Professional Documents

Culture Documents

Steyr Marine Engines: MO256H45 I MO256K43

Uploaded by

Ayegba AchimuguOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steyr Marine Engines: MO256H45 I MO256K43

Uploaded by

Ayegba AchimuguCopyright:

Available Formats

I N N O VAT I O N W I T H L I G H T N E S S

STEYR MARINE ENGINES

I MO256H45 I MO256K43

184 KW (250 HP)

6-Cylinder

The state-of-the-art STEYR Marine Diesel Engine

with dual cooling circuit fulfilling the strengthened

future marine emission regulation.

The STEYR Marine Engine 256 is designed for high performance TRANSMISSION MO256K43

and continuous pleasure boat rating. The innovative fuel injection The STEYR Marine Engine MO256K43 was especially developed for Water

technology enables an excellent torque and speed range. Jet adaptation and surface drives.

The complete engine package is conceived especially for sterndrive

systems. Remarkable features of the STEYR Marine Engines are TECHNICAL DESCRIPTION

the dynamic behaviour and immediate response as well as the ENGINE MONOBLOCK

impressive acceleration. Our unique and robust MONOBLOCK design, engine block and cylinder

head made from high grade alloy cast iron, without limitation in cooling and

SERVICE LIFE unrivaled roundness of the cylinder gives exceptional life time for the liner.

The STEYR Marine Engines are manufactured using high alloy materials to • Chrome-Molybdenum forged crankshaft, dynamically balanced

provide enduring longevity for all running components. Using corrosion • Pistons are cast from high silicon aluminum, with oil cooling channel in

resistant materials for the entire seawater system as a standard in the dual 3-ring technology

circuit cooling system. Consequently designed solutions to meet the criteria • Hardened valve-seats high performance NIMONIC valve material

of marine environment guarantee the best corrosion protection for any • Elastic coupling on flywheel, design matched depending on application

auxiliaries and electronic components in marine ambience.

ENGINE MOUNTING

COMFORT Adjustable front and rear silent blocks capable to take propeller thrust.

The patented STEYR 2-stage UNIT INJECTOR fuel injection technology

provides for a worldwide approved and smooth operation noise. LUBRICATION SYSTEM

Noise emission levels are over the most important operating range below • Exchangeable oil filter cartridge

the running noise of gasoline engines. The additional elastic separation of • Oil scavenging through dipstick pipe

the Monoblock against the aluminum casted engine housing reduces the • Closed crankcase breathing system

engine related vibration transmitted into the hull therefore the noise level

on board is further reduced. FUEL SYSTEM

Torque and speed range characteristic enable optimal matching to individual • Integrated high pressure UNIT INJECTOR up to 2,000 bar with dual stage

application while maintaining transmission, gear ratio and propeller dimensions. fuel-injection technology, operated by overhead camshaft and rocker arms.

The big choice of matched accessories fulfills the highest level of quality and • Electric fuel pump (automatic bleeding capability)

comfort for you on board of your vessel. • Exchangeable fuel filter cartridge

EXHAUST EMISSIONS EXHAUST SYSTEM

The trend-setting UNIT INJECTOR system is most environmentally friendly. Freshwater cooled exhaust manifold and seawater cooled exhaust elbow

We can fulfill the BSO II regulations as well as the announced EPA – Tier 2

and suchlike emission regulations. COOLING SYSTEM

• Freshwater cooling system with thermostat control

TRANSMISSION MO256H45 • Heat exchanger with integrated expansion tank system

STEYR Marine Engines allow the installation with different driving system • Connection prepared for boiler/cabin heating system

in your boat. Adaptation for Marine transmission with different output • Sea water pump with impeller, integrated and replaceable wear plates

configuration (direct, horizontal down-angle 8°,V-drive 12°), to choose from

as well as an intermediate housing for propeller shaft and kits for installation

to MerCruiser Bravo I, Bravo II and Bravo III Stern-Drives.

