Professional Documents

Culture Documents

Checklist For Risk Assessment in Construction Sector

Uploaded by

IndreTankeliaviciute0 ratings0% found this document useful (0 votes)

42 views3 pagesRISK ASSESSMENT CHECKLIST FOR CONSTRUCTION SECTOR

Original Title

Checklist for Risk Assessment in Construction Sector

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRISK ASSESSMENT CHECKLIST FOR CONSTRUCTION SECTOR

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

42 views3 pagesChecklist For Risk Assessment in Construction Sector

Uploaded by

IndreTankeliaviciuteRISK ASSESSMENT CHECKLIST FOR CONSTRUCTION SECTOR

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Project Name: Project Location:

Inspected By : Date:

RISK ASSESSMENT CHECKLIST FOR CONSTRUCTION

SECTOR

WALKWAYS, ACCESS ROUTES, STAIRS AND LADDERS Yes No

Ladders in good condition, used only for temporary access, or for short-

1. term light work with one hand

Handrails and mid rails to prevent fall of persons when falling distance is

2. more than 0,5 m.

3. Wide enough

4. Free off obstacles, not slippery

5. No openings or cracks, which may cause falling

6. Proper roofing in entrance of the building to stop falling objects

SCAFFOLDING, TEMPORARY PLATFORMS AND WORK STANDS Yes No

1. Erected properly, and inspected before use

2. Proper handrails, mid rails and toe-boards

3. Safe access route to work platform (ladders or stairs)

4. Working platform wide enough, free off obstacles, not slippery no

openings or cracks, which may cause falling

5. Fixed scaffolding: Footings, anchoring and reinforcement are proper

6. Movable scaffolding : Lockable wheels, inner ladders

7. Hanging scaffolding: Fixed not to move right or left, report to determine

maximum load capacity, checked daily

PROTECTION AGAINST FALLING AND COLLAPSING Yes No

1. Open sides of floors, elevator openings etc. protected with triple-part side

protection; handrail, mid rail, and toe board.

2. Areas without railings separated off with proper barriers

3. Openings on floor, covered with firm and marked covers

4. Excavations protected against collapsing, when necessary.

5. Excavation separated with proper barriers or railings

ELECTRICITY AND LIGHTING

1. Distribution of site electricity planned properly

2. Distribution boards and cables in good condition (Appropriately located

and protected)

3. Artificial lighting is adequate for safety and quality

ORDER AND TIDINESS

1. Waste disposal management planned properly

2. Proper waste containers for different types of waste exist

3. Waste containers are emptied periodically

4. Wastes roughly cleaned up after each work stage

5. Materials are stored properly

6. Traffic routes and walk ways are clearly indicated

MACHINERY AND EQUIPMENT Yes No

1. In proper condition and clean

2. Safety devices are in place

3. Electric wires undamaged

4. Proper for construction environment

5. The area around the machines in good order

6. Proper footing and support

7. Statutory inspections are completed

8. Maximum load capacity indicated (cranes and lifting devices)

9. Qualified operators (cranes and lifting devices)

FIRE SAFETY Yes No

1. No extra burnable materials on floors or on ground

2. Proper fire extinguishers available at marked places

3. Smoking is not allowed on places with combustible materials

4. Electric distribution boxes (boards) and wires in good condition

5. Lighting devices proper for site conditions and properly located.

6. Hot works (welding, grinding, etc.) conducted in special hot work areas, or

under a special work permit

6a Flammable and combustible materials and dust near of hot work removed

or protected

6b. Any openings or cracks in the walls, floors covered or protected.

6c. Fire extinguisher of the proper type and size available

6d. Workers properly trained

6e. A Fire Watch has been posted, when necessary

7. Emergency exits are properly marked and clear

PHYSICAL HAZARDS Yes No

1. Employees use proper hearing protectors when the noise level is more than

85 dB(A)

2. Audiometric tests are done according to the regulations

3. Hand vibration has avoided by choosing less vibrating work methods and

tools, when possible.

