Professional Documents

Culture Documents

Synchronous-Rectified Buck MOSFET Drivers: General Description Features

Uploaded by

Daniel Norberto DemariaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Synchronous-Rectified Buck MOSFET Drivers: General Description Features

Uploaded by

Daniel Norberto DemariaCopyright:

Available Formats

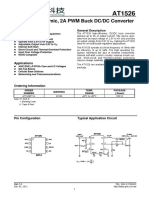

RT9619/A

Synchronous-Rectified Buck MOSFET Drivers

General Description Features

The RT9619/A is a high frequency, dual MOSFET driver Drives Two N-Channel MOSFETs

specifically designed to drive two power N-Channel Adaptive Shoot-Through Protection

MOSFETs in a synchronous-rectified buck converter Embedded Boot Strapped Diode

topology. This driver combined with Richtek's series of Supports High Switching Frequency

Multi-Phase Buck PWM controller form a complete core- Fast Output Rise Time

voltage regulator solution for advanced micro-processors. Small SOP-8 Package

Tri-State Input for Bridge Shutdown

The RT9619/A drives both the lower/upper gate in a

Supply Under Voltage Protection

synchronous-rectifier bridge with 12V. This drive-voltage

RoHS Compliant and 100% Lead (Pb)-Free

flexibility provides the advantage of optimizing applications

involving trade-offs between switching losses and

Applications

conduction losses.

Core Voltage Supplies for Desktop, Motherboard CPU

RT9619A has longer UGATE/LGATE deadtime which can High Frequency Low Profile DC-DC Converters

drive the MOSFETs with large gate RC value, avoiding the High Current Low Voltage DC-DC Converters

shoot-through phenomenon. RT9619 is targeted to drive

low gate RC MOSFETs and performs better efficiency.

Ordering Information

The output drivers in the RT9619/A can efficiently switch RT9619/A

power MOSFETs at frequency up to 500kHz. Switching

Package Type

frequency above 500kHz has to take into account the S : SOP-8

thermal dissipation of SOP-8 package. RT9619/A is Operating Temperature Range

capable to drive a 3nF load with a 30ns rise time. P : Pb Free with Commercial Standard

G : Green (Halogen Free with Commer-

RT9619/A implements bootstrapping on the upper gate with cial Standard)

an external capacitor and an embedded diode. This reduces

Long Dead Time

implementation complexity and allows the use of higher Short Dead Time

performance, cost effective N-Channel MOSFETs. Adaptive

shoot-through protection is integrated to prevent both Note :

MOSFETs from conducting simultaneously. Richtek Pb-free and Green products are :

RoHS compliant and compatible with the current require-

Pin Configurations ments of IPC/JEDEC J-STD-020.

Suitable for use in SnPb or Pb-free soldering processes.

(TOP VIEW)

BOOT 8 UGATE

PWM 2 7 PHASE

NC 3 6 PGND

VCC 4 5 LGATE

SOP-8

DS9619/A-05 February 2009 www.richtek.com

1

2

www.richtek.com

RT9619/A

L1

2.2uH

ATX_12V VIN

Typical Application Circuit

C8 C9 C10 C11 C12 C13 C14

10uF 10uF 1000uF 1000uF 1000uF 10uF 10uF

C2

R2 1uF

D1 1

1

R1 BOOT R3

10 8 2.2

ATX_12V 4 VCC

UGATE Q1

C1

1uF L2

RT9619/A

7 1uH

3 PHASE VCORE

+

+

+

+

NC

R4 R5

2 5 0 2.2 C4 C5 C6 C7

PWM PWM LGATE Q2 2200uF 2200uF 10uF 10uF

C3

PGND 3.3nF

6

DS9619/A-05 February 2009

RT9619/A

Functional Pin Description

Pin No. Pin Name Pin Function

1 BOOT Floating bootstrap supply pin for upper gate drive.

2 PWM Input PWM signal for controlling the driver.

3 NC No Connection Pin.

4 VCC +12V Supply Voltage.

5 LGATE Lower Gate Drive Output. Connected to gate of low-side power N-Channel MOSFET.

6 PGND Common Ground.

Connected this pin to the source of the high-side MOSFET and the drain of the low-side

7 PHASE

MOSFET.

8 UGATE Upper Gate Drive Output. Connected to gate of high-side power N-Channel MOSFET.

Function Block Diagram

VCC

Internal

5V

POR

R

BOOT

Tri-State

PWM Detect Shoot-Through

UGATE

Protection

R

Turn off Detect PHASE

VCC

Shoot-Through

Protection LGATE

PGND

Timing Diagram

PWM

tpdlLGATE

LGATE 90%

tpdlUGATE

2V 2V

90%

2V 2V

UGATE

tpdhUGATE tpdhLGATE

DS9619/A-05 February 2009 www.richtek.com

3

RT9619/A

Absolute Maximum Ratings (Note 1)

Supply Voltage, VCC ------------------------------------------------------------------------------------- −0.3V to 15V

BOOT to PHASE ----------------------------------------------------------------------------------------- −0.3V to 15V

BOOT to GND

DC ------------------------------------------------------------------------------------------------------------ −0.3V to VCC + 15V

< 200ns ----------------------------------------------------------------------------------------------------- −0.3V to 42V

PHASE to GND

DC ------------------------------------------------------------------------------------------------------------ −5V to 15V

< 200ns ----------------------------------------------------------------------------------------------------- −10V to 30V

LGATE

DC ------------------------------------------------------------------------------------------------------------ GND − 0.3V to VCC + 0.3V

< 200ns ----------------------------------------------------------------------------------------------------- −2V to VCC + 0.3V

UGATE ------------------------------------------------------------------------------------------------------ VPHASE − 0.3V to VBOOT + 0.3V

< 200ns ----------------------------------------------------------------------------------------------------- VPHASE − 2V to VBOOT + 0.3V

PWM Input Voltage -------------------------------------------------------------------------------------- GND − 0.3V to 7V

Power Dissipation, PD @ TA = 25°C

SOP-8 ------------------------------------------------------------------------------------------------------- 0.625W

Package Thermal Resistance (Note 4)

SOP-8, θJA ------------------------------------------------------------------------------------------------- 160°C/W

Lead Temperature (Soldering, 10 sec.) -------------------------------------------------------------- 260°C

Storage Temperature Range --------------------------------------------------------------------------- −40°C to 150°C

ESD Susceptibility (Note 2)

HBM (Human Body Mode) ----------------------------------------------------------------------------- 2kV

MM (Machine Mode) ------------------------------------------------------------------------------------- 200V

Recommended Operating Conditions (Note 3)

Supply Voltage, VCC ------------------------------------------------------------------------------------- 12V ±10%

Junction Temperature Range --------------------------------------------------------------------------- 0°C to 125°C

Ambient Temperature Range --------------------------------------------------------------------------- 0°C to 70°C

Electrical Characteristics

(Recommended Operating Conditions, TA = 25°C unless otherwise specified)

Parameter Symbol Test Conditions Min Typ Max Units

VCC Supply Voltage

Power Supply Voltage VCC 7.3 -- 13.5 V

VCC Supply Current

Power Supply Current IVCC VBOOT = 12V, PWM = 0V -- 1 2.5 mA

Power-On Reset

POR Threshold VVCCrth VCC Rising 5.5 6.4 7.3 V

Hysteresis VVCChys -- 2.2 -- V

To be continued

www.richtek.com DS9619/A-05 February 2009

4

RT9619/A

Parameter Symbol Test Conditions Min Typ Max Units

PWM Input

Maximum Input Current I PWM PWM = 0V or 5V -- 300 -- A

PWM Floating Voltage VPWMfl VCC = 12V -- 2.4 -- V

PWM Rising Threshold VPWMrth 3.2 3.6 3.9 V

PWM Falling Threshold V PWMfth 1.1 1.3 1.5 V

Shutdown W indow 1.5 -- 3.2 V

Timing

UGATE Rise Time trUGATE VCC = 12V, 3nF load -- 27 35 ns

UGATE Fall Time tfUGATE VCC = 12V, 3nF load -- 32 45 ns

LGATE Rise Time trLGATE VCC = 12V, 3nF load -- 35 45 ns

LGATE Fall Time tfLGATE VCC = 12V, 3nF load -- 27 38 ns

RT9619 -- 20 --

tpdhUGATE VB OOT VPHASE = 12V

RT9619A See Timing Diagram -- 90 --

Propagation Delay tpdlUGATE -- 15 -- ns

RT9619/A tpdhLGATE -- 20 --

See Timing Diagram

tpdlLGATE -- 8 --

Output

UGATE Drive Source RUGATEsr VB OOT – VPHASE = 12V -- 1.9 3

UGATE Drive Sink RUGATEsk VB OOT – VPHASE = 12V -- 1.4 3

LGATE Drive Source RLGATEsr VCC = 12V -- 1.9 3

LGATE Drive Sink RLGATEsk VCC = 12V -- 1.1 2.2

Note 1. Stresses listed as the above “Absolute Maximum Ratings” may cause permanent damage to the device. These are for

stress ratings. Functional operation of the device at these or any other conditions beyond those indicated in the operational

sections of the specifications is not implied. Exposure to absolute maximum rating conditions for extended periods may

remain possibility to affect device reliability.

Note 2. Devices are ESD sensitive. Handling precaution recommended.

Note 3. The device is not guaranteed to function outside its operating conditions.

Note 4. θJA is measured in the natural convection at T A = 25°C on a low effective thermal conductivity test board of

JEDEC 51-3 thermal measurement standard.