MO256K43

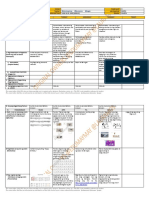

90 100 110 120 130 140 150 160 170 180 190 [kW]

[HP]

150 200 250 300 350 400 450 500 550

STEYR MARINE ENGINES

240

M

Torque [Nm]

TECHNICAL DATA

MO256H45

210

Engine type MO256H45 MO256K43

P

4-stroke, turbocharged, intercooled

180

direct-injection, fresh water cooling

Output (crankshaft) kW [HP] 184 (250), acc. ISO 8665 or ISO 3046-1

Rpm at full load 4500 4300

150

Cylinders 6 in line 6 in line

Displacement [cm3] 3200 (195 cid) 3200 (195 cid) Prop

120

Bore [mm] 85 (3.35’) 85 (3.35’)

80

Stroke [mm] 94 (3.7’) 94 (3.7’)

70

Compression ratio 17 : 1 17 : 1

90

Spec. fuel consumption [g/kWh]

60

270

Max. torque [Nm] 500 450

50

at speed [rpm] 2800 3300

60

250

40

[lb-ft] 369 335

30

Injection system two stage unit injectors

230

BE

30

20

Standard alternator [A] 90 90

Electronic engine diagnostic yes yes

10

210

Weight [kg] 322 (708.4 lbs) 322 (708.4 lbs) 500 1000 1500 2000 2500 3000 3500 4000 4500

Weight per unit of power [kg/HP] 1.29 (2.84 lbs/HP) 1.29 (2.84 lbs/HP) Engine speed [rpm]

MARINE GEAR BOX (optional)

Dimensions (not for installation) – MO256H45 for Sterndrive transmission, shaft installation

Model ZF 45, ZF 63 or similar 1028.5 (40.49’) 682 (26.9’)

Clutch system Hydraulic disc 715 (28.15’) 292.5 (11.52’) 359 (14.1’) 324 (12.7’)

Gear ratio 2.52 / 2.04 / 1.56 : 1

Output configuration direct / horizontal /

8° down-angle / V-drive 12°

527 (20.7’)

Dry weight [kg] 44 (97 lbs)

62±8 (2.4±0.3’)

778 (30.6’)

STERNDRIVE (optional) only for MO256H45

MerCruiser Bravo I, II, III

(5.8’)

252 (9.9’)

147

Propeller DuoProp (SST optional)

Gear ratio 1.65/1.81/2.0/2.2/2.43

Dry weight [kg] 113 (226 lbs) 140 266 (10.5’)

(5.51’)

572 (22.5’)

ELECTRICAL SYSTEM

• 12V system plug-in solution Dimensions (not for installation) – MO256K43 for jetdrives and surface drives

• 14V/90 A marine suitable alternator 337 (13.27’)

669 (26.34’)

332 (13.07’)

1033 (40.67’)

• 2-Pole installation (optional)

• Voltage regulator in alternator cares for optimum charging conditions

of the batteries

• Glow plugs for a trouble-free cold start

526 (20.71’)

Ø 90

• Electric starter motor (3.54’)

62±8 (2.44’±0.32’)

• Extension cable with plug-in-connection available in various lengths and

260 (10.24’)

778 (30.63’)

for fly bridge installations (optional) 15

(0.59’)

INSTRUMENT PANEL

Standard panel includes:

137 (5.39’)

252 (9.92’)

• Key switch – ignition and start function

• Control lamps for battery charging, oil pressure, glow plug indication and 140

(5.51’)

service code storage 196 (7.72’) 572 (22.52’) 31

• Revolution counter with hourmeter 265 (10.43’) 895 (35.24’) (1.22’)

• Temperature gauge for engine coolant temperature 572 (22.52’)

• Instrument illumination

• Audible alarm Water pick up, sea cock, siphon valve, cooling hose, exhaust system and transom exhaust, fuel filter

and fuel pipes, pulleys, filler cap and brackets for auxiliaries - just contact your STEYR Marine Partner

he will be delighted to serve you.

NEW (optional): The STEYR Control Center is an integrated display unit Not all models, standard equipment and accessories are available in all countries. All specifications

including the functions of digital instruments, switch board, fuel management are subject to change without notice.

