to

concentrate at the interface and form a tough film around the globules.

Based on the type of the films they form; emulsifying agents are

classified as:

(A) Surface active agents, examples are soaps, spans, tweens.

(B) Hydrophilic colloids, examples are acacia, gelatin.

(C) Finely divided solids, examples are bentonite, veegum.

Based on the nature of films formed at the interface, the mechanisms

of action of emulsifying agents can be discussed under the following

headings.

Monomolecular Adsorption and Film Formation

(1) Surfactants adsorb at the oil-water interface and form a

monomolecular film. This film rapidly envelopes the droplets as soon

as they are formed. Agents having higher interfacial activity are better

suited for this purpose. The monomolecular film should be compact

and strong enough so that it cannot be easily disturbed or broken. For

any

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 10 of

24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

reason, if the film is broken, it should be elastic and flexible enough, so

that it can be reformed rapidly on moderate agitation.

The physical, chemical and mechanical properties of the interfacial

films are of importance in stabilising emulsions. Attempts have been

made to use a combination of surfactants rather than a single one to

impart these characteristics to the interface. It is assumed that they

support each other and strengthen the monomolecular film (Figure 2).

Fig. 2 Schematic representation of the orientation of Tween 40 & Span

80 molecules at the o/w interface.

The surfactant blend consists of a water-soluble and an oil-soluble

surfactant. The hydrophilic surfactant approaches the interface from

aqueous phase-side, while the oil-soluble surfactant approaches from

the oil phase-side. At the interface, the two surfactants interact to form

a complex and condense as a monomolecular film.

The interaction within a mixture of emulsifying agents at the interface

and nature of film formed is depicted in Figure 3. A combination of

sodium cetyl sulfate (hydrophilic) and cholesterol (lipophilic) leads to a

close packed, complex film at the interface that produces an excellent

emulsion (Figure 3a).

Thus, a blend of surface-active agents produces good emulsions.

However, it should be stressed that a blend of surfactants may also

produce poor quality emulsion, if the interaction between them is not

stronger at the interface. Sodium cetyl sulfate and oleyl alcohol do not

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 11 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

form a close packed film and therefore, their combination produces a

poor emulsion (Figure 3b). Cetyl alcohol and sodium oleate produce a

close packed film, but complexation is negligible and therefore, again

produce poor emulsions (Figure 3c).

Fig. 3 Representation of combinations of emulsifying agents at the oil

water interface of an emulsion.

(2) Surfactants are capable of reducing the interfacial tension. This

facilitates the immediate formation of small droplets. Furthermore, its

importance can be understood by considering the surface free energy

changes during emulsification. In equation (1), ΔA is increased due to

formation of small globules. Usually, these small globules tend to

combine with each other and form separate phases. But formation of

smaller droplets is important in the preparation of an emulsion. So, ΔA

cannot be altered to get ΔG = 0. The only option is to reduce the

interfacial tension, γolw. Surfactants achieve this objective and produce

stable emulsions. This factor is of secondary importance in

stabilisation.

(3) Ionic surfactants impart charges on interfacial films. These films

exert repulsive forces between two approaching globules and prevent

their coalescence. This mechanism is of minor importance. Non-ionic

surfactants also produce good emulsions. In such cases, ions present

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 12 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

in the aqueous phase often get adsorbed onto the monomolecular film,

thereby preventing the coalescence of droplets.

Multimolecular Adsorption

The emulsifying agents such as acacia and gelatin (isoelectric point)

tend to form a multimolecular film around the globules and prevent

coalescence (Figure 4A). They also reduce the interfacial tension

moderately, though it is of secondary importance. They are effective at

high concentrations and promote the formation of o/w emulsion owing

to their hydrophilicity. They also have affinity towards the oil phase

and facilitates interfacial adsorption. Normally, the stability is improved

by adding viscosity inducing agents such as tragacanth, methyl

cellulose, CMC etc. The disadvantage is that these undergo hydrolysis

and sensitive to variations in the pH.

Fig. 4 Film formation at the o/w interface

(A) Multimolecular film (B) Solid particle film

Solid Particle Adsorption

The finely divided solid particles adsorb at the oil-water interface and

form a rigid film of closely packed solids (Figure 4B). This film acts as a

mechanical barrier and prevents the coalescence of globules.

These tend to produce coarse emulsions. Depending on the affinity of

the emulsifier to a particular phase, one can prepare both types of

emulsions. Examples are:

Bentonite (hydrated aluminum silicate, pH-9) - o/w and w/o

Veegum (magnesium aluminum silicate, > 1%) – o/w

The stability of an emulsion depends on the finer state of subdivision of

solid particles, irregular surface and charge on the surface. These

should have appropriate angle of contact at the three-phase boundary.

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 13 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

PHYSICAL INSTABILITY-MARKERS

Emulsifying agents help to stabilize the emulsion. In spite of best

efforts, emulsions tend to be unstable. Signs of instability are

enumerated below (Figure 5).

