Professional Documents

Culture Documents

WS02 Welding Oxyfuel - MIG

Uploaded by

sherif115040 BueOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WS02 Welding Oxyfuel - MIG

Uploaded by

sherif115040 BueCopyright:

Available Formats

Faculty of Engineering

Mechanical Engineering Department

Semester 2 / 2019-2020

[19MECH04I] Production Technology (3)

Workshop 2

Welding; Oxyfuel Welding & MIG Welding

General Rules and Instructions:

1- Safety First. Follow the rules and regulations imposed by the workshop and the technician in

charge.

2- Do not use any tool unless supervised by one of workshop technicians.

3- Lab coats are mandatory while being in the workshop.

4- Failure to follow these instructions will result in failure in this part of the assessment.

Welding Equipment #1: Oxyfuel (Oxyacetylene welding) Process

A typical oxyacetylene welding operation (OAW).

The objectives for this workshop are to:

1. Provide students the ability to lead/direct the technician during the welding process.

2. Identify Oxyfuel welding and equipment and tools.

3. Select the welding parameters

4. Inspect the quality of the weld and decide whether to accept or reject the welded joint.

Welding Equipment #2: Metal Inert Gas (MIG) welding Process

Page 1 of 2 Prof I ElMahallawi

Faculty of Engineering

Mechanical Engineering Department

Semester 2 / 2019-2020

[19MECH04I] Production Technology (3)

Metal Inert Gas Welding.

The objectives for this workshop are to:

1. Provide students the ability to lead/direct the technician during the welding process.

2. Identify MIG welding and equipment and tools.

3. Select the welding parameters

4. Inspect the quality of the weld and decide whether to accept or reject the welded joint.

Methodology:

In this workshop each student will be assigned thee sets of tensile test specimen in the form of sheet

metal cut to size. Each student will decide based on the samples given, electrodes size, and the welding

machine available his welding parameters to make the tensile test specimen and evaluate the strength of

welded joint.

Report:

Each student will submit a report on this lab including:

1. Complete description of the welding machine, electrodes, and welding parameters selected with

justifications for his selections.

2. Comments on the quality of the welded specimens.

3. Preparation steps for welding, post welding, and tensile testing.

Page 2 of 2 Prof I ElMahallawi

You might also like

- Answers For Nanotechnology Question Bank DIATDocument14 pagesAnswers For Nanotechnology Question Bank DIATAbhishek Shrimali100% (2)

- ASTM C 158 Standard Test Methods For Strength of Glass by Flexure (Determination of Modulus of RuDocument9 pagesASTM C 158 Standard Test Methods For Strength of Glass by Flexure (Determination of Modulus of RuRyan Lasaca100% (1)

- Thermodynamics 1 - Energy Analysis of Closed SystemsDocument26 pagesThermodynamics 1 - Energy Analysis of Closed SystemsFlorasaurus17100% (2)

- Workshop 1 Welding : Arc Welding & Spot WeldingDocument2 pagesWorkshop 1 Welding : Arc Welding & Spot Weldingsherif115040 BueNo ratings yet

- WS03 Machining CNC - Lathe - Process SheetDocument2 pagesWS03 Machining CNC - Lathe - Process Sheetsherif115040 BueNo ratings yet

- Basic Welding GMAW Lab SheetDocument2 pagesBasic Welding GMAW Lab SheetMUHAMMAD AFIQ IQWAN KAMARUL BADRINNo ratings yet

- Advanced Welding Lab Sheet PDFDocument2 pagesAdvanced Welding Lab Sheet PDFnurhazwaniNo ratings yet

- MECH Lab ManualDocument64 pagesMECH Lab ManualDiksha PadiyarNo ratings yet

- Benchwork: Fitting ProcessDocument3 pagesBenchwork: Fitting ProcessJohn WalkerNo ratings yet

- BEM GAP Guideline Info Update 2023 1Document3 pagesBEM GAP Guideline Info Update 2023 1Pritib KumarNo ratings yet

