Professional Documents

Culture Documents

Stick or MSAW Welding: Process Characteristics of Shielded Metal Arc Welding (SMAW/Stick)

Uploaded by

senthil4youOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stick or MSAW Welding: Process Characteristics of Shielded Metal Arc Welding (SMAW/Stick)

Uploaded by

senthil4youCopyright:

Available Formats

Stick or MSAW welding

Advantage Fabricated Metals performs a number of welding processes. The two most

common welding processes we use include TIG, an acronym for Tungsten Inert Gas welding

and MIG, an acronym for Metal Inert Gas welding. TIG is also referred to as GTAW (Gas T

ungsten Arc Welding) and Heliarc®. MIG also is referred to as GMAW (Gas Metal Arc

Welding). We also provide stick or MSAW welding.

Shielded Metal Arc Welding (SMAW) is frequently referred to as "stick" or "covered

electrode" welding. Stick welding is among the most widely used welding processes.

The flux covering on the electrode melts during welding. This forms the gas and slag to

shield the arc and molten weld pool. The slag must be chipped off the weld bead after

welding. The flux also provides a method of adding scavengers, deoxidizers, and alloying

elements to the weld metal.

When an arc is struck between the metal rod (electrode) and the workpiece, both the rod and

workpiece surface melt to form a weld pool. Simultaneous melting of the flux coating on the

rod will form gas and slag which protects the weld pool from the surrounding atmosphere.

The slag will solidify and cool and must be chipped off the weld bead once the weld run is

complete (or before the next weld pass is deposited).

The process allows only short lengths of weld to be produced before a new electrode needs to

be inserted in the holder. Weld penetration is low and the quality of the weld deposit is highly

dependent on the skill of the welder.

Process characteristics of Shielded Metal Arc Welding

(SMAW/Stick)

SMAW welding:

Uses a electrode rod that is quickly consumed,

Uses equipment that is simple, inexpensive, and highly portable,

Uses an electrode that provides and regulates its own flux,

Provides all position flexibility,

Is less sensitive to wind or drafts,

Yields a weld with a variable quality and appearance based on operator skill,

During the SMAW welding process the arc is established, the flux coating on the rod

disintegrates and then forms a gas that shields the weld from the atmosphere. The slag that is

produced by the flux coating prevents the weld metal from oxidizing.

Equipment required to perform the SMAW welding process includes a constant current

power source that supplies the power to the consumable rod electrode.

The SMAW welding process typically is capable of producing three types of welded joints.

They are:

Butt joint

Lap joint,

T-joint, and

Fillet weld.

The illustration below shows these four common welded joints.

Flux-coated electrodes are available in many core wire diameters and lengths. Matching the

electrode properties to the base materials as a general rule for choosing the type of electrode.

Available electrodes types include aluminum bronze, bronze, mild steel, nickel, and stainless

steel.

Materials commonly welded using the SMAW process include mild steel, cast iron, and

stainless steel.

You might also like

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Arc Welding Methods GuideDocument115 pagesArc Welding Methods GuideRajesh Routray100% (2)

- EML 2322L - Welding - MAE Design and Manufacturing LabDocument21 pagesEML 2322L - Welding - MAE Design and Manufacturing LabBhaiJan59No ratings yet

- Arc Welding Techniques ExplainedDocument4 pagesArc Welding Techniques ExplainedFaris Kadesh50% (2)

- Introduction to Welding Processes and Safety PrecautionsDocument15 pagesIntroduction to Welding Processes and Safety PrecautionsRAMALAKSHMI SUDALAIKANNANNo ratings yet

- Welding Is ADocument19 pagesWelding Is AAnthony ValinNo ratings yet

- Electric WeldingDocument28 pagesElectric WeldingmayankNo ratings yet

- Stick: Arc WeldingDocument4 pagesStick: Arc WeldingmohitshuklamarsNo ratings yet

- Welding (WorkShop) Assig # 1Document7 pagesWelding (WorkShop) Assig # 1Muhammad Talha ZaroonNo ratings yet

- Advanced Welding Technology Ca2Document3 pagesAdvanced Welding Technology Ca2Monglafru MogNo ratings yet

- Welding: Welding Is A Fabrication Process That Joins Materials, Usually Metals or Thermoplastics, byDocument6 pagesWelding: Welding Is A Fabrication Process That Joins Materials, Usually Metals or Thermoplastics, byTarun ChandraNo ratings yet

- Arc Welding Processes w3Document73 pagesArc Welding Processes w3snananrNo ratings yet

- Introduction to Welding ProcessesDocument45 pagesIntroduction to Welding ProcessesberhaneNo ratings yet

- What Is Welding. History of WeldingDocument11 pagesWhat Is Welding. History of WeldingNell Sabas AdolfoNo ratings yet

- Welding WorkshopDocument11 pagesWelding WorkshopMuhammad Tauseef ZafarNo ratings yet

- Welding Is A Fabrication Process Which Is Used To Join MaterialsDocument23 pagesWelding Is A Fabrication Process Which Is Used To Join Materialsjagadish madiwalarNo ratings yet

- Welding Types Procedures ParametersDocument156 pagesWelding Types Procedures ParametersVinodh Kumar YallaNo ratings yet

- 3 Unit 2 - Arc, Gas, Plastic Welding, LBW, EBW and Thermit WeldingDocument96 pages3 Unit 2 - Arc, Gas, Plastic Welding, LBW, EBW and Thermit WeldingAditya KumarNo ratings yet

- Welding ShopDocument10 pagesWelding ShopAsifJavedNo ratings yet

- SMAW Welding Guide for 4130 SteelDocument39 pagesSMAW Welding Guide for 4130 SteelSwapnil ModakNo ratings yet

- Welding Processes Presentation GuideDocument12 pagesWelding Processes Presentation GuideJawed AkhterNo ratings yet

- 2) Welding Process, SMAWDocument128 pages2) Welding Process, SMAWDivyang MistryNo ratings yet

- Introduction To WeldingDocument18 pagesIntroduction To WeldingledaswanNo ratings yet

- Krishna Engineering College Department of Mechanical EngineeringDocument5 pagesKrishna Engineering College Department of Mechanical EngineeringVivek BajpaiNo ratings yet

- Manufactura GuíaDocument3 pagesManufactura GuíaIrwin VelozNo ratings yet

- Welding MP-IDocument28 pagesWelding MP-IPIYUSH SHARMANo ratings yet

- Shielded Metal Arc WeldingDocument16 pagesShielded Metal Arc WeldingAshif IqubalNo ratings yet

- Guide to MIG, TIG, Stick & Flux Welding ProcessesDocument3 pagesGuide to MIG, TIG, Stick & Flux Welding ProcessesKoya ThangalNo ratings yet

- Types of Electric WeldingDocument7 pagesTypes of Electric WeldingSUKhanNo ratings yet

- Welding Types and Their Applications - 1Document18 pagesWelding Types and Their Applications - 1tgu1eramos100% (3)

- Chapter-4 Principle of Selected Joining and Assembling Process A Brief History of WeldingDocument12 pagesChapter-4 Principle of Selected Joining and Assembling Process A Brief History of WeldingFira tubeNo ratings yet

- Manufacturing Processes Lab WeldingDocument8 pagesManufacturing Processes Lab WeldingKhalid EwigNo ratings yet

- Common Welding ProcessDocument4 pagesCommon Welding ProcessLalit Bom MallaNo ratings yet

- Mig Gmaw Welding 1Document26 pagesMig Gmaw Welding 1HAZEL BELLONo ratings yet

- Welding Processes SummaryDocument2 pagesWelding Processes SummaryDiego AlonsoNo ratings yet