Fig. 5 Different stages of instability of emulsions

Flocculation

Flocculation is defined as the association of globules within an

emulsion to form large aggregates, which can be easily dispersed upon

shaking.

In an emulsion, neighbouring globules come closer to each other and

form colonies in the external phase (Figure 5). Aggregation of globules

is not clearly visible. This is probably the initial stage that leads to

instability. The extent of flocculation of globules depends on-

a) Globule size distribution

b) Charge on the globule surface

c) Viscosity of the external medium

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 14 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

Uniform sized globules prevent flocculation. This can be achieved by

proper size reduction process. A charge on the globules exert repulsive

forces with the neighbouring globules. This can be achieved by using

ionic emulsifying agent, electrolytes etc. If the viscosity of the external

medium is increased, the globules become relatively immobile and

flocculation can be prevented. This can be achieved by adding viscosity

improving agents (bodying agents or thickening) such as hydrocolloids

or waxes. Flocs slowly move either upward or downward leading to

creaming. Flocculation should not be confused with creaming.

Flocculation is due to the interaction of attractive and repulsive forces,

whereas creaming is due to density differences in the two phases.

Creaming

Creaming is the concentration of globules at the top or bottom of the

emulsion.

The floccules move either upward or downward leading to creaming.

Creaming may also be observed on account of the movement of

individual globules (Figure 5). It can be observed by a difference in

colour shade of the layers. It is a reversible process, i.e., cream can be

dispersed easily by agitation. This is possible because the oil globules

are still surrounded by the protective sheath of the emulsifier. This is a

potential step towards complete coalescence of internal phase. Hence,

this stage is also considered to be the mark of instability. In creaming,

the drug is not uniformly distributed. This leads to variable dosage.

Therefore, the emulsion should be shaken thoroughly before use.

Creaming is of two types. Upward creaming, this is due to the less

dense internal phase (Figure 5). This is normally observed in o/w

emulsions. On the other hand, downward creaming is also possible if

the internal phase is heavier. Due to gravitational pull, the globules

settle down. This is normally the case in w/o emulsions. Since

creaming process involves the movement of globules in an emulsion,

Stokes' law can be applied.

Therefore, creaming is influenced by:

❖ Globule size

❖ Viscosity of the dispersion medium

❖ Difference in the densities of dispersed phase and dispersion

medium

Creaming can be reduced/prevented by:

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 15 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

1. Reducing the particle size by homogenisation. Doubling the

diameter of oil globules increases the creaming rate by a factor of four.

2. Increasing the viscosity of the external phase by adding the

thickening agents such as tragacanth or sodium alginate.

3. Reducing the difference in the densities between the dispersed

phase and dispersion medium. In general, the density of aqueous

phase is higher than the oil phase. To make densities equal, oil soluble

substances such as B-bromonaphthalene, bromoform are added to the

oil phase. This technique is rarely used in practice.

Coalescence

A few globules tend to fuse with each other and form bigger globules

(Figure 5). In this process, the emulsifier film around the globules is

destroyed to a certain extent. This step can be recognised by increased

globule size and reduced number of globules. Coalescence is followed

by creaming stage. Coalescence is observed due to:

* insufficient amount of the emulsifying agent

* altered partitioning of the emulsifying agent

* incompatibilities among emulsifying agents

Phase volume ratio represents the relative volume of water to oil in an

emulsion. At higher ratio (>74% of oil to water), globules are closely

packed, wherein small globules occupy the void spaces between bigger

globules. Thus, globules get compressed and become irregular in

shape, which leads to fusion of adjacent globules.

Breaking

This is indicated by complete separation of oil and aqueous phases

(Figure 5). It is an irreversible process, i.e., simple mixing fails to

resuspend the globules into a uniform emulsion. In breaking, the

protective sheath around the globules is completely destroyed.

Phase Inversion

This involves the change of emulsion type from o/w to w/o or vice

versa. When we intend to prepare one type of emulsion say o/w, and if

the final emulsion turns out to be w/o, it can be termed as a sign of

instability.

FACTORS IMPROVING PHYSICAL STABILITY

Theories related to the stability of emulsions are same as those

mentioned in suspension, i.e., Brownian movement and sedimentation

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 16 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

(Stokes' law). Factors which are empirically obtained from these

theories and their influence on stability are discussed here. Factors

that influence stability are monitored closely during production.

(A) Particle Size

As the globule size is reduced (to fine state of subdivision), they tend to

exhibit Brownian movement (Example is microemulsion, size 0.01 um).

According to Stokes' law, the diameter of the globule is considered as a

major factor in creaming of emulsions. In general, the rate of creaming

decreases four-fold, when the globule diameter is halved. In

microemulsions, the rate of creaming is insignificant. It is necessary to

choose the optimum globule size for maximum stability. On the

industrial scale, emulsions are passed through a colloid mill in order to

achieve size reduction of globules. After preparation and during aging,

emulsions are also evaluated for particle size.

(B) Particle Size Distribution

In general, globules of uniform size (mono-size) impart maximum

stability. In such emulsions, globules pack loosely and globule to

globule contact is less. However, it is difficult to achieve a

monodisperse system due to a variety of factors such as viscosity,

phase volume ratio, density of phases etc. Hence, an optimum degree

of size dispersion range should be chosen to achieve maximum

physical stability. If the size of globules is not uniform, globules of

smaller size occupy the spaces between the larger globules. This type of

closed packing induces greater cohesion of globules which leads to

coalescence. Size distribution analysis has been a common procedure

in the evaluation of physical stability of emulsions.

(C) Viscosity

As the viscosity increases, flocculation of globules will be reduced

because the mobility of globules is restricted. Simultaneously the

Brownian movement of globules will also be hindered, leading to

creaming. Due to this antagonistic effect, an optimum viscosity is

desirable for good stability. Viscosity factor is normally considered for

the industrial production of emulsions.

Various thickening agents such as tragacanth, veegum and cellulose

derivatives (methylcellulose, CMC sodium etc.,) are employed to

formulate emulsions for internal use (o/w type). Long chain fatty acids

and/or alcohols such as beeswax, stearic acid, stearyl alcohol etc., are

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 17 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

used when oil is the continuous phase in an emulsion (for external

use). Viscosity determination is also an important quality control tool

in product evaluation.

(D) Phase Volume Ratio

In an emulsion the relative volume of water and oil is expressed as

phase volume ratio. In general, most medicinal emulsions are prepared

with a volume ratio of 50:50. This proportion brings about loose

packing of globules. Uniform spherical globules in loose packing have a

porosity of 48% of the bulk volume. The remaining volume (52%) is

occupied by the globules.

The upper limit 74% of oil can be incorporated in an emulsion, but this

may lead to breaking of the emulsion. This value is referred to as

critical point of phase volume ratio. This critical point is defined as the

concentration of internal phase above which the emulsifying agent

cannot produce a stable emulsion of the desired type. Beyond the

critical point, the globules become irregular in shape. The packing of

globules is closest leading to coalescence and defects in its morphology.

(E) Charge of Electrical Double Layer

When ionic type of emulsifier is employed, the electrical double layer

(interface between oil and water) possesses charge. The repulsive

forces, due to like charges on the surface of the globules, prevent the

flocculation (aggregation) of globules. The charge on the electrical

double layer also depends on the pH of the preparation. In general, the

influence of charge of electrical double layer is of secondary

importance.

When non-ionic emulsifiers are used, this factor has no importance.

(F) Physical Properties of Interface

The interfacial film of the emulsifier is responsible for enhancing the

stability of the product. The film should be elastic enough to form

rapidly as soon as droplets are produced. This behaviour facilitates the

production of emulsions. Similarly, on moderate shaking, the emulsion

should be reconstituted. After manufacture, the film should be tough

so that coalescence of globules can be prevented. Suitable emulsifying

agents such as surfactants should be selected to achieve the above film

properties at the interface. The physical properties of interface depend

on the pH of the preparation. Therefore, optimum pH has to be

maintained for maximum stability.

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 18 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

(G) Densities of Phases

It is not a usual practice to adjust the density of the phases to the

same value. Oil phase (paraffin or vegetable oil) density can be

enhanced by adding brominated oil, when the oil is an external phase.

(H) Temperature Fluctuations

Elevated temperatures alter the partition characteristics of the

emulsifiers and preservatives. The net result is instability. Temperature

also enhances the chemical degradation of drugs and other ingredients.

The chemical instability also leads to physical instability.

At high temperatures, the external phase water may evaporate making

the product (o/w) more concentrated. At lower temperature, the

aqueous phase may contain ice crystals, which rupture the interfacial

film and break the emulsion. Care should be taken to prevent

temperature fluctuations during manufacture and storage.

(I) Poor Experimental Techniques

These often lead to incomplete emulsification. Hence, the process

conditions including the sequence of steps should be meticulously

followed during manufacture. Besides, factors mentioned above, it is

also important to prevent the growth of microorganisms.

PHASE INVERSION

Phase inversion means a change of emulsion type from o/w to w/o or

vice versa. This technique is used to prepare stable and fine emulsions.

Phase inversion can be obtained by two ways:

(1) Changing the Chemical Nature of Emulsifier

For instance, an o/w emulsion is prepared using sodium stearate. Then

calcium chloride is added to form calcium stearate, which is oil soluble.

Therefore, oil phase becomes the continuous phase and w/o emulsion

is produced. Example is white liniment.

(2) Altering the Phase Volume Ratio

In this method, o/w type of emulsifier is mixed with an oil and then a

small amount of water is added. Since the volume of water is small

compared to the oil, w/o emulsion will be formed. As more water is

added slowly, the inversion point is gradually reached and the water as

well as emulsifier envelop the oil to small globules yielding an owl

emulsion. If the method is not properly controlled, phase inversion can

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 19 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

give a bad emulsion, which can cause considerable difficulty in

manufacture.

