Professional Documents

Culture Documents

ISRI Repair Manual 6500

Uploaded by

Mehrdad Ghaffari LalehCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ISRI Repair Manual 6500

Uploaded by

Mehrdad Ghaffari LalehCopyright:

Available Formats

WORKSHOP MANUAL

DRIVER SEATS ISRI

6000/517

6500/517

ISRI 6000/517,6500/517.(EDI.JAN.2000) REV.1

ASIENTOS ESTEBAN

ISRI 6000/517,6500/517

0.- INDEX

0.- INDEX

1.- GENERAL RECOMMENDATIONS 1.1.0

2.- FAILURE LOCALISATION 2.1.0

3.- REPAIR MODULES

Backrest 3.1.0

Cushion 3.1.0

Seat housing 3.1.0

Suspension 3.1.0

Horizontal adjustment 3.1.0

Accordion bellows 3.1.0

Cushion cover/ heating 3.2.0

Backrest heating cover/ elements 3.2.0

Air chambers LS/IPS 3.2.0

Compressor 3.2.0

Backrest bolt mechanism 3.2.0

Reclining height and adjustment handles 3.2.0

Lumbar support valve(LS/IPS) 3.3.0

Pneumatic cushion ISRI 6500 3.3.0

Vertical damper 3.3.0

Valve 3.3.0

Control disc ISRI 6000 3.3.0

Control disc adjustment instructions 3.3.0

Horizontal adjustment closure 3.4.0

Vertical closure/ Knob ISRI 6000 3.4.0

Spring tightener 3.4.0

4.- REPAIR TIMES 4.1.0

ISRI 6000/517,6500/517.(EDI.JAN.2000) REV.1 0.1.0

ASIENTOS ESTEBAN

ISRI 6000/517,6500/517

1.- GENERAL RECOMMENDATIONS

1.- GENERAL RECOMMENDATIONS :

- Remember seat number and series must be specified in spare part orders.

- Seat repairs are to be carried out by qualified personnel.

- The lefthand side seat repair is illustrated in this catalogue, the righthand is repaired in like

manner.

- Replacement of several parts are detailed in the following sections, installations are carried out

exactly opposite.

- Remove compressed air connector prior to changing component control.

- After repairs, pneumatic lines and electric cables are to be assembled and secured as they

were originally.

- Subsequent to each repair, a functional test is done and a leak test is also to be done if there

are pneumatic parts

- Tubes and cables must not be folded.

- Do not stand on seat with backrest reclined .

- Inside more details are offered together with diagrams to carry out changes.

CONNECTION DATA:

OPERATING PRESSURE RANGE: 7-10 bar

COLOUR: Black: compressed air (P hose)

Grey: exhaust air (E hose)

OPERATING PRESSURE RANGE: 7...........10 bar

HEATING: Operating voltage 12V / 24V

Power up ca. 22ºC

Cut off ca. 39ºC

ISRI 6000/517,6500/517.(EDI.JAN.2000) REV.1 1.1.0

ASIENTOS ESTEBAN

ISRI 6000/517,6500/517

2.- FAILURE LOCALISATION

2.- FAILURE LOCATION

FAILURE DESCRIPTION CAUSE SOLUTION

Seat does not rise Leakage in tubes and Change tube or connecter,

connectors and where necessary repair

Air leak:

Neither valve nor actioning Change valve

function

Valve, gas spring or air Change faulty part

tubes have leaks

Seat rises to highest position Gas spring absolutely

full:

Neither valve nor actioning Change valve

function

Exit air tube or connecter Change tube or connecter,

blocked and where necessary repair

Lumbar support does not Entrance air tube or Change air tube or connecter,

function connecter blocked and where necessary repair

LS valve does not function Change LS valve

Deflating noises (LS valve, Change faulty part

tube or connector losses)

Mechanical functioning Foreign body in pulley Clean and grease pulley (note:

mechanism goes hard grease front part only)

Seat rises brusquely Oily damper, check tensor Change damper

and compression force.

