Professional Documents

Culture Documents

POLYMERS

Uploaded by

Kim ChuaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

POLYMERS

Uploaded by

Kim ChuaCopyright:

Available Formats

POLYMERS

Group 2

Members:

Kim Cezar Chua Michael Bryan Cuer

Vangie Lopez Aspirin Kenneth Cabarubias

Shofie Binarao Christian Dave Cabalda

Rachelle Fritz Jesus

Polymers are macromolecules or very large molecules those that contain several thousands of

atoms formed by the repetitive bonding together of many smaller molecules called monomers.

HISTORY

1500’s – The Mayans are assumed to be among the first to find an application for polymers, as

their children were fond of playing with balls made from local rubber trees.

1839 – Charles Goodyear discovers vulcanization by combining natural rubber with sulfur and

heating it to 270˚F.

1907 – The oldest recorded synthetic plastic is fabricated by Leo Bakelord. Bakelites hardness and

high heat resistivity made it an excellent choice as an electrical insulator.

1917 – X-ray crystallography is invented as a method of analyzing crystal structure Eight years

later, this method used by Michael Polyani to discover the chemical structure of

cellulose.

1920 – Hermann Staudinger published his classic entitled “Uber Polymerization.”

1927 – Large scale production of vinyl – chloride resins begin. This polymeric compound continues

to be widely used today to make plumbing (PVC) pipe.

1930 – Polystyrene is invented. These polymeric materials are used in video cassettes and other

packaging.

PHYSICAL AND CHEMICAL PROPERTIES

Physical properties of polymers include molecular weight, molar volume, density, degree of

polymerization, crystallinity of material, and so on.

PROCESSES

Injection Molding – This very common process for forming plastics. Advantages of injection

molding include rapid processing little waste, and easy automation. Molded parts

include combs, toothbrush bases, pails, pipe fillings and model airplane parts.

Compression Molding – This type of molding was among the first ti be used to form plastics.

Transfer Molding – This process is a modification of compression molding. It is used primarily to

produce thermosetting plastics.

Blow Molding – This produces bottle, globe light fixtures, tubs, automobile gasoline tanks and d

rums.

Extrusion – This process makes parts of constant cross section like pipes and rods.

APPLICATIONS/USES

Polymers are a highly diverse class of materials which are available in all fields of engineering form

avionics through biomedical applications, drug delivery system, biosensor devices, tissue

engineering, cosmetics etc. and the improvement and usage of these depends on polymer

applications and data obtained through rigorous testing.

In aircraft, aerospace and sports equipment

Printed circuit board substrates

3D printing plastics

Polymers in holography

Biopolymers in molecular recognition

Polymers in bulletproof vests and fire-resistant jacket

Organic polymer flocculants in water purification

Green chemicals: Polymers and Biopolymers

Polymeric Biomolecules

Monomeric units

Renewable Biomass sources

QUESTIONS:

1. It is formed by the repetitive bonding of many smaller molecules called monomers.

2. They are assumed to be the first to find an application for polymers.

3. Who has the oldest recorded synthetic plastic and made it as excellent choice as an

electrical insulator?

4. These polymeric materials are used in video cassettes and other packaging.

5. It is a very common process for forming plastics which includes rapid processing little waste

and easy automation.

6. This process is used primarily to produce thermosetting plastics.

7. This process makes parts of constant cross section like pipe and rods.

8. – 10. Give 3 Application or uses of polymers.

You might also like

- Polymers, Polymeric Materials & Plastics and Ceramics & GlassDocument48 pagesPolymers, Polymeric Materials & Plastics and Ceramics & GlassB03Kavya MNo ratings yet

- Plastics: Mohammed Bilal 1 N S 1 9 AT 0 2 7 MMBC VDocument21 pagesPlastics: Mohammed Bilal 1 N S 1 9 AT 0 2 7 MMBC Vlalu mikeyNo ratings yet

- Thermoplastics: Group III Cayabyab, Shield R. Espiritu, Micoh L. Mendoza, Maynard T. Radia, Rezvani MDocument20 pagesThermoplastics: Group III Cayabyab, Shield R. Espiritu, Micoh L. Mendoza, Maynard T. Radia, Rezvani MMaynard Trinidad MendozaNo ratings yet

- Plastics 140928093734 Phpapp02Document27 pagesPlastics 140928093734 Phpapp02Siyyadula Chandra SekharNo ratings yet

- Chapter 1 Introduction To PolymerDocument64 pagesChapter 1 Introduction To PolymerNur Fatiha Aziera Ain Binti Mohd KhimeNo ratings yet

- Polymer ScienceDocument49 pagesPolymer ScienceGeeNo ratings yet

- PolymerDocument31 pagesPolymerBen MenNo ratings yet

- Plastics: (Chapter 12)Document88 pagesPlastics: (Chapter 12)Shawn Ann SilanNo ratings yet