EVALUATION OF PHYSICAL STABILITY OF EMULSIONS

Emulsions are evaluated for their chemical and physical stability. (a)

Chemical stability study involves the study of degradation of active

drugs, emulsifiers, preservatives, anti-oxidants etc. Chemical instability

also leads to physical instability.

(b) Physical stability study indicates the retaining of the integrity of the

dosage form during shelf life. An emulsion is considered to be

physically stable, if it can restore its initial properties on moderate

shaking. The physical stability of emulsions can be evaluated by the

following methods:

1. Extent of Phase Separation

The practical and commercial aspect of stability is the study of phase

separation. This is a quick method and can be applied for poorly

formed and rapidly breaking emulsions. Separation of phases is visible

after a definite period of time, though the signs of instability (creaming

and coalescence) begin quite early.

2. Globule Size Distribution

An early sign of instability is indicated by the appearance of bigger size

globules. This is due to aggregation and coalescence of small globules

from time to time, during storage. Therefore, microscopic examination

of globule size distribution analysis is a useful tool to evaluate the

physical stability. The method is similar to the procedure described for

particle size analysis by optical microscopy in micromeritics.

The specific surface of the globules gives better correlations than the

globule size distribution regarding physical stability. Immediately after

manufacture, the emulsion exhibits active coalescence stage for some

period. During this period, the emulsion gets stabilised and is relieved

of the stresses induced in the preparation. Beyond this period, the

emulsion remains stable on extended storage.

3. Accelerated Stability Studies-Centrifugation

Normally, flocculation and creaming are slow processes. However, these

processes can be hastened by inducing stress conditions using

ultracentrifuge. The emulsions are subjected to different centrifugal

speeds 2000-3000 rpm) at room temperature and the separation of

phases is observed at different time periods (Figure 6). A bad emulsion,

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 20 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

normally, separates the oil instantly. A good emulsion does not exhibit

detectable separation of oil phase, until certain time period, i.e.,

induction period (Figure 6).

Fig. 6 Oil coalescence-time profile of different emulsions (o/w type).

Curve A is a bad emulsion, curve B, C and D are good emulsions.

4. Microwave Irradiation

The emulsion is exposed to microwave irradiation. Then the surface

temperature of the emulsion tends to be highest and the temperature

gradient between the surface and the bottom of the emulsion must be

small for the most stable emulsion.

PRESERVATION OF EMULSIONS

It is important that an emulsion should be free from microbial

contamination and growth. Microorganisms, such as fungi, bacteria

and yeast, use some of the ingredients (carbohydrates, proteins, sterols

and gums) of the emulsion for their growth. As a result, these

ingredients get digested leading to instability of the product. The mere

presence of lipid water interface allows the growth of microorganisms.

In case of parenteral emulsions, however, sterility of the product is

essential. Preservatives, such as benzoic acid, sodium benzoate, methyl

paraben and propyl paraben, are employed in the preparation of

emulsions for non parenteral use. Adequate concentration of these

preservatives has to be established. Some of the factors to be

considered for the selection of preservatives are: Nutritive value, Degree

of aeration, Type of container, Type of emulsion (o/w or w/o), Volume

fraction of aqueous phase, pH of the aqueous phase, Binding of

ingredients in the formulation.

The optimum concentration of a preservative is decided by considering

the following features:

1. Aqueous phase: Bacteria are generally grown in the aqueous

phase, and at the oil-water interphase. Therefore, the preservative

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 21 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

should partition in favour of the aqueous phase. Special care should be

taken on the use of preservative in oil emulsions.

2. The volume fraction of the aqueous phase: The higher the

volume fraction of the aqueous phase, the higher is the concentration

of the preservative required.

3. pH of the aqueous phase: The preservative should be in an

undissociated form for its transport across the membranes of the

organism. The undissociated form is effective as a bacteriostatic agent.

The pH of an aqueous phase should favour the formation of the

undissociated form.

RHEOLOGIC PROPERTIES OF EMULSIONS

Emulsions are evaluated for its flow behaviour. The following flow

related attributes are desirable for the overall performance of an

emulsion:

(a) Removal of an emulsion from a bottle or tube.

(b) Flow of an emulsion through a hypodermic needle.

(c) Spreadability of an emulsion on the skin.

(d) Stress induced flow changes during manufacture (milling etc).

In general, dilute emulsions exhibit Newtonian flow and the comparison

of flow curves among different batches is easy. Analysis becomes

complicated in case of concentrated emulsions owing to their non-

Newtonian flow. Multipoint viscometers such as cone and plate or cup

and bob type can be employed for evaluation. Different factors

influencing the viscosity of an emulsion have been discussed in earlier

sections. A rough guide regarding the type of flow can be obtained

based on phase volume ratio. They are:

An optimum level of viscosity is to be identified for maximum physical

stability. The factors mentioned earlier, which are related to dispersed

phase, continuous phase and the emulsifying agent should be

considered.