Faulty damper Change damper

ISRI 6000/517,6500/517.(EDI.JAN.2000) REV.1 2.1.0

ASIENTOS ESTEBAN

ISRI 6000/517,6500/517

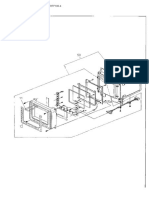

3.- REPAIR MODULES

Backrest

Loosen screws(1).

Fold front seat.

If assembled disconnect electrical and pneumatic line

connectors.

Unhook backrests from side platform.(2).

Cushion (without cushion adjustment)

Unscrew two screws (3) and remove cushion from crossed

housing tube.

Remove connection plugs from electric cables if necessary.

Cushion (With cushion adjustment )

Move cushion to forward position.

Press down on retain spring (5) towards one of the cushion

slide side openings. Likewise press release button (6).

Pull cushion as far forward as possible.

Seat housing

Remove cushion and backrest (see previous sections).

Remove housing bellows.

Loosen nut (8) and (9) (detail X for ISRI 6000).

Disconnect electrical and pneumatic line connectors if

necessary.

Suspension

Remove cushion (as explained above).

Remove bellows underneath the suspension unit housing

(13).

Disconnect electrical and pneumatic lines if necessary.

Loosen nuts (8) and (9) from housing (7).

Dismantle horizontal adjustment.

Horizontal adjustment

Push slides upwards and back (10), remove nuts (11)

(slides Type A for ISRI 1000 must be screwed as in diagram

Y to the metallic housing).

Accordion bellows

Remove vehicle seat.

Remove plugs (12) from seat housing (7) and suspension

system underneath housing (13) , likewise the four clamps

(14) of the crossed housing tube (4).

ISRI 6000/517,6500/517.(EDI.JAN.2000) REV.1 3.1.0

ASIENTOS ESTEBAN

ISRI 6000/517,6500/517

3.- REPAIR MODULES

Cushion covering/ Heating

Remove cushion (see page 3.1.0).

Remove circular loop covering (1) from under the seat.

Carefully remove heating elements (4) from the pad (use

knife to separate if necessary ).

Secure heating elements with double-faced adhesive tape.

Backrest heating covering / Elements

Remove cushion (see page 3.1.0).

Remove backrest section C covering (2) from backrest

structure pushing upwards.

Release clamps (3) from wire inside pad (cutting if

necessary).

Heating elements (5) ( same as for seat cushion) do not

remove covering securing clamps.

Lumbar support air chamber (LS/IPS) / Compressor

LS/IPS

Remove part of backrest covering (same as above but

without clamps(3)).

Disconnect pneumatic lines in connector.

Release backrest pad from housing part.

Release retain clips (1) for LS chamber and retainer plugs if

they exist (2) for the side chambers.

Compressor

Remove part of backrest covering.

(same as above but without clamps (3)).

Remove backrest from structure.

Disconnect pneumatic lines from connector.

Cut electric feed cable from the compressor.

Remove screws (4).

Bolt mechanism for backrest

Remove backrest (see page 3.1.0).

Remove screws (1) for toothed segment (2).

For welded versions, change is conditioned to feasibility

(probably better to contact ISRI service ISRI).

Release cushion (see page 3.1.0).

Release Cir-clip (4).

Release tension spring (15).

For nut versions: loosen nut (6) and remove parts (8), (9),

(10) and (11).

Reclination adjustment and height handles

Remove lever handle (1).

Release housing bellow where lever is located.

Remove slide lever support (3) from seat structure and

unhook tension spring.

ISRI 6000/517,6500/517.(EDI.JAN.2000) REV.1 3.2.0

ASIENTOS ESTEBAN

ISRI 6000/517,6500/517

3.- REPAIR MODULES

Lumbar support valve LS (2 buttons) IPS(3 buttons)

Remove cushion (see page 3.1.0).

