Professional Documents

Culture Documents

R3S - Shortcut Crude Oil Distillation: Process Data

R3S - Shortcut Crude Oil Distillation: Process Data

Uploaded by

nico123456789Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R3S - Shortcut Crude Oil Distillation: Process Data

R3S - Shortcut Crude Oil Distillation: Process Data

Uploaded by

nico123456789Copyright:

Available Formats

PRO/II Application Briefs

R3S - Shortcut Crude Oil Distillation

The feed to a refinery often changes every few days. An existing

refinery has received an Indonesian crude oil and you must simulate

the atmospheric distillation column to establish the correct

operating conditions for a throughput of 120,000 barrels/day.

Process Data

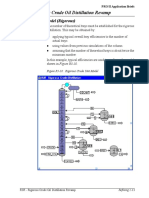

The crude unit configuration and typical operating data are shown

in Figure R3-1. This simulation uses the stripping stream and

pumparound cooling shown in Figure R3-1.

Figure R3-1: Crude Oil Distillation

R3S - Shortcut Crude Oil Distillation Refining 2-1

PRO/II Application Briefs

The products must meet the specified D86 and TBP points in Table

R3-1, and the yields are to be calculated.

Table R3-1: ASTM D86 (F)

LV% Naptha Kerosene Diesel Gas Oil Topped Crude

0 - 301 446 490 652

5 79 379 516 625 738

95 340 520 665 843 1438

100 376 565 669 889 1464

The crude oil has been analysed as an atmospheric TBP curve and

defined lightend components as shown in Table R3-2.

Table R3-2: Crude Oil Data

TBP at 7600 mmHg Lightends

LV% Temp (F) LV% Temp (F) Components LV%

3 98 50 690 Ethane 0.1

5 149 60 770 Propane 0.2

10 208 70 865 i-Butane 0.3

20 330 80 980 n-Butane 0.7

30 459 100 1600 i-Pentane 0.5

40 590 n-Pentane 1.2

Average API 29.2 Total 3.0

Gravity

The laboratory data for the TBP curve are supplied only up to the

80% point. A typical value is assumed for the 100% point to assist

the extrapolation of the curve.

Methods and Data

The GS thermodynamic system is recommended for calculating

K-values and enthalpies in crude and vacuum systems. The BK10

system may also be used, but it tends to predict slightly less

vaporization. Column temperatures can generally be matched with

either system.

Accurate characterization of the crude oil is vital for good

simulation results. The greatest errors often appear in the residue

stream and can lead to poor results when simulating the

2-2 Refining R3S - Shortcut Crude Oil Distillation

PRO/II Application Briefs

downstream vacuum column. The characterization may be

improved by supplying gravity and molecular weight curves if they

are available.

The program automatically generates a number of petroleum

fractions and calculates the molecular weight, gravity, and boiling

point for each. These are then used in standard petroleum

correlations to generate all the other required properties.

The TBP curve must be matched to the lightends data to produce a

smooth curve. To assist this, the boiling point (97 F) of the

n-pentane is input as an additional 3.0% point at the front of the

curve.

Viscosity and thermal conductivity data are generated for the

streams for use in other calculations. The API Data Book method is

selected for the liquid viscosities. For crude oil streams, these data

are more accurate than the ©PETROª option used for the other

transport properties.

Simulation Model

The first step in the simulation is to ensure that it is possible to

produce the specified products from the crude oil feed and establish

the material balance. The multidraw shortcut distillation model

(MODEL = REFINE) is a quick and easy tool for these

calculations. This model uses the Fenske calculation method and

considers the column to be a series of two-product columns as

shown in Figure R3-2. The condenser is simulated with an external

flash drum.

The specifications chosen for the shortcut model define the

separation in each section. For this simulation, the 95% distillation

points and 5-95% gaps are used. The data are taken from Table R3-

1.

Five percent and 95% points should always be used instead of

initial and end points, as they are generally more accurate. The

simulated end points are affected by the number of petroleum cuts,

the parameter TBPEP (on the ASSAY statement in Component

Data) which defaults to 98%, and the Fenske model itself, which

tends to overfractionate on the product tails. In addition, the

shortcut simulation ignores the sidestrippers, which also affect the

ends of the curves.

R3S - Shortcut Crude Oil Distillation Refining 2-3

PRO/II Application Briefs

As crude oil has no defined components, the component flowrate

output is suppressed, and only the stream summary is printed. The

PRINT TBP option gives the TBP and ASTM curves for all

hydrocarbon streams.