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 22 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

PREPARATION OF EMULSIONS

Before attempting to prepare an emulsion, it may be necessary to select

the important components, viz., oil phase and emulsifying agent. Of

course, water will be the other component.

Selection of Oil Phase

A variety of substances have been used for oil phase. A few examples

are:

Fixed oils (corn, soya bean, peanut, sunflower oils), Aliphatic

hydrocarbons (liquid paraffin, turpentine oil etc.), Beeswax, spermaceti,

Glycerides (long and medium chain), Fatty acids and alcohols.

Many of them are prone to oxidation. Therefore, it is necessary to

include suitable antioxidant in the formulation. Selection of oil phase is

determined by several factors:

(a) Desired physical properties of the product.

(b) Potential toxicity of the oil to the route of administration.

(c) Solubility of active product in the oil.

(d) Consistency of the product qualities.

(e) Any possible incompatibilities.

Based on these factors, the optimum volume of oil should be selected.

Generally, it is advisable to prepare an emulsion containing less than

about 25% of dispersed phase in oil-in-water emulsions. Such products

are very susceptible to severe creaming. Conversely, products

containing a high percentage (more than about 70%) of dispersed

phase are likely to exhibit phase inversion. The phase-volume ratio is

also applicable to water when it is used as dispersed phase.

Selection of Aqueous Phase

Mostly water is used. Sometimes, the organoleptic features of the

emulsion demand the need of adding sweeteners and flavouring agents.

Sensitivity of skin and nature of absorption determine the pH of

aqueous phase. In addition, electrolytes and preservatives are included.

Based on the factors, optimum volume of aqueous phase should be

decided. Appropriate phase volume ratio should be selected.

Selection of Emulsifying Agent

An emulsifying agent is selected depending on the type of emulsion

required. Selection of emulsifying agents is also based on the intended

use (internal or external). For internal use, non-ionic and water-soluble

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 23 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

emulsifying agents are chosen. For external use, both ionic and

nonionic emulsifying agents are employed.

Another guiding principle is the Bancroft rule, which suggests the

nature (oil-soluble or water-soluble) of an emulsifying agent for each

emulsion. Furthermore, the principles of HLB scale can be applied in

its selection. The required HLB value can be determined using

allegation method based on the nature of oil phase and type of

emulsion. HLB calculations do not take into account the total

concentration of surfactant to be used. As a guide, 2% w/w is

considered optimum and 5% w/w is maximum. It is essential to

prepare a series of samples to study the stability. Then, the optimum

concentration of an emulsifying agent (or blend) should be obtained.

It is better to avoid emulsifying agents obtained from natural origin,

because they show considerable batch-to-batch variation. In addition,

they also support the microbial growth.

Emulsion (Physical Stability) Considerations

The rheological character of an emulsion is important in stabilising it

against creaming. The viscosity of the medium surrounding the

droplets prevent the collision of globules. When the collisions are less,

the physical stability of such an emulsion will be higher. This factor

overrides the influence of the interfacial barrier.

Small Scale Preparation

The mortar and pestle is a simple and inexpensive equipment for the

extemporaneous preparation of small quantities of emulsions. It is

used for batch process. Normally, these emulsions are stabilised by the

presence of emulsifying agents such as acacia and tragacanth. The

basic methods in the preparation of emulsion with mortar and pestle

are:

* Wet Gum (English) Method

* Dry Gum (Continental) Method

Currently, emulsions are prepared using synthetic emulsifying agents,

especially of the non-ionic type. Their wide spread use is due to the

simplicity of the method, which is described here.

1. Group the ingredients on the basis of their solubilities in aqueous

and oil phases.

2. Dissolve the oil-soluble ingredients and the 'emulsifier in the oil.

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 24 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

3. If necessary, heat the mixture to approximately 5 to 10°C over the

melting point of the highest melting ingredients or to a maximum

temperature of 70 to 80°C.

4. Dissolve the water-soluble ingredients (except acids and salts) in

sufficient quantity of water.

5. Heat the aqueous phase to a temperature, which is 3 to 5°C higher

than that of the oil.

6. Add the aqueous phase to the oil phase with suitable agitation.

7. If acids or salts are employed, dissolve them in water and add the

solution to the cold emulsion.

8. Transfer the preparation into a measurer and adjust the final

volume with the water (or dispersion medium).

9. Pack the emulsion in a narrow-mouthed container and label it.

Agitation is a critical factor in order to produce a desired globule size.

Mortar and pestle produce a coarse emulsion and the efficiency of

shear is limited. Now-a-days, even for small scale preparations,

efficient handoperated homogenizers are available. A rough emulsion

may be prepared in a bottle by simple mixing. It is, then, passed

through several times through the homogenizers.

Large Scale Preparation

The basic steps involved in the preparation of an emulsion on a

commercial scale are same as those mentioned in the small scale

preparation.

The oil and water phases containing hydrophobic and hydrophilic

components respectively, are often heated separately in large tanks.

