Professional Documents

Culture Documents

Starting System PDF

Starting System PDF

Uploaded by

jimmyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Starting System PDF

Starting System PDF

Uploaded by

jimmyCopyright:

Available Formats

STARTING SYSTEM

In an automobile, starting system cranks the engine initially. It has replaced manual

effort to crank the engine with the help of cranking rod that was used in ancient days.

Initially, the engine requires cranking but once the cycle is completed it starts and runs on

its own. In two wheelers, it is common to ‘kick start’ the engine but in recent times a

number of manufacturers have introduced ‘button start’. For initial cranking an electric

motor is provided that gets electric current as input from battery. The mechanical energy,

in the form of rotation of shaft, is transmitted to engine. This provides initial movement of

crankshaft, connecting rod and piston. As soon as spark occurs the fuel is ignited and output

becomes available from engine. No more cranking is needed and starting system stops

working and engine runs on its own. The starting system makes starting of vehicle convenient.

A starting system consists of starting motor, magnetic switch, safety switch, battery,

cables and ignition switch. These components are connected with each other through two

circuits. One is starting circuit, in which high current flows which is used to start the

engine. Second is control circuit, in which low current flows. The ignition switch acts as

switch for starting circuits also. In starting circuit, the current flows from battery to starter

motor through solenoid or magnetic switch. The control circuit connects magnetic switch

with, battery through ignition switch.

STARTER MOTOR

The starter motor is like any other electrical motor but it is designed to work under

high electrical overloads and produces very high power. Due to this, the motor can operate

for short durations. High current is needed to operate it that generates heat. Time is also required to

dissipate this heat. Therefore, it is advisable that the motor be given enough

gaps between more than one starting attempts.

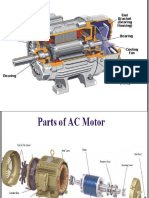

The motor has got field coils with pole shoes, armature and a housing that encloses

them. Apart from these it has brushes, bushings that make its operation efficient.

The field coils and pole shoes produce strong stationary electromagnetic fields as current

is passed through them. Magnetic polarity (N or S) depends upon the direction in which the

current flows. The magnetic fields produced are opposite in nature.

The armature is located between drive and end frames. It has windings and the

commutator mounted on the armature shaft. The windings are made of a number of coils

of a single loop each. These are insulated from each other and fit into slots in the armature

shaft. The commutator has heavy copper segments surrounding the shaft but are insulated

from each other and the shaft. The armature is surrounded by field coils. Current is supplied

to armature and it produces magnetic field in each conductor. The magnetic fields are also

produced by field coils. The reaction between these magnetic fields causes the rotation of

armature. The rotation is transferred to crankshaft of the engine through armature shaft.

This causes cranking of engine.

The current from field coils to the armature is transferred through brushes. These

brushes are held with the help of springs against the commutator. The brushes can be from

two to six in number for smooth motion and constant torque delivery.

You might also like

- Group 2 Ac Motors Technical ReportDocument12 pagesGroup 2 Ac Motors Technical Reporttristan jeff bautistaNo ratings yet

- The Starting SystemDocument20 pagesThe Starting SystemRuth MwendaNo ratings yet

- Group-2 Two and Three Wheeled Vehicle Assignment PresentationDocument20 pagesGroup-2 Two and Three Wheeled Vehicle Assignment PresentationTäð Œvê MîðNo ratings yet

- Automotive Electrical & Electronics Unit II: Presented byDocument58 pagesAutomotive Electrical & Electronics Unit II: Presented bymharitms100% (1)

- Automotive Electrical & Electronics Unit II: Presented byDocument58 pagesAutomotive Electrical & Electronics Unit II: Presented bymharitmsNo ratings yet

- Automotive Electrical & Electronics Unit II: Presented byDocument58 pagesAutomotive Electrical & Electronics Unit II: Presented bymharitmsNo ratings yet

- Starting Motor OperationDocument11 pagesStarting Motor OperationBishoo ShenoudaNo ratings yet

