Professional Documents

Culture Documents

CGO 001 Before Operations

Uploaded by

Abu Syeed Md. Aurangzeb Al MasumCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CGO 001 Before Operations

Uploaded by

Abu Syeed Md. Aurangzeb Al MasumCopyright:

Available Formats

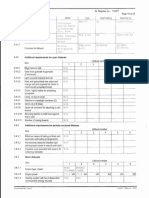

CGO 001

PRIOR CARGO OPERATIONS CHECKLIST ISSUED DATE : 01.08.18

ISSUE No: 01

Page 1 of 2

VESSEL: MT. ELISE DATE:

PORT: PORT LOUIS OPERATION: LOADING / DISCHARGING

Initial Preparation

1. Ensure crew is aware of both intention to cargo and emergency response

procedures.

2. Discuss operation plan & tank sequence with officers involved.

3. Close and secure all associated overboard discharge valves.

4. Close and blank off all unnecessary manifold valves/connections.

5. Plug all deck scuppers and make watertight.

6. Empty out and plug save-alls.

7. Place oil absorbent materials in key positions.

8. Provide means of draining off any accumulations of water on deck.

9. Establish communication link between cargo station, duty officer & E/R

10. Check all cargo tank air pipes are open and unblocked.

11. Ensure all sounding pipe caps are tight except when sounding tank

12. Reconfirm space remaining in all cargo tanks to be filled.

13. Check all cargo tank high level alarms are functioning.

14. Ensure all fire precautions are observed.

Prior to Operation

1. Check hose is of sufficient length.

2. Inspect hose and couplings for damage.

3. Check weight of hose does not exceed SWL of vessel's lifting gear.

4. Place drip trays under hose couplings & flanges.

5. Check delivery note quantity and specification are correct.

6. Discuss operation plan with supplier.

7. Discuss vessel's emergency response procedures with supplier.

8. Discuss suppliers own emergency response procedures.

9. Establish communication link between vessel and supplier.

10. Agree signaling system with supplier for:

Commence Pumping.

Reduce Pumping Rate.

Stop Pumping.

Emergency stop.

11. Agree with the supplier the quantity to be pumped aboard.

12. Agree unit of measurement (Metric Tons, Cubic Meters etc.).

13. Agree maximum pumping rate and pressure.

14. Agree and record shore barge meter readings and/or soundings.

15. Appoint seaman to tend mooring lines during operation.

16. Rig fire lines fore and aft of operation station.

17. Ensure designated overflow tank is prepared.

18. Fit vessel's sampling equipment & explain it to supplier.

19. Prepare filling lines and open all relevant valves.

DATE/TIME VESSEL ALONGSIDE

DATE/TIME GAUGING COMPLETED ____________

CGO 001

PRIOR CARGO OPERATIONS CHECKLIST ISSUED DATE : 01.08.18

ISSUE No: 01

Page 2 of 2

DATE/TIME LOADING /DISHCARGING STARTED ______

NAME OF ACTUAL SUPPLIER/RECIEVER

NAME OF TERMINAL SUPPLYING/RECIEVEING CARGO ______________________________

HOW MANY MDO SAMPLES TAKEN ______________________________

SAMPLES IDENTIFICATION

ENTER SAMPLE RETAINED BY RETAINED BY RETAINED BY RETAINED BY RETAINED BY

IDENTIFICATIO SHIP SUPPLIER OWNER'S CHARTERER'S OTHER

N NUMBERS SURVEYOR SURVEYOR SURVEYOR

DUTY OFFICER CHIEF OFFICER

You might also like

- Safe Bunkering PracticesDocument2 pagesSafe Bunkering Practiceskabirsharma76No ratings yet

- Pc23 06 MPA Singapore Bunkering Checklist 2023-03-22Document7 pagesPc23 06 MPA Singapore Bunkering Checklist 2023-03-22kyaw zin tun TunNo ratings yet

- Ships Bunkering Operation - Planning, Preparation, Safety Checks & ConfirmationDocument15 pagesShips Bunkering Operation - Planning, Preparation, Safety Checks & ConfirmationTammam HassanNo ratings yet

