Professional Documents

Culture Documents

D&WO Lifting Equipment Matrix

Uploaded by

Mohammed Nabil AVOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D&WO Lifting Equipment Matrix

Uploaded by

Mohammed Nabil AVCopyright:

Available Formats

#

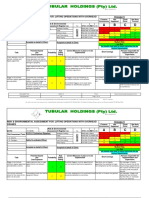

D&WO LIFTING EQUIPMENT MATRIX - JANUARY-14-2020

INITIAL INSPECTION / 5 Year

D&WO LIFTING EQUIPMENT MATRIX - JANUARY 14TH 2020 NDT LOAD TEST / PROOF LOAD TEST OTHER BELOW THE HOOK LIFTING DEVICES - Items 19-65 SA.G.I. REQUIREMENTS / D&WO REQUIREMENTS

SCHEDULE INSPECTIONS Inspections

The American Society of Mechanical Engineers (ASME) states that a below-the-hook LIFTING EQUIPMENT MATRIX (LEM) - G.I. 7.030 Section # 8. Onshore fixed cranes and

RECOMMENDATIONS / INDUSTRY STANDARDS

PROVIDE LOAD TEST CERTIFICATION FOR NEW

BASED ON OEM RECOMMENDATIONS / API

PRIOR TO FIRST USAGE INSTALLATION OEM

lifting device is a device used for attaching a load to a Hoist . The device may contain hoists, covered by ASME Standards, shall receive a periodic annual inspection or as

PROOF LOAD TEST AFTER MODIFICATION /

/ REFER TO REFERENCES SECTION BELOW

components such as slings, hooks, and rigging hardware. In other words, a below-the-hook determined by the manufacturer’s recommendation, whichever is less, including D&WO

AFTER REPAIR - MODIFICATION

LIFTING EQUIPMENT REGISTER

(BTH) lifting device is a tool or mechanical device that attaches to a crane or other lifting recommendations. 3rd Party Inspection companies shall conduct these inspections as per

apparatus, and grabs and secures a load so that it can be moved safely from one location the matrix. Issue a Sticker of Inspection conducted. D&WO Inspection Frequency

REPAIR OR OVERHAUL

EVERY 6 MONTHS

to another. ASME-B30-20. 2108 Requirements may exceed those stipulated in the G.I,s , based on Risk.

CERTIFICATION

EVERY 90 DAYS

COLOR CODE

EQUIPMENT

12 MONTHS

6 MONTHS

6 MONTHS

ANNUALLY

I.D. LABEL

Note: 1. SA. (CIU) Approved Inspection companies can perform inspections

ANNUAL

STICKER

5 YEARS

ARAMCO MANUFACTURING

EQUIPMENT TYPE on items FROM 1-18 in this Matrix (LEM) as per G I 7.030.

STANDARDS CODES / STANDARDS

Note:2. Only Approved D&WO Pre Qualified Companies for (BLH) Below the Note: Lifting Equipment Matrix international standards include;

Hook can perfom Items 19 to 65. (LOLER) Lifting Operations and Lifting Equipment Regulations 1998.

Note: 3. Only SA Inspection Department Approved CNDT companies can

perform NDT inspections related to Above the Hook Items 1-18 as well as

Items 66-131 in Drilling Rig and Service Equipment Inspection - NDT MATRIX

below.

APPROVED (BY CIU) COMPANIES FOR G.I.7.030 EQUIPMENT - ITEMS 1 TO 18 ABOVE APPROVED (BY CIU) COMPANIES FOR G.I.7.030 EQUIPMENT - ITEMS 1 TO 18 ABOVE

ABOVE THE HOOK - S.A. CIU APPROVED COMPANIES

ELEVATING LIFTING EQUIPMENT SAUDI ARAMCO G.I 7.030 - ABOVE THE HOOK

THE HOOK THE HOOK

1 OFFSHORE CRANES G.I. 7.030 ASME B30.2, 4, 8, 16, 17, 22 API Spec 2C & API RP 2D

/ S.A INSPECTION DEPARTMENT APPROVED

Y Y Y Y Y Y Y Y Y Y Y Y Crane Inspection & Maintenance Services (CIMS) Contact: IMAD A.AL GHAMDI / AL MANSOORI: Fajarul Majeed M/ Mohammed Sajid/ Tamer Ragab Mohamed Tel: 013-

