Professional Documents

Culture Documents

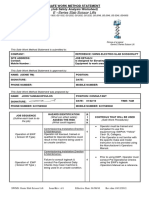

Towell Engineering HSE lifting procedure

Uploaded by

ibrahimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Towell Engineering HSE lifting procedure

Uploaded by

ibrahimCopyright:

Available Formats

Towell Engineering HSE PROCEDURE

CONTENTS

Page

1.0 Introduction 4

2.0 Scope 4

3.0 Reference 4

4.0 Responsibilities 5

4.1 Contract Manager 5

4.2 Construction Manager 5

4.3 HSE Advisor 5

4.4 Lifting Supervisor 5

4.5 Operator 5

4.6 Banksman & Riggers 6

5.0 PROVISIONS 6&7

6.0 PROVISIONS FOR LIFTING 7&8

PREPARATION & EXECUTION

7.0 PROVISIONS FOR CONTROL OF 8&9

HEAVY AND CRITICAL LIFTS

8.0 LIFTING OPERATION CHECKLIST 10

DISTRIBUTION LIST:

DOC. No. TE-HSE-PRO-035 Rev 1 REV. No. 1 Page 2 OF 8

Towell Engineering HSE PROCEDURE

S.NO. DESIGNATION COPY NO. LOCATION

1. Contract Manager 1 H.O

2. CQHSE Manager 2 H.O

5. Construction 3 Site

Manager/Contractor Site Rep.

6. HSE Advisor 4 Site

7. Mechanical Engineer/ Lifting 5 Site

Supervisor (Site)

8. Sub contractors

As applicable

As applicable

1.0 INTRODUCTION

DOC. No. TE-HSE-PRO-035 Rev 1 REV. No. 1 Page 3 OF 8

Towell Engineering HSE PROCEDURE

Towell Engineering. personnel carry out various lifting operations during activities like construction,

erection, commissioning & maintenance.

Purpose of this document is to guide TE personnel in planning & executing various lifting operations

successfully, effectively & safely.

This procedure includes various lifting operations, which are carried out by using mobile, or vehicle

mounted cranes and lifting gears.

2.0 SCOPE

The procedure shall be implemented in all interior based projects of Towell Engineering.

3.0 REFERENCE

Specification for lifting equipment and lifting operations SP-1239

Training requirements For Lifting Operations Personnel SP-1251

PDO procedures for lifting operations PR 1058.

Established practices & client instructions.

4.0 RESPONSIBILITIES

4.1 CONTRACT MANAGER

It is the responsibility of the Contract manager to ensure that the procedure is implemented at project

level. It is also his duty to ensure that the information is cascaded to all workforces.

DOC. No. TE-HSE-PRO-035 Rev 1 REV. No. 1 Page 4 OF 8

Towell Engineering HSE PROCEDURE

4.2 CONSTRUCTION MANAGER

Construction manager as the CONTRACTOR SITE REPRESENTATIVE shall ensure that all

the provisions of this procedure are strictly adhered to.

He shall ensure that all lifting appliances are compliant to various requirements of Client &

Government. He shall ensure that all personnel assigned with the responsibility of lifting operations

are suitably experienced, trained according to requirements and are competent to carry out the lifting

operation safely.

He shall ensure that all necessary authorizations are obtained from PDO before start of work.

4.3 HSE Advisor

HSE advisor shall randomly monitor & report to higher management about compliance of the

provisions of this procedure.

He shall also check that the provisions of this procedure are not violated.

He shall cross check the compliance of lifting appliance to the standard specifications.

He shall also check the compliance of lifting personnel to various training requirements.

He shall randomly check that proper authorizations from PDO are obtained prior to start of critical

lifting activities.

He shall immediately bring to the notice of Construction manager & senior management about non

compliances, if any.

He shall be responsible for cascading information in relation to this procedure to all concerned team

members and he shall accomplish this thru various interaction platforms.