3a. Tools are maintained properly.

3b. Exposure time of the worker is limited, and the workers are informed about

the long term health risks of the hand vibration.

3c. Health surveillance is organized for exposed workers

4. The controls of exposures to other physical hazards, like radiation, high or

low temperature etc. meet the safety regulations and standards.

CHEMICAL HAZARDS

1. Processes that pollute the air equipped with local exhaust ventilation

2. Employees wear respirators

3. Less hazardous substances in use when possible

4. Material safety data sheets available

5. Exposure monitored by occupational health service, when necessary

6. Work in confined spaces conducted under a special work permit

6a Atmosphere tested before entering, cleaned and ventilated when necessary

(oxygen, flammable or toxic gases/fumes)

6b. Isolation is done properly, when necessary to prevent dangerous materials

entering to the place while working

6c. Atmosphere is monitored during the work, when necessary

6d. Workers are trained to work safely

6e. Standby person outside and proper means of rescue, when necessary

MUSCULOSKELETAL STRAIN FACTORS Yes No

1. Manual lifting and carrying materials avoided by proper planning the site

layout and work processes

2. Proper tools and machines used for lifting and moving materials (carts,

lifters, elevators, tele handlers, cranes, mobile elevating work platforms

etc.)

3. Health surveillance organized for exposed workers

PSYCHOSOCIAL STRESS FACTORS Yes No

1. Insulting treatment and discrimination not accepted

e.g. name-calling based on sex, race or personal characters, sexual

harassment

2. Employees instructed properly for right working methods

3. Employees are informed of changes that concern them or their work

4. Employees have given a chance to express their opinions and ideas of their

work and improvements in health and safety

5. Employees receive regular feedback on their success

6. Supervisors give support when problems arise

7. Supervisors act fairly

FIRST AID AND EMERGENCY PREPAREDNESS Yes No

1. Proper first-aid equipment available

2. Trained employees to give first-aid available

3. Actions in a fire or other emergency scenes planned, instructed and

rehearsed

WELFARE FACILITIES Yes No

1. Proper facilities for employees to change cloths, wash, eat, and rest

available.

2. Cleaned daily

Source: İSGİP Project Documents

You might also like

- Lathe Wood SopDocument1 pageLathe Wood SopLucas BienertNo ratings yet

- Fes TBT Housekeeping PDFDocument1 pageFes TBT Housekeeping PDFsalem enwaijiNo ratings yet

- SS 616-2016 - PreviewDocument10 pagesSS 616-2016 - PreviewMagenNo ratings yet

- Safety in the Chemical Laboratory and Industry: A Practical GuideFrom EverandSafety in the Chemical Laboratory and Industry: A Practical GuideNo ratings yet

- TBT 30 HousekeepingDocument2 pagesTBT 30 HousekeepingfrancisNo ratings yet

- Sample SWMS SP003 - Margate Parade Boardwalk Concrete WorkDocument10 pagesSample SWMS SP003 - Margate Parade Boardwalk Concrete WorkadiNo ratings yet

- Plant HazrdDocument3 pagesPlant Hazrdayuzme123No ratings yet

- Ohs Legal - Ohsa Act 1994Document1 pageOhs Legal - Ohsa Act 1994Nurul HidayahNo ratings yet

- Safety Inspection Course (With Workshop)Document86 pagesSafety Inspection Course (With Workshop)YeddaMIlaganNo ratings yet

- Emami Infrastructure Limited: Safety Inspection ReportDocument1 pageEmami Infrastructure Limited: Safety Inspection ReportvarunstuffNo ratings yet

- PPE ProgramDocument8 pagesPPE ProgramAldrin BanaayNo ratings yet

- Use of Personal Protective Equipments: Manoj Kr. Ray SM (F&S)Document33 pagesUse of Personal Protective Equipments: Manoj Kr. Ray SM (F&S)mujeebtalibNo ratings yet

- Safety Management - PDFDocument43 pagesSafety Management - PDFMansi PatelNo ratings yet