Remove cushion adjustment slide, on the valve if

necessary.

Remove housing valve (1) (not always possible without

breaking valve and support.

Unscrew screws (3) until removal and remove support.

Remove hose clamp (5) from tube middle.(PU D= 3 mm)

Warning: This pneumatic tube is continually pressurised

(vehicle air supply).

Disconnect pneumatic lines from valve connectors.

Pneumatic cushion

Release vehicle seat (separate pneumatic lines).

Release cushion (see page 3.1.0).

Safety suspension unit must be in upmost position.

Remove spring from under housing. Release hose nut (3)

and separate tube.

Remove pneumatic cushion angular connector.

Remove pneumatic cushion from suspension.

Do not assemble pneumatic cushion twisted. Loosen screw

(1) a bit.

Release and compress low pressure suspension unit.

Hermetically screw nut (1) while pneumatic cushion is

pressurised.

Vertical damper

Ensure suspension unit in highest part.

Remove cushion (see page 3.1.0).

Valve (1)

Unscrew knobs (2) and separate from tubes.

Loosen two nuts (3) away from the valve (1).

Control disc

Release retainer washer (6).

Warning : Bear in mind adjustment instructions for control

disc installation.

Adjustment instructions for control disc

Remove seat cushion and loosen under front section.

Apply weight to seat and lower it until a distance of 60 mm.

(for vehicle seats) and 70 mm (for bus seats) respectively,

between suspension unit upper (1) and lower (2) structures.

Lower seat a bit more until pressure supply via valve

commences.

Distance travelled to this point must be 18mm below

previous position (60mm /70mm less 18mm).

Otherwise (A) and (B) screw adjustments must be made as

follows:

Tighten screw (A), if lowered more than 18mm.

Loosen screw (A), if less than 18 mm.(One screw turns

equals a height variation of 2 mm.).

Adjust screw (B) to a distance of 12 mm from screw (A).

ISRI 6000/517,6500/517.(EDI.JAN.2000) REV.1 3.3.0

ASIENTOS ESTEBAN

ISRI 6000/517,6500/517

3.- REPAIR MODULES

Closure for horizontal adjustment

Release cushion (see page 3.1.0).

Take height adjustment to highest point.

Remove the 2 retainer washers (1) .

Vertical closure /Knob

Vertical closure

Release cushion (see page 3.1.0) and slightly loosen.

Loosen two nuts (1) and remove closure (2).

Knob

Release cushion (see page 3.1.0) and slightly loosen.

Use a pointer to take bolt (3) from grip (4) (This can be

reached opening knob support ).

Tension spring

Release cushion (see page 3.1.0) and slightly loosen.

Ensure suspension units against drops

Adjust knob to lowest weight.

Release one of the support springs (1) (2) using the

appropriate lever.

Unhook the second spring.

ISRI 6000/517,6500/517.(EDI.JAN.2000) REV.1 3.4.0

ASIENTOS ESTEBAN

ISRI 6000/517, 6500/517

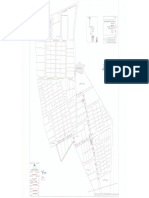

4.- REPAIR TIMES

4.- TABLE OF REPAIR TIMES

TASK DESCRIPTION Item repair time

Nº Operation (Minutes)

1 Change height adjustment valve 30

2 Change level adjustment valve 18

3 Change valve 18

4 Change pneumatic spring 36

5 Change gas spring 36

6 Change vertical trigger 18

7 Change adjustment roller 18

8 Change element O (selective valve) 24

9 Change control disc 24

10 Change Bowden cable 30

11 Change reclining control 18

12 Change height regulation control 18

13 Change backrest control 6

14 Change control 6

15 Change cushion elevation adjustment anchoring 12

16 Change lumbar support 60

17 Change Cousin slide 24

18 Adjust slides 12

19 Change side trim 12

20 Change front trim 12

21 Change bellows 54

22 Change frame 30

23 Change cushion cover 36

24 Change backrest cover 48

25 Change cushion 6

26 Change backrest 18

27 Change cushion heating element 24

28 Change backrest heating element 24

29 Change heating control 18

30 Change three-point belt 30

31 Change belt closure 18

Times shown on table established for workshop repair operations with the seat mounted on the

bus.