4.4 LIFTING SUPERVISOR

Lifting supervisor is the designated person assigned with the responsibility of carrying out a certain

lifting operation. He shall ensure, at site levels, the compliance to this procedure & PDO

requirements.

He shall follow a checklist prior to start of work.

4.5 OPERATOR

Operator as an important part of lifting team shall be responsible of compliance to established safe

working procedures.

He shall possess proper licenses, training & experience to carryout lifting operations.

He shall follow only the hand signals of banksman.

He shall strictly adhere to the safe working load limits of his lifting appliance.

He shall follow the requirements as are described in this procedure.

4.6 BANKSMAN & RIGGERS

These being the part of lifting team shall be fully conversant with lifting activities & their own role.

They shall follow the requirements of this procedure & other established safe working procedures.

Riggers are responsible for selection of proper lifting gear & proper rigging of load.

5.0 PROVISIONS

DOC. No. TE-HSE-PRO-035 Rev 1 REV. No. 1 Page 5 OF 8

Towell Engineering HSE PROCEDURE

a. Lifting operation preparations shall include crane operator, a designated lifting supervisor,

banks man & riggers.

b. Lifting supervisor shall follow a checklist to ensure that all precautionary measures have been

taken.

c. Written permissions & PTW wherever applicable shall be obtained.

d. A lifting plan shall be discussed amongst crane operator, lifting supervisor, banks man &

riggers. Potential hazards shall be identified and the plan shall identify the means to avoid them.

The lifting plan shall also take account of any environmental factors i.e. temperature, moisture,

wind etc. that may affect the operation.

e. Before lifting it shall be ensured that when clear of ground, the load will remain both balanced &

stable. To achieve this, the hook must be positioned vertically above the centre of gravity (C.G)

the load. The legs of the sling(s) should be distributed as evenly as possible according to the

lifting points available

f. Load shall be assessed properly before carrying out the lifting operation. Weight, Centre of

gravity, lifting points & their compatibility with lifting gears shall be carefully assessed.

g. Lifting appliances shall have a current valid Inspection / Test certificate in accordance with PDO

specifications.

h. The lifting appliance shall be positioned above the centre of gravity of the load. It must, in

particular, be of sufficient Safe Working Load (SWL) and be able to move the load in a

controlled manner to allow positioning.

i. If a lifting point is to be used to be suitable it must also have sufficient Safe Working Load

(SWL)

j. Lifting gear shall have been inspected and marked with the current colour code in accordance

with SP 1239. It must have sufficient SWL to execute the lift.

k. Lifting Gear shall be marked or punched with I.D. Number, SWL and angle of lift.

l. The site where lifting is to take place shall be clear of obstructions including overhead power

lines.

m. Ground conditions shall be suitable to support and travel with the load (if applicable) There shall

be a clear and safe path from the lifting site to the landing site.

n. The landing site shall be level and strong enough to take the load.

o. The landing site may need preparation in which case this shall be done before the lift

commences.

6.0 PROVISIONS FOR LIFTING PREPARATION & EXECUTION:

The crane operator shall be satisfied that site conditions are suitable to execute the lift. He

should check the weight of the load against the crane capacity. The operator shall assess the radii

at which the crane will be required to operate during the lift and consult the load charts to verify

crane capacity to work under the load/radii combinations. He shall ensure the crane set up has an

adequate number of wire rope falls to accommodate the load.

All checks shall be completed and the lifting plan discussed and agreed between the crane

operator, riggers and banksman.

Suitable lifting gear shall be used considering Size and Weight of the load, physical nature of the

load, Attachments, Lifting points and supports, Position of load whether it is vertical or

horizontal, Height and range of lift

Outriggers shall be positioned so the crane is level with the wheels just clear from ground.

The operator shall verify he can receive and send signals to the riggers and banksman.

DOC. No. TE-HSE-PRO-035 Rev 1 REV. No. 1 Page 6 OF 8

Towell Engineering HSE PROCEDURE

Hand signal communication shall be in accordance with standard hand signal requirement but

during the actual lift signals shall be from a single banksman except for the emergency stop

signal which may be given by any person.

