Professional Documents

Culture Documents

Supply Fan

Uploaded by

jones mythOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Supply Fan

Uploaded by

jones mythCopyright:

Available Formats

PLANNED PREVENTIVE MAINTENANCE PROGRAM

Discipline : HVAC / Mechanical PPMP Schedule : Weekly

Equipment Name : Supply Fan Week No. : ________

Equipment Code : ME-SF 00 Period : ___________

Project Code : ____________ Location Code : ___________________

Item Task No. of

Work Description Status

No. Code No. Hours

1.0 Check noise, vibration and rotation. 0001

(e.g., belt slippage during operation, bearing)

2.0 Check Fan Safety guards if properly secured. 0002

3.0 Check / adjust damper and damper linkage if needed. 0003

4.0 Check Fan wheel for any wear or corrossion. 0004

5.0 Check / clean / wash filters and grilles. 0005

6.0 Check line voltage and amperage. 0016

Reading:

Test Points Voltage Test Points Ampere

L1 - L2 L1

L2 - L3 L2

L1 - L3 L3

7.0 Check Air Flow Switch. 0019 ________

nothing follows Total Hours:

Remarks:

01.

02.

03.

Spare Parts Used: Consumable Used:

01. 01.

02. 02.

03. 03.

04. 04.

Date Start: Date Finish:

Performed by: Checked by: Noted by:

__________ _____________ ______________

Bldg. Tech. Chief Engr. Property Manager

Standard PPMP Form of:

Colliers International Philippines Inc. - 2009 75

PLANNED PREVENTIVE MAINTENANCE PROGRAM

Discipline : HVAC / Mechanical PPMP Schedule : Monthly

Equipment Name : Supply Fan Week No. : ________

Equipment Code : ME-SF 00 Period : ___________

Project Code : ____________ Location Code : ___________________

Item Task No. of

Work Description Status

No. Code No. Hours

1.0 Check noise, vibration and rotation. 0001

(e.g., belt slippage during operation, bearing)

2.0 Check Fan Safety guards if properly secured. 0002

3.0 Check / adjust damper and damper linkage if needed. 0003

4.0 Check mounting bolts and base, tighten all the 0007

fasteners, bolts, set screws and keys. Check the

tightness of the hanger bracket.

5.0 Check / clean fan wheel for build up of material 0008

which can cause unbalance resulting in vibration,

bearing wear and serious safety hazards. Check /

clean fan framing / enclosures and supports.

6.0 Check Shaft: Loose in bearing / loose in impeller / 0009

bent shaft / misaligned shaft and bearing.

7.0 Check fan screws, inlet louvers. Remove any dirt 0011

and debris.

continuation on the next page

Remarks:

01.

02.

03.

Spare Parts Used: Consumable Used:

01. 01.

02. 02.

03. 03.

04. 04.

Date Start: Date Finish:

Performed by: Checked by: Noted by:

Standard PPMP Form of:

Colliers International Philippines Inc. - 2009 76

PLANNED PREVENTIVE MAINTENANCE PROGRAM

Discipline : HVAC / Mechanical PPMP Schedule : Monthly

Equipment Name : Supply Fan Week No. : ________

Equipment Code : ME-SF 00 Period : ___________

Project Code : ____________ Location Code : ___________________

__________ _____________ ______________

Bldg. Tech. Chief Engr. Property Manager

Item Task No. of

Work Description Status

No. Code No. Hours

8.0 Measure Insulation Resistance (Megger Test). 0020

Reading:

Test Points Megohm Value

L1 - G

L2 - G

L3 - G

9.0 Check / clean Fan Selector switch. Adjust as needed. 0021 ________

nothing follows Total Hours:

Remarks:

01.

02.

03.

Spare Parts Used: Consumable Used:

01. 01.

02. 02.

03. 03.

04. 04.