- WeldingDocument3 pagesWeldingRehan AmeenNo ratings yet

- WeldingDocument93 pagesWeldingPradeepNo ratings yet

- Welding MachinesDocument53 pagesWelding MachinesDeepak Kumar Kant Kesri100% (2)

- Gas Metal Arc Welding (MIG) Presented by N.Sankar/Ap /mechDocument50 pagesGas Metal Arc Welding (MIG) Presented by N.Sankar/Ap /mechlastjohnNo ratings yet

- Manufacturing Process: Chapter 5 Joining ProcessesDocument53 pagesManufacturing Process: Chapter 5 Joining ProcesseshizanorhudaNo ratings yet

- QC Engineer's Guide to Welding Processes and TerminologyDocument22 pagesQC Engineer's Guide to Welding Processes and TerminologyIrfan MehmoodNo ratings yet

- Types of WeldingDocument10 pagesTypes of WeldingMuhammad Tauseef ZafarNo ratings yet

- New Microsoft PowerPoint Presentation (2)Document10 pagesNew Microsoft PowerPoint Presentation (2)ommkarNo ratings yet

- WELD-Arc Welding - Maine Welding CompanyDocument7 pagesWELD-Arc Welding - Maine Welding CompanypeterNo ratings yet

- 4 MPDocument23 pages4 MPAmaresh Movies ASNo ratings yet

- Fundamentals of Welding ProcessesDocument80 pagesFundamentals of Welding ProcessesVivek Satapathy100% (1)

- Arc Welding Types MP IIDocument40 pagesArc Welding Types MP IISyedUbaidRehman100% (1)

- CH 4Document63 pagesCH 4tariku seyoumNo ratings yet

- UnitDocument41 pagesUnitsawravkblNo ratings yet

- Welding TechnologyDocument26 pagesWelding TechnologyHiren Kumar100% (1)

- Shipyard Welding ProcessesDocument6 pagesShipyard Welding ProcessesPawan KumarNo ratings yet

- MANUFACTURING PROCESS WELDING OVERVIEWDocument70 pagesMANUFACTURING PROCESS WELDING OVERVIEWAzmeer Mohamed100% (1)

- 4 5816871528360313106 PDFDocument114 pages4 5816871528360313106 PDFAsif AhmedNo ratings yet

- Weld Bead Exp MigDocument14 pagesWeld Bead Exp MigBhavyaGargNo ratings yet

- Submerged Arc Welding (SAW) Is A Common Arc Welding Process. The First Patent On The Submerged-Arc WeldingDocument31 pagesSubmerged Arc Welding (SAW) Is A Common Arc Welding Process. The First Patent On The Submerged-Arc Weldingankit gargNo ratings yet

- Welding 2 PDFDocument7 pagesWelding 2 PDFPratyush BhattacharyaNo ratings yet

- MIG Welding Guide Under 40 CharactersDocument21 pagesMIG Welding Guide Under 40 Charactersvishnu0751No ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Standard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsFrom EverandStandard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsNo ratings yet

- 50 quiz questions and answers on history, geography and moreDocument5 pages50 quiz questions and answers on history, geography and moresenthil4youNo ratings yet

- Sno STN Code STN Name Route No. Arriv Al Time Dep. Time Halt Time (In Minutes) Distan Ce Da Y Rema RKDocument1 pageSno STN Code STN Name Route No. Arriv Al Time Dep. Time Halt Time (In Minutes) Distan Ce Da Y Rema RKsenthil4youNo ratings yet

- 15 Booster Pulse Rate Price of Pack (RS.) Free Airtime On Pack (RS.) Incoming Calls (RS.)Document19 pages15 Booster Pulse Rate Price of Pack (RS.) Free Airtime On Pack (RS.) Incoming Calls (RS.)senthil4youNo ratings yet

- BESTARC The Most Power Efficient ElectrodeDocument1 pageBESTARC The Most Power Efficient Electrodesenthil4youNo ratings yet

