Professional Documents

Culture Documents

Flow Detector Maintenance PDF

Flow Detector Maintenance PDF

Uploaded by

Supriya ManojOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flow Detector Maintenance PDF

Flow Detector Maintenance PDF

Uploaded by

Supriya ManojCopyright:

Available Formats

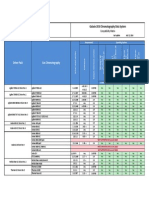

041222 Chapter 9 Maintenance Page 9 - 191

9.7.3 Goniometer Flow Detector Maintenance

The user can carry out a number of maintenance tasks on the goniometer flow detector. These include:

• Changing the detector anode wire.

• Changing the entrance window.

• Changing the exit window.

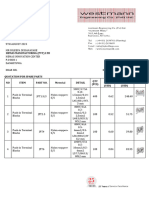

To carry out these tasks, some of the following spare parts will be required:

50µ detector wire 5322 694 15016

1µ entrance window PW2417/11 9430 024 17111

2µ entrance window PW2417/12 9430 024 17121

6µ entrance window PW2417/16 9430 024 17161

6µ exit window PW2417 9430 024 17161

Some of the detector anode wire is delivered with the system. More wire and the windows can be ordered

from your normal PANalytical representative.

9.7.3.1 Removing the Detector Assembly

To remove the detector assembly, refer to Figure 9.26:

1. Switch off the HT.

2. Set the goniometer to 90° 2θ.

3. Switch the chamber to an air medium, using the analytical software or the TDS.

4. Remove the two centre front covers.

GOTO CHAPTER LIST

Page 9 - 192 PW2400/PW2404 and PW2600/PW2606 Service Manual 041222

5. Unscrew and remove the upright chassis bar from in front of the crystal chamber.

6. Disconnect the lead to the crystal changer motor from its socket, above and to the left of the

crystal chamber.

7. Undo the 3 Allen headed screws securing the plate onto the front of the crystal chamber.

Figure 9.26 Removing the Detector Assembly

GOTO CHAPTER LIST

041222 Chapter 9 Maintenance Page 9 - 193

8. Lift the cover plate away from the chamber and lay it on the internal base plate of the

spectrometer.

CAUTION: Extreme care must be taken while working inside the crystal chamber, to

avoid damaging any of the crystals or collimators.

9. Cut and remove the ty-wrap, nearest the detector assembly, from around the hoses.

10. Undo the Allen headed screw holding the detector assembly to the detector mounting bracket.

11. Support the detector assembly and remove the long bolt holding it to the mounting bracket.

12. Carefully, withdraw the detector assembly from the crystal chamber.

13. Remove the two flow gas hoses, by loosening the spring clips and then pulling the hoses off.

The detector assembly is now clear of the crystal chamber and can be fitted to the special detector

support bracket (supplied) which can be mounted outside the chamber for service.

GOTO CHAPTER LIST

Page 9 - 194 PW2400/PW2404 and PW2600/PW2606 Service Manual 041222

Figure 9.27 Detector Assembly

9.7.3.2 Replacing the Entrance Window

This section details how to replace the flow detector entrance window.

CAUTION: Care must be taken when handling the windows as they are extremely

fragile.

GOTO CHAPTER LIST

041222 Chapter 9 Maintenance Page 9 - 195

9.7.3.2.1 Removing the Old Entrance Window

To remove the entrance window from the flow detector:

1. Loosen the 2 recessed Allen headed bolts that secure the flow detector housing to the detector

assembly.

2. Carefully, lift off the flow detector housing.

CAUTION: Extreme care must be taken when removing the housing from the detector

assembly as this exposes the, extremely fragile, detector wire.

3. Undo the 2 large Allen headed bolts that hold the entrance collimator and the housing together.

4. Lift the collimator off the housing, this now gives access to the entrance window.

5. Lift the window off the detector housing.

9.7.3.2.2 Checking the Flow Detector Collimator

If the window has mechanically broken down the collimator must be checked for the following:

1. The blades and distance pieces must be in contact with the brass mask, i.e. the blades at the

window side must be positioned equally high!