Date Start: Date Finish:

Standard PPMP Form of:

Colliers International Philippines Inc. - 2009 77

PLANNED PREVENTIVE MAINTENANCE PROGRAM

Discipline : HVAC / Mechanical PPMP Schedule : Monthly

Equipment Name : Supply Fan Week No. : ________

Equipment Code : ME-SF 00 Period : ___________

Project Code : ____________ Location Code : ___________________

Performed by: Checked by: Noted by:

__________ _____________ ______________

Bldg. Tech. Chief Engr. Property Manager

Standard PPMP Form of:

Colliers International Philippines Inc. - 2009 78

PLANNED PREVENTIVE MAINTENANCE PROGRAM

Discipline : HVAC / Mechanical PPMP Schedule : Quarterly

Equipment Name : Supply Fan Week No. : ________

Equipment Code : ME-SF 00 Period : ___________

Project Code : ____________ Location Code : ___________________

Item Task No. of

Work Description Status

No. Code No. Hours

1.0 Check noise, vibration and rotation. 0001

(e.g., belt slippage during operation, bearing)

2.0 Check Fan Safety guards if properly secured. 0002

3.0 Check / adjust damper and damper linkage if needed. 0003

4.0 Check mounting bolts and base, tighten all the 0007

fasteners, bolts, set screws and keys. Check the

tightness of the hanger bracket.

5.0 Check Shaft: Loose in bearing / loose in impeller / 0009

bent shaft / misaligned shaft and bearing.

6.0 Check / Lubricate motor and fan shaft bearings or 0012 ________

fan shaft sleeve bearings (every 1000 hours or after

3-months whichever comes first).

OR LUBRICATE ACCORDING TO THE

MANUFACTURER'S INSTRUCTION.

nothing follows Total Hours:

Remarks:

01.

02.

03.

Spare Parts Used: Consumable Used:

01. 01.

02. 02.

03. 03.

04. 04.

Date Start: Date Finish:

Performed by: Checked by: Noted by:

__________ _____________ ______________

Bldg. Tech. Chief Engr. Property Manager

Standard PPMP Form of:

Colliers International Philippines Inc. - 2009 78

PLANNED PREVENTIVE MAINTENANCE PROGRAM

Discipline : HVAC / Mechanical PPMP Schedule : Semi-Annually

Equipment Name : Supply Fan Week No. : ________

Equipment Code : ME-SF 00 Period : ___________

Project Code : ____________ Location Code : ___________________

Item Task No. of

Work Description Status

No. Code No. Hours

1.0 Check noise, vibration and rotation. 0001

(e.g., belt slippage during operation, bearing)

2.0 Check Fan Safety guards if properly secured. 0002

3.0 Check / adjust damper and damper linkage if needed. 0003

4.0 Check mounting bolts and base, tighten all the 0007

fasteners, bolts, set screws and keys. Check the

tightness of the hanger bracket.

5.0 Check Shaft: Loose in bearing / loose in impeller / 0009

bent shaft / misaligned shaft and bearing.

6.0 Check / Lubricate motor and fan shaft bearings or 012

fan shaft sleeve bearings (every 1000 hours or after

3-months whichever comes first).

OR LUBRICATE ACCORDING TO THE

MANUFACTURER'S INSTRUCTION.

continuation on the next page

Remarks:

01.

02.

03.

Spare Parts Used: Consumable Used:

01. 01.

02. 02.

03. 03.

04. 04.

Date Start: Date Finish:

Performed by: Checked by: Noted by:

Standard PPMP Form of:

Colliers International Philippines Inc. - 2009 79

PLANNED PREVENTIVE MAINTENANCE PROGRAM

Discipline : HVAC / Mechanical PPMP Schedule : Semi-Annually

Equipment Name : Supply Fan Week No. : ________

Equipment Code : ME-SF 00 Period : ___________

Project Code : ____________ Location Code : ___________________

__________ _____________ ______________

Bldg. Tech. Chief Engr. Property Manager

Item Task No. of

Work Description Status

No. Code No. Hours

7.0 Check and clean control panels. Check power wiring 0023 ________

contactors. overloads and terminal blocks to ensure Total Hours:

connections are tight. Check for any corrossion in

the wires that may lead to overheating.

nothing follows

Remarks:

01.