- IntroductionDocument5 pagesIntroductionHarsh GuptaNo ratings yet

- Ignition SystemDocument5 pagesIgnition SystemPankaj GauravNo ratings yet

- Starting SystemDocument9 pagesStarting SystemTesfahun TegegneNo ratings yet

- Automotive Electrical SystemDocument55 pagesAutomotive Electrical SystemMoriel J. NudoNo ratings yet

- Learning Guide - 41: Vehicle Servicing and RepairingDocument28 pagesLearning Guide - 41: Vehicle Servicing and RepairingNøhá Akå NõåhNo ratings yet

- Starting SystemDocument19 pagesStarting SystemJonathan Javier Ceballos Bonilla100% (1)

- Defination of Ignition SystemDocument28 pagesDefination of Ignition SystemDawood KhanNo ratings yet

- What Is A Solar Motor?Document11 pagesWhat Is A Solar Motor?D K SHARMANo ratings yet

- Introduction To DC Electric MotorsDocument31 pagesIntroduction To DC Electric MotorsJames Adrian Abalde SaboNo ratings yet

- New Microsoft Office Word DocumentDocument11 pagesNew Microsoft Office Word DocumentVishal SharmaNo ratings yet

- Ignition SystemDocument43 pagesIgnition SystemHAMZA YOUSAFNo ratings yet

- IntroductionDocument9 pagesIntroductiongalihwidiastoNo ratings yet

- AC MotorDocument8 pagesAC MotorSmai HondoNo ratings yet

- Electromagnetic InductionDocument16 pagesElectromagnetic InductionSebastianNo ratings yet

- What Is An AlternatorDocument16 pagesWhat Is An AlternatorSanrasni100% (1)

- Ex 3Document7 pagesEx 3Feras Al-AzzehNo ratings yet

- Ignition System: Internal Combustion Engines Boilers Electric SparkDocument9 pagesIgnition System: Internal Combustion Engines Boilers Electric SparkManu ChakkingalNo ratings yet

- Eddy Current Brakes: Published On Feb 12, 2016Document4 pagesEddy Current Brakes: Published On Feb 12, 2016BALAJINo ratings yet

- Simple Electric Motor and GeneratorDocument17 pagesSimple Electric Motor and GeneratorAyla BonitaNo ratings yet

- Assignment Ac DCDocument10 pagesAssignment Ac DCKamil KhairiNo ratings yet

- Distributor CamDocument3 pagesDistributor CamJovy0% (1)

- 4 Motors: D.C. Motors Principles of D.C. MotorsDocument10 pages4 Motors: D.C. Motors Principles of D.C. MotorsmanjunathagNo ratings yet

- AC MachinesDocument3 pagesAC MachinesjelizajordanNo ratings yet

- Charging SystemDocument28 pagesCharging SystemAnanta Kumar NandiNo ratings yet

- Alternator ToyotaDocument5 pagesAlternator ToyotaAYON_MSNNo ratings yet

- D3.2 ActuatorsDocument9 pagesD3.2 ActuatorsTanya AayogNo ratings yet

- Generato RS: Prepared By: Ms. Clydine Jethna O. SigueDocument33 pagesGenerato RS: Prepared By: Ms. Clydine Jethna O. SigueChamain MarreroNo ratings yet

- Solar Grass Cutter With Linear Blades by Using Scotch Yoke MechanismDocument38 pagesSolar Grass Cutter With Linear Blades by Using Scotch Yoke MechanismAakash DindigulNo ratings yet

- Module IiDocument14 pagesModule Iisarath.mNo ratings yet

- Electrical System: Systems OperationDocument9 pagesElectrical System: Systems OperationMbahdiro KolenxNo ratings yet

- Type of NC SystemDocument20 pagesType of NC Systemamit kumarNo ratings yet

- Electric MotorsDocument16 pagesElectric MotorsReszler ArnoldNo ratings yet

- Parts of Ignition SystemDocument16 pagesParts of Ignition SystemAnthony ArgandaNo ratings yet

- Skip To ContentDocument17 pagesSkip To Contentkidanemariam teseraNo ratings yet

- Ggenerator AlternatorDocument4 pagesGgenerator AlternatorShakir FadzliNo ratings yet

- Theory Ignition SystemDocument4 pagesTheory Ignition SystemJareewat Arnamnart100% (1)