The engine illustrated may not be entirely identical to production standard engines.

& driving range calculation, GPS-position, speed over ground, digital manual

and diagnostic system (optional).

Your partner

ACCESSORIES / OPTIONS

• Oil pressure gauge

• Additional key switch for governed speed

• Connecting cable for secondary helm

• Extra alternator kits

• Hot water systems

• Separate expansion tanks

• Sea water filters

• Front power take off

• Fuel pre-filter with water separator

• Chemical products – paints, oils, cleaners etc.

I N N O VAT I O N W I T H L I G H T N E S S

STEYR MOTORS GmbH

www.steyr-motors.com Im Stadtgut B1, A-4407 Steyr, AUSTRIA

E-mail: e.sales@steyr-motors.com

You might also like

- RILEM TC 205 Report on Durability of Self-Compacting ConcreteDocument9 pagesRILEM TC 205 Report on Durability of Self-Compacting ConcretealiNo ratings yet

- 41012008-Masonry Facade EvaluationDocument48 pages41012008-Masonry Facade EvaluationPeter GriemNo ratings yet

- Proceeding of Rasce 2015Document245 pagesProceeding of Rasce 2015Alex ChristopherNo ratings yet

- Report of The Joint Review Panel: Site C Clean Energy ProjectDocument471 pagesReport of The Joint Review Panel: Site C Clean Energy ProjectThe Globe and Mail100% (1)

- Eurocode 2 GUIDE (How To Design With EC2 - 2007)Document248 pagesEurocode 2 GUIDE (How To Design With EC2 - 2007)itai100% (1)

- EB001 CH19 - High-Performance ConcreteDocument29 pagesEB001 CH19 - High-Performance ConcretePtp AbyNo ratings yet

- Crack Preparation and Capping for Concrete InjectionDocument59 pagesCrack Preparation and Capping for Concrete Injectiongonzalez_m_aNo ratings yet

- EB001 CH20 - Special Types of ConcreteDocument25 pagesEB001 CH20 - Special Types of ConcreteAbdisamed AhmedNo ratings yet

- R o A D W o R K S: Problems and SolutionsDocument16 pagesR o A D W o R K S: Problems and SolutionsFITSUM BerheNo ratings yet

- Icri Terminology 2022Document112 pagesIcri Terminology 2022IELCA100% (1)

- EB001 CH6 - Aggregates For ConcreteDocument46 pagesEB001 CH6 - Aggregates For Concretebeto pagoadaNo ratings yet

- EB001 CH11 - DurabilityDocument58 pagesEB001 CH11 - DurabilityJuan MartinezNo ratings yet

- RACE 2011 ProceedingDocument680 pagesRACE 2011 Proceedingrace2590No ratings yet

- Hoeg. Kaare-1993Document85 pagesHoeg. Kaare-1993BertrandNo ratings yet

- Concrete Institute of Australia - Recomended Practice - Z12 Pumped ConcreteDocument30 pagesConcrete Institute of Australia - Recomended Practice - Z12 Pumped ConcretetimNo ratings yet

- Mtu Series 2000 MarineDocument2 pagesMtu Series 2000 Marinehelen TasiopoulouNo ratings yet

- Bokk, Fiber, Naam 1985, BasedDocument210 pagesBokk, Fiber, Naam 1985, BasedDoddy UskonoNo ratings yet

- Rockfall BarrierDocument12 pagesRockfall BarrierĐorđe RadisavljevićNo ratings yet

- Designing Facings and Contraction Joints for RCC DamsDocument11 pagesDesigning Facings and Contraction Joints for RCC DamsAnonymous KHIyWRIWma100% (1)

- Ccanz-Cp 01 2011Document130 pagesCcanz-Cp 01 2011Namdeo YengadeNo ratings yet

- ICRIDocument19 pagesICRIObaid Ul AhadNo ratings yet

- AGPT08-19 Guide To Pavement Technology Part 8 Pavement ConstructionDocument243 pagesAGPT08-19 Guide To Pavement Technology Part 8 Pavement ConstructionFábio LibórioNo ratings yet