- Lifting SafetyDocument1 pageLifting SafetyAaquil RaziNo ratings yet

- Safety Flash - FlagmanDocument1 pageSafety Flash - FlagmanarslanahmedkhawajaNo ratings yet

- Risk Assessment PDE HS PoliciesDocument21 pagesRisk Assessment PDE HS PoliciesVuong BuiNo ratings yet

- Intel Construction EHS: Processes and Procedures ManualDocument116 pagesIntel Construction EHS: Processes and Procedures ManualbasshotNo ratings yet

- TBT Manual HandlingDocument1 pageTBT Manual HandlingNishadh NishNo ratings yet

- Safe Working PracticesDocument7 pagesSafe Working PracticesDiana ParkerNo ratings yet

- RA For Nitoflor FC150Document4 pagesRA For Nitoflor FC150kkhafajiNo ratings yet

- (Alex) Explosive Safety (Instructor)Document40 pages(Alex) Explosive Safety (Instructor)Lolita Mamore-gandiaNo ratings yet

- Welding Safety: Lesson 1Document9 pagesWelding Safety: Lesson 1cyrelle rose jumentoNo ratings yet

- Constructionsafetymanagement 150817114845 Lva1 App6892Document67 pagesConstructionsafetymanagement 150817114845 Lva1 App6892Oliver DimailigNo ratings yet

- Company Name: Sacffold Location Completed By: Date: TimeDocument1 pageCompany Name: Sacffold Location Completed By: Date: Timesadashiv puneNo ratings yet

- SAFETY CAMPAIGN-30 Tips For Hand and Power Tool SafetyDocument2 pagesSAFETY CAMPAIGN-30 Tips For Hand and Power Tool SafetyRomaine MillerNo ratings yet

- Crane Safety Tool Box TalkDocument2 pagesCrane Safety Tool Box Talksathees4329No ratings yet

- Health and Safety-ProficiencyDocument79 pagesHealth and Safety-ProficiencySHEM AGBETORNo ratings yet

- Hotworks and Welding SafetyDocument21 pagesHotworks and Welding SafetyprokjongNo ratings yet

- Accident Incident Investigation and ControlDocument6 pagesAccident Incident Investigation and ControlEdmil PabellanoNo ratings yet

- RiggingDocument2 pagesRiggingpruncu.alianmNo ratings yet

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplatePanchdev KumarNo ratings yet

- Vwa Hotspots Office WorkDocument2 pagesVwa Hotspots Office WorkwiwuweNo ratings yet

- Method Statement ExampleDocument4 pagesMethod Statement ExampleAya MagdyNo ratings yet

- TOPIC: Demolition SafetyDocument1 pageTOPIC: Demolition SafetyMohamed HamdallahNo ratings yet

- HSE AwarenessDocument85 pagesHSE AwarenessMrityunjay DhanrajNo ratings yet

- A Complete Guide To Working at Height Regulations by At-HeightDocument6 pagesA Complete Guide To Working at Height Regulations by At-Heightat-height0% (1)

- Electric Arc Weldin SafetyDocument5 pagesElectric Arc Weldin SafetynickurfriendNo ratings yet

- Hse Plan 3Document14 pagesHse Plan 3YcRij SeYerNo ratings yet

- Portable Fire Extinguisher Safety: Facilities Planning and ManagementDocument18 pagesPortable Fire Extinguisher Safety: Facilities Planning and ManagementAnnisa ZaririmaNo ratings yet

- HIRAC Work at HeightDocument7 pagesHIRAC Work at HeightMitchRappNo ratings yet

- Safety-Overhead CraneDocument2 pagesSafety-Overhead CraneaisyahNo ratings yet

- SWMS 71 - Use of Curing ChemicalDocument2 pagesSWMS 71 - Use of Curing ChemicaleastNo ratings yet

- Iso 2201Document11 pagesIso 2201kirandevi1981No ratings yet

- Anp Safety Induction ProgramDocument46 pagesAnp Safety Induction ProgramRickz CabaloNo ratings yet