Each time refers to a complete dismantling and assembly operation of the part considered

Certain operations include others in their process whose times are also given on the table,

however the total time is not an arithmetic sum of the individual times of the same, since the more

complex ones also require the most basic ones be undergone, therefore the time of some, are

already included in that of others.

ISRP 6000/517, 6500/517 (EDI. JAN. 2000) REV.1 4.1.0

You might also like

- Toyota 4efe - Correa de Distribucion PDFDocument11 pagesToyota 4efe - Correa de Distribucion PDFRonald Gareca RuedaNo ratings yet

- Al-Ko Overrun Hitches - CatálogoDocument51 pagesAl-Ko Overrun Hitches - CatálogoGabrielNunesNo ratings yet

- Balance Shaft DC 9Document12 pagesBalance Shaft DC 9Hari100% (1)

- LR2 2009 3.2LDocument348 pagesLR2 2009 3.2LRamsez Leonel100% (1)

- Peças TL 60e, 75e, 85e, 95eDocument858 pagesPeças TL 60e, 75e, 85e, 95eLinio Calixto De Jesus100% (1)

- BMW 04 - N73 Engine Workbook PDFDocument23 pagesBMW 04 - N73 Engine Workbook PDFkukumarcic100% (1)

- Yam Aha Pipe TuningDocument5 pagesYam Aha Pipe Tuningkartracer100% (6)

- Isri Repair ManualDocument8 pagesIsri Repair ManualPaweł B100% (1)

- Clutch Hino 5.5Document5 pagesClutch Hino 5.5Yeam_90No ratings yet

- FTR 900 Singular Cab y Crew Cab Australia PDFDocument4 pagesFTR 900 Singular Cab y Crew Cab Australia PDFdionymackNo ratings yet

- DTC Check ClearDocument2 pagesDTC Check ClearDaniel Mamani ParedezNo ratings yet

- MAN TGX26.440 6x2Document4 pagesMAN TGX26.440 6x2Abrar Hussain100% (1)

- Volume 2-01 Truck SpecificationDocument2 pagesVolume 2-01 Truck SpecificationnurrahmatNo ratings yet

- Minor Sweeping Machines: Technical Operating and Basic Maintenance InstructionsDocument46 pagesMinor Sweeping Machines: Technical Operating and Basic Maintenance InstructionsBogdan NgrNo ratings yet

- 01 0565 ENG 01 01v31 10 2017Document500 pages01 0565 ENG 01 01v31 10 2017LorenzoNo ratings yet

- Gaz560 Steyr Mo236, 246Document47 pagesGaz560 Steyr Mo236, 246Marinko100% (1)

- Maxus Axle Assembly GuideDocument19 pagesMaxus Axle Assembly GuidepeckerrNo ratings yet

- 16s181 Ahelical TeethaDocument11 pages16s181 Ahelical Teethaعبدالغني القباطي100% (1)

- How Does GM EPS (Electric Power Steering) WorkDocument4 pagesHow Does GM EPS (Electric Power Steering) Workmhulot100% (1)

- Om 401 La Mercedes EngineDocument1 pageOm 401 La Mercedes EngineMessi EmetievNo ratings yet

- New Renault Clio specsDocument2 pagesNew Renault Clio specsValerio ColciagoNo ratings yet

- Hyundai HD78 Wheels and TiresDocument19 pagesHyundai HD78 Wheels and TiresBigfair HD78No ratings yet

- Ar-1000m-1-90101 5 Boom + Jib RTF100-4: PH1 710001 - 00 DisplayDocument2 pagesAr-1000m-1-90101 5 Boom + Jib RTF100-4: PH1 710001 - 00 DisplaySaraiva EquipamentosNo ratings yet