DS9619/A-05 February 2009 www.richtek.com

5

RT9619/A

Typical Operating Characteristics

PWM to Drive Waveform PWM to Drive Waveform

PWM

(5V/Div)

PWM

(5V/Div)

UGATE UGATE

(20V/Div) (20V/Div)

LGATE LGATE

(10V/Div) (10V/Div)

PHASE PHASE

(10V/Div) (10V/Div)

No Load No Load

Time (25ns/Div) Time (25ns/Div)

Dead Time Dead Time

Full Load Full Load

UGATE UGATE

PHASE PHASE

(5V/Div) (5V/Div)

LGATE LGATE

Time (20ns/Div) Time (20ns/Div)

Dead Time Dead Time

No Load No Load

UGATE UGATE

PHASE PHASE

(5V/Div) (5V/Div)

LGATE LGATE

Time (20ns/Div) Time (20ns/Div)

www.richtek.com DS9619/A-05 February 2009

6

RT9619/A

Short Pulse Internal Diode I-V Curve

0.06

IOUT = 119A to 24A

0.05

UGATE

0.04

Current (A)

PHASE

LGATE

0.03

0.02

(5V/Div)

0.01

0.00

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2

Time (20ns/Div)

Voltage (V)

DS9619/A-05 February 2009 www.richtek.com

7

RT9619/A

Application Information

The RT9619/A is designed to drive both high side and low Also to prevent the overlap of the gate drives during LGATE

side N-Channel MOSFET through externally input PWM turn low and UGATE turn high, the non-overlap circuit

control signal. It has power-on protection function which monitors the LGATE voltage. When LGATE go below 1.2V,

held UGATE and LGATE low before VCC up across the UGATE is allowed to go high.

rising threshold voltage. After the initialization, the PWM

signal takes the control. The rising PWM signal first forces Driving Power MOSFETs

the LGATE signal turns low then UGATE signal is allowed The DC input impedance of the power MOSFET is

to go high just after a non-overlapping time to avoid shoot- extremely high. When Vgs at 12V (or 5V), the gate draws

through current. The falling of PWM signal first forces the current only few nano-amperes. Thus once the gate

UGATE to go low. When UGATE and PHASE signal reach has been driven up to "ON" level, the current could be

a predetermined low level, LGATE signal is allowed to turn negligible.

high.

However, the capacitance at the gate to source terminal

The PWM signal is acted as "High" if above the rising should be considered. It requires relatively large currents

threshold and acted as "Low" if below the falling threshold. to drive the gate up and down 12V (or 5V) rapidly. It also

Any signal level enters and remains within the shutdown required to switch drain current on and off with the required

window is considered as "tri-state", the output drivers are speed. The required gate drive currents are calculated as

disabled and both MOSFET gates are pulled and held follows.

low. If left the PWM signal floating, the pin will be kept D1

d1 s1 L

around 2.4V by the internal divider and provide the PWM VIN VOUT

controller with a recognizable level. Cgd1 Cgs1

The RT9619/A typically operates at frequency of 200kHz Igd1 Igs1 Cgd2 d2

to 500kHz. It shall be noted that to place a 1N4148 or Ig1

Ig2 Igd2

g1 g2 D2

schottky diode between the VCC and BOOT pin as shown Igs2

in the typical application circuit for ligher efficiency. s2

Cgs2

GND

Non-overlap Control

Vg1

To prevent the overlap of the gate drives during the UGATE VPHASE +12V

turn low and the LGATE turn high, the non-overlap circuit

monitors the voltages at the PHASE node and high side

gate drive (UGATE-PHASE). When the PWM input signal t

goes low, UGATE begins to turn low (after propagation Vg2

12V

delay). Before LGATE can turn high, the non-overlap

protection circuit ensures that the monitored voltages have t

gone below 1.2V. Once the monitored voltages fall below

Figure 1. Equivalent Circuit and Associated Waveforms

1.2V, LGATE begins to turn high. For short pulse condtion,

if the PHASE pin had not gone high after LGATE turns In Figure 1, the current Ig1 and Ig2 are required to move the

low, the LGATE has to wait for 200ns before turn high. By gate up to 12V. The operation consists of charging Cgd

waiting for the voltages of the PHASE pin and high side and Cgs. Cgs1 and Cgs2 are the capacitances from gate to

gate drive to fall below 1.2V, the non-overlap protection source of the high side and the low side power MOSFETs,

circuit ensures that UGATE is low before LGATE turns respectively. In general data sheets, the Cgs is referred as

high. "Ciss" which is the input capacitance. Cgd1 and Cgd2 are the

capacitances from gate to drain of the high side and the

www.richtek.com DS9619/A-05 February 2009

8

RT9619/A

low side power MOSFETs, respectively and referred to the the total current required from the gate driving source is

data sheets as "Crss" the reverse transfer capacitance. For

example, tr1 and tr2 are the rising time of the high side and Ig1 Igs1 Igd1 (1.428 0.326) 1.754 (A) (9)

the low side power MOSFETs respectively, the required Ig2 Igs2 Igd2 (0.88 0.4) 1.28 (A) (10)

current Igs1 and Igs2 are showed below :

,

By a similar calculation, we can also get the sink current

dVg1 C gs1 12

Igs1 C gs1 (1) required from the turned off MOSFET.

dt t r1

dVg2 C gs1 12 Select the Bootstrap Capacitor

Igs2 C gs1 (2)

dt t r2

Figure 2 shows part of the bootstrap circuit of RT9619/A.

Before driving the gate of the high side MOSFET up to The VCB (the voltage difference between BOOT and PHASE

12V (or 5V), the low side MOSFET has to be off; and the on RT9619/A) provides a voltage to the gate of the high

high side MOSFET is turned off before the low side is side power MOSFET. This supply needs to be ensured

turned on. From Figure 1, the body diode "D2" had been that the MOSFET can be driven. For this, the capacitance

turned on before high side MOSFETs turned on. CB has to be selected properly. It is determined by following

constraints.