- Hanafi Assasment VDocument6 pagesHanafi Assasment VGhaniyatul Ulum JemberNo ratings yet

- Chemical Section 8 - Preparation For Discharge and Discharge Operations1Document10 pagesChemical Section 8 - Preparation For Discharge and Discharge Operations1ZIAUL KARIMNo ratings yet

- BUNKERINGDocument4 pagesBUNKERINGMeghali Borle100% (1)

- Ship Shore Safety Checklist Part ADocument5 pagesShip Shore Safety Checklist Part AAZWAR SIDINo ratings yet

- Mehr OtraDocument13 pagesMehr OtraThomas JoseNo ratings yet

- Performance of Engine Room Watch Keeping DutiesDocument17 pagesPerformance of Engine Room Watch Keeping DutiesMike Bunoan Dumangeng83% (6)

- Checklist - NEW ORLEANSDocument2 pagesChecklist - NEW ORLEANSjoreyvilNo ratings yet

- LESSON 7 Bunkering OperationsDocument12 pagesLESSON 7 Bunkering OperationsPotin LerotiboNo ratings yet

- Operations & Precautions For The BunkeringDocument3 pagesOperations & Precautions For The BunkeringVlad EnacheNo ratings yet

- Cargo Handling PDFDocument26 pagesCargo Handling PDFRivano Tetrapoik100% (1)

- PRO-03-06 Pigging OperationsDocument7 pagesPRO-03-06 Pigging OperationsNikhil DangariyaNo ratings yet

- Discharging Operations 3Document14 pagesDischarging Operations 3Subir BairagiNo ratings yet

- Survey Report East of EnglandDocument55 pagesSurvey Report East of EnglandThan Htet100% (1)

- Tanker ChecklistDocument3 pagesTanker ChecklistRoshan PandeyNo ratings yet

- Cargo Operations Manual - Tankers TemplateDocument61 pagesCargo Operations Manual - Tankers TemplateMai Pham100% (1)

- 2.10-Watch On Bunkering +transfer OperationsDocument3 pages2.10-Watch On Bunkering +transfer OperationsKush UpadhyayNo ratings yet

- Bunkering Checklist - Attachment XXVIDocument3 pagesBunkering Checklist - Attachment XXVIFaiqah AzmirNo ratings yet

- 10 Important Points To Remember After Completing Cargo Operations On TankersDocument5 pages10 Important Points To Remember After Completing Cargo Operations On TankerscassandraNo ratings yet

- Cargo OpsDocument61 pagesCargo OpsTabu La Rasa100% (3)

- Purging Instruction PDFDocument11 pagesPurging Instruction PDFramanmangat5777No ratings yet

- Instruction For Bunkering Fuel Oil & Lube OilDocument3 pagesInstruction For Bunkering Fuel Oil & Lube Oilconst fwvnNo ratings yet

- Fast Rescue Boat PROCEDURESDocument34 pagesFast Rescue Boat PROCEDURESDERELL DEL ROSARIONo ratings yet

- 10 Important Points To Remember After Completing Cargo Operations On TankersDocument4 pages10 Important Points To Remember After Completing Cargo Operations On Tankersindumarnicaragua100% (3)

- Check List For SOBM Take On BoardDocument5 pagesCheck List For SOBM Take On BoardVimal SinghNo ratings yet

- Bunker-Checklist 0618Document8 pagesBunker-Checklist 0618Putra SeptiadyNo ratings yet

- Bunker Note of Protest PDFDocument1 pageBunker Note of Protest PDFMichael Epshtein100% (1)

- Cargo Loss Control Non Grain - Weight by Draft SurveyDocument3 pagesCargo Loss Control Non Grain - Weight by Draft Surveylademeister.rudov100% (1)

- Liquid Cargo Load PlanDocument13 pagesLiquid Cargo Load PlanNaresh Sharma100% (3)

- Bunker Supervision ProceduresDocument12 pagesBunker Supervision Proceduresweselyi26No ratings yet

- Bunkering Checklist 08ADocument1 pageBunkering Checklist 08Ayvonne22No ratings yet