2. The blades and distance pieces must not have shifted with respect to each other and the

distance between the blades must be equal.

3. The distance pieces must not be visible in the window of the brass mask.

4. The edges of the brass mask and the collimator blades must be free of burrs.

5. The blades must be flat and parallel to the long edge of the mask.

GOTO CHAPTER LIST

Page 9 - 196 PW2400/PW2404 and PW2600/PW2606 Service Manual 041222

If any of the above faults are present, the collimator must be repaired or replaced. The collimator can

only be repaired by following the repair procedure of C.S. in Eindhoven.

9.7.3.2.3 Unpacking the New Window

1. Open the vacuum sealed aluminium bag at one end, with a pair of scissors (see Figure 9.24).

2. Remove the flow detector window in its glass sandwich and place it on a table, with the visible

brass frame facing down.

3. With a sharp knife, cut through transparent tape on one side and open the sandwich by lifting

the top glass plate away, it is hinged by the remaining tape.

4. Remove the cardboard frame, then wait a few minutes for the foil to loosen from the glass.

5. With a sharp knife loosen both ends of the brass window frame, by scraping with the sharp edge

of knife firmly over the glass.

6. Remove the flow detector window from the glass plate.

GOTO CHAPTER LIST

041222 Chapter 9 Maintenance Page 9 - 197

Figure 9.28 Opening the Detector Window Package

9.7.3.2.4 Mounting the New Window

1. Carefully remove any dust from the surface of the flow detector housing and collimator, with a

clean, dry brush.

2. Clean the collimator blades, if necessary, by blowing clean and dry compressed air ALONG the

blades.

CAUTION: Do not touch the collimator blades and do not blow the compressed air

ACROSS the blades.

3. Fit a new O-ring into the groove in the flow detector housing.

CAUTION: Do not grease the O-ring.

GOTO CHAPTER LIST

Page 9 - 198 PW2400/PW2404 and PW2600/PW2606 Service Manual 041222

4. Ensure the positioning bushes are mounted in the detector housing and place the window

gently onto the flow detector housing, with the brass frame facing the collimator (see Figure

9.29).

5. Place the collimator carefully on the window.

6. Replace the 2 large Allen headed screws that secure the collimator to the detector housing.

Figure 9.29 Flow Detector Window

GOTO CHAPTER LIST

041222 Chapter 9 Maintenance Page 9 - 199

IMPORTANT - (For <2µ windows)

Slight variations in the thickness of the windows are unavoidable during the manufacturing process. This

may lead to intensity variations, especially for the light elements where absorption of radiation in the

window is significant. The spectrometer must be re calibrated after changing the flow detector

window or anode wire.

9.7.3.3 Changing the Detector Wire

While the flow detector housing is removed from the detector assembly, the flow detector wire is

accessible. The wire can be replaced as follows:

1. Undo the 3 Allen headed screws from the end plate of the detector assembly.

2. Carefully disconnect the push-on HV connector from underneath the connection post, inside the

detector assembly (see Figure 9.30).

3. Lift off the plate complete with the wire and connection posts.

4. Using a pair of tweezers, remove the tapered pins from the top of the connection posts.

5. Remove the old wire.

CAUTION: Do not touch the part of the new wire that will be stretched between the

mounting posts. This must be clean!

6. Take a straight piece of the new detector wire.

GOTO CHAPTER LIST

Page 9 - 200 PW2400/PW2404 and PW2600/PW2606 Service Manual 041222

Figure 9.30 Flow Detector HV Connector

7. Place the new wire into the groove in the top of one connection post.

8. Replace the tapered pin to secure the wire into the post.

GOTO CHAPTER LIST

041222 Chapter 9 Maintenance Page 9 - 201

9. Pull the wire taught across the top of the second connection post.

10. Replace the second tapered pin, to secure the wire.

NOTE: The wire should be reasonably tight between the 2 connection posts.