2 OFFSHORE PEDESAL CRANES G.I. 7.030 ASME B30.2, 4, 8, 16, 17, 22 API Spec 2C & API RP 2D Y Y Y Y Y Y Y Y Y Y Y Y VENANCIO Z. VERA Tel: 013 814 6861-6862, 013 847 8822 Ext. 100 Emails: 868-2077 Email: msesaudi@almansoori.biz / fmajeed@almansoori.biz -

3 DECK MOUNTED MOBILE CRANES G.I. 7.024 ASME B30.2, 4, 8, 16, 17, 22 API Spec 2C & API RP 2D Y Y Y Y Y Y Y Y Y Y Y info@cims.com.sa - operation-m@cims.com.sa - imad@cims.com.sa MSajid@almansoori.biz trmohamed@almansoori.biz

4 ONSHORE CRANES (PEDESTAL / MOBILE) G.I. 7.030 ASME B30.5 Y Y Y Y Y Y Y Y Y Y Y Testing Equipment Specialist Team Co. (TEST) Contact: Moath Al Zahrani & Mahmoud

Bureau Veritas (BV) Contact: Eyad Abdulhadi or Sami Uddin Tel: +966 (13) 882 1071 Ext –

5 ONSHORE TOWER CRANES G.I. 7.030 ASME B30.5 Y Y Y Y Y Y Y Y Y Y Y Fahmy Tel No: +966-13-808-4277 Ext: 333 & 106 & 440 Email: sales@testcosa.com -

115\123 Emails: iyad.fathi@ae.bureauveritas.com or sami.uddin@ae.bureauveritas.com

6 FIXED CRANES & HOISTS (ONSHORE) G.I. 7.030 ASME B30.2, 3, 4, 6, 11, 16 & 17 Y Y Y Y Y Y Y Y Y Y Y Y Y moath@testcosa.com - info@testcosa.com

COMPANIES

7 ELEVATORS / ESCLATORS G.I. 7.030 ASME A17.1 Y Y Y Y Y Y 3 Y Y Y (ABS) Group Saudi Arabia Company Ltd. Mohammed Al Aithan Jaber S. Alhanwah and

Engineering Corner for Inspection (ECI) Contact: Nassir M. Balharith Tel: 013-6676999

8 ELEVATING WORK PLATFORMS / MAN-LIFTS G.I. 7.030 ASME A92.3, 5, 6 & 9 Y Y Y Y Y Y Y Y Y Abdul Wahab Enthi Tel: +966 3 868 9999 Ext. 217

Email: eci@eccgroupksa.com / insp@eccgroupksa.com

9 ARTICULATING BOOM CRANES G.I. 7.030 ASME B30.22 Y Y Y Y Y Y Y OEM Y Y Y Emails: Malaithan@absconsulting.com / jalhanwah@absconsulting.com /

10 OPERATOR RIDDEN STORAGE / RETRIEVAL MACHINES G.I. 7.030 ASME B30.13 Y Y Y Y Y Y OEM Y Y Velosi Saudi Arabia Company Ltd. Contact: Nafa ALRowaie Lifting & Rig Services Manager AEnthi@absconsulting.com

11 CRANE SUSPENDED PERSONNEL PLATFORMS (MAN BASKETS) G.I. 7.030 ASME B30.5, 23 & S.A G.I. 7.027 Y Y Y Y OEM Y Y Y Y Y Y Kingdom of Saudi Arabia Tel No. +966 13 839 42 92 EXT: 600 Fax No. +966 13 839 36 71 TUV SUD Middle East L.L.C. Contact: Dany Tafla, Senior Inspector Engineer Tel No: +966

12 SPREADER BEAMS G.I. 7.030 ASME B30.20 Y Y Y Y Y Y Y Y Y Y Mobile No. +966 54 332 1541 E-Mail : nafa.alrowaie@applusvelosi.com 33612121 Emails: dany.tafla@tuvsudme.com - mg.mirah@tuvsudme.com -