- Polymers: The Material of ChoiceDocument89 pagesPolymers: The Material of ChoicearieljuwoNo ratings yet

- Handbook of Polypropylene and Polypropylene Composites (Harutun Karian) PDFDocument740 pagesHandbook of Polypropylene and Polypropylene Composites (Harutun Karian) PDFAlexGaitanB100% (3)

- Experiment No. 3 Title: Burning Plastic Materials I. ObjectivesDocument9 pagesExperiment No. 3 Title: Burning Plastic Materials I. ObjectivesPedro AmorsoloNo ratings yet

- Ms 4 Ss A Introduction To PolymersDocument132 pagesMs 4 Ss A Introduction To Polymersbianca reyesNo ratings yet

- Plastics and The Environment: Recycling HandbookDocument20 pagesPlastics and The Environment: Recycling HandbookAbdul Quddus Mat IsaNo ratings yet

- Print IpeDocument7 pagesPrint IpePamPeñeraSanchezNo ratings yet

- Polymers and MonomersDocument2 pagesPolymers and MonomersEricNo ratings yet

- 1979 - Polymer Alloys IIDocument284 pages1979 - Polymer Alloys IIRiot DangerNo ratings yet

- PolymerDocument2 pagesPolymerRazaNo ratings yet

- PolymersDocument3 pagesPolymersKenneth LewisNo ratings yet

- Polymer ProcessingDocument26 pagesPolymer ProcessingPrincess_Ira_E_2471No ratings yet

- Polyurethane: Partial Fulfillment in Physical Science Submitted To: Mrs. Filamae J. MapareDocument11 pagesPolyurethane: Partial Fulfillment in Physical Science Submitted To: Mrs. Filamae J. MapareTrishia SeñoronNo ratings yet

- HlouhgDocument14 pagesHlouhgyakendraneupane123No ratings yet

- Lecture 3 - ECE 2215 PDFDocument30 pagesLecture 3 - ECE 2215 PDFRando ClintonNo ratings yet

- Transfer MoldingDocument10 pagesTransfer MoldingShemarNo ratings yet

- Exploring Everyday Chemistry (Week 4)Document44 pagesExploring Everyday Chemistry (Week 4)My GirlNo ratings yet

- Assignment 03 by AlemuDocument11 pagesAssignment 03 by AlemuAlemu MergaNo ratings yet

- Chem Project 2022 23Document42 pagesChem Project 2022 23zakafuNo ratings yet

- Plastic QuestionnaireDocument6 pagesPlastic QuestionnaireNea RomeroNo ratings yet

- Assignment 03 by AlemuDocument11 pagesAssignment 03 by AlemuAlemu MergaNo ratings yet

- History of PlasticDocument3 pagesHistory of PlasticVikneshwaran BalakrishnanNo ratings yet

- Polymeric MaterialsDocument37 pagesPolymeric MaterialsZain Ul AbdeenNo ratings yet

- Assigment 1 Engineering Materials BFM 1113: Name: Sharifah Syahira Bte Syed Mohamad Matrix Card: FB10060Document19 pagesAssigment 1 Engineering Materials BFM 1113: Name: Sharifah Syahira Bte Syed Mohamad Matrix Card: FB10060Sharifah Leha100% (1)

- Module 3.3 - POLYMERS & CERAMICS - STUDENT COPY - PDFDocument44 pagesModule 3.3 - POLYMERS & CERAMICS - STUDENT COPY - PDFhey yutNo ratings yet

- Module-3 Additive Manufacturing 18 SchemeDocument62 pagesModule-3 Additive Manufacturing 18 SchemeSANTOSHNo ratings yet

- Polymer IndustryDocument7 pagesPolymer Industryzubairahmed27272No ratings yet

- Polymers Used in Everyday LifeDocument11 pagesPolymers Used in Everyday LifeEditor IJTSRDNo ratings yet

- Unit Iv Polymers - PPTDocument69 pagesUnit Iv Polymers - PPTAbhishek GuptaNo ratings yet

- Coupling Agents and Composites: Group 2Document5 pagesCoupling Agents and Composites: Group 2Nicole Anne BorromeoNo ratings yet

- APPLIED CHEMISTRY.Q1 Module 4Document4 pagesAPPLIED CHEMISTRY.Q1 Module 4Justine ZablanNo ratings yet

- Unit 3 Civil Mech, Unit 4 Eee and Ece Polymer TechnologyDocument57 pagesUnit 3 Civil Mech, Unit 4 Eee and Ece Polymer Technologymaheshbabugandupalli7No ratings yet

- Ciofu Ciprian 1 PDFDocument20 pagesCiofu Ciprian 1 PDFeduardo_umNo ratings yet

- Investigation of Mechanical Properties of Corn Fiber Reinforced With Biodegradable ResinDocument4 pagesInvestigation of Mechanical Properties of Corn Fiber Reinforced With Biodegradable ResinRaja SajinNo ratings yet

- NCASM 20DPSInvitedTalk PDFDocument9 pagesNCASM 20DPSInvitedTalk PDFnathnael samsonNo ratings yet

- Folio Chemistry 4SC2Document15 pagesFolio Chemistry 4SC2Nadia ZulkefliNo ratings yet

- PolymerDocument7 pagesPolymerShabbir TamboliNo ratings yet

- Plastic PDFDocument32 pagesPlastic PDFMuhammad Fathin100% (1)

- Polymer Viscoelasticity: Stress and Strain in PracticeDocument900 pagesPolymer Viscoelasticity: Stress and Strain in Practicerin karin100% (1)

- Glasspolymersandplastics 140915105005 Phpapp01Document33 pagesGlasspolymersandplastics 140915105005 Phpapp01mohansaiNo ratings yet

- 2nd Unit - PlasticDocument31 pages2nd Unit - PlasticAvantikaNo ratings yet

- My Class NoteDocument9 pagesMy Class NoteCeylon BudgetNo ratings yet

- Chem Viii CH3 Synthetic Fibres and PlasticsDocument5 pagesChem Viii CH3 Synthetic Fibres and PlasticsPulkitNo ratings yet

- Program: B.Tech Subject Name: Manufacturing Technology Subject Code: ME-405 Semester: 4thDocument22 pagesProgram: B.Tech Subject Name: Manufacturing Technology Subject Code: ME-405 Semester: 4thROHIT MEHRANo ratings yet

- Plastic IntroductionDocument15 pagesPlastic IntroductionEmeth TeoNo ratings yet

- Polymer Nanocomposite FoamsDocument20 pagesPolymer Nanocomposite FoamsNguyễn KhánhNo ratings yet

- Block Copolymers in NanoscienceFrom EverandBlock Copolymers in NanoscienceMassimo LazzariNo ratings yet

- Production of Plastic MaterialsDocument24 pagesProduction of Plastic Materialsfadhillah ivanNo ratings yet

- De AssignmentDocument9 pagesDe AssignmentManish MohapatraNo ratings yet

- Chemistry Project On Polymer Chemistry Cbse Class 12thDocument27 pagesChemistry Project On Polymer Chemistry Cbse Class 12thvikasNo ratings yet

- Pyramus and ThisbeDocument5 pagesPyramus and ThisbeKim ChuaNo ratings yet

- Newton's Law of Cooling: DE 730 MWDocument2 pagesNewton's Law of Cooling: DE 730 MWKim Chua100% (1)

- Activity Number 6.Document2 pagesActivity Number 6.Kim ChuaNo ratings yet

- Microbial Fuel Cell: A Source of BioelectricityDocument7 pagesMicrobial Fuel Cell: A Source of BioelectricityKim ChuaNo ratings yet

- Ra 8491Document3 pagesRa 8491Kim ChuaNo ratings yet

- UC - Main College of Engineering: Preliminary ExaminationDocument2 pagesUC - Main College of Engineering: Preliminary ExaminationKim ChuaNo ratings yet

- Activity # 3:: Solve The Following Problems Using Triangle MethodDocument2 pagesActivity # 3:: Solve The Following Problems Using Triangle MethodKim ChuaNo ratings yet

- Microbial Fuel Cell: A Source of BioelectricityDocument20 pagesMicrobial Fuel Cell: A Source of BioelectricityKim ChuaNo ratings yet

- Microbial Fuel CellDocument9 pagesMicrobial Fuel CellKim ChuaNo ratings yet

- BIOMATERIALSDocument2 pagesBIOMATERIALSKim ChuaNo ratings yet

- Latest Biofertilizer Cyanobacteria 1Document10 pagesLatest Biofertilizer Cyanobacteria 1Kim ChuaNo ratings yet

- Microbial Fuel Cell: A Source of BioelectricityDocument13 pagesMicrobial Fuel Cell: A Source of BioelectricityKim ChuaNo ratings yet

- Latest Biofertilizer Cyanobacteria 1Document10 pagesLatest Biofertilizer Cyanobacteria 1Kim ChuaNo ratings yet

- Punching ShearDocument2 pagesPunching ShearJulianNo ratings yet

- Capitagreen: The Green Jewel of The Central Business DistrictDocument4 pagesCapitagreen: The Green Jewel of The Central Business Districtoguz kayaNo ratings yet

- Building Restoration TechniquesDocument14 pagesBuilding Restoration TechniquesSandi Prashanth Reddy100% (1)