- Mr. Mohanbir Singh: TopicDocument6 pagesMr. Mohanbir Singh: TopicGagan BoparaiNo ratings yet

- TechportDocument6 pagesTechportMaureen TatadNo ratings yet

- Automatic Drain CleanerDocument45 pagesAutomatic Drain CleanerArun Kumar Yadav70% (10)

- Automotive Ignition SystemDocument8 pagesAutomotive Ignition SystemA A.DevanandhNo ratings yet

- Electric Motor: Rotor (Document3 pagesElectric Motor: Rotor (qwert qwertNo ratings yet

- 936E WHEEL LOADER 33Z03091-UP (MACHINE) POWERED BY 3304 ENGINE (SEBP1761 - 02) - Systems & Compon54entsDocument17 pages936E WHEEL LOADER 33Z03091-UP (MACHINE) POWERED BY 3304 ENGINE (SEBP1761 - 02) - Systems & Compon54entsTransportation MaintananceNo ratings yet

- History: Electric Motor Alternating Current Stator RotorDocument14 pagesHistory: Electric Motor Alternating Current Stator RotorManas NagNo ratings yet

- Chapter 2 Prime MoversDocument90 pagesChapter 2 Prime Moversaimi wahabNo ratings yet

- Study of Electricity Generated by Ceiling Fan & Car WheelDocument6 pagesStudy of Electricity Generated by Ceiling Fan & Car WheelSaru TVNo ratings yet

- Electric Vehicle Starting MotorsDocument29 pagesElectric Vehicle Starting MotorsRuth Mwenda100% (1)

- Aircraft Electrical, and Ignition SystemDocument32 pagesAircraft Electrical, and Ignition SystemKim RioverosNo ratings yet

- Secondary CircuitDocument4 pagesSecondary CircuitIrfan Khan0% (1)

- Self-Check Minor EESServiceDocument9 pagesSelf-Check Minor EESServiceMulugeta AbebeNo ratings yet

- Electrical Motors 2013Document28 pagesElectrical Motors 2013Stephen StewartNo ratings yet

- What Is An Alternator?: Battery Voltage Regulator AlternatorDocument5 pagesWhat Is An Alternator?: Battery Voltage Regulator AlternatorNeverhhhNo ratings yet

- Home-made Toy Motors: A practical handbook giving detailed instructions for building simple but operative electric motorsFrom EverandHome-made Toy Motors: A practical handbook giving detailed instructions for building simple but operative electric motorsNo ratings yet

- A New System of Alternating Current Motors and Transformers and Other EssaysFrom EverandA New System of Alternating Current Motors and Transformers and Other EssaysRating: 5 out of 5 stars5/5 (1)

- Preparing A Resume: Personal InformationDocument1 pagePreparing A Resume: Personal InformationjimmyNo ratings yet

- Technician Pay MethodsDocument2 pagesTechnician Pay Methodsjimmy100% (1)

- Developing An Employment PlanDocument2 pagesDeveloping An Employment PlanjimmyNo ratings yet

- Telescopic Direct-Acting-Type DampersDocument3 pagesTelescopic Direct-Acting-Type DampersjimmyNo ratings yet

- Battery and Charging SystemDocument1 pageBattery and Charging SystemjimmyNo ratings yet

- IRMT Emergency PlanDocument96 pagesIRMT Emergency PlanjimmyNo ratings yet

- 04 Appraisal DisposalDocument16 pages04 Appraisal DisposaljimmyNo ratings yet

- Digital DivideDocument28 pagesDigital DividejimmyNo ratings yet

- Presentation On DC GeneratorDocument36 pagesPresentation On DC GeneratorShubham prajeshNo ratings yet

- Unit - Ii DC Machines: Sri Vidya College of Engineering & TechnologyDocument16 pagesUnit - Ii DC Machines: Sri Vidya College of Engineering & TechnologyBALAKRISHNANNo ratings yet

- Energy Conversion Module 2Document8 pagesEnergy Conversion Module 2Arvin Palma Dela RocaNo ratings yet

- Class - 16 - DC Motors Power FlowDocument14 pagesClass - 16 - DC Motors Power FlowHafsa AlhaddabiNo ratings yet