- Damage To Bulk Cargo (Edited)Document4 pagesDamage To Bulk Cargo (Edited)Asif Siddiqui100% (2)

- Bunkering Operation Training - Cercs-2Document25 pagesBunkering Operation Training - Cercs-2Julia AbalosNo ratings yet

- Cargo Op Checklist FormsDocument8 pagesCargo Op Checklist FormsMeraz AhmedNo ratings yet

- HSAC Transporter Tote Transfer ChecklistDocument1 pageHSAC Transporter Tote Transfer ChecklistPat BNo ratings yet

- PRO-03-31 FOR LINE BLOCKAGE NewDocument7 pagesPRO-03-31 FOR LINE BLOCKAGE NewNikhil DangariyaNo ratings yet

- COO 07 Loading ProcedureDocument14 pagesCOO 07 Loading Procedureimgesu tahtaNo ratings yet

- Bunkering OperationDocument10 pagesBunkering OperationMahatirNo ratings yet

- E23a ISGOTT Bunker ChklistDocument4 pagesE23a ISGOTT Bunker Chklistvic.barca2012100% (1)

- Alam Maritim (M) SDN BHD: Appendix 3.1 - Fuel Oil Bunker ChecklistDocument3 pagesAlam Maritim (M) SDN BHD: Appendix 3.1 - Fuel Oil Bunker ChecklistJeet SinghNo ratings yet

- S-18 - Bunkering ChecklistDocument3 pagesS-18 - Bunkering Checklistmaxuya2001No ratings yet

- Bunkering ProceduresDocument6 pagesBunkering ProceduresCRHFNo ratings yet

- 8 Points Tanker Ship Chief Officer Must Consider While Dealing With Port Terminal RepresentativesDocument6 pages8 Points Tanker Ship Chief Officer Must Consider While Dealing With Port Terminal RepresentativescassandraNo ratings yet

- Last CargoDocument31 pagesLast Cargoashwin devaliyaNo ratings yet

- Dry DockDocument80 pagesDry DockSwopon MollahNo ratings yet

- Scupper PlugDocument21 pagesScupper PlugMcrislb100% (3)

- RONDocument7 pagesRONRonnel Ganuelas100% (1)

- Pre-Bunkering Safety Checklist - V.13-10-14Document1 pagePre-Bunkering Safety Checklist - V.13-10-14Ramson RaymondNo ratings yet

- AramcoDocument18 pagesAramcoeriyantooNo ratings yet

- Form M 060B Safety Check List Prior To RefloatingDocument1 pageForm M 060B Safety Check List Prior To Refloatingigor1968kiselevNo ratings yet

- FUNCTION 3 Anang FINISHDocument58 pagesFUNCTION 3 Anang FINISHAdiiNo ratings yet

- SBO 11 Set QuestionsDocument11 pagesSBO 11 Set QuestionsMamunNo ratings yet

- Petronas Assessment Q&ADocument7 pagesPetronas Assessment Q&AEncik AnatNo ratings yet

- B - 9.11.2. Bulk Transfer Operations in PortDocument2 pagesB - 9.11.2. Bulk Transfer Operations in PortCesar Augusto Arias CastroNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Marine and Offshore Pumping and Piping SystemsFrom EverandMarine and Offshore Pumping and Piping SystemsRating: 4.5 out of 5 stars4.5/5 (2)

- The Pontoon and Deckboat Handbook: How to Buy, Maintain, Operate, and Enjoy the Ultimate Family BoatsFrom EverandThe Pontoon and Deckboat Handbook: How to Buy, Maintain, Operate, and Enjoy the Ultimate Family BoatsRating: 5 out of 5 stars5/5 (1)

- 0.situation RorDocument50 pages0.situation RorAbu Syeed Md. Aurangzeb Al Masum100% (2)

- Ry Explorer: Cha:io T"dater LDocument1 pageRy Explorer: Cha:io T"dater LAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- 1 - Class-1 Computer TestDocument19 pages1 - Class-1 Computer TestShoaib0% (1)

- 0perational Use of Ecdis Question SetDocument17 pages0perational Use of Ecdis Question SetAbu Syeed Md. Aurangzeb Al Masum100% (2)

