Professional Documents

Culture Documents

Reac

Uploaded by

Madel IsidroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reac

Uploaded by

Madel IsidroCopyright:

Available Formats

5.

1 Reactor

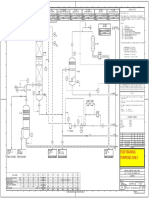

The optimum conditions for the operation of Reactor 201 was determined from simulating in

ASPEN HYSYS. The alkylation reactor is designed to allow for a feed flowrate of 20430 kg/hr.

Given that the reactor is operating at high temperatures and pressures, the material of

construction chosen for the body of the reactor was stainless steel. Knowing that the reaction is

highly exothermal, heating element is used to maintain the operating temperature of the

reactor at 450°C.

The design of the reactor was optimized to achieve the desired conversion using zeolite based

catalyst. This was done by designing the reactor for a total volume of 94.23 m3 with tubes with

total length of 2m. The void fraction used was 0.5 giving a void volume of 42.17 m3.

You might also like

- BOILERDocument36 pagesBOILERAditya Aggarwal100% (1)

- Lecture 4-Combustion and Boilers PDFDocument39 pagesLecture 4-Combustion and Boilers PDFjuan maganNo ratings yet

- DR NTTPSDocument41 pagesDR NTTPSnagasuresh100% (1)

- 11 Steam Generators 3-2Document26 pages11 Steam Generators 3-2Omar AhmedNo ratings yet

- Boiler Calculation/ Stack DesignDocument32 pagesBoiler Calculation/ Stack DesignZohaib AliNo ratings yet

- Steam BoilerDocument41 pagesSteam BoilerRhydham PNo ratings yet

- Experiment 4 Plate and Frame FiltrationDocument22 pagesExperiment 4 Plate and Frame FiltrationMadel Isidro100% (1)

- Lecture-3, Practical, 3Document30 pagesLecture-3, Practical, 3Asasira IradNo ratings yet

- BoilersDocument20 pagesBoilersKristian Taruc100% (2)

- Boilers - Thermal EngineeringDocument45 pagesBoilers - Thermal Engineeringommech2020No ratings yet

- Study of Circulating Coal Fluidized BoilersDocument5 pagesStudy of Circulating Coal Fluidized BoilersSwaraj BiswasNo ratings yet

- 4.1 BoilersDocument11 pages4.1 BoilersIvy Joy UbinaNo ratings yet

- Problem Set No. 2 Steam Power Plant "Steam Generator Ratings" 1. A Steam Generator Equipped With A Superheater and Economizer Received Feedwater atDocument17 pagesProblem Set No. 2 Steam Power Plant "Steam Generator Ratings" 1. A Steam Generator Equipped With A Superheater and Economizer Received Feedwater atMiguel Dominic BernardoNo ratings yet

- BoilersDocument47 pagesBoilersAshish RawatNo ratings yet

- Lecture Three: Process DesignDocument57 pagesLecture Three: Process DesignAsasira IradNo ratings yet

- Unit 2: BoilersDocument43 pagesUnit 2: Boilersommech2020No ratings yet

- PDF DocumentDocument2 pagesPDF DocumentSweet Dimple May SalvanNo ratings yet

- Pirolisis Pak SugengDocument4 pagesPirolisis Pak SugengRud CasperNo ratings yet

- Study of Boiler Efficiency in Visakhapatnam Steel PlantDocument39 pagesStudy of Boiler Efficiency in Visakhapatnam Steel PlantPhanindra Guttula50% (2)

- ATD Unit-4 NotesDocument44 pagesATD Unit-4 NotesSanjay KatreddyNo ratings yet

- Process Details: Reactor Feed Preheat/ Effluent CoolerDocument4 pagesProcess Details: Reactor Feed Preheat/ Effluent CoolerMohamed TarekNo ratings yet

- Boiler 1Document44 pagesBoiler 1Emmanuel AyisiNo ratings yet

- BoilersDocument76 pagesBoilers58-Sanket TupkarNo ratings yet

- Conversion of Coal Particles in Pyrolysis and Gasification: Comparison of Conversions in A Pilot-Scale Gasifier and Bench-Scale Test EquipmentDocument10 pagesConversion of Coal Particles in Pyrolysis and Gasification: Comparison of Conversions in A Pilot-Scale Gasifier and Bench-Scale Test EquipmentRoberto Macias NNo ratings yet

