Professional Documents

Culture Documents

Benemérita Universidad Autónoma de Puebla: SEPTEMBER 27th, 2018

Uploaded by

veronica ruiz perezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Benemérita Universidad Autónoma de Puebla: SEPTEMBER 27th, 2018

Uploaded by

veronica ruiz perezCopyright:

Available Formats

SEPTEMBER 27th, 2018

BENEMÉRITA

UNIVERSIDAD

AUTÓNOMA DE PUEBLA

FACULTY OF ING. CHEMISTRY

SCHOOL OF ING. IN FOOD

FOOD ING LABORATORY

TUBE AND HEAD EXCHANGER

STUDENTS:

Jonathan Simón Cortes 201454594 jonsim_p13@hotmail.com

Verónica Ruíz Pérez 201547265 vero-ruiz@live.com.mx

Andrea Janay Trejo Romero 201551955 Romero janay3231@gmail.com

Mónica moreno Moctezuma 201400603 moni_mor.moc@hotmail.com

TEACHER:

DRA. EDITH CORONA JIMÉNEZ

PERIOD: AUTUMN 2018

ABSTRACT

In this practice we tested the known theoretical knowledge of a heat exchanger tube and shell, we conducted

experimentation using two different fluids depending on hot and cold, ethylene glycol as a coolant (cold)

and oil as a hot fluid to obtain our delta Of temperature; The type of flow that is handled in a heat exchanger

offers a great variation for the obtaining of our delta of temperature, in the same way the type of current

used in the process offers considerable variations of heat transfer, in this way, in In our experiment, we made

process arrangements, modifying the refrigerant inlet and outlet, thus causing what is known as parallel flow

and countercurrent flow in our exchanger.

INTRODUCTION magnitude of the local temperature difference,

which varies along said exchanger. (Yunus Cengel)

Experience tells us that if a cold can of carbonated

drink is left on the table, at some point it will reach TYPES OF HEAT EXCHANGERS

room temperature, while a hot potato will cool.

The simplest type of heat exchanger consists of two

When a body is placed in a medium that is at a

concentric tubes of different diameters, as shown in

different temperature, the energy transfer takes

the following figure called double tube heat

place between the body and the medium until

exchanger. In a double tube heat exchanger two

thermal equilibrium is established, that is, when

types of flow arrangement are possible: in the

both reach the same temperature. parallel flow the two fluids, cold and hot, enter the

Heat is defined as the form of energy that is exchanger at the same end and move in the same

transferred between systems (or between a system direction. On the other hand, in the backflow the

and the outside) due to a temperature difference. fluids enter the exchanger at the opposite ends and

That is, an interaction of half the time has a short flow in opposite directions.

duration. Then it follows that there can be no

Another type of heat exchanger, designed

transfer of calories between systems that are at the

specifically to achieve a large surface area of heat

same temperature.

transfer per unit volume, is compact. (Fig. 1).

HEAT EXCHANGERS

The heat exchangers are devices that facilitate the

exchange of heat between two fluids that are at

different temperatures and at the same time

prevent them from mixing with each other

In an exchanger heat transfer usually involves

convection in each fluid and conduction through the

wall that separates them. In the analysis of heat

exchangers, it is convenient to work with a total heat

Fig. 1 Different flow res and associated temperature profiles in a double

transfer coefficient U that takes into account the tube heat exchanger.

contribution of all these effects on said transfer. The In compact exchangers the two fluids tend to move

ratio of the heat transfer between the two fluids at perpendicularly to each other and that flow

a given location to an exchanger depends on the configuration is known as cross flow, which is still

classified as unmixed or mixed flow, depending on

its configuration. (Fig. 2)

OBJECTIVES

GENERAL

The purpose of this report is to demonstrate the

characteristics, operation and evidence of the

descriptive analysis of heat transfer, using a tube

and shell heat exchanger that uses parallel flow and

countercurrent through temperature changes.

Fig. 2 Different flow configurations in cross flow heat exchangers. ESPECIFIC

• Identify and quantify heat transfer between

experimentation and the use of

Perhaps the most common type of heat exchanger

mathematical models.

in industrial applications is that of pipes and shell.