The operator shall position the hook above the center of the load and ensure the riggers attach

the load correctly to the cranes hook.

The operator shall keep the boom angle at 40 degrees or higher during the course of the lift.

Following signals from the rigger, the load shall be hoisted approximately 300mm from the

ground. At this point the operator shall cross check the reading on the load indicator with

relevant load chart to ensure the load indicator is operating correctly.

The riggers shall check the load to see that it will remain stable. If it looks unstable the load

must be lowered to the ground and additional supports added.

If the load is satisfactory, a tag line(s) shall be attached and the load traveled to the prepared

landing site.

The operator shall lower the load to approximately 12” from the ground, when it shall be

checked to see whether additional supports are required to land the load safely. The load can

then lowered to the ground onto supports if necessary.

The rigging tackle can then be removed and the banksmen shall give the shutdown signal.

Mobile cranes shall not be used to transport a load,

Mobile cranes shall not be used when the wind conditions are more than 25 knots.

7.0 Provisions for Control of Heavy and Critical Lifts:

Following minimum requirements shall be met for the execution of heavy & critical lifts.

Lifting operations are classed as heavy and / or critical if any of the following conditions apply.

All lifts exceeding 100 Tonnes

All lifts exceeding 75% of the rated capacity of Cranes in as rigged condition.

All lifts requiring use of more than one crane simultaneously.

All lifts involving equipment made of thin /fragile members susceptible to deformation during lifting

Lifting in close vicinity of a live plant where lifting operation can endanger the safety of the plant.

The lifting operation shall be planned and performed taking in account all the foreseeable

risks. As a minimum following shall be ensured.

Necessary permissions shall be obtained.

Verification of crane capacity versus load.

Selection of lifting gear suitable for the operation.

The characteristics of load and method of rigging for lifting.

The position of crane and load, before, during and after the operation.

To the scale, sketch shall be prepared, detailing the stages and sequence of operation (Details of

the operation in plan and elevation, on a min A3 size paper is preferable)

Relevant calculations supporting the safety limits of the operation considering effects of

dynamic loading and weather conditions.

Specific instructions for handling of equipment supplied by the manufacturer.

The ground conditions and requirements for leveling and compacting, if necessary.

Clear identification and defining of responsibilities for various activities. A lifting team

comprising engineers, Lifting /Rigging supervisor, crane operator, rigger, banksman and a safety

DOC. No. TE-HSE-PRO-035 Rev 1 REV. No. 1 Page 7 OF 8

Towell Engineering HSE PROCEDURE

officer is essential for the operation. The crane operator shall not be placed in charge of the

lifting operation.

THIS PROCEDURE IS INTENDED TO PROVIDE A GUIDLINE TO THE PERSONNEL

ASSIGNED WITH THE RESPONSIBILITY OF CARRYING OUT LIFTING OPERATIONS

SAFELY. IN CASE OF ANY DOUBTS & FOR MORE INFORMATION STANDARD

SPECIFICATIONS AS MENTIONED IN CLAUSE 3.0 SHALL BE REFERRED & THOSE

PROVISIONS SHALL BE BINDING.

DOC. No. TE-HSE-PRO-035 Rev 1 REV. No. 1 Page 8 OF 8

You might also like

- Safe Use of Cranes: Site Lifting PlanDocument26 pagesSafe Use of Cranes: Site Lifting PlanMuhammad BabarNo ratings yet

- Bulldozer SOP FinalDocument10 pagesBulldozer SOP Finaljean claude BledouNo ratings yet

- Lifting Plan V - 409 18ins Con ValDocument9 pagesLifting Plan V - 409 18ins Con ValAhmed Butt100% (1)

- PM 01 Hira For Excavation of Boiler FoundationDocument3 pagesPM 01 Hira For Excavation of Boiler FoundationSyed Shariq Hassan100% (1)