- BP Safety AlertDocument2 pagesBP Safety AlertRikza AhmadNo ratings yet

- GC3 ObservationDocument16 pagesGC3 ObservationjithinNo ratings yet

- ILO - PPE PresentationDocument69 pagesILO - PPE PresentationLeo Mr-ChuốiNo ratings yet

- Electrical Hazards ConstructionDocument77 pagesElectrical Hazards Constructiondh25881No ratings yet

- Example Hs PolicyDocument2 pagesExample Hs PolicyellyusanaNo ratings yet

- Risk Assessment Procedure: By: Arañez, Raymond John VDocument12 pagesRisk Assessment Procedure: By: Arañez, Raymond John VLast UnknownNo ratings yet

- 8.EXACAVATION and Confined SpaceDocument16 pages8.EXACAVATION and Confined SpaceIhuhwa Marta TauNo ratings yet

- Accident Investigation and ReportingDocument19 pagesAccident Investigation and Reportingvebsdgr8No ratings yet

- EHS Absolute Rules With BanglaDocument1 pageEHS Absolute Rules With BanglaAsaduzzaman0% (1)

- Scaffolding-Fixed and Mobile: Safety Operating ProceduresDocument1 pageScaffolding-Fixed and Mobile: Safety Operating Proceduresmohammed muzammilNo ratings yet

- Emergency Action Plan - 3Document18 pagesEmergency Action Plan - 3Nasih TrNo ratings yet

- Officeriskassess 259943Document2 pagesOfficeriskassess 259943api-332787463No ratings yet

- PPE Notice PolicyDocument1 pagePPE Notice PolicyLenaj EbronNo ratings yet

- Incident & Investigation Report Procedure - Near Miss-EVidence Communication Report-Hse Statistics & RecordsDocument83 pagesIncident & Investigation Report Procedure - Near Miss-EVidence Communication Report-Hse Statistics & RecordsAhmed Reda100% (1)

- ISO 45001 Occupational Health and Safety Management Systems: Information GuideDocument14 pagesISO 45001 Occupational Health and Safety Management Systems: Information GuideHélio René Lopes da RochaNo ratings yet

- hsg245 PDFDocument88 pageshsg245 PDFYousef OlabiNo ratings yet

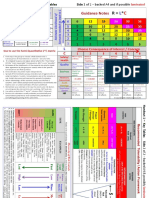

- Handout 1 - Key Reference TablesDocument2 pagesHandout 1 - Key Reference TablesIndreTankeliaviciuteNo ratings yet

- Quality Risk Management - Risk Based Thinking For ISO9001-RDocument68 pagesQuality Risk Management - Risk Based Thinking For ISO9001-RIndreTankeliaviciute100% (1)

- Project Risk ManagementDocument122 pagesProject Risk Managementdeeptimanney93% (14)

- RHA - Open Cut Piping & Manhole Iinstallation (Page 4)Document5 pagesRHA - Open Cut Piping & Manhole Iinstallation (Page 4)tanaNo ratings yet

- Procurement of Projects: InfrastructureDocument74 pagesProcurement of Projects: InfrastructureChristopher PostigoNo ratings yet

- Block Industry Business Plan in Nigeria Amp Feasibility Study Business PlanDocument9 pagesBlock Industry Business Plan in Nigeria Amp Feasibility Study Business PlanNwogboji EmmanuelNo ratings yet

- Course Code: CET 408 Kolp/Rw - 19 / 9605 Eighth Semester B. E. (Civil Engineering) ExaminationDocument3 pagesCourse Code: CET 408 Kolp/Rw - 19 / 9605 Eighth Semester B. E. (Civil Engineering) ExaminationanonymousNo ratings yet

- No - Reff 02 - 035 - 11 - 11 - 14 IAR - PT - TRISAKTI PURWOSARI MAKMURDocument4 pagesNo - Reff 02 - 035 - 11 - 11 - 14 IAR - PT - TRISAKTI PURWOSARI MAKMURKhoir HarahapNo ratings yet