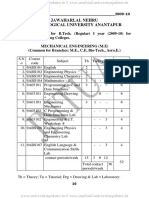

- 591 - Syllabus (4th Sem) Mechanical Engg. Dept.Document22 pages591 - Syllabus (4th Sem) Mechanical Engg. Dept.Rushikesh WakodeNo ratings yet

- 3rd Sem Mechanical EnggDocument22 pages3rd Sem Mechanical EnggTabish SamarNo ratings yet

- DMX3206 - Tma 1Document2 pagesDMX3206 - Tma 1Thushith WithanageNo ratings yet

- Metal Cutting and Production LAB Manual-New (ME452)Document58 pagesMetal Cutting and Production LAB Manual-New (ME452)Ravichandran GNo ratings yet

- Development of An Undergraduate Welding Laboratory For Research and EducationDocument7 pagesDevelopment of An Undergraduate Welding Laboratory For Research and Educationahmed jemalNo ratings yet

- VA - SRT FitterDocument6 pagesVA - SRT FitterjimharoldpaliganNo ratings yet

- 2D Machining Lab Sheet - PLasma Arc Cutting PDFDocument2 pages2D Machining Lab Sheet - PLasma Arc Cutting PDFnurhazwaniNo ratings yet

- 1143 EWF IIW Diploma Overview - August 2013Document2 pages1143 EWF IIW Diploma Overview - August 2013Sean ฌอนNo ratings yet

- A Brief Introduction About The PlaceDocument2 pagesA Brief Introduction About The PlaceMohd FahmiNo ratings yet

- Politeknik Nilai, Negeri Sembilan Jabatan Kejuruteraan MekanikalDocument5 pagesPoliteknik Nilai, Negeri Sembilan Jabatan Kejuruteraan MekanikalDKM3C-F1056-PRAVINESHNo ratings yet

- Engineering Workshop Practice PDFDocument8 pagesEngineering Workshop Practice PDFGeorge Camacho0% (1)

- Workshop & Machineshop Practice Lab Manual: (18MEL38A/48A)Document101 pagesWorkshop & Machineshop Practice Lab Manual: (18MEL38A/48A)MAN MOHAN VATS100% (1)

- MCET226 - Workshop Report - SampleDocument3 pagesMCET226 - Workshop Report - SampleahmedNo ratings yet

- DJF 3012 - Manufacturing Workshop Practice 2Document7 pagesDJF 3012 - Manufacturing Workshop Practice 2Leeahna JkNo ratings yet

- Fabrication TechnologyDocument11 pagesFabrication Technologyhiren mandaliaNo ratings yet

- 3.1welding (Arc Welding) Lab Sheet Mem160 - V1Document5 pages3.1welding (Arc Welding) Lab Sheet Mem160 - V1MUHAMMAD AIMAN MOHD ROZINo ratings yet

- Lab Report Latte - Group 2Document9 pagesLab Report Latte - Group 2engineer.mohammedtahhanNo ratings yet

- EM - Laboratory Manual - 2021Document68 pagesEM - Laboratory Manual - 2021sai tejaNo ratings yet

- Workshop Processes & PracticeDocument8 pagesWorkshop Processes & PracticeGavaine MattisonNo ratings yet

- 18MEL38B, 48B - Foundry, Forging and Welding LabDocument119 pages18MEL38B, 48B - Foundry, Forging and Welding LabNaveen Kumar B JNo ratings yet

- B.tech R09 Mech Engg SyllabusDocument167 pagesB.tech R09 Mech Engg SyllabusSHAIK NOOR AHAMEDNo ratings yet

- Perform Routine Manual Metal Arc Welding: (MEM5.12C)Document27 pagesPerform Routine Manual Metal Arc Welding: (MEM5.12C)umuhuza salomonNo ratings yet

- ProjectDocument41 pagesProjectpratheekiaNo ratings yet

- Robot WeldingDocument6 pagesRobot WeldingAmilin HatiaraNo ratings yet

- NVC InFabrication and WeldingDocument83 pagesNVC InFabrication and WeldingabyzenNo ratings yet

- Module Welding TechnologyDocument5 pagesModule Welding TechnologySurendra SenanayakeNo ratings yet