- AUSTROADS - Bridge Manual - Part 2 - Materials - AGBT02-09 PDFDocument144 pagesAUSTROADS - Bridge Manual - Part 2 - Materials - AGBT02-09 PDFmiddlepermianNo ratings yet

- Steyr Monoblock Diesel: For Heavy Duty DemandsDocument6 pagesSteyr Monoblock Diesel: For Heavy Duty DemandsSrikanth Sridharan0% (1)

- CHALMERS (Fibre-Reinforced Concrete For Industrial Construction PDFDocument162 pagesCHALMERS (Fibre-Reinforced Concrete For Industrial Construction PDFsochiva pramestiNo ratings yet

- ConcreteWorks V2 User ManualDocument176 pagesConcreteWorks V2 User Manualramya_an2411No ratings yet

- Concrete Institute of Australia - Recomended Practice - Z39 Render FinishesDocument40 pagesConcrete Institute of Australia - Recomended Practice - Z39 Render FinishestimNo ratings yet

- Brochure - Marine Engines - STEYR MOTORS DigitalDocument11 pagesBrochure - Marine Engines - STEYR MOTORS DigitalAyegba AchimuguNo ratings yet

- EB001 CH5 - Mixing Water For ConcreteDocument26 pagesEB001 CH5 - Mixing Water For ConcreteJuan MartinezNo ratings yet

- Concrete Surface ProfilesDocument3 pagesConcrete Surface ProfilesLarry Wayne Sumpter, JrNo ratings yet

- Mtu Series 2000 IndDocument2 pagesMtu Series 2000 Indhelen TasiopoulouNo ratings yet

- Quick Installation Guide 01Document17 pagesQuick Installation Guide 01Harish SivakumarNo ratings yet

- TM 26 PDFDocument99 pagesTM 26 PDFjmusopoleNo ratings yet

- Design of RCC Gravity Dam and FEM Modelling in GeoStudioDocument125 pagesDesign of RCC Gravity Dam and FEM Modelling in GeoStudiolorenzojovanot100% (1)

- Business Portal Online Print 16-10-2019Document330 pagesBusiness Portal Online Print 16-10-2019Victor Medrado100% (1)

- ConcreteDocument132 pagesConcreteThái TrầnNo ratings yet

- Sloped Layers To Improve RCC Dam Construction - ForBESDocument5 pagesSloped Layers To Improve RCC Dam Construction - ForBESsharvan10No ratings yet

- XIII DBMC Proceedings Final DraftDocument1,166 pagesXIII DBMC Proceedings Final DraftEloy F. Viegas Jr.100% (1)

- 10.1007@978 94 024 0867 6 PDFDocument735 pages10.1007@978 94 024 0867 6 PDFutsav_koshtiNo ratings yet

- Mix Design for Durable Concrete Using Fly Ash and SlagDocument185 pagesMix Design for Durable Concrete Using Fly Ash and SlagMIL RAB100% (1)

- BRE Digest 318Document13 pagesBRE Digest 318Andre DaleyNo ratings yet

- Concrete Jul 09 BRE Digest 330 Alkali Silica Reaction in Concrete The Case For Revision Part IDocument3 pagesConcrete Jul 09 BRE Digest 330 Alkali Silica Reaction in Concrete The Case For Revision Part IHAFEEL100% (1)

- Concrete Institute of Australia - Recomended Practice - Z17 Tremie Concrete For Deep FoundationsDocument42 pagesConcrete Institute of Australia - Recomended Practice - Z17 Tremie Concrete For Deep FoundationstimNo ratings yet

- Concrete Institute of Australia - Recomended Practice - Z40 Super Workable ConcreteDocument30 pagesConcrete Institute of Australia - Recomended Practice - Z40 Super Workable Concretetim100% (2)

- Shrinkage (CEB FIP)Document4 pagesShrinkage (CEB FIP)Sabbir SiddiqueNo ratings yet