When waxes are present, both phases must be heated above the

highest melting point of any component present. Then, one phase is

pumped into the tank containing second phase. Constant agitation is

provided during the addition. After cooling the emulsion is

homogenized.

The agitation and shearing of dispersed phase should be vigorous so as

to produce very small globule size. Considerable amount of energy

should be expended for heating and mixing. A number of equipments

may be used for the emulsification. Some of them are: Ordinary

agitators, Mechanical mixers (Propeller type mixer Turbine mixers),

Colloid mills, Ultrasonic devices.

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 25 of 24

E-Notes Physical Pharmacy B. Pharmacy 4th Semester

The use of colloid mill is illustrated here. Colloid mill consists of two

steel discs having a very small clearance between them. The clearance

between rotor and stator is adjustable, usually from 0.001 and upward.

After cooling, the emulsion mixture is passed between the rotor and

stator. In this process, tremendous shearing action is produced, which

results in the formation of fine dispersion of uniform size. This process

is repeated until the desired size of dispersion is obtained. Then the

product is packed.

The shearing force applied is usually results in an increase in

temperature within the emulsion. Therefore, it may be necessary to

cool the equipment during the homogenization. In spite of our best

efforts, emulsions still have shorter shelf life (less than 2 years). These

systems are also widely employed in dermatological and cosmetic

preparations.

Compiled By: Mr. Nishant Yadav, Associate Professor, BSAIP Page 26 of 24

You might also like

- House - Hold Products FormulationsDocument11 pagesHouse - Hold Products FormulationsEthanpj Linchoco100% (1)

- Modified Release Dosage FormsDocument36 pagesModified Release Dosage FormsCHARLES RONALD GENATONo ratings yet

- Formulation of Dishwashing LiquidDocument3 pagesFormulation of Dishwashing LiquidTots Holares100% (6)

- Lesson 1 Prescription and Medication OrderDocument30 pagesLesson 1 Prescription and Medication OrderAngelica GomezNo ratings yet

- Quality Control of Tablets Lecture 1Document15 pagesQuality Control of Tablets Lecture 1Muhammad AzeemNo ratings yet

- Monophasic Liquid Formulation OptimizationDocument25 pagesMonophasic Liquid Formulation OptimizationAamir KhanNo ratings yet

- Physical Pharmacy Lecture NotesDocument34 pagesPhysical Pharmacy Lecture NotesNoorul Alam100% (1)

- Chapter 27 Suspensions and EmulsionsDocument49 pagesChapter 27 Suspensions and EmulsionsKate Montenegro67% (3)

- PHARDOSE REPORT - Powders and GranulesDocument58 pagesPHARDOSE REPORT - Powders and GranulesBiyaya San PedroNo ratings yet

- Pharmaceutical EmulsionsDocument55 pagesPharmaceutical EmulsionschandramohanNo ratings yet

- Unit IV. Solid Modified Release Dosage FormsDocument24 pagesUnit IV. Solid Modified Release Dosage FormsMary-Ann Valencia SapnuNo ratings yet

- Liquid Dosage Forms: Classification, Manufacturing and Quality Control TestsDocument43 pagesLiquid Dosage Forms: Classification, Manufacturing and Quality Control Testsbee859550% (4)

- 79Document49 pages79khalilNo ratings yet

- Activity #1 - Physico-Chemical Properties of Drugs by Jasher Dave C. AcabalDocument9 pagesActivity #1 - Physico-Chemical Properties of Drugs by Jasher Dave C. AcabaldavenNo ratings yet

- SuspensionDocument56 pagesSuspensionHarnil SoniNo ratings yet

- Effervescent Granules Lab ManualDocument2 pagesEffervescent Granules Lab Manuallalag yanNo ratings yet

- 03 Solutions PDFDocument77 pages03 Solutions PDFIra MoranteNo ratings yet

- Solubility of Drugs PDFDocument66 pagesSolubility of Drugs PDFPrabhas MeherNo ratings yet

- Dosage - Chapter 14Document57 pagesDosage - Chapter 14Kim Manlangit100% (1)

- Drug incompatibilities guide for pharmacistsDocument45 pagesDrug incompatibilities guide for pharmacistsANKUR JAIN100% (1)

- Dispensing2 Lab - Therapeutic IncompatibilitiesDocument2 pagesDispensing2 Lab - Therapeutic IncompatibilitiesAlyssa Erika Azores100% (1)

- Physical Pharmacy: Solubility and Distribution PhenomenaDocument6 pagesPhysical Pharmacy: Solubility and Distribution PhenomenaAishwarya PawarNo ratings yet

- C 14 SuspensionsDocument12 pagesC 14 SuspensionsAli Uy100% (1)

- Semi Solids PDFDocument55 pagesSemi Solids PDFYogesh apurwaNo ratings yet

- Particle Size Effects and Granulation Techniques for PowdersDocument4 pagesParticle Size Effects and Granulation Techniques for PowdersMXLTR100% (1)