02.

03.

Spare Parts Used: Consumable Used:

01. 01.

02. 02.

03. 03.

04. 04.

Date Start: Date Finish:

Standard PPMP Form of:

Colliers International Philippines Inc. - 2009 80

PLANNED PREVENTIVE MAINTENANCE PROGRAM

Discipline : HVAC / Mechanical PPMP Schedule : Semi-Annually

Equipment Name : Supply Fan Week No. : ________

Equipment Code : ME-SF 00 Period : ___________

Project Code : ____________ Location Code : ___________________

Performed by: Checked by: Noted by:

__________ _____________ ______________

Bldg. Tech. Chief Engr. Property Manager

Standard PPMP Form of:

Colliers International Philippines Inc. - 2009 81

PLANNED PREVENTIVE MAINTENANCE PROGRAM

Discipline : HVAC / Mechanical PPMP Schedule : Annually

Equipment Name : Supply Fan Week No. : ________

Equipment Code : ME-SF 00 Period : ___________

Project Code : ____________ Location Code : ___________________

Item Task No. of

Work Description Status

No. Code No. Hours

1.0 Check noise, vibration and rotation. 0001

(e.g., belt slippage during operation, bearing)

2.0 Check Fan Safety guards if properly secured. 0002

3.0 Check / adjust damper and damper linkage if needed. 0003

4.0 Check mounting bolts and base, tighten all the 0007

fasteners, bolts, set screws and keys. Check the

tightness of the hanger bracket.

5.0 Check Shaft: Loose in bearing / loose in impeller / 0009

bent shaft / misaligned shaft and bearing.

6.0 Check / Lubricate motor and fan shaft bearings or 012

fan shaft sleeve bearings (every 1000 hours or after

3-months whichever comes first).

OR LUBRICATE ACCORDING TO THE

MANUFACTURER'S INSTRUCTION.

7.0 Inspect and clean protective finish if necessary. 0015

continuation on the next page

Remarks:

01.

02.

03.

Spare Parts Used: Consumable Used:

01. 01.

02. 02.

03. 03.

04. 04.

Date Start: Date Finish:

Performed by: Checked by: Noted by:

Standard PPMP Form of:

Colliers International Philippines Inc. - 2009 81

PLANNED PREVENTIVE MAINTENANCE PROGRAM

Discipline : HVAC / Mechanical PPMP Schedule : Annually

Equipment Name : Supply Fan Week No. : ________

Equipment Code : ME-SF 00 Period : ___________

Project Code : ____________ Location Code : ___________________

__________ _____________ ______________

Bldg. Tech. Chief Engr. Property Manager

Item Task No. of

Work Description Status

No. Code No. Hours

8.0 Check gauges and meters on control panels, 0024 ________

calibrate as needed. Total Hours:

nothing follows

Remarks:

01.

02.

03.

Spare Parts Used: Consumable Used:

01. 01.

02. 02.

03. 03.

04. 04.

Date Start: Date Finish:

Standard PPMP Form of:

Colliers International Philippines Inc. - 2009 82

PLANNED PREVENTIVE MAINTENANCE PROGRAM

Discipline : HVAC / Mechanical PPMP Schedule : Annually

Equipment Name : Supply Fan Week No. : ________

Equipment Code : ME-SF 00 Period : ___________

Project Code : ____________ Location Code : ___________________

Performed by: Checked by: Noted by:

__________ _____________ ______________

Bldg. Tech. Chief Engr. Property Manager

Standard PPMP Form of:

Colliers International Philippines Inc. - 2009 83

You might also like

- Transfer FanDocument11 pagesTransfer Fanjones mythNo ratings yet

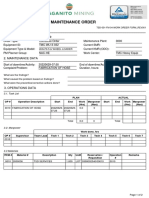

- Maintenance OrderDocument2 pagesMaintenance OrderFrancis DedumoNo ratings yet

- Maintenance OrderDocument2 pagesMaintenance OrderFrancis DedumoNo ratings yet

- Maintenance OrderDocument2 pagesMaintenance OrderFrancis DedumoNo ratings yet

- Maintenance OrderDocument2 pagesMaintenance OrderFrancis DedumoNo ratings yet

- Maintenance OrderDocument2 pagesMaintenance OrderFrancis DedumoNo ratings yet

- Maintenance OrderDocument2 pagesMaintenance OrderFrancis DedumoNo ratings yet

- Em40go030 D enDocument28 pagesEm40go030 D enEhsan ArbabtaftiNo ratings yet

- Form Inspeksi ExcavatorDocument2 pagesForm Inspeksi ExcavatorAnnisa AgustinaNo ratings yet

- B Machine RoomDocument27 pagesB Machine RoomSopyan PermanaNo ratings yet

- EKR - APP A Annual Inspection SheetDocument1 pageEKR - APP A Annual Inspection SheetNats NatoyNo ratings yet

- Work PermitDocument2 pagesWork PermitDoita Dutta ChoudhuryNo ratings yet

- Maintenance OrderDocument2 pagesMaintenance OrderFrancis DedumoNo ratings yet

- JOB OrderDocument3 pagesJOB OrderRamesh VundavilliNo ratings yet

- Inspeksi Alat ExcavatorDocument1 pageInspeksi Alat ExcavatorYudaNo ratings yet

- Mech Inspection Checklist PDFDocument11 pagesMech Inspection Checklist PDFDesigner Forever100% (1)

- BHT - Technical Publications 1 MDocument1 pageBHT - Technical Publications 1 Mmarcelo juniorNo ratings yet

- QA-QC Checklist - Fire ExtinguisherDocument1 pageQA-QC Checklist - Fire Extinguisherabdullah albahraniNo ratings yet

- Maintenance OrderDocument2 pagesMaintenance OrderFrancis DedumoNo ratings yet

- SOP - 03 - Job Execution Procedure - Rev02Document9 pagesSOP - 03 - Job Execution Procedure - Rev02HasnainNo ratings yet

- Monthly Progress Report - DecemberDocument2 pagesMonthly Progress Report - Decemberzunair.noorNo ratings yet

- SOP For Machine Maintenance - For UpdateDocument3 pagesSOP For Machine Maintenance - For UpdatePeracha Engineering60% (5)

- SARENS HEAVY CalibarationDocument2 pagesSARENS HEAVY CalibarationSusil Kumar SahooNo ratings yet

- WP-HSE-010 (Bored Pile)Document1 pageWP-HSE-010 (Bored Pile)Armando AballeNo ratings yet

- Monthly Progress Report - NovemberDocument2 pagesMonthly Progress Report - Novemberzunair.noorNo ratings yet

- 3eetr Manual en v2012.1.0Document36 pages3eetr Manual en v2012.1.0Boeroaia Georgian100% (1)

- Section 05-10 Hot TapDocument15 pagesSection 05-10 Hot TapAcid HadiNo ratings yet

- (CMO-F-038) Daily Detailed Safety Supervision ChecklistDocument1 page(CMO-F-038) Daily Detailed Safety Supervision ChecklistOlan PrinceNo ratings yet

- Operation, Installation, Maintenance Manual Air Intake Silencer Item: 02D001 Ton: 1021D001Document6 pagesOperation, Installation, Maintenance Manual Air Intake Silencer Item: 02D001 Ton: 1021D001Arun KarthikeyanNo ratings yet

- PM Checklist Option 3Document2 pagesPM Checklist Option 3garis24bNo ratings yet

- FLT M02 0004Document44 pagesFLT M02 0004DanielDeFrancescoNo ratings yet

- Desfibrilador s3 s5Document219 pagesDesfibrilador s3 s5Ailen Lazarte100% (1)

- 6970-000-TM-ER-6010 Rev ADocument2 pages6970-000-TM-ER-6010 Rev Apiyush_surti2025No ratings yet