- 0perational Use of Ecdis Question SetDocument17 pages0perational Use of Ecdis Question SetAbu Syeed Md. Aurangzeb Al Masum100% (2)

- FundamentalDocument1 pageFundamentalAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Exam RoutinDocument15 pagesExam RoutinAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Mathematics: Class - 3Document5 pagesMathematics: Class - 3Abu Syeed Md. Aurangzeb Al MasumNo ratings yet

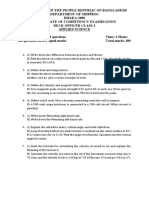

- Physics Question Set - 082544Document8 pagesPhysics Question Set - 082544Abu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Coastal NavigationDocument16 pagesCoastal NavigationAbu Syeed Md. Aurangzeb Al Masum100% (1)

- General Ship KnowledgeDocument11 pagesGeneral Ship KnowledgeAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Safety Drill Evaluvation Report: CommentsDocument2 pagesSafety Drill Evaluvation Report: CommentsAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Class-3 Meteorology: Topic: The Atmosphere, Its Composition and Physical PropertiesDocument3 pagesClass-3 Meteorology: Topic: The Atmosphere, Its Composition and Physical PropertiesAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Applied PhysicsDocument6 pagesApplied PhysicsAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Extracted Pages From Book 4-Subra Ship Stability at The Operational Level (2nd Edition Mar 2016)Document1 pageExtracted Pages From Book 4-Subra Ship Stability at The Operational Level (2nd Edition Mar 2016)Abu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Bashundhara Oil and Gas Company Limited: Defect ListDocument1 pageBashundhara Oil and Gas Company Limited: Defect ListAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Function 2 - Cargo Handling and Stowage by Sagar Samrat DasDocument84 pagesFunction 2 - Cargo Handling and Stowage by Sagar Samrat DasGurjit Singh100% (1)

- Meenhar Sea Foods Limited: Sea Service Testimonial Watch Keeping ServiceDocument1 pageMeenhar Sea Foods Limited: Sea Service Testimonial Watch Keeping ServiceAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Fast Maridian SDN BHD: Service TestimonialDocument1 pageFast Maridian SDN BHD: Service TestimonialAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- AIS Over WiFi With The DT-06 ModuleDocument2 pagesAIS Over WiFi With The DT-06 ModuleAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Extracted Pages From Book 4-Subra Ship Stability at The Operational Level (2nd Edition Mar 2016) LastDocument1 pageExtracted Pages From Book 4-Subra Ship Stability at The Operational Level (2nd Edition Mar 2016) LastAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Loading RecordDocument6 pagesLoading RecordAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Draft Survey Report: - 98.100 MT Total CargoDocument10 pagesDraft Survey Report: - 98.100 MT Total CargoAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Feed Back NewDocument1 pageFeed Back NewAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- ABC Tables (Refined)Document59 pagesABC Tables (Refined)Abu Syeed Md. Aurangzeb Al Masum100% (1)

- Safety Drill Evaluvation Report: CommentsDocument2 pagesSafety Drill Evaluvation Report: CommentsAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Fire Drill DECK CARGO FIRE 18Document2 pagesFire Drill DECK CARGO FIRE 18Abu Syeed Md. Aurangzeb Al MasumNo ratings yet

- E-Mail Addresses ListDocument1 pageE-Mail Addresses ListAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- ABAÖNDON SHIP & Lower RESCUE BOATDocument2 pagesABAÖNDON SHIP & Lower RESCUE BOATAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Safety Drill Evaluvation Report: CommentsDocument2 pagesSafety Drill Evaluvation Report: CommentsAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Instant Download Ebersole and Hess Gerontological Nursing and Healthy Aging Canadian 2nd Edition Touhy Test Bank PDF Full ChapterDocument33 pagesInstant Download Ebersole and Hess Gerontological Nursing and Healthy Aging Canadian 2nd Edition Touhy Test Bank PDF Full Chapteroutcomegoavesqhqj6l100% (7)

- TOS HA LONG PIPE LAY Spec (Updated 30 12 19)Document3 pagesTOS HA LONG PIPE LAY Spec (Updated 30 12 19)Mr. DNo ratings yet