11. Cut off the excess wire as close to each post as possible.

It is recommended that the entrance window is also changed, when the wire is replaced.

9.7.3.4 Re-assembling the Goniometer Flow Detector

When the required parts (wire and/or window) have been changed the flow detector can be

reassembled, as follows:

1. Place the wire mounting plate back onto the detector assembly (if removed).

2. Carefully, fit the flow detector housing, over the wire, onto the detector assembly.

CAUTION: Extreme care must be taken that the wire is not damaged as the housing is

replaced.

3. Tighten the 2, recessed, Allen headed screws, that secure the housing to the assembly.

4. Refit the push-on HV connector to the underneath of the wire connector post, using a pair of

tweezers (if removed).

5. Replace the detector assembly end-plate (if removed).

GOTO CHAPTER LIST

Page 9 - 202 PW2400/PW2404 and PW2600/PW2606 Service Manual 041222

9.7.3.5 Changing the 6µ Exit Window

The exit window for the flow detector provides the input to the optional sealed detector, which is mounted

in tandem to the flow detector. If this option is not fitted a metal plate is fitted in place of the window at

the rear of the flow detector.

Figure 9.31 Flow Detector Exit Window

GOTO CHAPTER LIST

041222 Chapter 9 Maintenance Page 9 - 203

To change the flow detector exit window:

1. Unpack the window.

2. Undo the screws securing the sealed detector to the detector assembly.

3. Lift the sealed detector slightly and disconnect the HV connection, between the detector and

the amplifier.

4. Remove the sealed detector (see Figure 9.27).

5. Remove the screws which hold the collimator and rear side of the flow detector in position.

6. Remove the rear side of the flow detector.

CAUTION: Be extremely careful not to damage the window support on the plate.

7. Remove the old window and the O-ring.

8. Carefully remove any dust from the surface of the flow detector housing, with a clean dry brush.

9. Ensure the positioning bushes are mounted in the detector housing.

CAUTION: DO NOT grease the new O-ring.

10. Fit the new O-ring into the groove in the flow detector housing.

11. Place the new window in position, with the copper side facing the window support plate.

12. Fix the rear side and collimator to the flow detector housing with the mounting screws.

13. Re-connect the HV to the sealed detector and fix the detector back onto the detector assembly.

GOTO CHAPTER LIST

Page 9 - 204 PW2400/PW2404 and PW2600/PW2606 Service Manual 041222

9.7.3.6 Mounting the Detector Assembly

The detector assembly can be replaced in the crystal chamber as follows:

CAUTION: Extreme care must be taken when fitting the detector assembly, into the

crystal chamber, to avoid damaging the crystals or collimators.

1. Fit the detector assembly over the locating pins on the detector mounting bracket, in the crystal

chamber.

2. Fit the Allen headed screw, that secures the assembly to the mounting bracket.

3. Replace the long bolt through the detector assembly.

4. Ensure both of the securing bolts are tight.

5. Re-clip the 2 flow gas hoses to the flow detector.

6. Secure the hoses, close to the detector assembly, with a new tie wrap.

7. Replace the plate on the front of the crystal chamber, securing it with the 3 Allen headed screws.

8. Reconnect the motor drive lead.

After replacing the detector assembly the HV and crystals must be aligned for optimum performance.

Refer to the PhleX-ray Operation manual for details of how to carry out these procedures.

9. Replace the front covers.

10. Switch the spectrometer and HT on.

11. Calibrate the goniometer, as detailed in Section 9.4.

Wait until the temperature has stabilised before carrying out measurements.