- dl2 PHP PDFDocument422 pagesdl2 PHP PDFjaiNo ratings yet

- Maintenance Methods For Concrete BridgesDocument52 pagesMaintenance Methods For Concrete Bridgesကိုနေဝင်းNo ratings yet

- Concrete Institute of Australia - Recomended Practice - Z13 Concrete in Marine EnvironmentsDocument42 pagesConcrete Institute of Australia - Recomended Practice - Z13 Concrete in Marine EnvironmentstimNo ratings yet

- Presentation-Rockfall Mitigation Measures-26.09.13 PDFDocument108 pagesPresentation-Rockfall Mitigation Measures-26.09.13 PDFAparna CkNo ratings yet

- 1065160, 1065161, 1068204, 1068205Document352 pages1065160, 1065161, 1068204, 1068205Anthony Lezcano MNo ratings yet

- Concrete Institute of Australia - Recomended Practice - Z3 Grouting of Prestressing DuctsDocument18 pagesConcrete Institute of Australia - Recomended Practice - Z3 Grouting of Prestressing DuctstimNo ratings yet

- Protecting Concrete: Solutions To Extend The Life of Your StructureDocument24 pagesProtecting Concrete: Solutions To Extend The Life of Your StructureCarlos GarcíaNo ratings yet

- Design and Control of Concrete Mixtures 16th Edition Komatka WilsonDocument633 pagesDesign and Control of Concrete Mixtures 16th Edition Komatka WilsonGeorgie Macha50% (2)

- Peças Arthur 527109845 - 858Document793 pagesPeças Arthur 527109845 - 858Herve Costa100% (1)

- Temperature Control of Mass Concrete For Dams Is 14591.1999Document17 pagesTemperature Control of Mass Concrete For Dams Is 14591.1999Phani Kanth VedulaNo ratings yet

- Significant Problems On Concrete Dams-Deterioration-selmo KupermanDocument218 pagesSignificant Problems On Concrete Dams-Deterioration-selmo KupermanMarcelo ProtzNo ratings yet

- Icri Guidelines On 11-14 Weeks Obstetric Scan July 2020Document19 pagesIcri Guidelines On 11-14 Weeks Obstetric Scan July 2020hasnainpasha100% (2)

- Liquid Retaining Reinforced Concrete Section To BS 8007& BS 8110Document1 pageLiquid Retaining Reinforced Concrete Section To BS 8007& BS 8110James LaurentNo ratings yet

- MO 4 cyl. marine engine delivers 40-125 kWDocument4 pagesMO 4 cyl. marine engine delivers 40-125 kWUmar ShamsudinNo ratings yet

- Basic EngineDocument2 pagesBasic EngineSuharto ZuhriNo ratings yet

- Study Centre App Form - GERMANY - JS-30-06-2020Document4 pagesStudy Centre App Form - GERMANY - JS-30-06-2020Ayegba AchimuguNo ratings yet

- Basic CalculusDocument292 pagesBasic Calculuslouis_kwan_10% (1)

- Respond to chargeback claims guideDocument6 pagesRespond to chargeback claims guideAyegba Achimugu100% (1)

- Qualification Process Self-Presentation GUIDE: The Complete Oil & Gas Service ProviderDocument24 pagesQualification Process Self-Presentation GUIDE: The Complete Oil & Gas Service ProviderramNo ratings yet

- Brochure - Marine Engines - STEYR MOTORS DigitalDocument11 pagesBrochure - Marine Engines - STEYR MOTORS DigitalAyegba AchimuguNo ratings yet

- Respond to chargeback claims guideDocument6 pagesRespond to chargeback claims guideAyegba Achimugu100% (1)

- Ayes DesignDocument9 pagesAyes DesignAyegba AchimuguNo ratings yet

- Cost AnalysisDocument3 pagesCost AnalysisAyegba AchimuguNo ratings yet

- Ayes DesignDocument9 pagesAyes DesignAyegba AchimuguNo ratings yet

- Oil Record Book InstructionsDocument6 pagesOil Record Book InstructionsNamal Fernando100% (1)