- 15 Quiz QuestionsDocument4 pages15 Quiz Questionssenthil4youNo ratings yet

- 20 General Knowledge Questions AnsweredDocument2 pages20 General Knowledge Questions Answeredsenthil4youNo ratings yet

- EPFO Missed Call Facility for UAN DetailsDocument1 pageEPFO Missed Call Facility for UAN Detailssenthil4youNo ratings yet

- Tamil Murugan Devotional mp3 Songs Free Download: Click Here To DownloadDocument2 pagesTamil Murugan Devotional mp3 Songs Free Download: Click Here To Downloadsenthil4youNo ratings yet

- A Marketing MoralDocument1 pageA Marketing Moralsenthil4youNo ratings yet

- Missed Call ServiceDocument1 pageMissed Call Servicesenthil4youNo ratings yet

- Tack-Welds: of Highest Quality For Strong StructuresDocument3 pagesTack-Welds: of Highest Quality For Strong Structuressenthil4youNo ratings yet

- 5 Things You MUST Understand If You Are Ever Going To Lose Your Belly FatDocument2 pages5 Things You MUST Understand If You Are Ever Going To Lose Your Belly Fatsenthil4youNo ratings yet

- Anagram Puzzle AnswersDocument1 pageAnagram Puzzle Answerssenthil4youNo ratings yet

- Stick Welding - How To Create High Quality WeldsDocument5 pagesStick Welding - How To Create High Quality Weldssenthil4youNo ratings yet

- Steel Metallurgy MattersDocument4 pagesSteel Metallurgy Matterssenthil4youNo ratings yet

- AISI 1045 Medium Carbon SteelDocument4 pagesAISI 1045 Medium Carbon Steelsenthil4you100% (1)

- Vinnolit 2011 Caustic Soda SolutionDocument5 pagesVinnolit 2011 Caustic Soda SolutiondhallbomNo ratings yet

- SteelDocument4 pagesSteelsenthil4youNo ratings yet

- BP RiskfactorsDocument12 pagesBP RiskfactorsKhayaalNo ratings yet

- AngerDocument28 pagesAngerRohit BediNo ratings yet

- AISI 1045 SteelDocument3 pagesAISI 1045 Steelsenthil4youNo ratings yet

- Estimation of HardnessDocument6 pagesEstimation of HardnessSagar SinghNo ratings yet

- BESTARC The Most Power Efficient ElectrodeDocument1 pageBESTARC The Most Power Efficient Electrodesenthil4youNo ratings yet

- Caustic Sada Flakes MsdsDocument9 pagesCaustic Sada Flakes Msdsapi-263411629No ratings yet

- Estimation of Hardness of Water by Edta Method: Vits Engineering Chemistry Lab ManualDocument37 pagesEstimation of Hardness of Water by Edta Method: Vits Engineering Chemistry Lab ManualNeelam AkhtarNo ratings yet

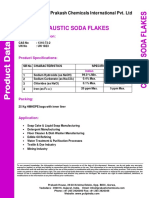

- TDS-CausticSoda 1Document2 pagesTDS-CausticSoda 1senthil4youNo ratings yet

- Dairy 2008Document2 pagesDairy 2008senthil4youNo ratings yet

- 192 Sample-Chapter PDFDocument39 pages192 Sample-Chapter PDFsenthil4youNo ratings yet

- Astm A 515 PDFDocument5 pagesAstm A 515 PDFsenthil4youNo ratings yet

- Hudbay CSR Full PrintableDocument125 pagesHudbay CSR Full PrintableEva Salvador CaldasNo ratings yet

- Factors affecting cement clinker formation and propertiesDocument5 pagesFactors affecting cement clinker formation and propertiesAnGahBasHa100% (1)

- Extrusion Ceramics PDFDocument2 pagesExtrusion Ceramics PDFNealNo ratings yet

- Cathodic Protection PERPRODocument34 pagesCathodic Protection PERPROEkoAndriAntoNo ratings yet