GOTO CHAPTER LIST

You might also like

- Service Handbook (UriScan Pro)Document52 pagesService Handbook (UriScan Pro)Usman AbbasNo ratings yet

- Manual Programacion Huebsch InglesDocument36 pagesManual Programacion Huebsch Ingleshengenber0% (1)

- WinLab32 InstallationDocument43 pagesWinLab32 InstallationEdgar Cobe�as VeneroNo ratings yet

- Thermo Accela 1250 - Pump - Service Training - ManualDocument90 pagesThermo Accela 1250 - Pump - Service Training - ManualOliver MüllerNo ratings yet

- Manual Genetic Pro BinoDocument19 pagesManual Genetic Pro BinoandreisandorNo ratings yet

- Clean Cut Trainning ManualDocument205 pagesClean Cut Trainning ManualPETROPATH FLUIDS INDIA PVT. LTD.No ratings yet

- ELAN Improvements Service Training RevBDocument19 pagesELAN Improvements Service Training RevBJOSE ABADNo ratings yet

- 66R EcolineDocument5 pages66R Ecolinetjianu100% (1)

- Dolphin Error CodesDocument11 pagesDolphin Error CodesVu Thieu Tuan100% (1)

- Savant PDFDocument32 pagesSavant PDFamarnath_b5986No ratings yet

- Genesis Anaesthesia Workstation enDocument8 pagesGenesis Anaesthesia Workstation enOla Gf OlamitNo ratings yet

- Verslag - Ilse-Tijman Op SmeijerspdfDocument64 pagesVerslag - Ilse-Tijman Op Smeijerspdfmaryalfandi11No ratings yet

- GC2014 MAnual Usuario PDFDocument318 pagesGC2014 MAnual Usuario PDFJHON ALEXANDER BEDOYA BUILESNo ratings yet

- S M Instruction Manual: Uper OdulyoDocument42 pagesS M Instruction Manual: Uper OdulyoJose luisNo ratings yet

- Sigma 1 14K-User ManualDocument43 pagesSigma 1 14K-User ManualAugusto VieiraNo ratings yet

- Fluorimeters Jenway Op Manual PDFDocument50 pagesFluorimeters Jenway Op Manual PDFNanjilaNo ratings yet

- WalkThrough and Handheld Metal DetectorDocument37 pagesWalkThrough and Handheld Metal DetectorEdward Camongol MañiboNo ratings yet

- ENG-Service Manual (IB-G) R0 IncubatorDocument47 pagesENG-Service Manual (IB-G) R0 Incubatorjose navaNo ratings yet

- ThermoregulationDocument64 pagesThermoregulationapi-3703371No ratings yet

- Visco Pro 2000Document63 pagesVisco Pro 2000Luz Stella Calixto GomezNo ratings yet

- BetastarDocument66 pagesBetastarSamuel MorenoNo ratings yet

- Service Manual I A Me RexDocument31 pagesService Manual I A Me Rexgabo2516100% (2)

- Gas Chromatography Driver Pack: Galaxie 2010 Chromatography Data SystemDocument3 pagesGas Chromatography Driver Pack: Galaxie 2010 Chromatography Data SystemmardonioandradeNo ratings yet

- Ultrafreezer VWR Thermoscientific 5615Document77 pagesUltrafreezer VWR Thermoscientific 5615Cesar ValenzuelaNo ratings yet

- Quick Guide For Connection of CBM-20A (Lite) and SPD-M20ADocument5 pagesQuick Guide For Connection of CBM-20A (Lite) and SPD-M20AAbdul KalimNo ratings yet

- Preventa Xps Xpsac5121Document2 pagesPreventa Xps Xpsac5121pedro torresNo ratings yet

- Savant Speedvac Concentrators: Quick and Efficient Sample PreparationDocument18 pagesSavant Speedvac Concentrators: Quick and Efficient Sample Preparationmmeneses07No ratings yet

- Manual Usuario - EscoDocument32 pagesManual Usuario - EscobioservanesNo ratings yet

- Mettler Toledo CablesDocument4 pagesMettler Toledo CablesRamesh KumarNo ratings yet

- DGU-403 DGU-405: Instruction ManualDocument30 pagesDGU-403 DGU-405: Instruction ManualCrystal LinNo ratings yet