• Know the heat transfer efficiency according

(Fig. 3) These heat exchangers contain a large to the counter current or parallel

number of tubes (sometimes several hundred) arrangement.

packed in a helmet with their axes parallel to it. The

• Identify the temperature deltas

transfer of heat takes place as one of the fluids

corresponding to cold and hot fluid.

moves inside the tubes, while the other moves

• Know the applied operation of a tube and

outside of these, passing through the shell. It is

shell heat exchanger.

common to place deviators in the shell to force the

fluid to move transverse to said shell in order to PROCESS FLOW DIAGRAM

improve heat transfer, and also to maintain a

uniform spacing between the tubes. Tube and shell

exchangers are further classified according to the

number of steps that are carried out by the shell and

the tubes. For example, exchangers in which all

tubes form a U in the shell are said to be one passage

through the shell and two passages through the

tubes. (Yunus Cengel)

Fig. 3 Diagram of a shell and tube heat exchanger (one passage

through the shell and one passage through the tubes).

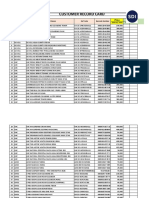

Table 4. Parallel operation 60 ° C

Proof T1 T2 T3 T4

1 62.4 43.6 24.8 27.5

2 60.1 40.9 23.4 27.6

Average 61.25 42.25 24.1 27.55

Table 5. Parallel flow

Reduction of the temperature of the hot fluid

ΔT hot = °C 19.95

Increase in the temperature of the cold fluid

ΔT cold = °C 2.5

Thermal efficiency for the hot fluid

ηc = % 54.95867769

RESULTS Thermal efficiency for cold fluid

ηf= % 6.887052342

Table 1. Oil data at 60 ° C Thermal efficiency

Flow ηh= % -24.03581267

Density

cp (KJ/kgK) mass volumetric Load emitted by the hot fluid

(Kg/L)

(kg/min) L/min Qe= W 1416.849

1675 0.9104 2.54912 2.8

(J/Kgk) kg/s

1675 0.0424

DISCUSION DE RESULTADOS

Table 2. Counter current operation 60 ° C

Proof T1 T2 T3 T4

1 59.9 40.2 23.8 26.2

2 59.8 39.6 23.3 25.9

Average 59.85 39.9 23.55 26.05

Table 3. Countercurrent fluid

Reduction of the temperature of the hot fluid

ΔT hot = °C 19

Increase in the temperature of the cold fluid

ΔT cold = °C 3.45

Thermal efficiency for the hot fluid

ηc = % 51.14401077

Thermal efficiency for cold fluid

ηf= % 9.286675639 Fig. 1 Engineering and schematic diagram of the heat

Thermal efficiency transfer equipment by pipe and shell manipulated in

ηh= % 20.92866756 practice.

Load emitted by the hot fluid

Qe= W 1349.38

DISCUSSION OF RESULTS 1. QUESTIONNAIRE

Based on the results obtained from heat transfer What is the mechanism of heat transfer in a heat

and expressed in tables 3 and 5, we determined that exchanger shell?

the most efficient and, in this case, slightly more

There are 2 types of heat transfers: conduction and

noticeable heat exchange, was obtained by the

convection. The contact of a fluid with a solid is the

countercurrent flow, by means of theoretical and

transfer by convection and the temperature delta

practical knowledge we can justify that this result is

suffered by the internal tubes of the exchanger from

due to the fact that each of the fluids enters the

side to side, there is transfer by conduction.

exchanger on different sides and that the fluid with

the lowest temperature exits in counterflow of the

heat exchanger at the end where the fluid with the 2. What variables can be controlled

highest temperature enters, the temperature of the exchangers?

coldest fluid it will approximate the temperature of • The inlet flow of the cold fluid (cooling

the inlet fluid, if necessary, to a parallel flow system)

exchanger. • The inlet flow of the hot fluid (substance to

be cooled)

We were able to perform the manipulation of a tube

• cold fluid inlet temperature

and shell exchanger handling the types of parallel

• Hot fluid inlet temperature

and countercurrent flow.