- 3 - 2017 - Superia X 5 StarDocument26 pages3 - 2017 - Superia X 5 Starsomnath serviceNo ratings yet

- ICICI Pru IProtect Smart Illustrated BrochureDocument56 pagesICICI Pru IProtect Smart Illustrated Brochuresoubhadra nagNo ratings yet

- Tugas UNtar 3Document28 pagesTugas UNtar 3Daniel Filemon PosoNo ratings yet

- 465 886 1 SMDocument8 pages465 886 1 SM17Annisa Muthmainnah067No ratings yet

- DC-FAST 1.000, 2.000, 3.000, 5.000, 6.000 e 7.000 - New Project - 2021 - PT - BRDocument65 pagesDC-FAST 1.000, 2.000, 3.000, 5.000, 6.000 e 7.000 - New Project - 2021 - PT - BRCentrifugal SeparatorNo ratings yet

- Ecosystem Components and InteractionsDocument31 pagesEcosystem Components and InteractionsBirraa TajuNo ratings yet

- DBXLH 8585B VTMDocument4 pagesDBXLH 8585B VTMmau_mmx5738No ratings yet

- HW5e Beg CEFR Placement Test ADocument8 pagesHW5e Beg CEFR Placement Test AGabriel LemesNo ratings yet

- CS Risk and Crisis Management FinalDocument62 pagesCS Risk and Crisis Management FinaldangermanNo ratings yet

- Passenger Ship SubdivisionDocument6 pagesPassenger Ship SubdivisionPunit Pandey100% (2)

- Structural Notes and Specifications for ConcreteDocument1 pageStructural Notes and Specifications for Concreteroger100% (2)

- SorghumDocument13 pagesSorghumMohaajanan AliNo ratings yet

- WordsDocument11 pagesWordsAref HoseyniNo ratings yet

- Opening SpeechDocument1 pageOpening SpeechTaniușa SavaNo ratings yet

- 1619928348861forensic Science UNIT - VII 1 PDFDocument159 pages1619928348861forensic Science UNIT - VII 1 PDFVyshnav RNo ratings yet

- Dapsone 2Document2 pagesDapsone 2JeanMENo ratings yet

- Fertilization to Implantation StagesDocument18 pagesFertilization to Implantation StagesNurulAqilahZulkifliNo ratings yet

- DLL - MAPEH 4 - Q4 - W8 - New@edumaymay@lauramos@angieDocument8 pagesDLL - MAPEH 4 - Q4 - W8 - New@edumaymay@lauramos@angieDonna Lyn Domdom PadriqueNo ratings yet

- Non-Digestible Oligosaccharides: A Review: Solange I. Mussatto, Ismael M. MancilhaDocument11 pagesNon-Digestible Oligosaccharides: A Review: Solange I. Mussatto, Ismael M. MancilhaPatrícia Felix ÁvilaNo ratings yet

- Constance Carroll Cosmetics) Final.1Document4 pagesConstance Carroll Cosmetics) Final.1api-26027438100% (1)

- Laporan FaalDocument25 pagesLaporan FaalAgnes NathaniaNo ratings yet

- BKTK-2010, Failure in Material ConstructionsDocument17 pagesBKTK-2010, Failure in Material ConstructionsSorulay Way-neyNo ratings yet

- Urban Heat Island effect document answersDocument4 pagesUrban Heat Island effect document answersAlainDelonTahilLanaNo ratings yet

- Technical Data Book: RAC For SEDA (INV, R410A, 60Hz, C/O)Document43 pagesTechnical Data Book: RAC For SEDA (INV, R410A, 60Hz, C/O)joserosineiassisdasilvaNo ratings yet

- Drug study on TegretolDocument2 pagesDrug study on TegretolSophia Kaye AguinaldoNo ratings yet

- Continuous Renal Replacement TherapyDocument9 pagesContinuous Renal Replacement Therapydoc_next_doorNo ratings yet

- Bab 06 PindahPanasDocument41 pagesBab 06 PindahPanasPurna Satria NugrahaNo ratings yet

- Manual de Partes Caterpillar C 27Document594 pagesManual de Partes Caterpillar C 27LuisPupiales100% (1)