Igd1 C gd1 dV C gd1 12V (3)

dt t r1

VIN

1N4148

Before the low side MOSFET is turned on, the Cgd2 have VCC

been charged to VIN. Thus, as Cgd2 reverses its polarity

BOOT

and g2 is charged up to 12V, the required current is

+

UGATE CB

VCB

Igd2 Cgd2 dV Cgd2 Vi 12V (4) PHASE -

dt t r2

VCC

It is helpful to calculate these currents in a typical case.

LGATE

Assume a synchronous rectified buck converter, input

PGND

voltage VIN = 12V, Vg1 = Vg2 = 12V. The high side MOSFET

is PHB83N03LT whose Ciss = 1660pF, Crss = 380pF, and

tr = 14ns. The low side MOSFET is PHB95N03LT whose Figure 2. Part of Bootstrap Circuit of RT9619/A

Ciss = 2200pF, Crss = 500pF and tr = 30ns, from the equation

In practice, a low value capacitor CB will lead the over-

(1) and (2) we can obtain

charging that could damage the IC. Therefore to minimize

the risk of overcharging and reducing the ripple on VCB,

Igs1 1660 10 12 1.428 (A)

-12

(5) the bootstrap capacitor should not be smaller than 0.1μF,

14 10 -9

and the larger the better. In general design, using 1μF can

Igs2 2200 10 12 0.88

-12

(A) (6) provide better performance. At least one low-ESR capacitor

30 10 -9 should be used to provide good local de-coupling. Here, to

adopt either a ceramic or tantalum capacitor is suitable.

from equation. (3) and (4)

Power Dissipation

-12 For not exceeding the maximum allowable power

Igd1 380 10 -9 12 0.326 (A) (7) dissipation to drive the IC beyond the maximum

14 10

-12

recommended operating junction temperature of 125°C, it

500 10 (12 12) is necessary to calculate power dissipation appro-priately.

Igd2 -9

0.4 (A) (8)

30 10

DS9619/A-05 February 2009 www.richtek.com

9

RT9619/A

This dissipation is a function of switching frequency and TJ = (160°C/W x 100mW) + 25°C = 41°C (11)

total gate charge of the selected MOSFET. Figure 3 shows where the ambient temperature is 25°C.

the power dissipation test circuit. CL and CU are the UGATE

The method to improve the thermal transfer is to increase

and LGATE load capacitors, respectively. The bootstrap

the PCB copper area around the RT9619/A first. Then,

capacitor value is 1μF.

CBOOT adding a ground pad under IC to transfer the heat to the

10 1N4148 1uF

+12V

peripheral of the board.

+12V

BOOT Layout Consideration

VCC UGATE 2N7002

Figure 5 shows the schematic circuit of a two-phase

1uF CU

RT9619/A 3nF synchronous buck converter to implement the RT9619/A.

PHASE The converter operates from 5V to 12V of VIN.

2N7002

PWM VIN LGATE 20 When layout the PCB, it should be very careful. The power-

PGND CL

3nF circuit section is the most critical one. If not configured

properly, it will generate a large amount of EMI. The junction

Figure 3. Test Circuit of Q1, Q2, L2 should be very close.

Next, the trace from UGATE, and LGATE should also be

Figure 4 shows the power dissipation of the RT9619/A as short to decrease the noise of the driver output signals.

a function of frequency and load capacitance. The value of PHASE signals from the junction of the power MOSFET,

the CU and CL are the same and the frequency is varied carrying the large gate drive current pulses, should be as

from 100kHz to 1MHz. heavy as the gate drive trace. The bypass capacitor C4

Power Dissipation vs. Frequency should be connected to PGND directly. Furthermore, the

1000 bootstrap capacitors (CB) should always be placed as close

900 CU=CL=3nF to the pins of the IC as possible.

Power Dissipation (mW)

800

L1 D1 R1

700 12V

VIN C4 10

600 12V 1.2uH

+

C2 1 4 1uF

C1 1uF

BOOT VCC

500 1000uF CB

CU=CL=2nF 1uF 2

400 Q1 8 VIN PWM

RT9619/A

UGATE

L2

300 VCORE 7

CU=CL=1nF PHASE

2uH PHB83N03LT

200

+

C3

1500uF Q2 PHB95N03LT 5 6

100 LGATE PGND

0

0 200 400 600 800 1000

Frequency (kHz) Figure 5. Two-Phase Synchronous Buck Converter Circuit

Figure 4. Power Dissipation vs. Frequency

The operating junction temperature can be calculated from

the power dissipation curves (Figure 4). Assume

VCC=12V, operating frequency is 200kHz and the

CU=CL=1nF which emulate the input capacitances of the

high side and low side power MOSFETs. From Figure 4,

the power dissipation is 100mW. For RT9619/A, the

package thermal resistance θJA is 160° C/W, the operating

junction temperature is calculated as :

www.richtek.com DS9619/A-05 February 2009

10

RT9619/A

Outline Dimension

H

A

J B

C

I

D

Dimensions In Millimeters Dimensions In Inches

Symbol

Min Max Min Max

A 4.801 5.004 0.189 0.197

B 3.810 3.988 0.150 0.157

C 1.346 1.753 0.053 0.069

D 0.330 0.508 0.013 0.020

F 1.194 1.346 0.047 0.053

H 0.170 0.254 0.007 0.010

I 0.050 0.254 0.002 0.010

J 5.791 6.200 0.228 0.244

M 0.400 1.270 0.016 0.050

8-Lead SOP Plastic Package

Richtek Technology Corporation Richtek Technology Corporation

Headquarter Taipei Office (Marketing)