- Lecture 8 Polymerization ProseccDocument4 pagesLecture 8 Polymerization ProseccOmer IkhlasNo ratings yet

- Mid - Tearm - Indusf - PDF Filename - UTF-8''mid Tearm Indusf PDFDocument8 pagesMid - Tearm - Indusf - PDF Filename - UTF-8''mid Tearm Indusf PDFAhmed Rabie Abd ElazeemNo ratings yet

- Mid - Tearm - Indusf - PDF Filename - UTF-8''mid Tearm IndusfDocument8 pagesMid - Tearm - Indusf - PDF Filename - UTF-8''mid Tearm IndusfAhmed Rabie Abd ElazeemNo ratings yet

- The Application Aspects of Self-Recuperative and Self-Regenerative Burners in Thermal DevicesDocument7 pagesThe Application Aspects of Self-Recuperative and Self-Regenerative Burners in Thermal DevicesGerardo LopezNo ratings yet

- Benson BoilerDocument4 pagesBenson Boilershivrant shivrantNo ratings yet

- Boiler Presentation - Shared - Updated 19 - 10 - 20Document51 pagesBoiler Presentation - Shared - Updated 19 - 10 - 20Lokesh ChourasiaNo ratings yet

- Steam Generators (EEE)Document39 pagesSteam Generators (EEE)RakibNo ratings yet

- Pag 1 Contract No. 511-4620 Pucala, Peru Description of Plant 1.1. GeneralDocument15 pagesPag 1 Contract No. 511-4620 Pucala, Peru Description of Plant 1.1. GeneralRony Joel Cordova SánchezNo ratings yet

- Auxiliary Boiler Construction Details: BY Mohammed Arif M Mechanical Engineer 41256Document81 pagesAuxiliary Boiler Construction Details: BY Mohammed Arif M Mechanical Engineer 41256Arif MechanicalNo ratings yet

- BoilerDocument8 pagesBoilerroronoa zoroNo ratings yet

- Boilersand Steam GenerationDocument86 pagesBoilersand Steam GenerationUyen LeNo ratings yet

- Super HeatersDocument31 pagesSuper HeatersharimadhavareddyNo ratings yet

- Module 2Document17 pagesModule 2Tristan Paul Guerra OrodioNo ratings yet

- Utility Line Size Calculation Chemical Reactor PDFDocument5 pagesUtility Line Size Calculation Chemical Reactor PDFIyappan MuruganNo ratings yet

- UCLM ME Department Review Material: Name: SchoolDocument32 pagesUCLM ME Department Review Material: Name: SchoolMark AllenNo ratings yet

- Steam Generator ExamDocument2 pagesSteam Generator ExamVon A. Damirez0% (1)

- The Steam Produced Is Used ForDocument26 pagesThe Steam Produced Is Used ForAshna FelixNo ratings yet

- Thermodynamic Exercise EntropyDocument2 pagesThermodynamic Exercise EntropyFarid AimanNo ratings yet

- Study of Steam Generation Units With Their Accessories and MountingsDocument64 pagesStudy of Steam Generation Units With Their Accessories and MountingsMasudur RahmanNo ratings yet

- G. L. Bajaj Institute of Technology & Management Greater NoidaDocument39 pagesG. L. Bajaj Institute of Technology & Management Greater NoidaAbhay TrivediNo ratings yet

- A1 4Document6 pagesA1 4Mohit PassiNo ratings yet

- A Large-Capacity Pressurized-Fluidized-Bed-Combustion-Boiler Combined-Cycle Power PlantDocument5 pagesA Large-Capacity Pressurized-Fluidized-Bed-Combustion-Boiler Combined-Cycle Power PlantDhanasekaran RNo ratings yet

- Best Choice BENSON BOILER. Excellent Performance Features Make The Benson Boiler The Most Widely Used Type of Once-Through BoilerDocument5 pagesBest Choice BENSON BOILER. Excellent Performance Features Make The Benson Boiler The Most Widely Used Type of Once-Through BoilerStefanos DiamantisNo ratings yet