- Mitsubishi DelicaDocument104 pagesMitsubishi DelicaGabriel BalcazarNo ratings yet

- 09e 5 PDFDocument26 pages09e 5 PDFruslan1580No ratings yet

- DAEWOO Ultra Novus Fault Codes EngDocument24 pagesDAEWOO Ultra Novus Fault Codes EngAli SoykanNo ratings yet

- Isuzu D-Max 2011 General Imformation Service ManualDocument28 pagesIsuzu D-Max 2011 General Imformation Service ManualDiego Arias GarciaNo ratings yet

- DVIN0014 M800 Plug-In To WRX 9-10 Installation NotesDocument21 pagesDVIN0014 M800 Plug-In To WRX 9-10 Installation NotesOlga Beaty MasterNo ratings yet

- Code P0705Document6 pagesCode P0705Elton ZotoNo ratings yet

- Great Wall Motors Company LimitedDocument10 pagesGreat Wall Motors Company Limitedsagar pajankarNo ratings yet

- Installation instructions for ZEPRO tail liftsDocument29 pagesInstallation instructions for ZEPRO tail liftsPavel100% (1)

- 0 Park 0 ShuntDocument4 pages0 Park 0 ShuntGligorijević DarkoNo ratings yet

- Index of Sub Assemblies GuideDocument22 pagesIndex of Sub Assemblies GuideJaime ArreolaNo ratings yet

- W201 Wiring Diagram PDFDocument290 pagesW201 Wiring Diagram PDFNadeem MohdNo ratings yet

- 2008 Mazda Tribute OgDocument288 pages2008 Mazda Tribute Ogmconroy42No ratings yet

- EN ET Kat SG WebDocument72 pagesEN ET Kat SG WebVictor HeasNo ratings yet

- Hino Parts Torque Summer 2012 PDFDocument8 pagesHino Parts Torque Summer 2012 PDFWahyu Bayu Aji100% (2)

- ZF - Description of The Fault CodesDocument53 pagesZF - Description of The Fault CodescesarNo ratings yet

- HOWO vehicle diagram 2016Document20 pagesHOWO vehicle diagram 2016Huda KoncrengNo ratings yet

- TelmaDocument8 pagesTelmaEduardo KalbermatterNo ratings yet

- TGS 6x2 DrawbarDocument4 pagesTGS 6x2 DrawbarAbrar HussainNo ratings yet

- Ranger p375 TKD Hb3b-19a321-Ckb Owner Manual Asean EngDocument447 pagesRanger p375 TKD Hb3b-19a321-Ckb Owner Manual Asean EngPaulo Margallo OrtegaNo ratings yet

- Diagnostic Tools and Test Equipment: Product OverviewDocument60 pagesDiagnostic Tools and Test Equipment: Product OverviewserafimasaNo ratings yet

- Hilux PDFDocument6 pagesHilux PDFEuler De Souza Silva CarvalhoNo ratings yet

- Ndsa Ud290wdDocument4 pagesNdsa Ud290wdsknambiarsNo ratings yet

- DAF Truck en b4511Document119 pagesDAF Truck en b4511Ashraf MostafaNo ratings yet

- UntitledDocument162 pagesUntitledjuan manuel lNo ratings yet

- Volvo Diagnostic Report Reveals Lighting and Transmission IssuesDocument3 pagesVolvo Diagnostic Report Reveals Lighting and Transmission IssuesRoni Socompi100% (1)

- PTO TF CustomerDocument3 pagesPTO TF CustomerYose RizalNo ratings yet

- Linde H16DDocument2 pagesLinde H16Dfox mulderNo ratings yet

- Anti Lock Brake System Tata Motors Information PDFDocument16 pagesAnti Lock Brake System Tata Motors Information PDFValBMSNo ratings yet