- Personal LetterDocument4 pagesPersonal LetterAskme AzmyNo ratings yet

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerFrom EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerRating: 4.5 out of 5 stars4.5/5 (53)

- The RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVFrom EverandThe RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVRating: 5 out of 5 stars5/5 (2)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]From EverandCDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]Rating: 5 out of 5 stars5/5 (2)

- Why We Drive: Toward a Philosophy of the Open RoadFrom EverandWhy We Drive: Toward a Philosophy of the Open RoadRating: 4.5 out of 5 stars4.5/5 (21)

- Driving the Green Book: A Road Trip Through the Living History of Black ResistanceFrom EverandDriving the Green Book: A Road Trip Through the Living History of Black ResistanceRating: 4.5 out of 5 stars4.5/5 (6)

- OBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceFrom EverandOBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceNo ratings yet

- CDL PREP EXAM : HAZARDOUS MATERIALS Endorsement: HAZARDOUS MATERIALS EndorsementFrom EverandCDL PREP EXAM : HAZARDOUS MATERIALS Endorsement: HAZARDOUS MATERIALS EndorsementRating: 5 out of 5 stars5/5 (1)

- Turbo: Real World High-Performance Turbocharger SystemsFrom EverandTurbo: Real World High-Performance Turbocharger SystemsRating: 5 out of 5 stars5/5 (3)

- AR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualFrom EverandAR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualRating: 4.5 out of 5 stars4.5/5 (2)

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!From EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!No ratings yet

- How to Fabricate Automotive Fiberglass & Carbon Fiber PartsFrom EverandHow to Fabricate Automotive Fiberglass & Carbon Fiber PartsRating: 5 out of 5 stars5/5 (4)

- New Hemi Engines 2003 to Present: How to Build Max PerformanceFrom EverandNew Hemi Engines 2003 to Present: How to Build Max PerformanceNo ratings yet

- The Real Book on Selling Cars and Making MoneyFrom EverandThe Real Book on Selling Cars and Making MoneyRating: 5 out of 5 stars5/5 (4)

- ASE A1 Engine Repair Study Guide: Complete Review & Test Prep For The ASE A1 Engine Repair Exam: With Three Full-Length Practice Tests & AnswersFrom EverandASE A1 Engine Repair Study Guide: Complete Review & Test Prep For The ASE A1 Engine Repair Exam: With Three Full-Length Practice Tests & AnswersNo ratings yet

- The Grand Tour A-Z of the Car: Everything you wanted to know about cars and some things you probably didn’tFrom EverandThe Grand Tour A-Z of the Car: Everything you wanted to know about cars and some things you probably didn’tNo ratings yet

- How to Design, Build & Equip Your Automotive Workshop on a BudgetFrom EverandHow to Design, Build & Equip Your Automotive Workshop on a BudgetRating: 4 out of 5 stars4/5 (10)

- 700 Driving Theory Test Questions & Answers: Updated Study Guide With Over 700 Official Style Practise Questions For Cars - Based Off the Highway CodeFrom Everand700 Driving Theory Test Questions & Answers: Updated Study Guide With Over 700 Official Style Practise Questions For Cars - Based Off the Highway CodeNo ratings yet

- Why We Drive: Toward a Philosophy of the Open RoadFrom EverandWhy We Drive: Toward a Philosophy of the Open RoadRating: 4 out of 5 stars4/5 (6)

- California DMV Exam Workbook: 400+ Practice Questions to Navigate Your DMV Exam With Confidence: DMV practice tests BookFrom EverandCalifornia DMV Exam Workbook: 400+ Practice Questions to Navigate Your DMV Exam With Confidence: DMV practice tests BookNo ratings yet

- Automotive Electronic Diagnostics (Course 1)From EverandAutomotive Electronic Diagnostics (Course 1)Rating: 5 out of 5 stars5/5 (6)

![CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]](https://imgv2-2-f.scribdassets.com/img/audiobook_square_badge/710834945/198x198/00b81cbbd3/1714482720?v=1)