It is not known whether or not there will be any vapor product from

the column. As there may be vapor, the condenser is defined as

mixed phase at the defined temperature.

The MODEL=REFINE option specifies no reflux between sections in

the column. The default would assume total reflux between the

sections. The product rate estimates are supplied as volume percent

cutpoints on the crude oil feed.

Figure R3-2: Shortcut Crude Unit Model

2-4 Refining R3S - Shortcut Crude Oil Distillation

PRO/II Application Briefs

In the shortcut model, the stripping steam is added with the feed.

The main effect of this on the simulation results is that the influence

of the steam on the product temperatures is not modeled, and the

calculated temperatures will be high.

Input Data

The shortcut crude unit model uses default English units of

measure, except for liquid volume where API barrels is specified

instead of cubic feet. Click on the UOM button to make this

change.

Click on the Component to enter the component slate. Note

the pseudocomponents shown in Figure R3-3 initially are not

present. They will be generated after the stream assay data are

supplied.

Figure R3-3: Component Selection After Pseudocomponent Generation

Click the Thermodynamics button to select the Grayson-

Streed thermodynamic system of method. Proceed to the Modify

Data button to cross check the default settings of K-values and

enthalpy methods shown in Figure R3-4.

R3S - Shortcut Crude Oil Distillation Refining 2-5

PRO/II Application Briefs

Figure R3-4: Thermodynamic Methods

Lay down a shortcut column onto the PFD. A dialog pops up

requesting whether you want a condenser (yes) or reboiler (yes).

Connect the column to a feed stream.

To enter the stream data (crude oil), lay down a stream on the PFD

and connect it to the column. Double-click on the stream, select

Petroleum Assay from the list box and click on the Flowrate and

Assay button.

Enter the flowrate of 5,000 bbl/day. Then click on Define/Edit

Assay to enter the assay data. TBP distillation data, API gravity

data and lightends data from Table R3-2 are entered as illustrated in

Figure R3-5.

2-6 Refining R3S - Shortcut Crude Oil Distillation

PRO/II Application Briefs

Figure R3-5: Assay Definition

Click the Lightends button to enter the assay lightends data.

After completing that dialog box, click OK to return to the PFD. A

dialog box pops up to inform you that the assay components have

been generated.

Figure R3-6: Message After Generating Pseudocomponents

By returning to the Components Selection dialog, it is possible to

verify the component slate now includes the pseudo-components,

as shown in Table R3-3. The component slate now is complete.

R3S - Shortcut Crude Oil Distillation Refining 2-7

PRO/II Application Briefs

Double-click the shortcut column icon to open the main Data Entry

Window for the shortcut column shown in Figure R3-7

Figure R3-7: Shortcut Column Main

Click the Condenser/Reboiler button to enter data for the

condenser. Because vapor may be present in the product, select

Mixed as the condenser type. As shown in Figure R3-8, set the

operating temperature at 110 F. Click OK to return to the main

shortcut DEW.

Figure R3-8: Shortcut Column Condenser/Reboiler

Click the Specifications button on the shortcut icon to enter the

product specifications that define the separation in each

2-8 Refining R3S - Shortcut Crude Oil Distillation

PRO/II Application Briefs

section. In this example, 95% distillation points and 5%-95%

gaps are used. Figure R3-9 illustrates one of the data entry

windows for specification number 2.

Figure R3-9: Shortcut Column Performance Specifications

Click the Fenske Estimates button and enter the estimated

Fenske Index for each product section. Table R3-3 lists the

estimates used in this example.

Table R3-3: Fenske Index Estimates

Section Index Estimate

1 2.00

2 3.00

3 2.00

4 2.00

Click the Products button and enter the product rate estimates

and set the phases and pressure of the product streams.

The keyword input listing that follows contains all the data used in

this example.