13 A-FRAME / GANTRIES G.I. 7.030 ASME B30.11 & 16 Y Y Y Y Y Y 1 Y Y Y Y salahsafah@tuvsudme.com

14 SUPERSACK OVERHEAD GANTRY WINCH / HOISTS G.I. 7.030 ASME B30.11 & 16 Y Y Y Y Y Y Y 1 OEM Y Y Y Y Inspection Services Saudi Arabia Ltd. (SGS) Contact: Fadel Shallhoub (Industrial Services National Inspection & Technical Co. Ltd (FAHSS/TUV) Contact: Aqeel S. Al-Darwish or

15 ONSHORE BOP HOISTS G.I. 7.030 API 7L Y Y Y Y Y Y Y 3 Y Y Y Y Y Division). Tel: +966 3 817 20 80 Ext 104 Mobile: +966 54-506-0123 Email: Zishan Qamar Afrin P.O. Box: 10771, Jubail 31961 Saudi Arabia Tel: 013-340-

16 OFFSHORE BOP HOISTS G.I. 7.030 API 7L Y Y Y Y Y Y Y Y Y Y Y Y Y fadel.shallhoub@sgs.com 7607/7608/7609 Fax: 013-340-7605 Email: darwisha@fahsstuv.com -

17 CRANE WIRE ROPE BS ISO 4309 / BS EN 12385 / ASME B30.9 Y x Y Y x Y Y Y TUV Rheinland Arabia LLC Co. Ltd (TUV- Rheinland) Contact: Ashraf Samir Tel: 013- zishanqa@fahsstuv.com

18 CRANE HOOK BLOCKS BS EN 13157 / ASME B30.10 Y Y Y Y Y Y Y Y Y Y Y 8664920 / 013-866 4915 / 0593672244/ Fax: 013-830-6593

Zamil Lifting & Industrial Supports (ZAMIL) Contact: Tel: 013-842-9328 /Mob: +966 55-

Email: ashraf.samir@sa.tuv.com; rami.mohamed@sa.tuv.com;

362-3687 Fax: 013-833-7586 Email: operations@zamil.sa, md@zamil.sa, admin@zamil.sa

waqas.munawar@sa.tuv.com

BELOW THE HOOK APPROVED PRE-QUALIFIED COMPANIES - BELOW THE HOOK APPROVED PRE-QUALIFIED COMPANIES - BELOW THE HOOK

OES Oilfield Services Group: Manager, Kevin Whinney. kevinwhinney@oesgroup.com |

19 MARINE LIFEBOAT DAVITS G.I. 7.021 BS MA41 / 15516 / SOLAS / IMO Y Y OEM OEM OEM Y Y Y Y OEM Y Y Y Y Allrig Group Middle East: James Griffin (Regional Sales Manager) , Mail:

Mob: +966 55 405 3488 / +973 3355 7094 Office: +971 43262822 Ext 6104 Office. +971

20 DAVIT BLOCKS & ASSOC. EQUIPMENT G.I. 7.021 BS MA41 / 15516 / SOLAS / IMO Y Y OEM OEM OEM Y Y Y Y OEM Y Y Y Y jgriffin@allriggroup.com / saudi@allriggroup.com , Cell: +966 50 451 1477 , Office: +971 4

43262822 Ext 6102, Kevin Middleton +966 50 171 0728 email

21 WINCH (DAVIT) G.I. 7.021 BS EN 13157/SOLAS /IMO 333 5504 Web: www.allriggroup.com

Y Y OEM OEM OEM Y Y Y Y OEM Y Y Y kevinmiddleton@oesgroup.com

22 ELECTRIC OVERHEAD TRAVELLING CRANES BS7121 / BS EN 13001 / ASME B30.2,11 & 17 MEGARME /SAJA: Tel: 00966138026318 Mob. 00966545240056 E Mail

Y Y Y Y Y OEM OEM Y Y Y Y Setcore Arabia Petroleum Services co. Ltd. PO. Box 2095 Dammam 31451 Ph. 966 13 802

abdullah@megarme.com Abdullah Al Hussein – Sales Manger Email:

23 WINCH (PNEUMATIC) SWIM 39 BS EN 14492 / ASME B30.7 / ASME B30.16 Y Y Y Y Y Y Y 1 Y Y Y Y Y 7458 Mob. +966 553553721 Mr. Mahmoud Aly Abou Ellail , Regional Manager Email.

abdullah@megarme.com Mobile : 054 524 0056 Benji George – Email :

WINCH (MAN-RIDING) SWIM 38 PUWER / LOLER / OEM Guidance Setcore.arabia@setcore.com / Mahmoud.Abouellail@setcore.com

24 Y Y Y Y Y Y Y 1 Y Y Y Y Y Benji@megarme.com Mobile : 00971 50 45 27 237

Gulf Energy International. Raouf Zienhom: e-mail:raouf@genergylw.com ,Mob.

25 WINCH (MANUAL) / CHAIN BLOCKS SWIM 3 BS EN 13157 / ASME B30.16 Y x FT Y Y x OEM OEM Y Y Y Y M. A. Al-Mutlaq Sons Co. for Trading & Cont. Middle East Area Manager Petroleum &

00966538546000 // Adel Rabea, Manager mail:adel.rabea@genergylw.com Mobile

26 POWERED HOISTS (ELECTRIC) BS EN 14492 /ASME B30.16 Y Y Y Y Y Y OEM OEM OEM Y Y Y Y Industrial Services Division Mr. Louis Shakarji Tel: +966 13 857 1945 ext 266 Fax: +966 13

00966539080071 // Akhil Pavithran (QA) e-mail: sandep@genergylw.com,

POWERED HOISTS (PNEUMATIC) DIN F.E.M. 9.751 / ASME B30.16 857 4006 Mob:+966 50 016 2457 Email: Louis@almutlaqest.com

27 Y Y Y Y Y Y OEM OEM OEM Y Y Y Y Mob:00966539080183

28 OILFIELD WINCH POLE TRUCKS SWIM 39 SAE J706 Y Y Y Y Y Y Y Y Y Y Y AL-NAJM AL-THAQIB CONTRACTING CO. (NTC) Mohamed Al Hanbali. Deputy General Vetco Saudi Arabia Ltd/ NOV-Tuboscope KSA. +966138538420 Ext. 16885 Area

29 FORKLIFT FORKS SWIM 44 BS.ISO 5057 / BS EN 1726-1/2 / BS EN ISO 3691 Y x Y Y Y x OEM OEM Y Y Manager Tel. : +966 3 361 7065/7004/7005 - EXT : 103 Fax: +966 3 361 7066 Cell #: +966 Manager, M: +971566867067, Tim.Fowles@nov.com DP/BHA Inspection:

50-682-7905 Email : mohammed@nteprojects.com +966596579617, Mustafa.algallaf@nov.com

BEAM TROLLEYS SWIM 3 BS EN 13157

D&WO PRE-QUALIFIED APPROVED COMPANIES - BELOW THE HOOK

30 Y Y Y Y Y Y Y Y Y Y Y

31 RUNWAY BEAMS BS2853 / ASME B30.2 Y Y Y Y Y 5 Y Y Y Y TUV Austria. Lifting Equipment Section Head : Ashraf Fayez Elshehry Mob : +966 55 123 Tubestar Oil & Gas Services Pvt Ltd. Tel : +966 13 802 0319 Fax : +966 13 899 9967, Mob:

32 WIRE ROPE (ON PASSENGER ELEVATOR LIFTS) BS ISO 4309 / BS EN 12385 Y x Y Y x Y Y Y 1560 Office: 966 11 827 8157 +966 54 691 9418 Rajesh Nair - Manager | Email : saudiarabia.sales@tubestar.com /

33 WIRE ROPE NON ROTATING BS ISO 4309 / BS EN 12385 Y x Y Y x OEM Y Y Y Email : afayez@tuvam.ae Website : www.tuv-gulf.com rajesh@tubestar.com