We verified that the deltas of temperature 3. Describe the operation of a plate heat

corresponding to cold and hot fluid are not exchanger

proportional as it is possible to be thought, that is to

say that the temperature that a fluid loses the other The total of the liquid that passes through the

does not acquire it, this because the process was not exchanger is divided into equal parts according to

handled to closed and isolated conditions of the the number of plates that the exchanger arranges.

environment, causing a loss of heat in the Every two plates generate a circulation channel by

which one of those portions of liquid flows. Thanks

environment.

to this mechanism, and to the corrugation of the

CONCLUSION plates, the speed of circulation is considerably

increased creating a turbulent flow that reduces the

The practice was based on tube heat exchangers and risk of incrustations while optimizing the heat

shell in parallel and counter-current, the difference exchange, in such a way that the fluid will achieve

being the direction of the fluids. The heat 100% of its temperature at the end of the course of

exchangers are of great importance in the industry, each plate. Three important aspects to consider

since in some processes it is useful to transfer heat regarding the plate heat exchanger are:

from a hot fluid to a cold fluid, for multiple purposes

such as: energy saving or to bring some fluid to an • Ultra-thin plates with high heat exchange

optimum temperature for example in the coefficient are more efficient.

pasteurization of beverages within the food • Current heat exchangers require very little

industry, ventilation in space conditioning systems, space for assembly, compared to old hull and

boilers, condensers, and preheaters or fluid cooling. tube.

Therefore, it is convenient to know the types of heat • In addition, they are easy to maintain

exchangers, their design, structure and principles of because in case of inlays, their dismantling

functionality. and cleaning is very simple and fast.

heat exchangers and currently around of the world

is offered in the market multitude of different

4. Mentions at least 3 computers using a heat

designs of these.

exchanger in which processes.

• Cooler

• Heater

• Fridge REFERENCES

• Capacitor

*Cengel, Yunus, Ghajar, Afshin. (2011).

• Evaporator

Transferencia de calor y masa. Fundamento y

• Reboiler

aplicaciones.4 ed. McGraw-Hill. México.

5. Mentions food exchangers are used *González D. (marzo, 2002). Intercambiadores de

• Milk Reception: Cooling of raw milk calor: tipos generales y aplicaciones. septiembre 25,

from 15 to 4 º C through ICP 2018, de Departamento de termodinámica y

• pasteurization — Termination: The fenómenos de transporte Universidad Simón Bolívar

product is treated up to 75 º C in Sitio web:

multistage pasteurizers https://es.slideshare.net/yumardiaz/intercambiado

• Wine and liquor SECTOR: res-decalortiposgeneralesyaplicaciones-8408335

✓ Cooling of must through ICP *MANUAL DEL INGENIERO QUÍMICO. Perry &

✓ Pasteurization of wine at low Chilton. Sección 10. “Transferencia de Calor”.

temperature by ICP Sección 11. “Equipos de Transferencia de Calor”. Mc

• Sugar SECTOR: Graw Hill.

✓ Treatment of syrups at high

temperatures through ICP *Jaramillo O. (noviembre 20, 2007). Comparación

✓ ICP Auxiliary equipment for de los tipos de intercambiadores. septiembre 25

cooling and warming of syrup 2018, de UNAM Sitio web:

• UHT treatment: At these ICP http://www.cie.unam.mx/~ojs/pub/HeatExchanger

temperatures are reached up to 147 /node27.html

º C of the product Brewing industry: *Zohuri, Bahman, and Patrick McDaniel. 2015.

✓ Cooling of must via ICP for Thermodynamics in nuclear power plant.

large volumes. Switzerland: Springer Publishing Company.

✓ Flash" pasteurization of

6. The design of the different heat exchangers

is due to exist?

Heat exchangers are one of the most common

equipment found in most industries.