- 2022 - Water Cooled Screw Chiller (20221202 - 110426162)Document18 pages2022 - Water Cooled Screw Chiller (20221202 - 110426162)Huy NguyễnNo ratings yet

- Alternative Foundation Option by Jet Grouting Pile MethodDocument8 pagesAlternative Foundation Option by Jet Grouting Pile MethodVanDuongNguyenNo ratings yet

- Table of Personnel ProtectionDocument1 pageTable of Personnel ProtectionnincitoNo ratings yet

- Transducer: TypesDocument39 pagesTransducer: Typestujuh belasNo ratings yet

- Header & Piping SizingDocument9 pagesHeader & Piping Sizingmedicbest0% (1)

- DEP 30.10.02.13 Non-Metallic Materials - Selection and ApplicationDocument53 pagesDEP 30.10.02.13 Non-Metallic Materials - Selection and ApplicationSergey Kichenko100% (1)

- ARC20011 Mechanics of Structures: Laboratory Session #2: Beam Bending Moment, Measurements and AnalysisDocument22 pagesARC20011 Mechanics of Structures: Laboratory Session #2: Beam Bending Moment, Measurements and AnalysisKushan HiranthaNo ratings yet

- CH 26 ProblemsDocument21 pagesCH 26 ProblemsIvan LlovitNo ratings yet

- ASME VIII CalculationDocument14 pagesASME VIII CalculationWan Wei100% (1)

- 3 Flexural Analysis/Design of Beam 3 Flexural Analysis/Design of Beam 3. Flexural Analysis/Design of Beam 3. Flexural Analysis/Design of BeamDocument146 pages3 Flexural Analysis/Design of Beam 3 Flexural Analysis/Design of Beam 3. Flexural Analysis/Design of Beam 3. Flexural Analysis/Design of BeamJm CampitanNo ratings yet

- ETABS 2016 Shear Wall Design: ETABS 2016 16.0.0 License # 1L4NYHW6GDTZBRADocument2 pagesETABS 2016 Shear Wall Design: ETABS 2016 16.0.0 License # 1L4NYHW6GDTZBRARajib MaharjanNo ratings yet

- Chopped Strand Mat EmulsionDocument2 pagesChopped Strand Mat EmulsionWaseem AkramNo ratings yet

- Sika Seal 105Document2 pagesSika Seal 105the pilotNo ratings yet

- Paper IIDocument44 pagesPaper IIThejaswiniNo ratings yet

- Product Data Sheet: Akzonobel Powder CoatingsDocument2 pagesProduct Data Sheet: Akzonobel Powder CoatingspmkarNo ratings yet

- Standards MaterialDocument19 pagesStandards MaterialnaveenkumarNo ratings yet

- Perforated Shear Wall DesignDocument5 pagesPerforated Shear Wall DesignLavNo ratings yet

- 3 Using Shear Strength Reduction Method For 2D and 3D Slope Stability Analysis ReadyDocument115 pages3 Using Shear Strength Reduction Method For 2D and 3D Slope Stability Analysis ReadyAnonymous D5s00DdUNo ratings yet

- Proposed House Plan For MR - NihalDocument1 pageProposed House Plan For MR - NihalSulaksha WimalasenaNo ratings yet

- WWW - Manaresults.Co - In: (Common To Me, MCT, MMT, Ae, Ame, MSNT)Document3 pagesWWW - Manaresults.Co - In: (Common To Me, MCT, MMT, Ae, Ame, MSNT)mahendra babu mekalaNo ratings yet

- MD Boiler Asme WTDocument159 pagesMD Boiler Asme WTdodikNo ratings yet

- Product Specifications: Model EZSTL8LCDocument2 pagesProduct Specifications: Model EZSTL8LCJames LoewenNo ratings yet

- Polybond 3150 TDSDocument1 pagePolybond 3150 TDSjai_dceNo ratings yet

- Shutdown Book 2007Document184 pagesShutdown Book 2007api-380385875% (8)

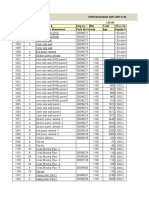

- Summary of Bid Prices DPWHDocument1 pageSummary of Bid Prices DPWHInsorPiNo ratings yet

- Pos. Quantity Designation & DWG No. / Mat. Total ) Doc. For No. Code and / or Dimensions Parts List Nocode Kgs. Supply FromDocument6 pagesPos. Quantity Designation & DWG No. / Mat. Total ) Doc. For No. Code and / or Dimensions Parts List Nocode Kgs. Supply FromBiswajet RouthNo ratings yet

- PriceList Royu Wires Devices JAN 2018 Issue V1Document6 pagesPriceList Royu Wires Devices JAN 2018 Issue V1Rafael VillafloresNo ratings yet