- Fy2023 Pb23 Shipbuilding Plan 18 Apr 2022 FinalDocument28 pagesFy2023 Pb23 Shipbuilding Plan 18 Apr 2022 FinalCDR SalamanderNo ratings yet

- Ever Given Was Human Error But It Won't Happen Again, Says Suez Canal Chair - Lloyd's ListDocument4 pagesEver Given Was Human Error But It Won't Happen Again, Says Suez Canal Chair - Lloyd's ListrkNo ratings yet

- All ROR CardsDocument66 pagesAll ROR CardsMahesh YadavNo ratings yet

- Nav 04 - Pilot CardDocument4 pagesNav 04 - Pilot Cardnikita danilovNo ratings yet

- Curriculum Vitae (3e)Document2 pagesCurriculum Vitae (3e)Alpebtra AndanaNo ratings yet

- NSCV C6a July2018Document112 pagesNSCV C6a July2018taddeoNo ratings yet

- Assignment 5 Review Unit 10 SafetyDocument3 pagesAssignment 5 Review Unit 10 SafetyChuncho xDNo ratings yet

- Lea Mer Industries, Inc. vs. Malayan Insurance Co IncDocument5 pagesLea Mer Industries, Inc. vs. Malayan Insurance Co IncVincent Rey BernardoNo ratings yet

- 2020 Leaflet-LDADocument4 pages2020 Leaflet-LDADavid PapelonNo ratings yet

- MOHIT MISHRA RESUME - CompressedDocument1 pageMOHIT MISHRA RESUME - CompressedMohit MishraNo ratings yet

- Damage Control SystemDocument4 pagesDamage Control SystemEmiljay ValenciaNo ratings yet

- Full Download Successful Project Management 7th Edition Gido Solutions ManualDocument35 pagesFull Download Successful Project Management 7th Edition Gido Solutions Manualaydlettivelisse97% (36)

- Intact Stability CodeDocument109 pagesIntact Stability CodeEmil John100% (1)

- How To Build A Wood SailboatDocument25 pagesHow To Build A Wood SailboatJoão JoséNo ratings yet

- Ind Hub FinalDocument88 pagesInd Hub Final1mmahoney0% (1)

- Mogok Star ExcelDocument2 pagesMogok Star ExcelAhmed Hossam0% (1)

- What Is International Grain CodeDocument3 pagesWhat Is International Grain CodeJames JarabeloNo ratings yet

- Full Download Test Bank For Media Society Technology Industries Content and Users 6th Edition by David Croteau William Hoynes PDF Full ChapterDocument33 pagesFull Download Test Bank For Media Society Technology Industries Content and Users 6th Edition by David Croteau William Hoynes PDF Full Chaptercapsizeastate.t2wpm100% (23)

- Ahmet Cihan Q88Document7 pagesAhmet Cihan Q88esamNo ratings yet

- R96 Terminal Information Book 020117 PDFDocument18 pagesR96 Terminal Information Book 020117 PDFAgung NugrahaNo ratings yet

- Model Course On Navigation in Polar WatersDocument72 pagesModel Course On Navigation in Polar WatersGeorgeVasiliu100% (1)

- Pocket Plan Mistral 2016 0Document2 pagesPocket Plan Mistral 2016 0Khalid AnahirNo ratings yet

- Fixturenote General CargoDocument6 pagesFixturenote General CargoTrần Phan Mai PhươngNo ratings yet

- Sailing: Sailing On The River ThamesDocument2 pagesSailing: Sailing On The River ThamesNatia SaginashviliNo ratings yet

- Ship Stability 5Document31 pagesShip Stability 5jeaneva guiaoNo ratings yet

- Deu Case Study Koniambo-Nickel-Mine-Project Rev06 WebDocument6 pagesDeu Case Study Koniambo-Nickel-Mine-Project Rev06 Webegy pureNo ratings yet

- Reviewer MathDocument6 pagesReviewer MathLuna Ronquillo100% (1)

- Seam 5 Activity 17Document9 pagesSeam 5 Activity 17Haeisy SimsuangcoNo ratings yet