The role of consumers has acquired great

importance in the face of need to save energy and

have optimal equipment not only depending on its

thermal analysis and economic performance in the

installation, but in function of other factors such as

the energy use of the system and the availability and

amount of energy and raw materials needed to

meet a certain function. There are several types of

You might also like

- Concentric Tube Heat ExchangerDocument19 pagesConcentric Tube Heat ExchangerAnisAsyiqinNo ratings yet

- Heat ExchangerDocument11 pagesHeat ExchangerSyafiyatulMunawarahNo ratings yet

- Lab 2 - Heat Exchanger - ManuscriptDocument11 pagesLab 2 - Heat Exchanger - ManuscriptSyafiyatulMunawarahNo ratings yet

- Project Report Format and GradingDocument24 pagesProject Report Format and GradingYaren ErelNo ratings yet

- Experiment of Shell & Tube Heat ExchangerDocument29 pagesExperiment of Shell & Tube Heat ExchangerNanaNaurah9578% (9)

- Abstract: Figure 1: Counter-Current Concentric Heat ExchangerDocument6 pagesAbstract: Figure 1: Counter-Current Concentric Heat ExchangerAy NinaNo ratings yet

- CFD Analysis of Shell and Tube Heat Exchanger PDFDocument6 pagesCFD Analysis of Shell and Tube Heat Exchanger PDFSrijan VermaNo ratings yet

- HMT ReportDocument12 pagesHMT ReportRushikeshNo ratings yet

- TurnitinDocument8 pagesTurnitinirfan hilmanNo ratings yet

- AME 365 Heat Transfer & Combustion (UNIT 5)Document73 pagesAME 365 Heat Transfer & Combustion (UNIT 5)somenewguyonthewebNo ratings yet

- Heat Exchangers LectureDocument37 pagesHeat Exchangers LectureTerna Orlanda100% (2)

- Group 2 - L2 - ManuscriptDocument5 pagesGroup 2 - L2 - ManuscriptAriff HaiqalNo ratings yet

- Heat ExchangerDocument25 pagesHeat ExchangerFarisRazzak67% (3)

- Faculty of Engineering and Technology Department of Chemical EngineeringDocument10 pagesFaculty of Engineering and Technology Department of Chemical Engineeringmasedi malatjiNo ratings yet

- Heat Exchangers and Heat Pipes: Figs. 1 2Document6 pagesHeat Exchangers and Heat Pipes: Figs. 1 2Ricardo Rincon VegaNo ratings yet

- Heat Exchanger CalculationsDocument19 pagesHeat Exchanger CalculationsJohnasGoodmanNo ratings yet

- Double Pipe Heat ExchangerDocument88 pagesDouble Pipe Heat ExchangerirfanNo ratings yet

- Heat ExchangerDocument19 pagesHeat ExchangerSydney Jaydean KhanyileNo ratings yet

- CHE38 Group1 LaboratoryReport1Document24 pagesCHE38 Group1 LaboratoryReport1Carl Anthony CabigonNo ratings yet

- Heat Exchanger Lab ReportDocument15 pagesHeat Exchanger Lab ReportOmar Samir100% (1)

- Heat ExchangerDocument33 pagesHeat ExchangerKhloud MadihNo ratings yet

- Heat ExchangerDocument21 pagesHeat ExchangersedamyrulNo ratings yet

- (Group 2) Plater Heat ExchangerDocument9 pages(Group 2) Plater Heat ExchangerRiethanelia UsunNo ratings yet

- ABSTRACTDocument2 pagesABSTRACTNameeraNo ratings yet

- Lab Heat ExchangerDocument16 pagesLab Heat Exchangerbaiti_atiqah86% (7)

- Evap5 PDFDocument20 pagesEvap5 PDFOsman TugayNo ratings yet

- Chapter 10. Heat Exchanger DevicesDocument36 pagesChapter 10. Heat Exchanger DevicesDayanidiNo ratings yet

- Final ReportDocument70 pagesFinal ReportSudarshan KulandhaivelNo ratings yet

- Double Pipe Heat ExchangerDocument21 pagesDouble Pipe Heat ExchangerIsabel GarciaNo ratings yet

- COUNTER FLOW HEAT EXCHANGE (Heat Transfer)Document9 pagesCOUNTER FLOW HEAT EXCHANGE (Heat Transfer)hayder alaliNo ratings yet