- Fall Protection Survey of RIG 40Document3 pagesFall Protection Survey of RIG 40Kevin Josh Bonales100% (1)

- Generic Lifting PlanDocument4 pagesGeneric Lifting Planayman coreNo ratings yet

- Checklist - Planning The Safe Use, Erection and Dismantling of Prefabricated or Modular ScaffoldingDocument13 pagesChecklist - Planning The Safe Use, Erection and Dismantling of Prefabricated or Modular ScaffoldingNoor Aimi Ayunie Mohd AzmiNo ratings yet

- JSA - Crane Setuppdf PDFDocument12 pagesJSA - Crane Setuppdf PDFChoko ChokriNo ratings yet

- Shailesh Job Safety Analysis in Steel Manufacturing Unit and Recommendations To Improve The Work Safety EnvironmentDocument21 pagesShailesh Job Safety Analysis in Steel Manufacturing Unit and Recommendations To Improve The Work Safety EnvironmentNandini RajNo ratings yet

- 10 Questions For Line of FireDocument2 pages10 Questions For Line of FireGary Moses100% (1)

- Suspended Loads Safety Tips (39Document3 pagesSuspended Loads Safety Tips (39my_agautamNo ratings yet

- Line of Fire Awareness (Safety Day)Document16 pagesLine of Fire Awareness (Safety Day)Muhammad SalmanNo ratings yet

- Crane Assembly and Dismantling and ModificationDocument1 pageCrane Assembly and Dismantling and Modificationsrinibas mohapatraNo ratings yet

- Confined Space Entry Program 11 2021Document16 pagesConfined Space Entry Program 11 2021zaka ullahNo ratings yet

- Safe excavation works plan for Cherrywood Project Phase 1Document46 pagesSafe excavation works plan for Cherrywood Project Phase 1Sajid ShahNo ratings yet

- Ramapo College Vehicle Fueling SOPDocument1 pageRamapo College Vehicle Fueling SOPAnees EkNo ratings yet

- Genie E Series Slab Scissor Lift Operation PDFDocument11 pagesGenie E Series Slab Scissor Lift Operation PDFRajesh gpNo ratings yet

- HSF-PR-0063 Work at HeightDocument32 pagesHSF-PR-0063 Work at HeightChris Bonnington0% (1)

- Work Method Statement: Wms Rev. NoDocument5 pagesWork Method Statement: Wms Rev. NoKarthik babu100% (1)

- Crane JHA OKDocument4 pagesCrane JHA OKSyed Ali HassanNo ratings yet

- Safe Operation of Overhead CranesDocument16 pagesSafe Operation of Overhead CranesviniciusgdelimaNo ratings yet

- Purpose:: Method StatementDocument10 pagesPurpose:: Method StatementIrfan ashrafNo ratings yet

- Health, Safety, and Environmental Management in Offshore and Petroleum EngineeringFrom EverandHealth, Safety, and Environmental Management in Offshore and Petroleum EngineeringRating: 5 out of 5 stars5/5 (1)

- Lifting Hoisting Hazard HuntDocument1 pageLifting Hoisting Hazard Hunt曹庆园100% (1)

- Excavation Method StatementDocument4 pagesExcavation Method StatementAnonymous 3eHGEDbxNo ratings yet

- NASDA WIND POWER SUB-STATION EXCAVATION SAFETYDocument2 pagesNASDA WIND POWER SUB-STATION EXCAVATION SAFETYRaza Muhammad SoomroNo ratings yet

- Fatigue Management ProcedureDocument12 pagesFatigue Management ProcedureWakarusa CoNo ratings yet

- Blinding and De-Blinding SWSDocument11 pagesBlinding and De-Blinding SWSThái Đạo Phạm Lê100% (1)

- Grating Safety AwarenessDocument25 pagesGrating Safety AwarenessMuneeb RehmanNo ratings yet

- Safe Lifting Operations ProcedureDocument7 pagesSafe Lifting Operations ProcedureJoozza MandaNo ratings yet