R3S - Shortcut Crude Oil Distillation Refining 2-9

PRO/II Application Briefs

Keyword Input File

TITLE PROJECT=APPBRIEF, PROBLEM=R3S

PRINT INPUT=ALL, STREAM=SUMMARY, TBP

DIMENSION ENGLISH, PRES=PSIG, LIQVOL=BBL

COMPONENT DATA

LIBID 1,H2O/ 2,C2/ 3,C3/ 4,IC4/ 5,NC4/ 6,IC5/ 7,NC5 &

BANK = SIMSCI, PROCESS

ASSAY CURVEFIT = IMPR, CONVERSION = API94

CUTPOINTS TBPCUTS=100,800.001,70/1200,20/1600,8,DEFAULT

THERMODYNAMIC DATA

METHOD SYSTEM=GS, VISCOSITY(L)=API, VISCOSITY(V)=PETR, &

CONDUCTIVITY(L)=PETR, CONDUCTIVITY(V)=PETR, SET=GS01

STREAM DATA

PROPERTY STREAM=CRUDE, TEMPERATURE=450, PRESSURE=14, &

PHASE=M, RATE(LV)=4999.99, ASSAY=LV

TBP STREAM=CRUDE, TEMPERATURE=F, PRESSURE(MMHG)=760 &

DATA= 3,97 / 5,149/ 10,208/ 20,330/ 30,459/ &

40,590/ 50,690/ 60,770/ 70,865/ 80,980/ &

100,1600

API STREAM=CRUDE, AVERAGE=29.2

LIGHTEND STREAM=CRUDE, PERCENT(LV)=3, NORMALIZE, &

COMP(LV)=2,0.1/3,0.2/4,0.3/ 5,0.7/ 6,0.5/7,1.2

PROPERTY STREAM=STEAM, TEMPERATURE=600, PRESSURE=60, &

PHASE=M, COMPOSITION(WT,LB/H)=1,20000

NAME CRUDE,CRUDE FEED/ NAPH,NAPHTHA/ KERO,KEROSENE/ &

DIES,DIESEL/ GASOIL,GAS OIL/ TOPPED,TOPPED CRUDE

UNIT OPERATIONS

SHORTCUT UID=SC01, NAME=CRUDE TOWER

FEED CRUDE,STEAM

PROD STREAM=OVER, CUTPOINT(LV)=25, PHASE=M, PRESS=8.4999

PROD STREAM=KERO, CUTPOINT(LV)=40, PHASE=L, PRESS=11.8

PROD STREAM=DIES, CUTPOINT(LV)=55, PHASE=L, PRESS=12.5

PROD STREAM=GASOIL, CUTPOINT(LV)=75, PHASE=L, PRESS=13.3

PROD STREAM=TOPPED, PHASE=L, PRESSURE=14.4

CONDENSER TYPE=MIX, TEMPERATURE=110

EVALUATE MODEL=REFINE, TRIAL=50

FINDEX 2,3,2,2

SPEC STREAM=OVER, D86(95,F), VALUE=340

SPEC STREAM=KERO, D86(5,F), MINUS, STREAM=OVER, &

D86(95,F), VALUE=40

SPEC STREAM=KERO, D86(95,F), VALUE=520

SPEC STREAM=DIES, D86(5,F), MINUS, STREAM=KERO, &

D86(95,F), VALUE=10

SPEC STREAM=DIES, D86(95,F), VALUE=665

2-10 Refining R3S - Shortcut Crude Oil Distillation

PRO/II Application Briefs

SPEC STREAM=GASOIL, D86(5,F), MINUS, STREAM=DIES, &

D86(95,F), VALUE=-30

SPEC STREAM=GASOIL, TBP(95,F,VOL), VALUE=885

SPEC STREAM=TOPPED, TBP(5,F,VOL), VALUE=695

FLASH UID=FL01, NAME=CONDENSER

FEED OVER

PRODUCT V=OFF_GAS, L=NAPH, W=DECANT

ISO TEMPERATURE=110, PRESSURE=5.3

END

Output

The shortcut column results are shown on the next page. The

shortcut model predicts the minimum number of trays, calculated at

total reflux, needed to meet the specified separations. Typical

values for crude oil separations for each column section are shown

in Table R3-4.

Table R3-4: Typical Shortcut Trays

Column Section Index Estimate

Naphtha - Kerosene 3.5 - 5.0

Kerosene - Diesel 2.5 - 3.5

Diesel - Gas Oil 2.0 - 3.0

Gas Oil - Topped Crude 1.3 - 1.8

As long as the shortcut model reports figures within these ranges,

the separations will be feasible. Significant departures from these

values mean a difficult, if not impossible, separation.

The simulation predicted no overhead vapor at the desired

condenser conditions. This is not unusual for crude unit simulations

because some lightends may have been lost in sampling the crude

oil, or because lightends produced by cracking in the furnace are

not included in the simulation model.

Once the shortcut model is solved, the material balance is defined.

If difficulties occur solving the rigorous model, then the heat

balance is likely to be at fault.

The shortcut column profiles can be obtained by clicking on the

Generate Report button, which generates the entire flowsheet

report, or by selecting the column and clicking View Results, which

will generate a table of results for just the column.