AL MANSOORI. Contact: Al-Mansoori Specialized Engineering (LLC) Contact: Fajarul

34 STRUCTURAL PAD EYES OFFSHORE SWIM 3 ASTM A521 / Y x Y Y Y Y 5 Y Y Y Testing Equipment Specialist Team Co. (TEST) Contact: Moath Al Zahrani & Mahmoud

Majeed M/ Mohammed Sajid/Tamer Ragab Mohamed Tel: 013-868-2077 Email:

35 STRUCTURAL PAD EYES ONSHORE SWIM 3 ASTM A521 / Y x Y Y Y Y 3 Y Y Y Fahmy Tel No: +966-13-808-4277 Ext: 333 & 106 & 440 Email: sales@testcosa.com -

msesaudi@almansoori.biz-fmajeed@almasoori.biz - MSajid2almansoori.biz

36 BEAM CLAMPS SWIM 3 BS EN 13157 Y Y Y Y Y Y Y Y Y Y Y moath@testcosa.com - info@testcosa.com

trmohamed@almansoori.biz

37 PLATE CLAMPS BS EN 13155 Y Y Y Y Y Y Y Y Y Y Y

Engineering Corner for Inspection (ECI) Contact: Nassir M. Balharith Tel: 013-6676999

38 SINGLE / MULTI SHEAVE BLOCKS BS EN 13157 Y x FT x Y x OEM x Y Y Y Email: eci@eccgroupksa.com / insp@eccgroupksa.com

39 BOP LIFTING PLATES API RP 7L Y x Y Y Y x OEM OEM Y Y Y Y

40 BIG BAG RING (SUPERSACK LIFTING RING) SWIM-35 ASME B30.20 Y x Y Y Y x Y Y Y Y Y REFERENCES

41 LIFTING PADEYES SWIM 3 ASTM A 521 / ASME BTH-1 Y x Y Y Y Y 3 Y Y Items 1 Through 18. Only Inspection Companies Approved by CIU (Crane Inspection Unit) are allowed to perform these lifting equipment inspections and certification.

42 LEVER HOISTS (PULLIFTS) / COME ALONG BS EN 13157 / ASME B30.21 Y x FT Y Y x OEM OEM x Y Y Three month inspection is visual & function test, inspection to ensure Equipment integrity.(Recommedned after each rig move). Inspection Report is required as per D&WO. Annual

43 MANUAL JACKS BS EN 1494 Y x Y x OEM OEM x Y Y Inspection is required for Blue Sticker issue as per G.I. 7.030

44 HYDRAULIC RAMS - & JACKS / ENERPAC BS EN 1494 Y x FT x Y x OEM OEM x Y Y *** Load tests shall be conducted in accordance with G.I. 7.030 and the applicable International standard (ASME-API) Note: If a Proof Load Test has previously been performed then only a

45 WIRE ROPE SLINGS G.I 7.029 BS EN 13414 / 1-3 / ASME B30.9 Y x Y Y x Y Y Y load test (function test to the OEM Specifications) is required. The Load test procedure DOES NOT need to be submitted to CIU for review. Load Tests will not be performed above the

46 WIRE ROPE SLINGS (MULTI-LEG) G.I 7.029 BS EN 13414 / 1-3 / ASME B30.9 Y x Y Y x Y Y Y recommended international Standard or OEM recommendation.

47 METAL MESH SLINGS G.I 7.029 ASME B30.9 Y x Y Y x Y Y Y

48 SYNTHETIC WEBBED SLINGS G.I 7.029 ASME B30.9 Y x Y Y x Y Y Y Five (5) Year Inspections. The five yearly Inspection / Repair / Overhaul requirements shall be based on OEM recommendations and Industry Standards. Each drilling contractor shall have

49 CHAIN HOOKS & FITTINGS - GRADE 80 G.I 7.029 BS EN 1677 / ASME B30.10 Y x Y Y x Y Y Y a computerized maintenance / Inspection system, which its annual records demonstrates regular preventive maintenance frequencies and inspections of the equipment. Note: Maximum

50 SHACKLES - ALLOY (UP TO 20t) G.I 7.029 RR-C 27 1D TYPE IV, 13889 / ASME B30 26 Y x Y Y x Y Y Y five (5) years according to the industry best practices.