- Agilent U1241A ManualDocument85 pagesAgilent U1241A ManualBobDNo ratings yet

- Whirlpool Awo D 41100Document29 pagesWhirlpool Awo D 41100Teodora OnciuNo ratings yet

- MS-70 MX-50 MF-50 ML-50: 1WMPD4000477FDocument86 pagesMS-70 MX-50 MF-50 ML-50: 1WMPD4000477FWage KarsanaNo ratings yet

- ABI - 7900HT SDS User GuideDocument384 pagesABI - 7900HT SDS User Guidesalman672003No ratings yet

- EM6 Installation ManualDocument37 pagesEM6 Installation ManualFrank Almenares Urzola0% (1)

- Challenger Lc2201sb Lc26sb Lc2601sb SMDocument40 pagesChallenger Lc2201sb Lc26sb Lc2601sb SMAntonioCésarUtreraNo ratings yet

- Leica EG1150 H Technical Data enDocument1 pageLeica EG1150 H Technical Data enrazaNo ratings yet

- Jenway 6310 Service ManualDocument84 pagesJenway 6310 Service ManualJorge OliveiraNo ratings yet

- Plazmax SpecDocument9 pagesPlazmax SpecmannspaarthNo ratings yet

- SK 0330 ProDocument2 pagesSK 0330 ProAnonymous l1fc6gNo ratings yet

- Lm700 Service ManualDocument86 pagesLm700 Service ManualDaniel GómezNo ratings yet

- User Manual 06/2013 Edition 2: © HACH Company, 2012, 2013. All Rights Reserved. Printed in GermanyDocument156 pagesUser Manual 06/2013 Edition 2: © HACH Company, 2012, 2013. All Rights Reserved. Printed in GermanyFlorin Neacsu100% (1)

- Service Manual - Heraeus - Cryofuge 6000i, 8500iDocument145 pagesService Manual - Heraeus - Cryofuge 6000i, 8500iHishamudin RaisNo ratings yet

- User Manual: Cypcut Laser Cutting Control SystemDocument51 pagesUser Manual: Cypcut Laser Cutting Control SystemПетя КартоевNo ratings yet

- Ref Centrifuge CL 21R PDFDocument83 pagesRef Centrifuge CL 21R PDFAshari EndraNo ratings yet

- WNK81mA Basınç TransmitterDocument5 pagesWNK81mA Basınç TransmitterErdi ErsoyNo ratings yet

- Instruction Manual For L-8900 High Speed Amino Acid Analyzer (Ezchrom Elite For Hitachi Aaa Operation)Document174 pagesInstruction Manual For L-8900 High Speed Amino Acid Analyzer (Ezchrom Elite For Hitachi Aaa Operation)Ajagwu EustaceNo ratings yet

- Milli-Q IQ 7003 - 05 - 10 - 15 - MK - BR2157EN - Merck - Web PDFDocument24 pagesMilli-Q IQ 7003 - 05 - 10 - 15 - MK - BR2157EN - Merck - Web PDFMiranti PuspitasariNo ratings yet

- BooksDocument44 pagesBooksSham-aan AliNo ratings yet

- LG RD - jt91 DLP ProjectorDocument34 pagesLG RD - jt91 DLP ProjectorMalay K GhoshNo ratings yet

- Elix Essential Manual Millipore - Water-PurificationDocument54 pagesElix Essential Manual Millipore - Water-PurificationDino Sk100% (1)

- Empyrean UG ED5 ENDocument145 pagesEmpyrean UG ED5 ENLiudmilaNo ratings yet

- LG Hecto Service ManualDocument98 pagesLG Hecto Service ManualKSnakeWNo ratings yet

- Leica Zoom 2000Document6 pagesLeica Zoom 2000HaienasrNo ratings yet

- URiSCAN Optima - Operating Manual - ENGrev10Document28 pagesURiSCAN Optima - Operating Manual - ENGrev10Jony MaiaNo ratings yet

- User Manual Iec Micro Cl17 Cl17r Cl21 Cl21rDocument83 pagesUser Manual Iec Micro Cl17 Cl17r Cl21 Cl21rFredy Fernando Huarhua Garcia0% (1)