R3S - Shortcut Crude Oil Distillation Refining 2-11

PRO/II Application Briefs

Shortcut Column Output

UNIT 1, 'SC01', 'CRUDE TOWER'

FEEDS

STREAM PHASE

------------ ------

CRUDE MIXED

STEAM VAPOR

PRODUCTS

------------- TOTAL STREAM RATES -------------

MOLES WEIGHT LIQUID VOL NORM VAPOR(1) NUM

STREAM + PHASE LB-MOL/HR LB/HR BBL/HR FT3/HR SECTION TRAYS

------------ - ---------- ---------- ---------- ---------- ------- -----

OVER M 2950.52 291750.51 1131.76 1119672.59 1 3.25

(FREE WATER) W 1106.44 19932.76 56.92 419874.17

KERO L 1006.35 181138.51 627.01 381894.69 2 3.10

DIES L 591.52 152295.47 499.80 224472.19 3 2.37

GASOIL L 687.83 230044.41 725.82 261019.00 4 1.33

TOPPED L 1317.16 686460.01 2015.80 499840.66

TOTALS 7659.82 1561621.67 5057.11 2906773.30 10.05

SPECIFICATIONS

PARAMETER COMP. SPECIFICATION SPECIFIED CALCULATED

TYPE NUM TYPE VALUE VALUE

----------------- ------- ------------- ---------- ----------

STRM OVER D86 95 PCT 3.400E+02 3.400E+02

STRM KERO D86 5 PCT 4.000E+01 4.000E+01

STRM KERO D86 95 PCT 5.200E+02 5.200E+02

STRM DIES D86 5 PCT 1.000E+01 9.997E+00

STRM DIES D86 95 PCT 6.650E+02 6.650E+02

STRM GASOIL D86 5 PCT -3.000E+01 -3.001E+01

STRM GASOIL TBP 95 PCT 8.850E+02 8.850E+02

STRM TOPPED TBP 5 PCT 6.950E+02 6.950E+02

(1) STANDARD VAPOR VOLUME IS 379.49 FT3/LB-MOLE (60 F AND 14.696 PSIA)

2-12 Refining R3S - Shortcut Crude Oil Distillation

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- BSI Standards Publication Carbon Dioxide Capture - Carbon Dioxide Capture Systems, Technologies and Processes - 2016 PDFDocument234 pagesBSI Standards Publication Carbon Dioxide Capture - Carbon Dioxide Capture Systems, Technologies and Processes - 2016 PDFToàn Thắng Vũ100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- DSTWU - A Shortcut Distillation Model in Aspen Plus® V8.0: 1. Lesson ObjectivesDocument39 pagesDSTWU - A Shortcut Distillation Model in Aspen Plus® V8.0: 1. Lesson Objectivesnico123456789No ratings yet

- Reference List - Haldor Topsoe Steam Reformer AssessmentOptimizationDocument2 pagesReference List - Haldor Topsoe Steam Reformer AssessmentOptimizationFaizan AhmedNo ratings yet

- FlexiROC T20 RDocument5 pagesFlexiROC T20 Rfabian castroNo ratings yet

- D7GDocument8 pagesD7Gfirman manaluNo ratings yet

- Problema 2.3.1 PDFDocument3 pagesProblema 2.3.1 PDFnico123456789No ratings yet

- Problema 3.3.1Document3 pagesProblema 3.3.1nico123456789No ratings yet

- Figure R4-1: Vacuum Column FlowsheetDocument18 pagesFigure R4-1: Vacuum Column Flowsheetnico123456789No ratings yet

- R6 - Sour Water Stripper: Process DataDocument8 pagesR6 - Sour Water Stripper: Process Datanico123456789No ratings yet

- R3R - Rigorous Crude Oil Distillation RevampDocument20 pagesR3R - Rigorous Crude Oil Distillation Revampnico123456789No ratings yet

- Basic Input: Introduction To Aspen PlusDocument27 pagesBasic Input: Introduction To Aspen Plusnico123456789No ratings yet

- R5 - FCC Main Fractionator: Process DataDocument24 pagesR5 - FCC Main Fractionator: Process Datanico123456789No ratings yet

- Cyclohexane Production Workshop: Introduction To Aspen PlusDocument2 pagesCyclohexane Production Workshop: Introduction To Aspen Plusnico123456789No ratings yet

- A2 - Phenol Distillation: Process DataDocument12 pagesA2 - Phenol Distillation: Process Datanico123456789No ratings yet