- Classification of Heat ExchangerDocument19 pagesClassification of Heat ExchangerSarayu GowdaNo ratings yet

- FEEDBACK Shell & Tube Heat ExchangerDocument8 pagesFEEDBACK Shell & Tube Heat ExchangerSuaid Tariq BalghariNo ratings yet

- Individual Report For Heat ExchangerDocument25 pagesIndividual Report For Heat ExchangerRuth sNo ratings yet

- Concentric Tube Heat ExchangerDocument19 pagesConcentric Tube Heat ExchangerBen Widdowson100% (2)

- Concentric Tube Heat Exchanger ReportDocument19 pagesConcentric Tube Heat Exchanger Reportillyzl100% (1)

- Lecture 6Document17 pagesLecture 6ahmed el-sayedNo ratings yet

- Shell and Tube Heat ExchangerDocument24 pagesShell and Tube Heat ExchangerAnonymous uYFklaAiNo ratings yet

- Heat and Heat ExchangerDocument20 pagesHeat and Heat ExchangerDamisha DamishaNo ratings yet

- Heat Exchangers: Fundamentals of Thermal-Fluid Sciences, 3rd EditionDocument64 pagesHeat Exchangers: Fundamentals of Thermal-Fluid Sciences, 3rd EditionJhoan Fernando Acevedo EspinosaNo ratings yet

- Heat ExchangerDocument58 pagesHeat ExchangercanyourunNo ratings yet

- Con Cent Eric Tube Heat ExchangerDocument15 pagesCon Cent Eric Tube Heat ExchangerAmr BanawanNo ratings yet

- 09 - Heat Transfer EquipmentDocument22 pages09 - Heat Transfer EquipmentsanelisofuturemoyoNo ratings yet

- Stirred Tank ReactorsDocument38 pagesStirred Tank ReactorsJimNo ratings yet

- Heat Exchanger PDFDocument9 pagesHeat Exchanger PDFsunita45No ratings yet

- 4 7 1 SM PDFDocument5 pages4 7 1 SM PDFTechnico TechnocratsNo ratings yet

- Shell and Tube Heat ExchangerDocument31 pagesShell and Tube Heat ExchangerDhiyyah Mardhiyyah100% (1)

- Introduction To Heat Exchangers BBDocument19 pagesIntroduction To Heat Exchangers BBgks5kc8bhdNo ratings yet

- Wa000777Document12 pagesWa000777RushikeshNo ratings yet

- 2151909Document24 pages2151909Kummitha Obula ReddyNo ratings yet

- Transpo Printable Lecture4Document10 pagesTranspo Printable Lecture4Jabin Sta. TeresaNo ratings yet

- Thermal Analysis of The Heat Exchanger Tubes Using Ansys PDFDocument4 pagesThermal Analysis of The Heat Exchanger Tubes Using Ansys PDFMuhammadBarrylAnggriawanNo ratings yet

- Heat Exchanger ReportDocument16 pagesHeat Exchanger ReportMahmoud Hendawy100% (4)

- Heat Transfer LMTDDocument6 pagesHeat Transfer LMTDFontanilla Mark AnthonyNo ratings yet

- Double Pipe Heat ExchangersDocument27 pagesDouble Pipe Heat ExchangersDURGA KASTURINo ratings yet

- Shell and Tube Heat ExchangerDocument30 pagesShell and Tube Heat ExchangerMurphy MofeNo ratings yet

- Introduction +objectivesDocument3 pagesIntroduction +objectivesSyafiyatulMunawarahNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Bus 5910 Written Assignment Unit 6Document10 pagesBus 5910 Written Assignment Unit 6Sheu BasharuNo ratings yet

- The Health Consequences of DehydrationDocument4 pagesThe Health Consequences of DehydrationJulio AlvesNo ratings yet

- 111 1第1次段考二年級英文Document5 pages111 1第1次段考二年級英文Alice luluNo ratings yet

- BPP Module 4 PDFDocument39 pagesBPP Module 4 PDFNeil Jean Marcos BautistaNo ratings yet