- Shaviv New Catalog 2010Document20 pagesShaviv New Catalog 2010harishkumar.ravichandranNo ratings yet

- Tungsten Oxide Web File PDFDocument2 pagesTungsten Oxide Web File PDFShameekaNo ratings yet

- ElectrolysisDocument32 pagesElectrolysischong5683% (6)

- Astm A747Document4 pagesAstm A747Srinivasan KrishnamoorthyNo ratings yet

- A106 Pipe Spec SheetDocument8 pagesA106 Pipe Spec SheetMostafizur RahmanNo ratings yet

- EN42 Spring Steel SuppliersDocument2 pagesEN42 Spring Steel SuppliersvyankateshNo ratings yet

- BBLB Venetian Glass GlossaryDocument7 pagesBBLB Venetian Glass GlossaryNaadirah JalilahNo ratings yet

- ISRO TENDER NOTICEDocument38 pagesISRO TENDER NOTICEjoydeep_d3232No ratings yet

- SPM Form 4 Chapter 7 Rate of Reaction. NoteDocument60 pagesSPM Form 4 Chapter 7 Rate of Reaction. NoteTIME DIDA滴答75% (4)

- Gold Dore BarsDocument2 pagesGold Dore BarsdaelingNo ratings yet

- Chemtex Speciality Limited Offers Wide Range of Corrosion Inhibitors For Industrial UsageDocument6 pagesChemtex Speciality Limited Offers Wide Range of Corrosion Inhibitors For Industrial UsagesinughoshNo ratings yet

- Elems 13Document101 pagesElems 13Reynald de VeraNo ratings yet

- Virgin PTFE Chemical Compatibility ChartDocument26 pagesVirgin PTFE Chemical Compatibility ChartsachinumaryeNo ratings yet

- Cambridge O Level: CHEMISTRY 5070/22Document20 pagesCambridge O Level: CHEMISTRY 5070/22Islamabad ALMA SchoolNo ratings yet

- Leaching Copper Sulfide OreDocument3 pagesLeaching Copper Sulfide OreJHPNo ratings yet

- 10 Structure and Synthesis of Alcohols WadeDocument52 pages10 Structure and Synthesis of Alcohols Wadebee tamezNo ratings yet

- Quiz 11Document6 pagesQuiz 11Hằng ThanhNo ratings yet

- IonsDocument14 pagesIonsapi-423980580No ratings yet

- Group: 1: Name: Ziad Mohamed Ahmed MohamedDocument6 pagesGroup: 1: Name: Ziad Mohamed Ahmed MohamedziadNo ratings yet

- Quiz-2 Manufacturing Processes (S1-16 - ETZC235)Document6 pagesQuiz-2 Manufacturing Processes (S1-16 - ETZC235)ssanthosh073No ratings yet

- Vitriol in The History of ChemistryDocument9 pagesVitriol in The History of ChemistrySeth Thomas MillerNo ratings yet

- Pressure Vessel Plates, Alloy Steel, Higher Strength Chromium-Molybdenum-TungstenDocument3 pagesPressure Vessel Plates, Alloy Steel, Higher Strength Chromium-Molybdenum-TungstenHoem ITNo ratings yet

- RioTinto Corppub Exploration PDFDocument12 pagesRioTinto Corppub Exploration PDFJoshep Arroyo QuiñonesNo ratings yet

- 1.1 Classification of Composite MaterialsDocument0 pages1.1 Classification of Composite MaterialsPhani GurijalaNo ratings yet

- Guide For M SC Inorganic Chemistry Practicals PDFDocument11 pagesGuide For M SC Inorganic Chemistry Practicals PDFAdil MehboobNo ratings yet

- BCS - SS-CRM 452 - 1 Aug2010Document2 pagesBCS - SS-CRM 452 - 1 Aug2010Ishmael WoolooNo ratings yet