- PE 560 Atomic Absorption Spectrophotometer ManualDocument176 pagesPE 560 Atomic Absorption Spectrophotometer ManualDavid Allan100% (1)

- Option Box Service Manual Assembling Procedure: Shimadzu Corporation Analytical & Measuring Instrument DivisionDocument48 pagesOption Box Service Manual Assembling Procedure: Shimadzu Corporation Analytical & Measuring Instrument DivisionDanCosminNo ratings yet

- Medical Electronic Laboratory Equipment 1967-68: Pergamon Electronics Data SeriesFrom EverandMedical Electronic Laboratory Equipment 1967-68: Pergamon Electronics Data SeriesNo ratings yet

- ZF 2Document49 pagesZF 2Silvio Roman100% (2)

- 20-2023 Modalities Regarding Submission of Joint Option For Higher Pension W.R.T. EPS'95Document14 pages20-2023 Modalities Regarding Submission of Joint Option For Higher Pension W.R.T. EPS'95Supriya ManojNo ratings yet

- IS17417-Part2-2020-ISO 4965-2Document14 pagesIS17417-Part2-2020-ISO 4965-2Supriya ManojNo ratings yet

- Cloete Huibrecht WtmsDocument367 pagesCloete Huibrecht WtmsSupriya ManojNo ratings yet

- CTC Guidelines PDFDocument7 pagesCTC Guidelines PDFSupriya ManojNo ratings yet

- Aiffi: OrffiDocument1 pageAiffi: OrffiSupriya ManojNo ratings yet

- RepeatabilityDocument6 pagesRepeatabilitySupriya ManojNo ratings yet

- Frftts A: or (FfiDocument1 pageFrftts A: or (FfiSupriya ManojNo ratings yet

- 663 2020 PDFDocument1 page663 2020 PDFSupriya ManojNo ratings yet

- Crffi: FtfresDocument1 pageCrffi: FtfresSupriya ManojNo ratings yet

- Sample Omr Sheet For Practice: 1. L-SAT Roll No. 3. Test Venue (School Name) 2. Test Code 8. Mobile NumberDocument1 pageSample Omr Sheet For Practice: 1. L-SAT Roll No. 3. Test Venue (School Name) 2. Test Code 8. Mobile NumberSupriya ManojNo ratings yet

- Retire 2021Document5 pagesRetire 2021Supriya ManojNo ratings yet

- 11th Exempler FullDocument305 pages11th Exempler FulljamsmithNo ratings yet

- Nested Gage R&R Study of A Measurement System Using Destructive TestingDocument5 pagesNested Gage R&R Study of A Measurement System Using Destructive TestingSupriya ManojNo ratings yet

- Universal Testing Machine Median - Up To 600 KNDocument32 pagesUniversal Testing Machine Median - Up To 600 KNSupriya ManojNo ratings yet

- Is Your Spectrometer in Calibration?: Quality MattersDocument2 pagesIs Your Spectrometer in Calibration?: Quality MattersSupriya ManojNo ratings yet

- Molecular Drag Pumps: MDP SeriesDocument12 pagesMolecular Drag Pumps: MDP SeriesSupriya ManojNo ratings yet

- User's ManualDocument42 pagesUser's ManualSupriya ManojNo ratings yet

- First Level of Maintenance: Lubrication SyringeDocument1 pageFirst Level of Maintenance: Lubrication SyringeSupriya ManojNo ratings yet

- MDP 11Document1 pageMDP 11Supriya ManojNo ratings yet

- Irg 4 PH 40 UDocument9 pagesIrg 4 PH 40 USupriya ManojNo ratings yet

- Plus ManualDocument155 pagesPlus ManualSupriya ManojNo ratings yet

- Oil Conservation SaurabhiDocument4 pagesOil Conservation SaurabhiSupriya ManojNo ratings yet