- Power Plant Engineering (SMEX1016) 2 PDFDocument28 pagesPower Plant Engineering (SMEX1016) 2 PDFshyam sundarNo ratings yet

- Steam and Power GenerationDocument343 pagesSteam and Power GenerationJulie Anne CristalesNo ratings yet

- Boilers and Steam GenerationDocument86 pagesBoilers and Steam GenerationArzo KhanNo ratings yet

- Straw Fired BoilerDocument4 pagesStraw Fired BoilerVijay KumarNo ratings yet

- Design For A High Temperature Shift ConverterDocument43 pagesDesign For A High Temperature Shift ConverterAaron GyamfiNo ratings yet

- Boiler AnalysisDocument16 pagesBoiler AnalysisBrian omondiNo ratings yet

- In Simple A Boiler May Be Defined As A Closed Vessel in Which Steam Is Produced From Water by Combustion of FuelDocument9 pagesIn Simple A Boiler May Be Defined As A Closed Vessel in Which Steam Is Produced From Water by Combustion of FuelJomari Tobes SatorreNo ratings yet

- CH116P - Problem Set 3 2QDocument1 pageCH116P - Problem Set 3 2QFlorenceNo ratings yet

- 4 - BoilersDocument60 pages4 - BoilersSiddharth SureshNo ratings yet

- Boiler ProblemsDocument2 pagesBoiler ProblemsAnthropophobe NyctophileNo ratings yet

- Steam Boiler Performance-1Document27 pagesSteam Boiler Performance-1Fagbolagun IdowuNo ratings yet

- Exergy ArticleDocument17 pagesExergy ArticleMuhammad Haris HamayunNo ratings yet

- 5-Boilers and CondensersDocument2 pages5-Boilers and Condensersnagwaibrahim3132002No ratings yet

- Cochran Boiler: Experiment No. 10Document5 pagesCochran Boiler: Experiment No. 10Abhishek KushwahaNo ratings yet

- Lesson 72Document1 pageLesson 72Madel IsidroNo ratings yet

- Yana Chemodities QuotationDocument1 pageYana Chemodities QuotationMadel IsidroNo ratings yet

- Experiment No. 10 Bare & Lagged Pipes: Chemical Engineering Department School Year 2019 - 2020Document13 pagesExperiment No. 10 Bare & Lagged Pipes: Chemical Engineering Department School Year 2019 - 2020Madel IsidroNo ratings yet

- Remarks AcadsocDocument1 pageRemarks AcadsocMadel IsidroNo ratings yet

- PATENT DRAFT TemplateDocument2 pagesPATENT DRAFT TemplateMadel IsidroNo ratings yet

- ChE - Project Design RubricDocument5 pagesChE - Project Design RubricMadel IsidroNo ratings yet

- MSD Sample 1Document1 pageMSD Sample 1Madel Isidro100% (1)

- Eldin1994 PDFDocument12 pagesEldin1994 PDFMadel IsidroNo ratings yet

- Practical Exam #1 Matrix Application On Distillation Mass BalanceDocument4 pagesPractical Exam #1 Matrix Application On Distillation Mass BalanceMadel IsidroNo ratings yet

- 20190112-Sodium Hydroxide, EtcDocument1 page20190112-Sodium Hydroxide, EtcMadel IsidroNo ratings yet

- G1 Unit 2 Tutoring SkillsDocument6 pagesG1 Unit 2 Tutoring SkillsMadel IsidroNo ratings yet

- 20200108-Sodium BisulfiteDocument1 page20200108-Sodium BisulfiteMadel IsidroNo ratings yet

- 3.1 Process Description 3.1.1 Unit 100 Raw Material Storage 3.1.2 Unit 200 Cumene Production 3.1.2 Unit 300 Product StorageDocument3 pages3.1 Process Description 3.1.1 Unit 100 Raw Material Storage 3.1.2 Unit 200 Cumene Production 3.1.2 Unit 300 Product StorageMadel IsidroNo ratings yet

- Prelim Prelab ReadinessDocument3 pagesPrelim Prelab ReadinessMadel IsidroNo ratings yet