- Alat Lorry CraneDocument1 pageAlat Lorry CraneDebi NovitaNo ratings yet

- HVAC Performance Test Quality Control and Inspection Report FormDocument6 pagesHVAC Performance Test Quality Control and Inspection Report Formhasan_676489616100% (1)

- Warranty Certificate For Lokotrack Lt106 S/N 77223Document7 pagesWarranty Certificate For Lokotrack Lt106 S/N 77223edycarlos7No ratings yet

- Functional Specification FOR Level GaugeDocument11 pagesFunctional Specification FOR Level Gaugesumit kumarNo ratings yet

- SOPEN004 FinalDocument4 pagesSOPEN004 FinalASI APINo ratings yet

- BHT - Technical PublicationsDocument2 pagesBHT - Technical PublicationsAbner Colín QuijanoNo ratings yet

- S8 - User ManualDocument232 pagesS8 - User ManualKarl Mamaril100% (1)

- 5-12-14 Inspection Phase 14Document1 page5-12-14 Inspection Phase 14Lady Laura Sierra RuizNo ratings yet

- 1.3d Air Conditioners Inspection RecordsDocument1 page1.3d Air Conditioners Inspection RecordsMusaib ChougleNo ratings yet

- Work Shop Manual: RY 125 Series Engines, P.no. 1-5302-633Document44 pagesWork Shop Manual: RY 125 Series Engines, P.no. 1-5302-633MardianNo ratings yet

- User Manual: Trolley For Patients Transportation WP-02.0Document18 pagesUser Manual: Trolley For Patients Transportation WP-02.0Arrigo PrietoNo ratings yet

- TB4 Series2 ManualDocument26 pagesTB4 Series2 ManualPPKPI2 KLIMNo ratings yet

- Maintenance Accomplishment Report FormDocument2 pagesMaintenance Accomplishment Report FormPatNo ratings yet

- PM-MEC-WI-31 Vickers Hardness TestDocument5 pagesPM-MEC-WI-31 Vickers Hardness TestOwais Manzoor MalikNo ratings yet

- Job Order Form UpdatedDocument1 pageJob Order Form UpdatedMuhammad SajidNo ratings yet

- Paul Brooks Homoeo Labs: Title: Maintenance & Servicing of Compressor Department: EngineeringDocument5 pagesPaul Brooks Homoeo Labs: Title: Maintenance & Servicing of Compressor Department: Engineeringlatif Qureshi100% (1)

- Maintenance OrderDocument2 pagesMaintenance OrderFrancis DedumoNo ratings yet

- Ti 002 enDocument199 pagesTi 002 enSONNo ratings yet

- FRM-9114-0201 Safe Work PermitDocument5 pagesFRM-9114-0201 Safe Work PermitNat OffeiNo ratings yet

- Siemens Arcadis Avantic Installations LaserIIDocument22 pagesSiemens Arcadis Avantic Installations LaserIINelson AltuveNo ratings yet

- Alex Rangasa Danilo Ponte: For Hot Work PermitDocument2 pagesAlex Rangasa Danilo Ponte: For Hot Work PermitJohn Lloyd MeconoNo ratings yet

- FINAL Scope of Work - STP EnhancementDocument3 pagesFINAL Scope of Work - STP EnhancementNaldre PhamhinthuanNo ratings yet

- General Work PermitDocument2 pagesGeneral Work PermitJareem PeesNo ratings yet

- Esp e Ing SBT 00035 - Eng R4Document37 pagesEsp e Ing SBT 00035 - Eng R4thiagoNo ratings yet

- Virtex 2 Pro FpgaDocument17 pagesVirtex 2 Pro FpgaKiran ModiniNo ratings yet

- An 01 en Motherboard Foxconn G41MXDocument75 pagesAn 01 en Motherboard Foxconn G41MXghettosoNo ratings yet

- Multimag Cyble DN15 20 MID Brochure EnglishDocument4 pagesMultimag Cyble DN15 20 MID Brochure EnglishdaskirNo ratings yet