- Safe Working Procedure ExcavationsDocument4 pagesSafe Working Procedure ExcavationsMunaku TafadzwaNo ratings yet

- Rescue Plan SRS 1Document4 pagesRescue Plan SRS 1Salah Abd EldayemNo ratings yet

- Slinging Tubulars, Scaffold, BeamsDocument3 pagesSlinging Tubulars, Scaffold, BeamsAngel AngeleyeNo ratings yet

- 3-Pre-Lift Checklist Rev A 06302015Document2 pages3-Pre-Lift Checklist Rev A 06302015Zubair Ahmed Khaskheli100% (1)

- SSR Competency Assurance Guidance Booklet SummaryDocument8 pagesSSR Competency Assurance Guidance Booklet SummarywavehayiathNo ratings yet

- Excavation Safety ProceduresDocument7 pagesExcavation Safety ProceduresHasanuddin HAMIDNo ratings yet

- JSA - Suface Preparationand Brush PaintingDocument5 pagesJSA - Suface Preparationand Brush PaintingAzad pravesh khanNo ratings yet

- General Crane Operations and LiftingDocument2 pagesGeneral Crane Operations and LiftingAhmedAmer1No ratings yet

- Safe Work Method Statement For Survey Work: CMS Surveyors Pty LTD ABN: 79 096 240 201Document18 pagesSafe Work Method Statement For Survey Work: CMS Surveyors Pty LTD ABN: 79 096 240 201mkash028100% (1)

- Night work permit checklistDocument1 pageNight work permit checklistankitNo ratings yet

- SWMS 1 Loading, Unloading & ShiftingDocument8 pagesSWMS 1 Loading, Unloading & ShiftingJ.j.JijoNo ratings yet

- OSHAC300 Excavation & Trenching SafetyDocument34 pagesOSHAC300 Excavation & Trenching SafetyShujaRehmanNo ratings yet

- Appendix A-Job Safety Analysis FormDocument3 pagesAppendix A-Job Safety Analysis Formjiks_i4uNo ratings yet

- MEWP Lifting PlanDocument21 pagesMEWP Lifting Planalex100% (1)

- Method Statement For Assembly of 200 Ton Crawler CraneDocument7 pagesMethod Statement For Assembly of 200 Ton Crawler CraneAnjo MolinaNo ratings yet

- SG-14 Safety Guideline For Work On Electric Overhead Travelling (EOT) CraneDocument19 pagesSG-14 Safety Guideline For Work On Electric Overhead Travelling (EOT) CraneAbhishek GadatiaNo ratings yet

- TA1 English - Hydraulic HammerDocument11 pagesTA1 English - Hydraulic Hammercarlos angelNo ratings yet

- Mobile Elevated Work Platforms (MEWP) Program: Provo, UtahDocument14 pagesMobile Elevated Work Platforms (MEWP) Program: Provo, UtahStephanie ScottNo ratings yet

- Accident Investigation PolicyDocument4 pagesAccident Investigation PolicyNorman AinomugishaNo ratings yet

- Recovery Plan For CraneDocument2 pagesRecovery Plan For CraneKen LeongNo ratings yet

- Rigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Document3 pagesRigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Cleiciane FrancoNo ratings yet

- JSA For Pressure Test 2ND REVISIONDocument10 pagesJSA For Pressure Test 2ND REVISIONMuthu AlaguRaj100% (1)

- Liting PlansDocument28 pagesLiting PlansFirdaus Ismail Jr.No ratings yet

- Scaffolding SafetyDocument20 pagesScaffolding SafetyKate Ann Baja IINo ratings yet

- TR-CA-MS-004 - B Shifting Concrete BarriersDocument14 pagesTR-CA-MS-004 - B Shifting Concrete Barrierssamer8saifNo ratings yet

- Noise: Revision/Approval HistoryDocument9 pagesNoise: Revision/Approval HistoryibrahimNo ratings yet

