100% found this document useful (1 vote)

541 views9 pagesHazard Analysis Critical Control Point

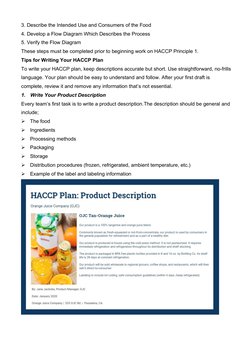

HACCP (Hazard Analysis Critical Control Point) is a systematic approach to identify, evaluate, and control food safety hazards. It focuses on prevention rather than post-production inspection. The document discusses the 7 principles of HACCP - conducting a hazard analysis, identifying critical control points, establishing critical limits, monitoring procedures, corrective actions, verification procedures, and record-keeping. It provides tips for developing an effective HACCP plan including describing the product and process flow diagram.

Uploaded by

judezaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

541 views9 pagesHazard Analysis Critical Control Point

HACCP (Hazard Analysis Critical Control Point) is a systematic approach to identify, evaluate, and control food safety hazards. It focuses on prevention rather than post-production inspection. The document discusses the 7 principles of HACCP - conducting a hazard analysis, identifying critical control points, establishing critical limits, monitoring procedures, corrective actions, verification procedures, and record-keeping. It provides tips for developing an effective HACCP plan including describing the product and process flow diagram.

Uploaded by

judezaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd