Professional Documents

Culture Documents

Final - Pump - Hydro Procedure - 5P0312ABCD - Antico - Code 4 PDF

Uploaded by

Rishabh Verma0 ratings0% found this document useful (0 votes)

19 views1 pageThe hydro test procedures for pumps outline that non-metallic pump casings will undergo hydro testing at 1.5 times the maximum allowable working pressure, calculated as 1.1 times the shut off head at maximum impeller diameter plus static pressure. The casings will be held at this pressure for 30 minutes while leakage and pressure drop are monitored, and no leakage or drop indicates an acceptable casing for further assembly. Pressure gauges used in testing are calibrated annually, and project-specific hydro test pressures will follow approved data sheets and quality assurance plans.

Original Description:

Original Title

Final_Pump_Hydro procedure_5P0312ABCD_Antico_Code 4.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe hydro test procedures for pumps outline that non-metallic pump casings will undergo hydro testing at 1.5 times the maximum allowable working pressure, calculated as 1.1 times the shut off head at maximum impeller diameter plus static pressure. The casings will be held at this pressure for 30 minutes while leakage and pressure drop are monitored, and no leakage or drop indicates an acceptable casing for further assembly. Pressure gauges used in testing are calibrated annually, and project-specific hydro test pressures will follow approved data sheets and quality assurance plans.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views1 pageFinal - Pump - Hydro Procedure - 5P0312ABCD - Antico - Code 4 PDF

Uploaded by

Rishabh VermaThe hydro test procedures for pumps outline that non-metallic pump casings will undergo hydro testing at 1.5 times the maximum allowable working pressure, calculated as 1.1 times the shut off head at maximum impeller diameter plus static pressure. The casings will be held at this pressure for 30 minutes while leakage and pressure drop are monitored, and no leakage or drop indicates an acceptable casing for further assembly. Pressure gauges used in testing are calibrated annually, and project-specific hydro test pressures will follow approved data sheets and quality assurance plans.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

HYDRO TEST PROCEDURES

DATE:10.02.2017

17.06.2019

BELOW MENTIONED PROCEDURE WILL BE FOLLOWED FOR HYDRO TEST OF

PUMPS

HYDRO TEST WILL BE CONDUCTED ONLY FOR CASING IN NON METALLIC

PUMPS .

HYDRO TEST PRESSURE FOR CASINGS WILL BE SET 1.5 TIMES MAWP.

MAWP WILL BE CALCULATED BY FORMULA = (1.1 X SHUT OFF HEAD AT

MAX IMPELLER DIA OF PROPOSED PUMP MODEL) + S.P.

HOLD TIME FOR HYDRO TEST PRESSURE WILL BE 30 MINS.

DURING THIS 30 MINS LEAKAGE OR PRESSURE DROP IS TO BE

MONITORED.

NO LEAKAGE OR NO PRESSURE DROP INDICATES THAT TESTED CASING

IS ACCEPTABLE FOR FURTHER ASSEMBLY.

PRESSURE GAUGE USED IN HYDRO TESTS ARE CALIBRATED ANNUALLY.

FOR PROJECTS HYDRO TEST PRESSURE WILL BE AS PER APPROVED

DATA SHEET & QAP.

CHLORIDE CONTENT OF LIQUID IS NOT APPLICABLE AS CASING TO BE

HYDRO TESTED ARE NON METALLIC MADE OF GFRPP M.O.C.

For Anticorrosive Equipment Pvt.Ltd.

You might also like

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Final - Pump - Hydro Procedure - 5P0312ABCD - Antico - Code 4 PDFDocument1 pageFinal - Pump - Hydro Procedure - 5P0312ABCD - Antico - Code 4 PDFRishabh VermaNo ratings yet

- Proceedings of the 41st International Conference on Advanced Ceramics and CompositesFrom EverandProceedings of the 41st International Conference on Advanced Ceramics and CompositesWaltraud M. KrivenNo ratings yet

- MS-HKSS-Pigging Testing Drying Rev A - YNB 16''Document64 pagesMS-HKSS-Pigging Testing Drying Rev A - YNB 16''AAISATNo ratings yet

- Fundamentals of Gas Shale ReservoirsFrom EverandFundamentals of Gas Shale ReservoirsReza RezaeeNo ratings yet

- Pneumatic Test Procedure DT 29112017 CompressDocument7 pagesPneumatic Test Procedure DT 29112017 Compressjamesvarghese2812No ratings yet

- Natural Gas Processing: Technology and Engineering DesignFrom EverandNatural Gas Processing: Technology and Engineering DesignRating: 5 out of 5 stars5/5 (8)

- Pipeline Calculation PDFDocument7 pagesPipeline Calculation PDFZulfitrizulkarnain ZulkarnainNo ratings yet

- Environmental Scenario in Indian Mining Industry - an OverviewFrom EverandEnvironmental Scenario in Indian Mining Industry - an OverviewNo ratings yet

- Asme PTC 4.1Document5 pagesAsme PTC 4.1dgmprabhakarNo ratings yet

- ClorinationDocument5 pagesClorinationPARMOD KUMAR VermaNo ratings yet

- STS Qac Sop 003 - 1 Hydrotest & Pnuematic Test ProcedureDocument11 pagesSTS Qac Sop 003 - 1 Hydrotest & Pnuematic Test Proceduremohd as shahiddin jafriNo ratings yet

- Investigate A Gas Well Performance Using Nodal AnalysisDocument15 pagesInvestigate A Gas Well Performance Using Nodal Analysisrafiullah353No ratings yet

- Development of Improved Testing Procedure For Wells With Sustained Casing PressureDocument15 pagesDevelopment of Improved Testing Procedure For Wells With Sustained Casing PressureHamza HamzaNo ratings yet

- Process Simulation: Flow Assurance Case StudyDocument25 pagesProcess Simulation: Flow Assurance Case Studyrooparn28391No ratings yet

- Impact of Thermophysical Properties Research On Acid Gas Injection Process DesignDocument15 pagesImpact of Thermophysical Properties Research On Acid Gas Injection Process DesignDeyokeNo ratings yet

- Process Transients AnalysisDocument25 pagesProcess Transients AnalysisOtis ArmsNo ratings yet

- Mahmud 2017 IOP Conf. Ser. Mater. Sci. Eng. 217 012022Document15 pagesMahmud 2017 IOP Conf. Ser. Mater. Sci. Eng. 217 012022Ayleen QuezadaNo ratings yet

- NG Sampling TechniquesDocument5 pagesNG Sampling TechniquesRohmat HidayatNo ratings yet

- SPE 114127 Reliability of Multiphase Flowmeters and Test Separators at High Water CutDocument9 pagesSPE 114127 Reliability of Multiphase Flowmeters and Test Separators at High Water Cutshakouri1370_8902064No ratings yet

- Troubleshooting Liquid Carryover in Gas Compression Systems MySep White PaperDocument11 pagesTroubleshooting Liquid Carryover in Gas Compression Systems MySep White Paperthlim19078656No ratings yet

- Instructions For Nitrogen Oxides Detector TubeDocument1 pageInstructions For Nitrogen Oxides Detector TubeJohn Anthony DanaNo ratings yet

- Sop For HydrotestDocument3 pagesSop For HydrotestShyam QCNo ratings yet

- NITON - HYDRO TEST PROCEDURE - Rev.0Document6 pagesNITON - HYDRO TEST PROCEDURE - Rev.0PRASHANT100% (2)

- Gpa 2174Document15 pagesGpa 2174Ceciliagorra100% (2)

- Che413 Fluid Mechanics For Chemical Engineers: Group AssignmentDocument9 pagesChe413 Fluid Mechanics For Chemical Engineers: Group AssignmentfaizfaizNo ratings yet

- Sample Problem - NPSHA Calculation For PumpsDocument6 pagesSample Problem - NPSHA Calculation For Pumpsanayo100% (1)

- Water Chemistry: 17 June 2013 PMI Revision 00 1Document21 pagesWater Chemistry: 17 June 2013 PMI Revision 00 1Anil SinghNo ratings yet

- Schopper-Riegler Method (Traduccion)Document8 pagesSchopper-Riegler Method (Traduccion)donattellojrNo ratings yet

- Ms For Hyrdo Pneumatic Testing of Spherical TANKS (730-TK-03 A/B & C) A-CON-PRO-730-38939Document15 pagesMs For Hyrdo Pneumatic Testing of Spherical TANKS (730-TK-03 A/B & C) A-CON-PRO-730-38939Ramzi ZoghlamiNo ratings yet

- Spe 123085Document7 pagesSpe 123085Jose Gregorio Fariñas GagoNo ratings yet

- Initial DefenceDocument19 pagesInitial DefenceUmair KhanNo ratings yet

- Method Statement of Hydro TestDocument4 pagesMethod Statement of Hydro Testsharan21v100% (2)

- 00-Studio ScaleChem CIBPDocument13 pages00-Studio ScaleChem CIBPthangNo ratings yet

- Hydrogen Content of Gases by Gas ChromatographyDocument3 pagesHydrogen Content of Gases by Gas ChromatographyDavinNo ratings yet

- Effective Managed Pressure Drilling ImplementationDocument31 pagesEffective Managed Pressure Drilling ImplementationNavya Puttagunta100% (1)

- Method 11 PDFDocument28 pagesMethod 11 PDFMichael StevenNo ratings yet

- Successful Placement CementDocument11 pagesSuccessful Placement CementOmerNo ratings yet

- SPE 53968 Intermittent Gas Lift Optimization in Rosa Mediano FieldDocument8 pagesSPE 53968 Intermittent Gas Lift Optimization in Rosa Mediano FieldariNo ratings yet

- Performance of Multiphase Twin-Screw Pump During The Period of Wet-Gas CompressionDocument5 pagesPerformance of Multiphase Twin-Screw Pump During The Period of Wet-Gas CompressionMaria AlfonzoNo ratings yet

- IADC/SPE-178860-MS Impact On Oil-Based Drilling Fluid Properties From Gas Influx at HPHT ConditionsDocument13 pagesIADC/SPE-178860-MS Impact On Oil-Based Drilling Fluid Properties From Gas Influx at HPHT ConditionsBruno HoinschyNo ratings yet

- Design & Operation of A Selective Sweetening Plant Using MDEADocument10 pagesDesign & Operation of A Selective Sweetening Plant Using MDEADiego1980bNo ratings yet

- Meeting MinutesDocument5 pagesMeeting Minutesshahid154205No ratings yet

- Procedure For The Pressure Mechanical Integrity Test For The Casing of An Underground Hydrocarbon Storage WellDocument3 pagesProcedure For The Pressure Mechanical Integrity Test For The Casing of An Underground Hydrocarbon Storage Wellvirnando nainggolanNo ratings yet

- Hydrocarbon Dewpoint DeterminDocument8 pagesHydrocarbon Dewpoint Determineng20072007No ratings yet

- SPE-177971-MS - Processing Formation Test Data To Reduce The Risk Inherent in Capturing Representative Samples in Zones With Highly Varying PermeabilitiesDocument13 pagesSPE-177971-MS - Processing Formation Test Data To Reduce The Risk Inherent in Capturing Representative Samples in Zones With Highly Varying PermeabilitiesSamanta MirandaNo ratings yet

- 10 1 1 623 274 PDFDocument7 pages10 1 1 623 274 PDFmirkoNo ratings yet

- An Evaluation of Recent Mechanistic Models of Multiphase Flow For Predicting Pressure Drops in Oil and Gas WellsDocument11 pagesAn Evaluation of Recent Mechanistic Models of Multiphase Flow For Predicting Pressure Drops in Oil and Gas WellsfanziskusNo ratings yet

- Amin Bagrezale PDFDocument5 pagesAmin Bagrezale PDFJavier E. Guerrero ArrietaNo ratings yet

- Optimization of Gas Field Thesis Report PDFDocument68 pagesOptimization of Gas Field Thesis Report PDFjorge_h_riveroNo ratings yet

- Samuel 2020Document18 pagesSamuel 2020aidaNo ratings yet

- The University of Bradford Institutional RepositoryDocument49 pagesThe University of Bradford Institutional Repositoryمصطفى العباديNo ratings yet

- Multiflow InformationDocument4 pagesMultiflow InformationsouthliNo ratings yet

- HoseDocument3 pagesHoseSangeetha RangarajanNo ratings yet

- Soluble Salt Meter Product DatasheetDocument8 pagesSoluble Salt Meter Product DatasheetRajeev KhanNo ratings yet

- Determination of Hydrocarbon Dew Point Measurement in Natural GasDocument13 pagesDetermination of Hydrocarbon Dew Point Measurement in Natural GasgabowinerNo ratings yet

- Gas Valves Interstage Pressure Between SRV and GCV high-SEP10 PDFDocument4 pagesGas Valves Interstage Pressure Between SRV and GCV high-SEP10 PDFsanjeevchhabraNo ratings yet

- 028 Flare Gas Metering (English)Document12 pages028 Flare Gas Metering (English)Sergio A. Rdz. F.No ratings yet

- Lynn 1993Document10 pagesLynn 1993Agilen MagalingamNo ratings yet

- Taha 2017 IOP Conf. Ser. Mater. Sci. Eng. 257 012057 PDFDocument21 pagesTaha 2017 IOP Conf. Ser. Mater. Sci. Eng. 257 012057 PDFShameem KNo ratings yet

- Painting SchemeDocument2 pagesPainting SchemeRishabh VermaNo ratings yet

- General Terms & Conditions - InsulationDocument3 pagesGeneral Terms & Conditions - InsulationRishabh VermaNo ratings yet

- Terms and Condition For Insulation WorkDocument5 pagesTerms and Condition For Insulation WorkRishabh VermaNo ratings yet

- Comparision Painting RatesDocument2 pagesComparision Painting RatesRishabh VermaNo ratings yet

- CRS Manual - PPPU PumpDocument27 pagesCRS Manual - PPPU PumpRishabh VermaNo ratings yet

- Technical Specification Sheet: Sr. No Project: Division: Doc. No: 3.1 IdentityDocument16 pagesTechnical Specification Sheet: Sr. No Project: Division: Doc. No: 3.1 IdentityRishabh VermaNo ratings yet

- 5p0102ab - KSB Megachem - O&m Manual PDFDocument12 pages5p0102ab - KSB Megachem - O&m Manual PDFRishabh VermaNo ratings yet

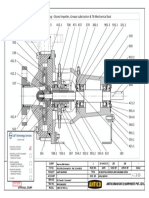

- Final - Pump - 5P0312ABCD - Antico - GAD - Code 1Document1 pageFinal - Pump - 5P0312ABCD - Antico - GAD - Code 1Rishabh Verma100% (1)

- Final - Pump - Cross Section - 5P0312 ABCD - Code 1 PDFDocument1 pageFinal - Pump - Cross Section - 5P0312 ABCD - Code 1 PDFRishabh VermaNo ratings yet

- Final - Pump - QAP - 5P0312ABCD - Antico - Code 4 PDFDocument1 pageFinal - Pump - QAP - 5P0312ABCD - Antico - Code 4 PDFRishabh VermaNo ratings yet

- Discipline: Rev. No.: Size: Document No.: Unit / Area NameDocument5 pagesDiscipline: Rev. No.: Size: Document No.: Unit / Area NameRishabh VermaNo ratings yet

- Final - Pump Datasheet - 5P0312ABCD - Code 1Document2 pagesFinal - Pump Datasheet - 5P0312ABCD - Code 1Rishabh VermaNo ratings yet

- AIL Dahej Operation Manual For 18 Inch Dia. 15 Plates Zero Hold Up Sparkler Filter SystemDocument4 pagesAIL Dahej Operation Manual For 18 Inch Dia. 15 Plates Zero Hold Up Sparkler Filter SystemRishabh VermaNo ratings yet

- Engicon Users Manua1lDocument16 pagesEngicon Users Manua1lRishabh VermaNo ratings yet

- 5ST0307 - 017-T1-Me-Das-259 - 1 PDFDocument5 pages5ST0307 - 017-T1-Me-Das-259 - 1 PDFRishabh Verma100% (1)

- Checklist For Project Approval: A General GuidelinesDocument15 pagesChecklist For Project Approval: A General GuidelinesRishabh VermaNo ratings yet

- Installation, Operation& Maintenance Manual For PLC&PLM Series PDFDocument25 pagesInstallation, Operation& Maintenance Manual For PLC&PLM Series PDFRishabh VermaNo ratings yet

- Installation, Operation& Maintenance Manual For PLC&PLM Series PDFDocument25 pagesInstallation, Operation& Maintenance Manual For PLC&PLM Series PDFRishabh VermaNo ratings yet

- 2 - RankinecycleDocument4 pages2 - RankinecycleRishabh VermaNo ratings yet

- Concept Note PSD LAB - PHARMA API PLANTDocument17 pagesConcept Note PSD LAB - PHARMA API PLANTRishabh VermaNo ratings yet

- Sodium Bicarbonate: Nature's Unique First Aid RemedyFrom EverandSodium Bicarbonate: Nature's Unique First Aid RemedyRating: 5 out of 5 stars5/5 (21)

- Piping Engineering Leadership for Process Plant ProjectsFrom EverandPiping Engineering Leadership for Process Plant ProjectsRating: 5 out of 5 stars5/5 (1)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- An Applied Guide to Water and Effluent Treatment Plant DesignFrom EverandAn Applied Guide to Water and Effluent Treatment Plant DesignRating: 5 out of 5 stars5/5 (4)

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Handbook of Cosmetic Science: An Introduction to Principles and ApplicationsFrom EverandHandbook of Cosmetic Science: An Introduction to Principles and ApplicationsH. W. HibbottRating: 4 out of 5 stars4/5 (6)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlFrom EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlRating: 4 out of 5 stars4/5 (4)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- A New Approach to HAZOP of Complex Chemical ProcessesFrom EverandA New Approach to HAZOP of Complex Chemical ProcessesNo ratings yet

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersFrom EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersRating: 4.5 out of 5 stars4.5/5 (2)

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- Piping and Instrumentation Diagram DevelopmentFrom EverandPiping and Instrumentation Diagram DevelopmentRating: 3.5 out of 5 stars3.5/5 (3)

- The Perfumed Pages of History: A Textbook on Fragrance CreationFrom EverandThe Perfumed Pages of History: A Textbook on Fragrance CreationRating: 4 out of 5 stars4/5 (1)

- Bioinspired Materials Science and EngineeringFrom EverandBioinspired Materials Science and EngineeringGuang YangNo ratings yet

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- The Periodic Table of Elements - Halogens, Noble Gases and Lanthanides and Actinides | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Halogens, Noble Gases and Lanthanides and Actinides | Children's Chemistry BookNo ratings yet