- Suspension: Pharmaceutical Preparations Dr. Asra HameedDocument64 pagesSuspension: Pharmaceutical Preparations Dr. Asra HameedGutu DoinaNo ratings yet

- 4-Drug Delivery Systems (Autosaved)Document41 pages4-Drug Delivery Systems (Autosaved)Chelle PaloNo ratings yet

- B322-99 (2014) Standard Guide For Cleaning Metals Prior To Electroplating PDFDocument9 pagesB322-99 (2014) Standard Guide For Cleaning Metals Prior To Electroplating PDFdiego rodriguezNo ratings yet

- PHD211 - Ointment 2019Document147 pagesPHD211 - Ointment 2019honeylemon.co100% (2)

- 7 SurfactantsDocument76 pages7 SurfactantsUsman HameedNo ratings yet

- Liquid Dosage FormsDocument8 pagesLiquid Dosage FormsRamkanth SNo ratings yet

- Dosage Forms ExplainedDocument6 pagesDosage Forms ExplainedAmaila Ch100% (1)

- MICROMERITICSDocument33 pagesMICROMERITICSsandymh67% (3)

- Drug Delivery System - AnswerDocument14 pagesDrug Delivery System - AnswerFred100% (1)

- Biphasic Liquid Dosage FromDocument8 pagesBiphasic Liquid Dosage FromSwaroopSinghJakhar100% (1)

- Slide 9 Patient Counseling and Other Special Considerations in CounselingDocument22 pagesSlide 9 Patient Counseling and Other Special Considerations in CounselingJean GanubNo ratings yet

- Surface Chemistry Guide to Adsorption and CatalysisDocument22 pagesSurface Chemistry Guide to Adsorption and CatalysisAfza MukaddamNo ratings yet

- Pharmaceutical Solutions For Oral Administration-2 PDFDocument31 pagesPharmaceutical Solutions For Oral Administration-2 PDFHanaa Abo Sweirh100% (1)

- Determine Specific Gravity and Melting PointsDocument15 pagesDetermine Specific Gravity and Melting PointsGen-Gen Belenio BillonesNo ratings yet

- HyDeX Technical Data SheetDocument4 pagesHyDeX Technical Data SheetIqbal Safirul BarqiNo ratings yet

- Softener, Textile FinishingDocument4 pagesSoftener, Textile FinishingArif NursyabaniNo ratings yet

- Household Chemicals and Personal Care Products (Chap 5, Lesson 20)Document8 pagesHousehold Chemicals and Personal Care Products (Chap 5, Lesson 20)Chester Andasan67% (3)

- Treatment of Soap & Detergent Industry WastesDocument56 pagesTreatment of Soap & Detergent Industry WastesMuhammad Syahrul Rizal100% (2)

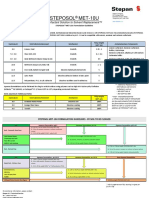

- Steposol MET-10U: Surfactant Solution To Solvent Replacement™Document2 pagesSteposol MET-10U: Surfactant Solution To Solvent Replacement™pkh29100% (1)

- Types of Titrimetric AnalysisDocument62 pagesTypes of Titrimetric AnalysisJacqueline BaquiranNo ratings yet

- 14 Disperse Systems With AnswersDocument5 pages14 Disperse Systems With AnswersPatricia Camryne Ambida100% (2)

- EmulsionDocument13 pagesEmulsionPriyanka KushwahaNo ratings yet

- Dispersi KasarklasiberDocument124 pagesDispersi KasarklasiberSari RamadhaniNo ratings yet

- Introduction to Pharmaceutics Powders and GranulesDocument84 pagesIntroduction to Pharmaceutics Powders and GranulesMompati Letsweletse100% (2)

- 634581643032102500Document130 pages634581643032102500DrVenu Madhav KNo ratings yet

- Granulation Process and MethodsDocument55 pagesGranulation Process and MethodsWalaa abo foolNo ratings yet

- Pharmaceutical Care Principles for Improving Patient HealthDocument9 pagesPharmaceutical Care Principles for Improving Patient HealthJesza IgnacioNo ratings yet

- DdsDocument9 pagesDdsClaudette JunioNo ratings yet

- Pharmaceutical Dosage Froms and Drug Delivery SystemsDocument14 pagesPharmaceutical Dosage Froms and Drug Delivery SystemsChantelle MeaNo ratings yet

- SUSPENSIONDocument11 pagesSUSPENSIONAnoosha FarooquiNo ratings yet

- Chocolate Syrup GuideDocument3 pagesChocolate Syrup GuideMikaela LaoNo ratings yet

- SolutionsDocument7 pagesSolutionsMARIE ERICKA ARONANo ratings yet

- Lecture 2 - Disperse SystemsDocument94 pagesLecture 2 - Disperse Systemsapi-370729792% (12)

- Ointments Guide: Topical Formulations, Uses, TypesDocument7 pagesOintments Guide: Topical Formulations, Uses, TypesAnonymous XuiUo2ThNo ratings yet