- Some Useful Points and Comments To Be Considered by The BidderDocument1 pageSome Useful Points and Comments To Be Considered by The Bidderﺣﻤﻴﺪ ﻫﻤﺪﺍﻥ ﺍﻻﺷﻮﻝNo ratings yet

- Valv e Tizer V15bDocument6 pagesValv e Tizer V15bVince WaldonNo ratings yet

- Be1-Flex (Uub)Document2 pagesBe1-Flex (Uub)Eliyanto E BudiartoNo ratings yet

- Set ADocument5 pagesSet AgregNo ratings yet

- First Order Differential Microphone ArraysDocument4 pagesFirst Order Differential Microphone ArraystatakillNo ratings yet

- Bowers Wilkins 600 Series 3 User ManualDocument14 pagesBowers Wilkins 600 Series 3 User ManualEd StepkoNo ratings yet

- Lucky Tech 5V-1A Motherboard ManualDocument7 pagesLucky Tech 5V-1A Motherboard Manualryan cooperNo ratings yet

- V-Strom Wiring ProjectsDocument8 pagesV-Strom Wiring ProjectsthingumybobNo ratings yet

- Total Consumption April21Document71 pagesTotal Consumption April21Saurabh Kumar SinghNo ratings yet

- Electro/Pneumatic Converter: Typical ApplicationsDocument7 pagesElectro/Pneumatic Converter: Typical ApplicationsGoran NovakovNo ratings yet

- Textbook 2.01.2019 PDFDocument34 pagesTextbook 2.01.2019 PDFBitupan ArandharaNo ratings yet

- Iec 60364 4 43 2008Document15 pagesIec 60364 4 43 2008KristofNo ratings yet

- Art InvertersDocument3 pagesArt InvertersManuel TorijaNo ratings yet

- Differences Between Steady-State and Dynamic SimulationDocument2 pagesDifferences Between Steady-State and Dynamic SimulationMustafa AhsanNo ratings yet

- Datasheet Navio Board PDFDocument2 pagesDatasheet Navio Board PDFluckyluck00100% (1)

- ELEC3300 10-Memory InterfaceDocument35 pagesELEC3300 10-Memory InterfaceKwun Hok ChongNo ratings yet

- D D D D D D: Description/ordering InformationDocument22 pagesD D D D D D: Description/ordering InformationSathish KssNo ratings yet

- Toyota 8fg Forklift Wiring DiagramDocument10 pagesToyota 8fg Forklift Wiring Diagrammarilyn100% (46)

- Vco-151215121140 Import PPTDocument60 pagesVco-151215121140 Import PPTRizwan SPNo ratings yet

- BAB 3: PearuhDocument14 pagesBAB 3: PearuhhafizeijaNo ratings yet

- APPENDIX I PRINCIPLES FOR LAYOUT PLANS AND SECTIONING DIAGRAMS FOR 25 KV Ac TRACTION PDFDocument19 pagesAPPENDIX I PRINCIPLES FOR LAYOUT PLANS AND SECTIONING DIAGRAMS FOR 25 KV Ac TRACTION PDFankitNo ratings yet

- Ger SS 108-94020 DDocument24 pagesGer SS 108-94020 DmegatornadoNo ratings yet

- (NOT Gate) DM7404 PDFDocument5 pages(NOT Gate) DM7404 PDFSai KumarNo ratings yet

- OFDMDocument137 pagesOFDMedemialemNo ratings yet

- Caterpillar - Tractor d10t - 03 - Plano ElectricoDocument2 pagesCaterpillar - Tractor d10t - 03 - Plano ElectricoLuis AlbertNo ratings yet

- MovitracLTP BDocument112 pagesMovitracLTP BtrutleptNo ratings yet

- Here's The Answer. What's Your Question?: ABB High Power Rectifier ServicesDocument8 pagesHere's The Answer. What's Your Question?: ABB High Power Rectifier Servicesluis_cabrera_49No ratings yet