- MMAW, TIG, MiG ClusterDocument7 pagesMMAW, TIG, MiG ClusterAdriano MendezNo ratings yet

- Mechanical: Workshop Practice Iii & IvDocument21 pagesMechanical: Workshop Practice Iii & Ivlamuye ayobamiNo ratings yet

- 5 6280779123619004524 PDFDocument143 pages5 6280779123619004524 PDFÀràvìñd CháñNo ratings yet

- CP2 Part 3 Plate Welding Practical 2nd Edition July 2015Document20 pagesCP2 Part 3 Plate Welding Practical 2nd Edition July 2015sathishvpNo ratings yet

- BMMP3533 LabSheet WireCutDocument5 pagesBMMP3533 LabSheet WireCutAmilin HatiaraNo ratings yet

- Design and Development of Special Purpose Machine Used For Circular Metal Inert Gas WeldingDocument8 pagesDesign and Development of Special Purpose Machine Used For Circular Metal Inert Gas Weldingwood_ksd3251No ratings yet

- 2019 ECITB Technical Test Catalogue V10Document16 pages2019 ECITB Technical Test Catalogue V10SaikrishnaNo ratings yet

- Automobile Complete SyllabusDocument94 pagesAutomobile Complete SyllabusShiva ShresthaNo ratings yet

- سلامة مهنيةDocument39 pagesسلامة مهنيةMahamed Ahmed SemiaNo ratings yet

- R16 III & IV Years SyllabusDocument133 pagesR16 III & IV Years SyllabusAnonymous 5HYsyrddpNo ratings yet

- University of MumbaiDocument20 pagesUniversity of MumbaitrimohitNo ratings yet

- Competency BSC in Mechanical EngineeringDocument9 pagesCompetency BSC in Mechanical EngineeringAbubeker AreboNo ratings yet

- Chapter 1 Introduction To Mechanical WorkshopDocument10 pagesChapter 1 Introduction To Mechanical WorkshopDipayan DasNo ratings yet

- Template Jawapan 2 Report BengkelDocument12 pagesTemplate Jawapan 2 Report BengkelSyfull musicNo ratings yet

- Aryan - Intership ReportDocument17 pagesAryan - Intership ReportSharana basavaNo ratings yet

- Welding PDFDocument5 pagesWelding PDFg-ipgp23271000No ratings yet

- Workshop Lab ManualDocument38 pagesWorkshop Lab ManualNISHANT GARGNo ratings yet

- Exp 8 PDFDocument3 pagesExp 8 PDFSakline Mostak SwadeshNo ratings yet

- SE To BE Mechanical Engineering CBCGS 2016Document184 pagesSE To BE Mechanical Engineering CBCGS 2016Naresh Gurajarapu ChinnaNo ratings yet

- Plastic Processing Lab Sheet - 3D PrintingDocument2 pagesPlastic Processing Lab Sheet - 3D PrintingAqil AzadNo ratings yet

- Jj303 - Mechanical Workshop Practise 3Document2 pagesJj303 - Mechanical Workshop Practise 3jayadarsini2113No ratings yet

- Lab Manual - MECH3800-2018-2019Document45 pagesLab Manual - MECH3800-2018-2019Sohar AlkindiNo ratings yet

- Production EngineeringDocument39 pagesProduction EngineeringkeepingbusyNo ratings yet

- MGF Lab Manual-IIDocument35 pagesMGF Lab Manual-IIdanielrita570No ratings yet

- Amitwa ReportDocument29 pagesAmitwa ReportshankarNo ratings yet

- Mechanical EngineeringDocument14 pagesMechanical EngineeringSamuel WozabNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Cracks in BuildingsDocument53 pagesCracks in BuildingsAbdisamed Ahmed75% (4)

- Engineering Mechanics of Solids PopovDocument395 pagesEngineering Mechanics of Solids PopovSudarson Karthikeyan36% (11)

- Sources and Remedies of High Freq Piping Vibration N Noise PDFDocument24 pagesSources and Remedies of High Freq Piping Vibration N Noise PDFSmith780512No ratings yet