- Reactor Models: Introduction To Aspen PlusDocument8 pagesReactor Models: Introduction To Aspen Plusnico123456789No ratings yet

- Rigorous Heat Exchanger: Schematic OfaDocument5 pagesRigorous Heat Exchanger: Schematic Ofanico123456789No ratings yet

- Process Advancement in Chemistry and Chemical Engineering Research (2015) PDFDocument378 pagesProcess Advancement in Chemistry and Chemical Engineering Research (2015) PDFnico123456789No ratings yet

- Manual VERONA RS PDFDocument36 pagesManual VERONA RS PDFjulioNo ratings yet

- Magnet Field Phenomenon PDFDocument97 pagesMagnet Field Phenomenon PDFMeenakshi ParimiNo ratings yet

- Marine Engine Programme 2024Document252 pagesMarine Engine Programme 2024bpidkhhNo ratings yet

- HEBT-5V - Manual de Serviço (En) (2017.07)Document82 pagesHEBT-5V - Manual de Serviço (En) (2017.07)Thiago AzevedoNo ratings yet

- 01 1SCA022845R8960-otm200e3cm230c-motorized-c-o-switch PDFDocument2 pages01 1SCA022845R8960-otm200e3cm230c-motorized-c-o-switch PDFNguyen AnhNo ratings yet

- Apicultura Sin FronterasDocument26 pagesApicultura Sin FronterasAvicultura AgrotecnicoNo ratings yet

- LED2Document2 pagesLED2api-19807868No ratings yet

- Möller - Elecrostatic Precipitator - Multi-TTSDocument4 pagesMöller - Elecrostatic Precipitator - Multi-TTSAhmad NilNo ratings yet

- Lecture 1 P4 Reverse Breakdown and Zener DIode - Other DiodesDocument14 pagesLecture 1 P4 Reverse Breakdown and Zener DIode - Other DiodesPhạm Minh KhôiNo ratings yet

- Leroy Somer R438Document16 pagesLeroy Somer R438Nasredine AlainNo ratings yet

- DLN IntructionDocument20 pagesDLN IntructionThanapaet Rittirut100% (2)

- Chipping HammerDocument4 pagesChipping HammerDwi Agung AriyonoNo ratings yet

- Low Skew 1 To 4 Clock Buffer: DatasheetDocument7 pagesLow Skew 1 To 4 Clock Buffer: DatasheetnevdullNo ratings yet

- Electrical Engineering (HVDC Transmission)Document13 pagesElectrical Engineering (HVDC Transmission)Prithwiraj BhowmikNo ratings yet

- Schrodinger Test QuestionsDocument3 pagesSchrodinger Test QuestionsCasonNo ratings yet

- 67 Directional Phase Over Current RelayDocument12 pages67 Directional Phase Over Current RelayYPV TECHNICAL SERVICESNo ratings yet

- Standard Green Office in Thailand - Journal (Terjemah Bebas)Document13 pagesStandard Green Office in Thailand - Journal (Terjemah Bebas)David DeagerNo ratings yet

- Atomic Electronic StatesDocument26 pagesAtomic Electronic Stateskamui74No ratings yet

- Effect of Parallel Misalignment in Rotating MachineryDocument3 pagesEffect of Parallel Misalignment in Rotating MachineryresearchparksNo ratings yet

- As Above So Below AcupunctureDocument5 pagesAs Above So Below AcupunctureDarren StarwynnNo ratings yet

- SrS60, ELITE, TARGET & LIIT - Jee-Main-GTM-22 - KEY & Sol'S - 220610 - 133348Document14 pagesSrS60, ELITE, TARGET & LIIT - Jee-Main-GTM-22 - KEY & Sol'S - 220610 - 133348ksvvslan raju kNo ratings yet

- Utility-Bill - OCTOBERDocument4 pagesUtility-Bill - OCTOBEREAZY CHARNo ratings yet

- KoteshwarDocument43 pagesKoteshwaranandhakrishnanr2800No ratings yet

- Inspection Procedure 21 Fuel Pump SystemDocument9 pagesInspection Procedure 21 Fuel Pump SystemMortada AlsonniNo ratings yet

- LAB IV-EXP 2 - Brief DepressurizationDocument3 pagesLAB IV-EXP 2 - Brief DepressurizationJageshwaranNo ratings yet

- LBS CatalogDocument16 pagesLBS CatalogMuhammad Fadly IshakNo ratings yet