- The Thirty-Nine StepsDocument184 pagesThe Thirty-Nine StepsAndrew WatNo ratings yet

- COUNTABLES AND UNCOUNTABLES PRACTICE - Amaya Garcia Angie Gracielita PDFDocument1 pageCOUNTABLES AND UNCOUNTABLES PRACTICE - Amaya Garcia Angie Gracielita PDFHkNo ratings yet

- Shakers Act 1Document36 pagesShakers Act 1Rebekah HesmondhalghNo ratings yet

- Cenovnik / Price List: WWW - Hotelmoskva.rsDocument28 pagesCenovnik / Price List: WWW - Hotelmoskva.rsFilmske LokacijeNo ratings yet

- Activity No. 8 Menu PlanningDocument5 pagesActivity No. 8 Menu PlanningGabrielle VizcarraNo ratings yet

- The Bro CodeDocument11 pagesThe Bro CodeLuka Dragic100% (2)

- Attachment - 9387 - 63bd823872cf8 - 63bd81f56e412 - A Man Like None Other 101 110Document29 pagesAttachment - 9387 - 63bd823872cf8 - 63bd81f56e412 - A Man Like None Other 101 110BURAK DEMIRNo ratings yet

- Bangladeshi TeaDocument7 pagesBangladeshi TeaShahriarNo ratings yet

- Present Simple ContinuousDocument4 pagesPresent Simple ContinuousGiangNo ratings yet

- About Yacht La Pinta: Technical Specifications Deck PlansDocument1 pageAbout Yacht La Pinta: Technical Specifications Deck Planshernan pardoNo ratings yet

- The Medical Medium On The Virtues of Celery JuiceDocument3 pagesThe Medical Medium On The Virtues of Celery JuiceIrma MonsalveNo ratings yet

- Barista CBLMDocument49 pagesBarista CBLMMicah RamosNo ratings yet

- UNIV340 Lecture Notes 5Document3 pagesUNIV340 Lecture Notes 5Aaron LskNo ratings yet

- Demo PPT Scie 7Document18 pagesDemo PPT Scie 7Tricia RodriguezNo ratings yet

- Ir Div - Notice Related To Oppositon-Notice PDFDocument422 pagesIr Div - Notice Related To Oppositon-Notice PDFshyam143225No ratings yet

- The Sunset Limited - Full Movie - enDocument70 pagesThe Sunset Limited - Full Movie - enPostole BogdanNo ratings yet

- Corrupting Cali Declan's Story Syndicate Daddies Book 1 by KateDocument216 pagesCorrupting Cali Declan's Story Syndicate Daddies Book 1 by Katechamonisabele100% (1)

- Coca Cola Business and Sustainability Report 2018 PDFDocument72 pagesCoca Cola Business and Sustainability Report 2018 PDFTrisha Jean LayosNo ratings yet

- WWW Kherysuryawan IdDocument8 pagesWWW Kherysuryawan IdXTD ChannelNo ratings yet

- COMPANY REPORTS Quaker Oats To Acquire Snapple The New York TimesDocument4 pagesCOMPANY REPORTS Quaker Oats To Acquire Snapple The New York Timesibs56225No ratings yet

- The Bacardi LimitedDocument25 pagesThe Bacardi LimitedJefree SarkerNo ratings yet

- Cookery Q4 Week 2 LAS 2Document1 pageCookery Q4 Week 2 LAS 2EssaNo ratings yet

- CRC Princess 2 Mei 2022Document52 pagesCRC Princess 2 Mei 2022Maulfaya NoorNo ratings yet

- Rose Garden Tea Room Menu 2023Document2 pagesRose Garden Tea Room Menu 2023Catherine ChaplinNo ratings yet

- David B. Cooper - Alcohol Use (2000)Document307 pagesDavid B. Cooper - Alcohol Use (2000)BrunoNo ratings yet

- Vikram's English Academy (ICSE) : ENGLISH Paper-1 Set BDocument3 pagesVikram's English Academy (ICSE) : ENGLISH Paper-1 Set BPrachi KiranNo ratings yet