- Design and Assembly of Hydraulic Power Pack System For Automation ApplicationDocument25 pagesDesign and Assembly of Hydraulic Power Pack System For Automation ApplicationSourav KarthikeyanNo ratings yet

- Promotion Price in December 1-30,2020. HFMEDDocument6 pagesPromotion Price in December 1-30,2020. HFMEDMD SUMON ALI0% (1)

- Punching of Concrete Slabs Without Shear Reinforcement - GuandaliniDocument9 pagesPunching of Concrete Slabs Without Shear Reinforcement - GuandaliniAnonymous YAHRBwSYnNo ratings yet

- The Effect of The Using Waste Marble Dust As FineDocument10 pagesThe Effect of The Using Waste Marble Dust As Finekyle encarnacionNo ratings yet

- Physics Perfect Score Module Form 5Document48 pagesPhysics Perfect Score Module Form 5jemwesleyNo ratings yet

- Super CBL and CBL EXP AdditivesDocument1 pageSuper CBL and CBL EXP AdditivesPither ZuritaNo ratings yet

- BarometerDocument13 pagesBarometerjanr123456No ratings yet

- Condensation HMTDocument22 pagesCondensation HMTbalakalees100% (1)

- SuperconductorsDocument14 pagesSuperconductorsanalysingamaetuerNo ratings yet

- Design and Analysis of Robot Gripper in ANSYSDocument15 pagesDesign and Analysis of Robot Gripper in ANSYSM YashNo ratings yet

- ElectrochemistryDocument90 pagesElectrochemistrydeathfrombelowpykeNo ratings yet

- 10 - Orr - Phase InversionDocument32 pages10 - Orr - Phase InversionSaurab DevanandanNo ratings yet

- 01 GG - 15-16 - 05 - SI - 028 - Excellent Realtor Developers - SPT & CS FinalDocument11 pages01 GG - 15-16 - 05 - SI - 028 - Excellent Realtor Developers - SPT & CS FinalKamal RaoNo ratings yet

- Student Exploration: Doppler Shift: Prior Knowledge Questions (Do These BEFORE Using The GizmoDocument4 pagesStudent Exploration: Doppler Shift: Prior Knowledge Questions (Do These BEFORE Using The GizmoCynta’jah AllisonNo ratings yet

- Chilleres in Wine Production. How To Calculate Fermentation HeatDocument4 pagesChilleres in Wine Production. How To Calculate Fermentation Heatv vNo ratings yet

- Civil EngineeringDocument137 pagesCivil EngineeringnaveenNo ratings yet

- 0625 s14 QP 32Document20 pages0625 s14 QP 32Hadi PrijonoNo ratings yet

- M E LAB 3 Experiment 4 Heat Losses From Pipes 3Document20 pagesM E LAB 3 Experiment 4 Heat Losses From Pipes 3Alister Mae ZafraNo ratings yet

- Atmopheric PressureDocument34 pagesAtmopheric PressureTaufik PamisNo ratings yet

- Ch.6 Shearing Stresses in Beams and Thin-Walled Members 29s - DR - Rafi'-1 Mechanical Engg PDFDocument29 pagesCh.6 Shearing Stresses in Beams and Thin-Walled Members 29s - DR - Rafi'-1 Mechanical Engg PDFHassan W. ZubairNo ratings yet

- 1 2 PressureDocument22 pages1 2 PressuretrojanfrpNo ratings yet

- Carbon Steel ENG 5 ArtikelnrsDocument5 pagesCarbon Steel ENG 5 ArtikelnrsNenadNo ratings yet

- ScrubberDocument68 pagesScrubberPitiporn Hasuankwan100% (1)

- QMKB-Ex-IR5: With High Multiple Digital Electric Zoom Auto Iris Lens, Easy To Monitor The Long-Range TargetDocument3 pagesQMKB-Ex-IR5: With High Multiple Digital Electric Zoom Auto Iris Lens, Easy To Monitor The Long-Range TargetTTB VisionNo ratings yet