- 2nd Term Syllabus For Class IX 2009-10Document7 pages2nd Term Syllabus For Class IX 2009-10AV ManojNo ratings yet

- Cebex 031Document4 pagesCebex 031Moatz HamedNo ratings yet

- Pattern Making PDFDocument7 pagesPattern Making PDFThulasi Ram75% (4)

- Dolby Vision Xbox Compatible-TVs Mar30Document3 pagesDolby Vision Xbox Compatible-TVs Mar30Luis Miguel Casabona SevillanoNo ratings yet

- TLC 081Document35 pagesTLC 081Félix PérezNo ratings yet

- Grade 9 Chemistry PT 2 Paper 2Document7 pagesGrade 9 Chemistry PT 2 Paper 2Naisha ParekhNo ratings yet

- MEGA AIR - Piston Compressor - EN - 950313 - SmallDocument8 pagesMEGA AIR - Piston Compressor - EN - 950313 - SmallAminSaadaouiNo ratings yet

- Fluid LBDocument10 pagesFluid LBPilyang BampiraNo ratings yet

- A23-28 656seriesDocument6 pagesA23-28 656serieskevinmathew27No ratings yet

- B - Draft EPC Agreement PDFDocument112 pagesB - Draft EPC Agreement PDFParamitaDanaNo ratings yet

- Impak HV Ind MotorDocument30 pagesImpak HV Ind MotorhashimNo ratings yet

- PCA Technical and Advice Note Handling of Bridge Beams at SiteDocument6 pagesPCA Technical and Advice Note Handling of Bridge Beams at SiteDukeNo ratings yet

- Qcs 2010 Part 10.01 GeneralDocument13 pagesQcs 2010 Part 10.01 GeneralRotsapNayrbNo ratings yet

- CV-X Series Version 4 Power Meets Simplicity PDFDocument41 pagesCV-X Series Version 4 Power Meets Simplicity PDFsgjqetNo ratings yet

- Installation Manual APS596C - IMDocument16 pagesInstallation Manual APS596C - IMMauro SteffenNo ratings yet

- ComlinDocument13 pagesComlinSammar AdhikariNo ratings yet

- C 274 - 99 Qzi3naDocument2 pagesC 274 - 99 Qzi3namohammad1361No ratings yet

- Module M-07: EquipmentDocument1 pageModule M-07: EquipmentRobles DreschNo ratings yet

- Lifting Plan For Erection of 2nd To 6th r.1Document10 pagesLifting Plan For Erection of 2nd To 6th r.1Rhannie GarciaNo ratings yet

- Ceramics: Ceramic Tile Adhesives From The Producer's Perspective: A Literature ReviewDocument13 pagesCeramics: Ceramic Tile Adhesives From The Producer's Perspective: A Literature ReviewEray GÜRNo ratings yet

- CIPLDocument8 pagesCIPLbountymaniNo ratings yet

- 6.CVP - E Day5Document54 pages6.CVP - E Day5João Paulo CostaNo ratings yet

- PSD 09 2018 30RB RQ 017-040 30rby 017 033Document26 pagesPSD 09 2018 30RB RQ 017-040 30rby 017 033Constantin294No ratings yet

- Portable Fluid Analysis Kit ManualDocument32 pagesPortable Fluid Analysis Kit ManualGabriel DittamoNo ratings yet

- Advantages of Using Filler Slab RoofDocument4 pagesAdvantages of Using Filler Slab Roofanjana susan johnNo ratings yet

- 01 - Basic Electrical CalculationsDocument17 pages01 - Basic Electrical Calculationsayah_ainaNo ratings yet

- A.M. No. 01-7-01-SCDocument10 pagesA.M. No. 01-7-01-SCKristal LeeNo ratings yet

- HydrocarbonDocument6 pagesHydrocarbonzahraNo ratings yet

- Westman USDDocument5 pagesWestman USDYasindu DamithNo ratings yet

- Computer Animation: Course OrientationDocument10 pagesComputer Animation: Course Orientationayhel geronaNo ratings yet