- pH = 4.78So oxalic acid can only be titrated as diprotic acidDocument35 pagespH = 4.78So oxalic acid can only be titrated as diprotic acidŠĭlệncěIšmyPŕIdệNo ratings yet

- Pharmaceutical dosage forms guideDocument10 pagesPharmaceutical dosage forms guideprinceamitNo ratings yet

- Understanding Dispensing PharmacyDocument67 pagesUnderstanding Dispensing Pharmacyneha_dand15910% (1)

- Chapter 14 Dispersed SystemsDocument4 pagesChapter 14 Dispersed SystemsRia MicuaNo ratings yet

- Pharmaceutical Dosage Forms, Drug Delivery Systems and Medical Devices Pharm 201L Name:Tallod, Emerson John L. Group:11 Year/Section:Q2A Final RatingDocument7 pagesPharmaceutical Dosage Forms, Drug Delivery Systems and Medical Devices Pharm 201L Name:Tallod, Emerson John L. Group:11 Year/Section:Q2A Final RatingJames AzurinNo ratings yet

- Pharm. Chem. - 2 Lab Exp No 5Document3 pagesPharm. Chem. - 2 Lab Exp No 5davenNo ratings yet

- Suspension & EmulsionsDocument57 pagesSuspension & Emulsionsimam mahdi tv officialNo ratings yet

- Controlled Release Oral Drug Delivery Systems 9Document46 pagesControlled Release Oral Drug Delivery Systems 9Rahul Nair50% (2)

- pdf 20221120 193206 ٠٠٠٠Document68 pagespdf 20221120 193206 ٠٠٠٠asma2002mhNo ratings yet

- Women Institute of Learning AbbottabadDocument15 pagesWomen Institute of Learning AbbottabadRida syedNo ratings yet

- Pharmaceutical Merits&Demerits of EmulsionDocument6 pagesPharmaceutical Merits&Demerits of EmulsionShemaj GurchumaNo ratings yet

- Pharmaceutical Merits&Demerits of EmulsionDocument6 pagesPharmaceutical Merits&Demerits of EmulsionShemaj GurchumaNo ratings yet

- 1 s2.0 0021979786901293 MainDocument5 pages1 s2.0 0021979786901293 MainAryamanNo ratings yet

- Chemical Modification of Triglyceride Oils and Their Industrial ApplicationsDocument28 pagesChemical Modification of Triglyceride Oils and Their Industrial ApplicationsDavis BeautiesNo ratings yet

- Plantacare 2000upDocument2 pagesPlantacare 2000upShivon LamNo ratings yet

- Lappaceum.: Surface-Active Properties of Extracted Saponin From The Leaves of NepheliumDocument6 pagesLappaceum.: Surface-Active Properties of Extracted Saponin From The Leaves of NepheliumThuong Vu ThanhNo ratings yet

- Silveira, 2020, An Overview of Biotechnological Processes in The Food IndustryDocument18 pagesSilveira, 2020, An Overview of Biotechnological Processes in The Food IndustryTuh JimmyNo ratings yet

- I It B Tech Brochure 23 Dec 2011Document144 pagesI It B Tech Brochure 23 Dec 2011Alex MarkNo ratings yet

- 7 e 78 Ea 2209843Document6 pages7 e 78 Ea 2209843Z100% (1)

- Surfactant Adsorption To Di Fferent Fluid Interfaces: AccessDocument6 pagesSurfactant Adsorption To Di Fferent Fluid Interfaces: AccessmL 2023No ratings yet

- Biobased Surfactants andDocument512 pagesBiobased Surfactants andgizemNo ratings yet

- A Review of Surfactant As Corrosion InhibitorsDocument66 pagesA Review of Surfactant As Corrosion InhibitorsafifiNo ratings yet

- Antifoam CompoundDocument7 pagesAntifoam CompoundMishra KewalNo ratings yet

- Construction Product GuideDocument9 pagesConstruction Product GuideAlexander Franco CastrillonNo ratings yet

- Pharmaceutical Suspension: Nahla S. Barakat, PH.DDocument43 pagesPharmaceutical Suspension: Nahla S. Barakat, PH.DRaisa Alvina100% (1)

- ScouringDocument25 pagesScouringIndhu IndhhuuNo ratings yet

- Semisolid Dosage Forms PDFDocument69 pagesSemisolid Dosage Forms PDFRahul LakhaniNo ratings yet

- Catalog+OilGas+2020 +vfinal+-+ENGDocument17 pagesCatalog+OilGas+2020 +vfinal+-+ENGLucas Matias AriasNo ratings yet

- Eor All 2023Document259 pagesEor All 2023gilberto monteiroNo ratings yet

- Preservatives For Hair Products and Cosmetics - IngreCoreDocument23 pagesPreservatives For Hair Products and Cosmetics - IngreCorekh.srm.ukNo ratings yet

- Catalog-Speciality Chemical - NOF - America PDFDocument76 pagesCatalog-Speciality Chemical - NOF - America PDFLim Chee SiangNo ratings yet