- The Essential Guide To Running Your Construction Project 1578284904 YhthcaDocument237 pagesThe Essential Guide To Running Your Construction Project 1578284904 YhthcaYolashes Id100% (1)

- 110 - Technical Specification 220kV Moose + Zebra WB - 10-ADocument255 pages110 - Technical Specification 220kV Moose + Zebra WB - 10-AwaniasimNo ratings yet

- Insight037 ProjectLogisticsDocument9 pagesInsight037 ProjectLogisticsSrushti JNo ratings yet

- 2023 Harmony Residential Rebate App PacketDocument2 pages2023 Harmony Residential Rebate App PacketSanta Teresa SumapazNo ratings yet

- EvaluationDocument14 pagesEvaluationbaib981283100% (2)

- SBC Code 302Document77 pagesSBC Code 302dyx67% (3)

- Design and Fabrication of Leaf JigDocument9 pagesDesign and Fabrication of Leaf JigAnonymous Clyy9NNo ratings yet

- Nik 888Document8 pagesNik 888chickenfeet021023No ratings yet

- BFC 35503 - Contract & Estimation Section 4 CQI: Submission Date: 20 July 2022Document5 pagesBFC 35503 - Contract & Estimation Section 4 CQI: Submission Date: 20 July 2022yukilimNo ratings yet

- May Anthonitte B. Relano General Construction SpecificationsDocument3 pagesMay Anthonitte B. Relano General Construction SpecificationsRamil SeriozaNo ratings yet

- MS For Fabrication & Construction of New Crude Tank 945-TK7 at PARCO MCRDocument28 pagesMS For Fabrication & Construction of New Crude Tank 945-TK7 at PARCO MCRMuhammad ZubairNo ratings yet

- Commissioning Process: Comm. Organization Chart PDFDocument15 pagesCommissioning Process: Comm. Organization Chart PDFAzeta RobertNo ratings yet

- Work Method Statements For Lifting - Rev.00 - 20150811Document15 pagesWork Method Statements For Lifting - Rev.00 - 20150811YusufNo ratings yet

- Ace Tech 2019 MumbaiDocument24 pagesAce Tech 2019 Mumbaimini nikNo ratings yet

- Job Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyDocument9 pagesJob Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyTeodoro Esquillo100% (1)

- Burj Khalifa: Project ManagementDocument8 pagesBurj Khalifa: Project ManagementNoman AmjadNo ratings yet

- Adwea Approved Contractors ListDocument215 pagesAdwea Approved Contractors Listshameelpt66No ratings yet

- Thohoyandou - NZG Renovation Project Baseline Risk Assessment G306 2018 PDFDocument17 pagesThohoyandou - NZG Renovation Project Baseline Risk Assessment G306 2018 PDFbubele pamlaNo ratings yet

- Q1 Module 1 TVL-Plumbing12ModulesDocument63 pagesQ1 Module 1 TVL-Plumbing12ModulesMARLA RUBY PAZ YTING100% (1)

- 00UMF611 - LAYOUT A ARRANGEMENT POWER HOUSE - Equipment Location Plan - 005Document2 pages00UMF611 - LAYOUT A ARRANGEMENT POWER HOUSE - Equipment Location Plan - 005Anonymous sLRlLluNo ratings yet

- Engr. Gerry C. Ocampo: ObjectiveDocument2 pagesEngr. Gerry C. Ocampo: ObjectiveNasir AhmedNo ratings yet

- Andreki, P. (2016) - Exploring Critical Success Factors of Construction Projects.Document12 pagesAndreki, P. (2016) - Exploring Critical Success Factors of Construction Projects.beast mickeyNo ratings yet

- Pre - Qualification Bid: Government of GujaratDocument49 pagesPre - Qualification Bid: Government of GujaratMAULIK RAVALNo ratings yet

- Schedule Q Latest Revisions ApplicationsDocument47 pagesSchedule Q Latest Revisions Applicationstuv srinuvasaNo ratings yet