5F, No. 20, Taiyuen Street, Chupei City 8F, No. 137, Lane 235, Paochiao Road, Hsintien City

Hsinchu, Taiwan, R.O.C. Taipei County, Taiwan, R.O.C.

Tel: (8863)5526789 Fax: (8863)5526611 Tel: (8862)89191466 Fax: (8862)89191465

Email: marketing@richtek.com

Information that is provided by Richtek Technology Corporation is believed to be accurate and reliable. Richtek reserves the right to make any change in circuit design,

specification or other related things if necessary without notice at any time. No third party intellectual property infringement of the applications should be guaranteed

by users when integrating Richtek products into any application. No legal responsibility for any said applications is assumed by Richtek.

DS9619/A-05 February 2009 www.richtek.com

11

You might also like

- Synchronous-Rectified Buck MOSFET Drivers: General Description FeaturesDocument12 pagesSynchronous-Rectified Buck MOSFET Drivers: General Description FeaturesFlavianoSilvaNo ratings yet

- Synchronous-Rectified Buck MOSFET Drivers: Features General DescriptionDocument12 pagesSynchronous-Rectified Buck MOSFET Drivers: Features General DescriptionALANRAFAELTECNICONo ratings yet

- Synchronous-Rectified Buck MOSFET Drivers: Features General DescriptionDocument5 pagesSynchronous-Rectified Buck MOSFET Drivers: Features General DescriptionTeles SilvaNo ratings yet

- 3A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesDocument12 pages3A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesAbdul MuhidNo ratings yet

- 5V/12V Synchronous Buck PWM DC-DC Controller: Features General DescriptionDocument17 pages5V/12V Synchronous Buck PWM DC-DC Controller: Features General DescriptionLuis Dark-passengerNo ratings yet

- Rt9008ge Apl5611aci-Trg Apl5611 9008ge 9008 La04 La12 La13 La14 La15 La16 La17 La0 La1Document9 pagesRt9008ge Apl5611aci-Trg Apl5611 9008ge 9008 La04 La12 La13 La14 La15 La16 La17 La0 La1laptophaianhNo ratings yet

- 3A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesDocument12 pages3A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesMarcius RodriguesNo ratings yet

- Asus h61 rt9612AB-03 PDFDocument15 pagesAsus h61 rt9612AB-03 PDFReballing PortatilNo ratings yet

- Ic rt9214Document17 pagesIc rt9214Franklin JimenezNo ratings yet

- Synchronous Rectified Buck MOSFET Drivers: RT9611A/BDocument15 pagesSynchronous Rectified Buck MOSFET Drivers: RT9611A/BSaulo DoteNo ratings yet

- Synchronous Rectified Buck MOSFET Drivers: RT9611C/DDocument13 pagesSynchronous Rectified Buck MOSFET Drivers: RT9611C/Dcyberpunk.tech.brNo ratings yet

- RT7296F 0.1Document96 pagesRT7296F 0.1Chiapin LeeNo ratings yet

- Ds8295a 04Document14 pagesDs8295a 04Bsm GwapuNo ratings yet

- 3A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesDocument12 pages3A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesJuan Carlos SrafanNo ratings yet

- Data SheetDocument15 pagesData Sheetzakie wahyuNo ratings yet

- 8T Rt5768aDocument12 pages8T Rt5768aVISHALNo ratings yet

- FR9888 FR9886 RT8296A RT8282 Step Down DC DC Converter Buck Ic Nguon Gan Giong Act 4523 PDFDocument11 pagesFR9888 FR9886 RT8296A RT8282 Step Down DC DC Converter Buck Ic Nguon Gan Giong Act 4523 PDFdinh vinh nguyenNo ratings yet

- DatasheetDocument12 pagesDatasheetWAN MOZESNo ratings yet

- 2A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesDocument14 pages2A, 23V, 340Khz Synchronous Step-Down Converter: General Description FeaturesGioVoTamNo ratings yet

- NCP1396A, NCP1396B Controller, High Performance Resonant Mode, With High and Low Side DriversDocument26 pagesNCP1396A, NCP1396B Controller, High Performance Resonant Mode, With High and Low Side DriversMaria VaccarielloNo ratings yet

- 2A, 2Mhz, Synchronous Step-Down Regulator: General Description FeaturesDocument15 pages2A, 2Mhz, Synchronous Step-Down Regulator: General Description FeaturesPedrolaura BethencourtNo ratings yet

- FAN7390 High-Current, High & Low-Side, Gate-Drive IC: Features DescriptionDocument14 pagesFAN7390 High-Current, High & Low-Side, Gate-Drive IC: Features DescriptionjoelpalzaNo ratings yet

- 2A, 23V, 1.2Mhz Synchronous Step-Down Converter: General Description FeaturesDocument14 pages2A, 23V, 1.2Mhz Synchronous Step-Down Converter: General Description FeaturesHaroldo VieiraNo ratings yet

- AT1526 GlobalMixed ModetechnologyDocument2 pagesAT1526 GlobalMixed ModetechnologyFafa MangstabNo ratings yet

- 23V, 3A, 650Khz Synchronous Step-Down DC/DC Converter: Description FeaturesDocument13 pages23V, 3A, 650Khz Synchronous Step-Down DC/DC Converter: Description FeatureswalmirNo ratings yet

- 3A Ultra Low Dropout Linear Regulator: General Description FeaturesDocument11 pages3A Ultra Low Dropout Linear Regulator: General Description FeaturesdejanNo ratings yet

- Cost-Effective, 2A Peak Sink/Source Bus Termination RegulatorDocument14 pagesCost-Effective, 2A Peak Sink/Source Bus Termination Regulatoronc3h 112No ratings yet

- 4895ec92 PDFDocument13 pages4895ec92 PDFEdgardoNo ratings yet

- 5V/12V Synchronous Buck PWM DC-DC and Linear Power ControllerDocument18 pages5V/12V Synchronous Buck PWM DC-DC and Linear Power Controllerraed hasaniaNo ratings yet

- RT8059Document10 pagesRT8059Bijan AmiriNo ratings yet

- RT8296A RichtekDocument14 pagesRT8296A Richtektecnicown eletricaNo ratings yet

- FAN7380 Half-Bridge Gate Driver: Features DescriptionDocument12 pagesFAN7380 Half-Bridge Gate Driver: Features Descriptionflo72afNo ratings yet

- rt8009 201Document14 pagesrt8009 201Алексей ГомоновNo ratings yet

- OsciladorDocument14 pagesOsciladorEmmanuel ZambranoNo ratings yet

- FR9723B Fiti PDFDocument12 pagesFR9723B Fiti PDFVictor AlzamoraNo ratings yet

- 3A, 18V, 340Khz Synchronous Step-Down Converter: General Description FeaturesDocument14 pages3A, 18V, 340Khz Synchronous Step-Down Converter: General Description FeaturesAgung KaryaNo ratings yet

- 433aschematic PDFDocument1 page433aschematic PDFCarlos Vasquez100% (1)

- Manual Air Band ReceiverDocument8 pagesManual Air Band Receiverdp500100% (1)

- 23V, 2A/2.5A, 340Khz Synchronous Step-Down DC/DC Converter: Description FeaturesDocument15 pages23V, 2A/2.5A, 340Khz Synchronous Step-Down DC/DC Converter: Description FeaturesJuan Carlos VillegasNo ratings yet

- Cost-Effective, 2A Peak Sink/Source Bus Termination RegulatorDocument13 pagesCost-Effective, 2A Peak Sink/Source Bus Termination RegulatoramitNo ratings yet

- 23V, 2.5A, 340Khz Synchronous Step-Down DC/DC Converter: Description FeaturesDocument14 pages23V, 2.5A, 340Khz Synchronous Step-Down DC/DC Converter: Description FeaturesFuadNo ratings yet

- Flyback Controller Improves Cross Regulation For Multiple Output ApplicationsDocument2 pagesFlyback Controller Improves Cross Regulation For Multiple Output Applications邹昊芃No ratings yet

- Up 7704Document13 pagesUp 7704Delwar HossainNo ratings yet

- Advanced Voltage Mode Pulse Width Modulator: Description FeaturesDocument24 pagesAdvanced Voltage Mode Pulse Width Modulator: Description Featuresvanhuong87No ratings yet

- A5268 3A, 28V, 340Khz Synchronous Rectified Step-Down ConverterDocument16 pagesA5268 3A, 28V, 340Khz Synchronous Rectified Step-Down ConverterAnderson Galarza CalderonNo ratings yet

- Single-Phase Synchronous Buck PWM Controller: RT8120G/HDocument16 pagesSingle-Phase Synchronous Buck PWM Controller: RT8120G/Hشعبان العواميNo ratings yet

- FR9886Document12 pagesFR9886abrkNo ratings yet

- uPI Confidential: 3A Ultra Low Dropout Linear RegulatorDocument13 pagesuPI Confidential: 3A Ultra Low Dropout Linear RegulatorLEONNo ratings yet

- 3A, 2Mhz, Synchronous Step-Down Converter: General Description FeaturesDocument13 pages3A, 2Mhz, Synchronous Step-Down Converter: General Description FeaturesKavinda Jayasinghege DonNo ratings yet

- UP1962SDocument14 pagesUP1962Stechgamebr85No ratings yet

- 5A, 36V, 500Khz Step-Down Converter: General Description FeaturesDocument14 pages5A, 36V, 500Khz Step-Down Converter: General Description FeaturesHitesh GambhavaNo ratings yet