- 45.employee Safety Evaluation UNISCO (F) - 45Document1 page45.employee Safety Evaluation UNISCO (F) - 45ibrahimNo ratings yet

- Epc1-Pop Card 23418 Close OutDocument3 pagesEpc1-Pop Card 23418 Close OutibrahimNo ratings yet

- Staff Vehicle Fuel StatementDocument1 pageStaff Vehicle Fuel StatementibrahimNo ratings yet

- Waste Management Guidelines: Revision / Approval HistoryDocument30 pagesWaste Management Guidelines: Revision / Approval HistoryibrahimNo ratings yet

- Powder Powder-Actuated & Pneumatic Tools Actuated & Pneumatic ToolsDocument9 pagesPowder Powder-Actuated & Pneumatic Tools Actuated & Pneumatic ToolsibrahimNo ratings yet

- Executive Hsse Inspection: Firefighting Yes No N/A NotesDocument9 pagesExecutive Hsse Inspection: Firefighting Yes No N/A NotesibrahimNo ratings yet

- Ladders: Revision / Approval HistoryDocument10 pagesLadders: Revision / Approval HistoryibrahimNo ratings yet

- United Industrial Services Co. L.L.C.: Hse Training PlanDocument8 pagesUnited Industrial Services Co. L.L.C.: Hse Training PlanibrahimNo ratings yet

- Immunization and VaccinationDocument33 pagesImmunization and VaccinationibrahimNo ratings yet

- Project Environmental Aspects RegisterDocument1 pageProject Environmental Aspects RegisteribrahimNo ratings yet

- Material Storage & Handling GuidelinesDocument11 pagesMaterial Storage & Handling GuidelinesibrahimNo ratings yet

- United Industrial Services Co - LLC: Erection of Steel Structural - (Primary & Secondary) SL No Do's Don'tDocument1 pageUnited Industrial Services Co - LLC: Erection of Steel Structural - (Primary & Secondary) SL No Do's Don'tibrahim100% (1)

- Minor Scope - Subcontractor HSSE Prequalification Grading FormDocument1 pageMinor Scope - Subcontractor HSSE Prequalification Grading FormibrahimNo ratings yet

- Hazards of Nitrogen AsphyxiationDocument10 pagesHazards of Nitrogen AsphyxiationRaja Senthil NathanNo ratings yet

- Audit Report: Velosi Quality Management International LLCDocument5 pagesAudit Report: Velosi Quality Management International LLCibrahimNo ratings yet

- Demarcation - Equipment Process Gas BoilerDocument6 pagesDemarcation - Equipment Process Gas BoileribrahimNo ratings yet

- Worker Interview QuestionnaireDocument1 pageWorker Interview QuestionnaireibrahimNo ratings yet

- Integrated Management System Procedure: Title: TrainingDocument3 pagesIntegrated Management System Procedure: Title: TrainingibrahimNo ratings yet

- Duqm Refinery Company Approval Status: Subcontractor Document Review Cover SheetDocument14 pagesDuqm Refinery Company Approval Status: Subcontractor Document Review Cover SheetibrahimNo ratings yet

- MIPP Permit TrackingDocument1 pageMIPP Permit TrackingibrahimNo ratings yet

- Warning Letter - RamaDocument1 pageWarning Letter - Ramaibrahim100% (1)

- Danger NeverDocument2 pagesDanger NeveribrahimNo ratings yet

- LIFE LINE TAGDocument1 pageLIFE LINE TAGibrahimNo ratings yet

- MEWP Inspection ReportDocument1 pageMEWP Inspection ReportibrahimNo ratings yet

- Towell Engineering: Bus ParkingDocument1 pageTowell Engineering: Bus ParkingibrahimNo ratings yet

- TRA - Scaffold Erection & ModificationDocument16 pagesTRA - Scaffold Erection & ModificationibrahimNo ratings yet