- Generato RS: Prepared By: Ms. Clydine Jethna O. SigueDocument33 pagesGenerato RS: Prepared By: Ms. Clydine Jethna O. SigueChamain MarreroNo ratings yet

- 2020 PriceDocument40 pages2020 Pricediesel.jabalpurNo ratings yet

- Power System Operation & Control - Lab ManualDocument33 pagesPower System Operation & Control - Lab Manualrakesh shuklaNo ratings yet

- DC Motor Maintenance - (03-2008) - Us-EnDocument30 pagesDC Motor Maintenance - (03-2008) - Us-EnChristian BedoyaNo ratings yet

- Separately Excited DC Motor - Electronic Components (Systems) - Electronics Tutorial PDFDocument3 pagesSeparately Excited DC Motor - Electronic Components (Systems) - Electronics Tutorial PDFSaurav kumarNo ratings yet

- 15A99301 Basic Electrical and Electronics Engineering - 4 PDFDocument2 pages15A99301 Basic Electrical and Electronics Engineering - 4 PDFMadhuSudanNo ratings yet

- Usn 2 B V: UNIT-II and Any ONE Full Question From UNIT-III. Use of Heat and Mass Transfer Data Hand Book Is PermittedDocument6 pagesUsn 2 B V: UNIT-II and Any ONE Full Question From UNIT-III. Use of Heat and Mass Transfer Data Hand Book Is PermittedAkshay ArksaliNo ratings yet

- DC MotorsDocument8 pagesDC MotorsgireeshNo ratings yet

- Syllabus Ee (3 To 8 Sem) 1585243639Document71 pagesSyllabus Ee (3 To 8 Sem) 1585243639Sahil MeshramNo ratings yet

- Roteiro Da Aula PraticaDocument18 pagesRoteiro Da Aula PraticaEberton SantosNo ratings yet

- Chapter 15 Class 10th PDFDocument12 pagesChapter 15 Class 10th PDFMuneer Kaleri75% (4)

- Roebel Windings For Hydro GeneratorsDocument69 pagesRoebel Windings For Hydro GeneratorsmihirthakkarNo ratings yet

- Top 42 Electrical Machines Interview Questions (2023) - JavatpointDocument15 pagesTop 42 Electrical Machines Interview Questions (2023) - JavatpointeeeshijaNo ratings yet

- Ec ControlDocument335 pagesEc ControladammathewsNo ratings yet

- Motor WindingDocument40 pagesMotor WindingALI AKBARNo ratings yet

- PDF Editor: Computer Aided Electrical Drawing (Caed)Document29 pagesPDF Editor: Computer Aided Electrical Drawing (Caed)tare tamiruNo ratings yet

- Week 9 - Chap28Document27 pagesWeek 9 - Chap28Viet PhamNo ratings yet

- Electrical InterviewDocument49 pagesElectrical InterviewRaed Mohsen100% (3)

- TUGASAN KUMPULAN (DC Generator)Document43 pagesTUGASAN KUMPULAN (DC Generator)Zainuddin BusuNo ratings yet

- Topic 2. DC Machines Part II - DC Motor 2019Document75 pagesTopic 2. DC Machines Part II - DC Motor 2019Lim Kai XuanNo ratings yet

- Design and Analysis of New Class Brushless DC Motor FSMDocument5 pagesDesign and Analysis of New Class Brushless DC Motor FSMKitaba TolesaNo ratings yet

- Drives and Control Lab ManualDocument36 pagesDrives and Control Lab ManualKabilanNo ratings yet

- University of Trinidad and Tobago (UTT) Department of Utilities EngineeringDocument14 pagesUniversity of Trinidad and Tobago (UTT) Department of Utilities Engineeringfaraherh amberNo ratings yet

- Cam Operated HammerDocument52 pagesCam Operated HammerSRL MECHNo ratings yet

- Assessment 1 - Questioning - Written Assessment - AURETR129Document22 pagesAssessment 1 - Questioning - Written Assessment - AURETR129Sana Siddique100% (1)

- EE 1916 FebDocument76 pagesEE 1916 FebJim Toews100% (1)