- CONVERTIDOR DC-DC REDUCTOR SMD RT8295AH O RT8295ADocument14 pagesCONVERTIDOR DC-DC REDUCTOR SMD RT8295AH O RT8295Ainggreg1No ratings yet

- Ds8204a 05Document19 pagesDs8204a 05marcelo Chiu LeonNo ratings yet

- DC To DC Converter rt8272Document14 pagesDC To DC Converter rt8272hadNo ratings yet

- 300/500ma Low Dropout Linear Voltage Regulator: General Description FeaturesDocument11 pages300/500ma Low Dropout Linear Voltage Regulator: General Description FeaturesPedro RodriguezNo ratings yet

- Tps 61197Document22 pagesTps 61197Sahaly RandNo ratings yet

- Fan7382 103101Document17 pagesFan7382 103101Oleksandr ShandurskyiNo ratings yet

- 500ma, Low Dropout, Low Noise Ultra-Fast Without Bypass Capacitor CMOS LDO RegulatorDocument13 pages500ma, Low Dropout, Low Noise Ultra-Fast Without Bypass Capacitor CMOS LDO RegulatoreugeneNo ratings yet

- Single-Channel: 6N138, 6N139 Dual-Channel: HCPL-2730, HCPL-2731 Low Input Current High Gain Split Darlington OptocouplersDocument15 pagesSingle-Channel: 6N138, 6N139 Dual-Channel: HCPL-2730, HCPL-2731 Low Input Current High Gain Split Darlington Optocouplersdevrim.kosalNo ratings yet

- Amplifier MAIN PCB IRS2092 Bottom Layer RasporedDocument1 pageAmplifier MAIN PCB IRS2092 Bottom Layer RasporedDaniel Norberto DemariaNo ratings yet

- TCL Service Manual: 39S62/NT63EP2-LADocument52 pagesTCL Service Manual: 39S62/NT63EP2-LADaniel Norberto DemariaNo ratings yet

- Tda7476 DiagnosticDocument20 pagesTda7476 DiagnosticDaniel Norberto DemariaNo ratings yet

- Service Manual: Audio SystemDocument58 pagesService Manual: Audio SystemDaniel Norberto DemariaNo ratings yet

- KDC-319/4019 KDC-5020: Service ManualDocument19 pagesKDC-319/4019 KDC-5020: Service ManualDaniel Norberto DemariaNo ratings yet

- MODEL: CH3000D: SpecificationsDocument10 pagesMODEL: CH3000D: SpecificationsDaniel Norberto DemariaNo ratings yet

- Samsung ln23 26 32 40 r81bx Chassis GBP 23 26 32 40 MlaDocument132 pagesSamsung ln23 26 32 40 r81bx Chassis GBP 23 26 32 40 MlaDaniel Norberto DemariaNo ratings yet

- Data Sheet Acquired From Harris Semiconductor SCHS043B - Revised July 2003Document15 pagesData Sheet Acquired From Harris Semiconductor SCHS043B - Revised July 2003Daniel Norberto DemariaNo ratings yet

- ST92F124/ST92F150/ST92F250Document429 pagesST92F124/ST92F150/ST92F250Daniel Norberto DemariaNo ratings yet

- PD78 Series Microcontroller EEPROM Programmer User's Guide: Engineering Technical LaboratoryDocument14 pagesPD78 Series Microcontroller EEPROM Programmer User's Guide: Engineering Technical LaboratoryDaniel Norberto DemariaNo ratings yet

- TDF8554J: 1. General DescriptionDocument56 pagesTDF8554J: 1. General DescriptionDaniel Norberto DemariaNo ratings yet

- Monitor - W2252TQ Service ManualDocument23 pagesMonitor - W2252TQ Service Manualelectricalengin100% (1)

- R01an0930ej0200 - V850essx3 BootDocument269 pagesR01an0930ej0200 - V850essx3 BootDaniel Norberto DemariaNo ratings yet

- LCD TV: Service ManualDocument44 pagesLCD TV: Service ManualDaniel Norberto DemariaNo ratings yet

- User Instruction !: Connecting To The Programming of Microcontrollers Using The Examples Presented in This DocumentDocument6 pagesUser Instruction !: Connecting To The Programming of Microcontrollers Using The Examples Presented in This DocumentDaniel Norberto DemariaNo ratings yet

- BMW Philips-Dc705 Cancheck Off ModDocument8 pagesBMW Philips-Dc705 Cancheck Off ModDaniel Norberto DemariaNo ratings yet

- TPS5117 1 PDFDocument33 pagesTPS5117 1 PDFDaniel Norberto DemariaNo ratings yet

- BQ24721CRHBTG4 Datasheet PDFDocument60 pagesBQ24721CRHBTG4 Datasheet PDFDaniel Norberto DemariaNo ratings yet

- SLG8SP513: Clock Synthesizer For Intel Mobile PCI-Express ChipsetDocument24 pagesSLG8SP513: Clock Synthesizer For Intel Mobile PCI-Express ChipsetDaniel Norberto DemariaNo ratings yet