- Daelim Tie inDocument967 pagesDaelim Tie inibrahimNo ratings yet

- Drop Object AwarenessDocument7 pagesDrop Object AwarenessibrahimNo ratings yet

- MEWP Inspection ReportDocument1 pageMEWP Inspection ReportibrahimNo ratings yet

- Ideal Home - Complete Guide To Christmas 2016 PDFDocument148 pagesIdeal Home - Complete Guide To Christmas 2016 PDFpetru555100% (2)

- Home Work Chapter 1 To 12Document50 pagesHome Work Chapter 1 To 12Haha JohnNgNo ratings yet

- Anchor ChairDocument3 pagesAnchor ChairrsubramaniNo ratings yet

- Assignment 2 QP MPMC - ITDocument1 pageAssignment 2 QP MPMC - ITProjectsNo ratings yet

- Fundamentals of Metal Matrix CompositesDocument19 pagesFundamentals of Metal Matrix CompositesAstriaNo ratings yet

- Working Capital Management OF: Submitted by Priya BanerjeeDocument102 pagesWorking Capital Management OF: Submitted by Priya BanerjeeSushmita BarlaNo ratings yet

- Ryanair Strategic AnalysisDocument36 pagesRyanair Strategic AnalysisAlmas Uddin100% (1)

- BSBPMG534 Task 2 - V2.4Document9 pagesBSBPMG534 Task 2 - V2.4Anoosha MazharNo ratings yet

- Channel CapDocument9 pagesChannel CapDeepika RastogiNo ratings yet

- Tekla - DocumentDocument2,005 pagesTekla - DocumentTranタオNo ratings yet

- Intel Optane Memory User InstallationDocument57 pagesIntel Optane Memory User InstallationAlonso LGNo ratings yet

- 4) Transport and InsuranceDocument10 pages4) Transport and InsuranceBianca AlecuNo ratings yet

- Liftking Forklift PDIDocument1 pageLiftking Forklift PDIManual ForkliftNo ratings yet

- Unit 1Document176 pagesUnit 1kassahun meseleNo ratings yet

- Mos Project Report-"Customer Satisfaction Survey: Telecom Sector"Document16 pagesMos Project Report-"Customer Satisfaction Survey: Telecom Sector"Kabejor Rahman Aka-NickyNo ratings yet

- 5 Dossier SampleDocument22 pages5 Dossier SampleSabeehuddin SafdarNo ratings yet

- SA-10/20 User ManualDocument31 pagesSA-10/20 User ManualJorgeLuis Anaya NúñezNo ratings yet

- PLC Ladder Examples 2021Document18 pagesPLC Ladder Examples 2021JosephNo ratings yet

- Electricity (Innovative Licence) Regulations 2023Document16 pagesElectricity (Innovative Licence) Regulations 2023BernewsAdminNo ratings yet

- Modeling Drop Structures in HEC-RAS 3.1Document29 pagesModeling Drop Structures in HEC-RAS 3.1reluNo ratings yet

- Dual Rectifier Solo HeadDocument11 pagesDual Rectifier Solo HeadВиктор АлимовNo ratings yet

- 638341140 (1)Document7 pages638341140 (1)Nishit BhanushaliNo ratings yet

- Sub Engineer Test Model PaperDocument8 pagesSub Engineer Test Model PaperZeeshan AhmadNo ratings yet

- Math CAD01Document6 pagesMath CAD01RR886No ratings yet

- Australia vs. France ReportDocument5 pagesAustralia vs. France ReportammeNo ratings yet

- Quy Trình AgencyDocument4 pagesQuy Trình Agencyson nguyenNo ratings yet

- Palacio VsDocument2 pagesPalacio VsRaymart SalamidaNo ratings yet

- ConclusionDocument1 pageConclusionSAVITHRINo ratings yet

- Power Semiconductor Devices ClassificationDocument9 pagesPower Semiconductor Devices ClassificationdevchandarNo ratings yet

- Solvents and Their Nomenclauture PDFDocument10 pagesSolvents and Their Nomenclauture PDFAashish GauravNo ratings yet