- 2008 Citroen c3 Pluriel 63711Document129 pages2008 Citroen c3 Pluriel 63711Dan DonciuNo ratings yet

- Eberspacher Heater D5WS Workshop ManualDocument27 pagesEberspacher Heater D5WS Workshop ManualDaniel OstapovichNo ratings yet

- Autocom Trucks CDP+ Release 2020 Fault Codes for MAN TGXDocument8 pagesAutocom Trucks CDP+ Release 2020 Fault Codes for MAN TGXAtochkavNo ratings yet

- 8700 RangeDocument14 pages8700 RangePhilippine Bus Enthusiasts SocietyNo ratings yet

- JLR 13 65 10 - 1E - Defender Puma 60th Anniversary Electric Wiring Diagrams - SupplementDocument24 pagesJLR 13 65 10 - 1E - Defender Puma 60th Anniversary Electric Wiring Diagrams - SupplementRiahi RezegNo ratings yet

- 01EJ3060.PDF Prueba en BancoDocument3 pages01EJ3060.PDF Prueba en BancoAlex PakitoNo ratings yet

- ENMTISRI6800Document26 pagesENMTISRI6800truck somogyiNo ratings yet

- International Harvester Front End Loader Service ManualDocument8 pagesInternational Harvester Front End Loader Service ManualDiegoNo ratings yet

- IP200 Cylinder Positioner Operation ManualDocument8 pagesIP200 Cylinder Positioner Operation Manualeduardo riquelmeNo ratings yet

- Imo-210en 06-11Document8 pagesImo-210en 06-11HASBUL AZIZI BIN MAHMUNNo ratings yet

- MDS-101 Dialysis System Air Separator Replacement GuideDocument60 pagesMDS-101 Dialysis System Air Separator Replacement GuideJHON EDISON Garcia mezaNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument1 pageYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterMehrdad Ghaffari LalehNo ratings yet

- Belt PK InformationDocument2 pagesBelt PK InformationMehrdad Ghaffari LalehNo ratings yet

- IKCO Samand Peugeot405 Pars Suspension FullManualServiceDocument69 pagesIKCO Samand Peugeot405 Pars Suspension FullManualServiceMehrdad Ghaffari LalehNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument38 pagesYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterMehrdad Ghaffari LalehNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument6 pagesYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterMehrdad Ghaffari LalehNo ratings yet

- How to improve communication skills through active listeningDocument13 pagesHow to improve communication skills through active listeningMehrdad Ghaffari LalehNo ratings yet

- Roshanayi ShahrakDocument2 pagesRoshanayi ShahrakMehrdad Ghaffari LalehNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument38 pagesYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterMehrdad Ghaffari LalehNo ratings yet

- 1.4. Geometric CharacteristicsDocument1 page1.4. Geometric CharacteristicsMehrdad Ghaffari LalehNo ratings yet

- 1.5. Conditions of Reception and Fabrication Control 1.5.1. Presentation at ReceptionDocument1 page1.5. Conditions of Reception and Fabrication Control 1.5.1. Presentation at ReceptionMehrdad Ghaffari LalehNo ratings yet

- Track Horn SwitchDocument1 pageTrack Horn SwitchMehrdad Ghaffari LalehNo ratings yet

- Mehrdad Ghaffari Laleh - Insulation Co-OrdinationDocument1 pageMehrdad Ghaffari Laleh - Insulation Co-OrdinationMehrdad Ghaffari LalehNo ratings yet

- Siemens Switch1Document1 pageSiemens Switch1Mehrdad Ghaffari LalehNo ratings yet

- BS EN 50124-2:2001: Railway Applications. Insulation Coordination. Overvoltages and Related ProtectionDocument2 pagesBS EN 50124-2:2001: Railway Applications. Insulation Coordination. Overvoltages and Related ProtectionMehrdad Ghaffari LalehNo ratings yet