- Synchronous Rectified MOSFET Driver Features: FN9240.0 Data Sheet November 2, 2005Document10 pagesSynchronous Rectified MOSFET Driver Features: FN9240.0 Data Sheet November 2, 2005Daniel Norberto DemariaNo ratings yet

- HIP6601, HIP6603: Synchronous-Rectified Buck MOSFET Drivers FeaturesDocument8 pagesHIP6601, HIP6603: Synchronous-Rectified Buck MOSFET Drivers FeaturesDaniel Norberto DemariaNo ratings yet

- B. DBMS (Answer) : I. Multi ChoiceDocument2 pagesB. DBMS (Answer) : I. Multi ChoiceTolaNo ratings yet

- MT8070iE1 Datasheet ENGDocument2 pagesMT8070iE1 Datasheet ENGIvan VillarroelNo ratings yet

- Hardware Manual: 1. Installing CabinetsDocument186 pagesHardware Manual: 1. Installing CabinetsPhan AnNo ratings yet

- NPN Matched PairDocument5 pagesNPN Matched PairNANo ratings yet

- m01 Connect Internal HardwareDocument64 pagesm01 Connect Internal Hardwaretewachew mitikeNo ratings yet

- MPMC Unit-II MCQDocument17 pagesMPMC Unit-II MCQRenit AntoNo ratings yet

- Manual Notebook Acer Aspire One D257 Drivers Win7 7 32bit: Read/DownloadDocument3 pagesManual Notebook Acer Aspire One D257 Drivers Win7 7 32bit: Read/DownloadHenrique 433444No ratings yet

- A Reliable Plasma SpeakerDocument11 pagesA Reliable Plasma SpeakerGASTON DUBOISNo ratings yet

- Troubleshooting PDFDocument95 pagesTroubleshooting PDFVince CentenoNo ratings yet

- Driver Gate Drv8353fDocument83 pagesDriver Gate Drv8353fricmf89No ratings yet

- Unit 3Document53 pagesUnit 3FrederickNo ratings yet

- Tph3202P Series: 600V Gan Fet To-220 SeriesDocument14 pagesTph3202P Series: 600V Gan Fet To-220 SeriesshounakroyNo ratings yet

- Huawei GPON Optical Module SFP C+ C++ PDFDocument2 pagesHuawei GPON Optical Module SFP C+ C++ PDFRicardo Andres Borja BenitezNo ratings yet

- Inventaris Hardware Data Elektronik RSDocument1 pageInventaris Hardware Data Elektronik RSZanitsa NasifahNo ratings yet

- Class23-24 Vias Connectors and PackagesDocument76 pagesClass23-24 Vias Connectors and PackagesspyeagleNo ratings yet

- Device-to-Device (D2D) Communication in Cellular Network - Performance Analysis of Optimum and Practical Communication Mode SelectionDocument6 pagesDevice-to-Device (D2D) Communication in Cellular Network - Performance Analysis of Optimum and Practical Communication Mode SelectionAnant SinhaNo ratings yet

- EEE 4133 Lec-Aug 16Document23 pagesEEE 4133 Lec-Aug 16Majba AhamadNo ratings yet

- Ericsson Nokia Feature Mapping - LTEDocument128 pagesEricsson Nokia Feature Mapping - LTEahyatalatal100% (1)

- Leica DMS1000 Brochure LSR enDocument12 pagesLeica DMS1000 Brochure LSR ensam madaniNo ratings yet

- UX31A2 SCHEMATIC Revision R2.0Document100 pagesUX31A2 SCHEMATIC Revision R2.0ficoNo ratings yet

- Quectel L96 Reference Design V1.1Document10 pagesQuectel L96 Reference Design V1.1Raul LunaNo ratings yet

- PIC18F06 16Q41 Data Sheet 40002214EDocument934 pagesPIC18F06 16Q41 Data Sheet 40002214EJosue MejíaNo ratings yet

- E532246 - 00E - Genset - CAN OPEN - J1939 PDFDocument86 pagesE532246 - 00E - Genset - CAN OPEN - J1939 PDFMouloud AcheroufeneNo ratings yet

- Student Name Ali Abdullah Mohammed Ameen: Class 3 BDocument13 pagesStudent Name Ali Abdullah Mohammed Ameen: Class 3 Bالزهور لخدمات الانترنيتNo ratings yet

- 計概Q3Document43 pages計概Q3楊喻妃No ratings yet

- Ov 4Document99 pagesOv 4marwen hassenNo ratings yet

- Based On May 2011 Occupational Standards: Ethiopian TVET-SystemDocument92 pagesBased On May 2011 Occupational Standards: Ethiopian TVET-SystemnatnaelNo ratings yet

- ELEN0037 Microelectronic IC Design: Prof. Dr. Michael KraftDocument46 pagesELEN0037 Microelectronic IC Design: Prof. Dr. Michael KraftDominiqueNo ratings yet

- College of Management: Case Analysis: Logitech: The Little Mouse That RoarsDocument4 pagesCollege of Management: Case Analysis: Logitech: The Little Mouse That RoarsEmy Rose DiosanaNo ratings yet

- APsystems ECU R Product 2.15.19Document2 pagesAPsystems ECU R Product 2.15.19SilviaNo ratings yet