Professional Documents

Culture Documents

Method Statement - Hot PDF

Method Statement - Hot PDF

Uploaded by

Rishabh Verma0 ratings0% found this document useful (0 votes)

13 views6 pagesOriginal Title

Method Statement - Hot.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views6 pagesMethod Statement - Hot PDF

Method Statement - Hot PDF

Uploaded by

Rishabh VermaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

METHOD STATEMENT

PROJECT: APPLICATION OF HOT INSULATION OF

PIPING & EQUIPMENTS FOR DIAMOND PROJECT AT

AARTI INDUSTRIES LIMTED

CLIENT:- AARTI INDUSTRIES LIMITED, DAHEJ

UE

CONTRACTOR:- LLOYD INSULATIONS (INDIA) LIMITED.

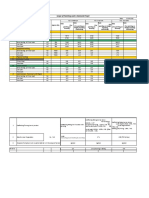

Document Reference : LIIL/AIL AINS/MS/H/001/

=| cs

Fy

| gal

Date: | "99, 79 .28/9

Name: | Kamlesh Yadav | H, kabie | Senevson) Vo Goh

L | |

| Prepared By LIL |"Reviewed By | Approved By | Approved By | Approved By |

un | tie | eaenie” | Aepered® |

| woraNsuLaTion

PROCEDURE FOR U

PIPING & EQUIPEMNTS

| AARTI INDUSTRIES LIMITED | | LLOYD INSULATIONS (1) LTD

PROPOSED METHOD STATEMENT (APPLICATION PROCEDURE)

FOR HOT INSULATION FOR PIPING & EQUIPMENT

Scope of work:

It covers the requirements for materials and execution of extemal thermal insulation

of above ground surfaces of piping, equipments, etc.

‘The scope of work involves Providing insulation for new ‘construction, which

includes supply of insulation materials, jacketing and fastening materials, We

(Lloyds) will be responsible for Proper coordination for our work, coordination with

the Engineer In charge (Aarti Industries Ltd) and the proper storage of the materials

and equipment.

The application of insulation shall be started after obtaining a release for insulation

duly signed by construction management (Aarti Industries Ltd. Engineer in charge)

Boxing up schedules and/or sequences for spading points should be made available

‘ous by Engineer in charge to ensure a safe and smooth start up

This specification describes the materials to be used and application procedure for the

insulation of equipments and piping,

Following are the specifications referred for preparation of this method statement:

1) The insulation of equipment and vessels, as per Specification Document No: 017+

GN-PE-SPC-003, dated 09-Jan-2019

AL the construction site, a copy of the work procedure Specification shall be

available for ready reference,

Piping Equipments, storage Tanks. and Vessel requiring insulations and the

temperature shall be normally specified, as applicable, on the following project

documents,

Piping and instrument diagram (P&ID) and line list.

Piping General arrangement drawings and isometric.

Instrument piping details and schedules,

‘Vessel, exchanger and storage tanks documents and insulation schedule,

Equipments suppliers Drawing for Equipments items in package plan.

Page Sof 5

HOT INSULATION =

@ PROCEDURE FOR G

PIPING & EQUIPEMNTS

AARTI INDUSTRIES LIMITED. LLOYD INSULATIONS (1) LTD

20

2a

22

23

3.0

31

MATERIAL TYPES

‘+ The types of insulation materials and it basic parameters are as per Specification

Document No: 017-GN-PE-SPC-003, dated 09-Jan-2019

Hot Insulations Materials

* Shall be preformed pipe section Density: 140 kg/im3 up to 8” diameter and above

that LRB Mattresses Density: 120 kg/m3 shall be used.

Cladding Materials

* For Equipment, Tanks, Column, Vessels etc. with Aluminum plain sheet 22 SWG

shall be used.

* For Piping up to 300 NB Pipe 24 SWG and above 300 NB Pipe 22 SWG Plain

Aluminum sheet.

Ancillary Materials

* For stitching of LRB mattresses GI Wire 20 sw shall be used and secured with

SS band 12 X 0.5 mm thick.

* For securing of pipe sections GI Wire 16 Sw shall be used,

* For securing of cladding materials by SS 304 screw (8 X 13mm) and SS 304

band 12 mm and 19 mm wide as per requirement and thickness 0.5 mm shall be

used.

‘+ For sealing of cladding metal sealant shall be used.

© For SS Pipe/Equipment 0.1 mm thick Aluminum foils shall be used,

Application of Insulation for Piping,

+ For pipes up to 8 inch preformed pipe sections are used shall be secured with GI

wire 16 SWG and above 8 inch LRB mattresses shall be used and stitched with

Gl wire 20 SWG and secured with $$ bands 12 X 0.5 mm thick.

Pipe Section

* End Joints of adjacent block shall be staggered one half of the length of the

block,

* Included angle between segments shall not be less than 30 deg. For both single

and double layer insulation.

* Further minimum are length segments should meet following staggering

requirements.

Page 5 of §

HOT INSULATI

PROCEDURE FOR U

PIPING & EQUIPEMNTS

| AARTL INDUSTRIES LIMITED LLOYD INSULATIONS (1) LTD

Lu

* When double Layer is applied both longitudinal and circumferential joints shall

‘be staggered. The are between longitudinal seam lines of the inside and the out

side layers of insulations shall have an angle of over 15 deg. Or the longitudinal

staggered by one layer thickness whichever is mote stringent, Circumferential

seams of the inside and outside layer shall be at least 100 mm apart.

3.2 LRB Mattresses

* Shall be applied over the surface with joints tightly butted and lazed tighter with

GT lacing wire.

* Each layer of insulation shall be secured firmly in place with binding wire. For

each section, binding wire shall be drawn above the insulation with ends tightly

twisted together.

33. Insulation of Elbows and Bends Tee. ete, (All Insulation Materials),

* For bends, elbows, tee, ete preformed section shall be cut in segments, Segments

and pipe section shall be close fitted to each other and pipe walls

* Pipe section and segments shall be fastened with SS wire, at least two wires per

section and one per segments, Ends of wires pushed in the insulation materials to

Prevent the damage of sheeting.

* Loose wool may be used for lining of valve and flanges,

3.4 Application of piping cladding

* Straight pipe shall have Aluminum plain metal jacketing cut and machine rolled,

wrapped, with $0 mm minimum overlaps on both longitudinal and

circumferential overlaps all laps shall be arranged to shed water.

* A single bid shall be made on all over laps to ensure tight metal-to-metal

watertight arrangements.

© Self-tapping screws at every 150 mm shall be provided at all longitudinal

overlaps for both horizontal and vertical piping,

* To prevent damage to insulation at flanges equipments nozzles, valve a distance

Gf bol length plus 20 mm shall be maintained between insulation and the langes,

thus allowing free removal of flange bolts and nuts.

4.0, Insulation for Personnel protection

* For protection from heat bums Personal protection has to be provided for pipes and

equipments having temperatures more than 60 degree temperatures are. accessible

from 2 meters from ground level/ Floor area or Platform. ‘The said equipment o

Page Sof S

HOT INSULATION

PROCEDURE FOR Q

| PIPING & EQUIPEMNTS

| AARTI INDUSTRIES LIMITED LLOYD INSULATIONS ()LTD

Piping shall be shielded with Aluminum perforated sheet of the thickness specified

for personal protection,

5.0 Equipments

5.1 Preparation

* {RE caulpment surface shall be fre from moisture and shall be thoroughly dry

before commencement of insulation application,

* Only insulation and accessory materials that have been properly stored, kept dry

and free from contamination shall be used,

* Surface to be insulated shall be free from grease, loose scale, dirt and other

foreign matter. The required degree of preparation of the surfaces shall be 2

combination of Cotton rags, dusting as found necessary and agreed before hend

with the Engineer in-Charge.

52 Insulation application for Equipments

* Equipment insulation work shall not be commenced until necessary testing have

been completed and released for insulation by the Engineer in-charge

* Por SS Equipments before applying lagging, required thickness of Aluminum foil

O.1 mm thick "shall be wrapped to prevent the equipment from coming in 10

direct contact with lagging materials

* Fauipment insulation work shall not be commenced until necessary testing have

been completed and released for insulation by the Engineer in-charge.

* Specified thickness of LRB Mattresses shall be fixed with joints properly butted

and laced together with GI Wire.

* Insulation applied in to two or more layers shall have staggered joints. Final layer

oF insulation shall be further secured by providing SS 304 band (12 mm X ).¢

mm thick) duly tighten,

Page 5 of §

[

HOT INSULATION

PROCEDURE FOR U

PIPING & EQUIPEMNTS

AARTI INDUSTRIES LIMITED LLOYD INSULATIONS (1) LTD

L

5.3 Application of cladding for Horizontal and Vertical Equipments,

* Aluminum plain sheet shall be provided with minimum over lap in the vertical

Joints will be 50 mm. For Horizontal overlap will be minimum SO mm, which

shall be secured by using self tapping screw at 150 mm c/c interval,

* Cladding to cladding fastening, at both horizontal and vertical overlaps shall be

alternately by “Pop” rivet or SS screws,

7 ‘+ Cladding joints shall be sealed with metal sealant,

* Finally cladding sheet shall be secured with SS 304 band (12 or 19 mm X 0.5 mm

thick) as applicable,

Mode of Measurement: As per IS 14164 : 1994

Page 5 of §

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

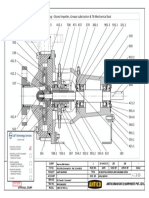

- AIL Dahej Operation Manual For 18 Inch Dia. 15 Plates Zero Hold Up Sparkler Filter SystemDocument4 pagesAIL Dahej Operation Manual For 18 Inch Dia. 15 Plates Zero Hold Up Sparkler Filter SystemRishabh VermaNo ratings yet

- Installation, Operation& Maintenance Manual For PLC&PLM Series PDFDocument25 pagesInstallation, Operation& Maintenance Manual For PLC&PLM Series PDFRishabh VermaNo ratings yet

- Installation, Operation& Maintenance Manual For PLC&PLM Series PDFDocument25 pagesInstallation, Operation& Maintenance Manual For PLC&PLM Series PDFRishabh VermaNo ratings yet

- Comparision Painting RatesDocument2 pagesComparision Painting RatesRishabh VermaNo ratings yet

- Painting SchemeDocument2 pagesPainting SchemeRishabh VermaNo ratings yet

- General Terms & Conditions - InsulationDocument3 pagesGeneral Terms & Conditions - InsulationRishabh VermaNo ratings yet

- Terms and Condition For Insulation WorkDocument5 pagesTerms and Condition For Insulation WorkRishabh VermaNo ratings yet

- CRS Manual - PPPU PumpDocument27 pagesCRS Manual - PPPU PumpRishabh VermaNo ratings yet

- 5p0102ab - KSB Megachem - O&m Manual PDFDocument12 pages5p0102ab - KSB Megachem - O&m Manual PDFRishabh VermaNo ratings yet

- Final - Pump - Cross Section - 5P0312 ABCD - Code 1 PDFDocument1 pageFinal - Pump - Cross Section - 5P0312 ABCD - Code 1 PDFRishabh VermaNo ratings yet

- Final - Pump - Hydro Procedure - 5P0312ABCD - Antico - Code 4 PDFDocument1 pageFinal - Pump - Hydro Procedure - 5P0312ABCD - Antico - Code 4 PDFRishabh VermaNo ratings yet

- Technical Specification Sheet: Sr. No Project: Division: Doc. No: 3.1 IdentityDocument16 pagesTechnical Specification Sheet: Sr. No Project: Division: Doc. No: 3.1 IdentityRishabh VermaNo ratings yet

- Final - Pump Datasheet - 5P0312ABCD - Code 1Document2 pagesFinal - Pump Datasheet - 5P0312ABCD - Code 1Rishabh VermaNo ratings yet

- Final - Pump - 5P0312ABCD - Antico - GAD - Code 1Document1 pageFinal - Pump - 5P0312ABCD - Antico - GAD - Code 1Rishabh Verma100% (1)

- Final - Pump - Hydro Procedure - 5P0312ABCD - Antico - Code 4 PDFDocument1 pageFinal - Pump - Hydro Procedure - 5P0312ABCD - Antico - Code 4 PDFRishabh VermaNo ratings yet

- Final - Pump - QAP - 5P0312ABCD - Antico - Code 4 PDFDocument1 pageFinal - Pump - QAP - 5P0312ABCD - Antico - Code 4 PDFRishabh VermaNo ratings yet

- Checklist For Project Approval: A General GuidelinesDocument15 pagesChecklist For Project Approval: A General GuidelinesRishabh VermaNo ratings yet

- Discipline: Rev. No.: Size: Document No.: Unit / Area NameDocument5 pagesDiscipline: Rev. No.: Size: Document No.: Unit / Area NameRishabh VermaNo ratings yet

- Engicon Users Manua1lDocument16 pagesEngicon Users Manua1lRishabh VermaNo ratings yet

- Gearbox Manual - Bonfiglioli PDFDocument22 pagesGearbox Manual - Bonfiglioli PDFRishabh Verma0% (1)

- 2 - RankinecycleDocument4 pages2 - RankinecycleRishabh VermaNo ratings yet

- 5ST0307 - 017-T1-Me-Das-259 - 1 PDFDocument5 pages5ST0307 - 017-T1-Me-Das-259 - 1 PDFRishabh Verma100% (1)

- Concept Note PSD LAB - PHARMA API PLANTDocument17 pagesConcept Note PSD LAB - PHARMA API PLANTRishabh VermaNo ratings yet