- Bir Gzi SevdimDocument1 pageBir Gzi SevdimMehrdad Ghaffari LalehNo ratings yet

- 10 Wartsila 18 V38 BGenerator Overhaul TanzaniaDocument1 page10 Wartsila 18 V38 BGenerator Overhaul Tanzaniaandres cortesNo ratings yet

- C1735 PDFDocument3 pagesC1735 PDFbob loblawNo ratings yet

- Injection Pump Test SpecificationsDocument3 pagesInjection Pump Test Specificationsadmin tigasaudaraNo ratings yet

- CH 14Document6 pagesCH 14Boss S.JNo ratings yet

- The Low-Inertia™ Super 18: Fuller 18-Speed TransmissionsDocument2 pagesThe Low-Inertia™ Super 18: Fuller 18-Speed TransmissionsCesar Cedano Vivar100% (1)

- Spec 5320 468Document105 pagesSpec 5320 4682791957No ratings yet

- Mine Ventilation - Fans and Flow DevicesDocument45 pagesMine Ventilation - Fans and Flow DevicesKudo ShinichiNo ratings yet

- XZ59634000010 Comap Marathon Seri 4000Document70 pagesXZ59634000010 Comap Marathon Seri 4000GiangDoNo ratings yet

- Motores TorqueDocument14 pagesMotores TorqueCARLOS JOSHUE ORTIZ BOLAÑOSNo ratings yet

- Vessel: M/V: KENZ Date: .22/02/2022 SO No. KENZ 1/22Document1 pageVessel: M/V: KENZ Date: .22/02/2022 SO No. KENZ 1/22amr allamNo ratings yet

- I.Manual For FSADocument11 pagesI.Manual For FSAVu DangNo ratings yet

- Man L2832a EngineDocument5 pagesMan L2832a EngineNam Anh TrầnNo ratings yet

- Gas Control Systems and IgnitionDocument44 pagesGas Control Systems and IgnitionRizwanAlamHashmi89% (9)

- Al115c Mio Cylinder PDFDocument2 pagesAl115c Mio Cylinder PDFIwen Tiga BitNo ratings yet

- 3000kVA 3300V 21651382Document6 pages3000kVA 3300V 21651382Farrukh AzharNo ratings yet

- Applied Thermodynamics D201 Self Assessment Solutions Tutorial 5 Self Assessment Exercise No. 1Document4 pagesApplied Thermodynamics D201 Self Assessment Solutions Tutorial 5 Self Assessment Exercise No. 1Alexander MugabeNo ratings yet

- TM 11-3895-209-14 Reeling Machine Cable RL-207 (A) /GDocument107 pagesTM 11-3895-209-14 Reeling Machine Cable RL-207 (A) /GAdvocateNo ratings yet

- Compressors Condition AnalysisDocument50 pagesCompressors Condition AnalysisBrobrt100% (1)

- Codes comparison of hydraulic valves chartDocument2 pagesCodes comparison of hydraulic valves chartAlaa saidNo ratings yet

- Anty Lock Braking SystemDocument23 pagesAnty Lock Braking SystemkishorehuntNo ratings yet

- Functions of The GovernorDocument5 pagesFunctions of The GovernoribnuharyNo ratings yet

- Snist Et Question PaperDocument2 pagesSnist Et Question PaperAzharNo ratings yet

- Electronic Control Module: Ref No Part Number Part Name Req RemarksDocument1 pageElectronic Control Module: Ref No Part Number Part Name Req RemarksBernard ApuritNo ratings yet

- Chain CouplingDocument3 pagesChain CouplingJong JavaNo ratings yet

- Is 14280 1995 PDFDocument18 pagesIs 14280 1995 PDFsimplyneerajNo ratings yet

- Example Results For A J1939 ScanDocument2 pagesExample Results For A J1939 ScanDenia Isalia Santana AnguianoNo ratings yet

- Chang Fa Zs1115g Manual enDocument46 pagesChang Fa Zs1115g Manual enrectificamos100% (1)