51 SHACKLES - HIGHER TENSILE G.I 7.029 ISO 2415 / ASME B30 26 Y x Y Y x Y Y Y

52 EYEBOLTS G.I 7.029 ASME B18 15M / ASME B30.26 Y x Y Y x Y Y Y INSPECTION CYCLE

53 RIGGING SCREWS (TURNBUCKLES) FF-T-791-TYPE 1 FORM 1 / AS / BS Y x Y Y x Y Y Y

Lifting accessories/-appliances, having passed the 6 monthly inspections, shall be coded

54 OPEN WEDGE SOCKETS RR-S-550D TYPE C / BS EN 13411-6 Y x Y Y x Y Y Y with the applicable color.

55 PALLET LIFTERS ASME B30.20 Y x Y Y x OEM OEM x Y Y Y

56 BARREL LIFTERS ASME B30.20 Y x Y Y x OEM OEM x Y Y Y

57 LIFTING BEAMS BS EN 13001 / ASME B30.20 Y Y Y Y Y Y Y Y Y

58 WIRE ROPE HOISTS (“TIRFORS”) BS EN 13157 / ASME B30.21 Y x FT Y Y x OEM OEM x Y Y All permanently attached lifting sets, which have been inspected and found fit for

59 SPIDER BASKETS SWIM 3 UL1325/ OSHA 1910.28/1926.421 Y x 30 OEM OEM OEM OEM OEM OEM Y Y Y purpose for a maximum six months. In addition, to indicate that the lifting set is

OFFSHORE CONTAINERS / SKIDS / ENCLOSURES / MATERIALS permanently attached.

60 BS EN 12079 / DNV 2.7-1

CARGO BASKETS Y Y Y Y Y Y Y Y Y

61 FREIGHT CONTAINERS BS ISO 1496-5 Y Y Y Y Y Y Y Y Y

62 SLEEPER CABINS -CONSTRUCTION CABINS BSO ISO 1496-5 Y Y Y Y Y Y OEM Y Y Y

63 PALLETS ASME MH1, BS ISO 6780 Y Painting of the color codes shall be the responsibility of the asset custodian or his

64 OILFIELD CABINS / MASTER SKIDS BSO ISO 1496-5 Y Y Y Y Y Y OEM Y Y Y nominee and shall be witnessed by the lifting equipment Inspector.

65 WASTE SKIPS Regulation 5 of PUWER 1998 Y Y Y Y

LEGEND

Y STATUTORY REQUIREMENT 3rd Party Inspection Companies Performing Inspections and NDT

All lifting accessories, which have been inspected and found fit for purpose for a

O.E.M - RECOMMENDATIONS / OWNER RECOMMENDATIONS 1. Check the Inspectors Certification.2. Inspector shall present Scope of work / Plan including which standards the inspections will follow. 3. Inspector shall present the equipment / Asset inspection

OEM maximum six months, shall be color coded. All items shall have as a minimum the unique

TO BE FOLLOWED checklist.

number and the safe working load (SWL).

1 STATUTORY REQUIREMENT = ANNUALLY 4.Inspector shall present verification the inspections tools and equipment is calibrated and fit for purpose.

3 STATUTORY REQUIREMENT = 3 YEARS 5. Inspector to IDENTIFY the wear tolerances in which shall be checked. These are usually in the the OEM manual.

5 STATUTORY REQUIREMENT = 5 YEARS 6. Inspector shall submit a comprehensive report with verified Asset / Equipment serial numbers and identification information before the report will be signed off. If the inspector does not meet Any lifting gear without a visible color band or is out of date, shall not be used. Such

x REPLACE - MODIFICATIONS NOT ALLOWED these requirements, then the inspection shall not be started. This shall be reported immediately to the inspection company management. Note: If the Drilling contractor signs off on poor quality equipment shall not be used until after satisfactory thorough examination by a lifting

FT FUNCTION TEST inspections after completion, then he is ultimately responsible. equipment Inspector.

# Saudi Aramco: Company General Use

#

D&WO DRILLING RIG AND SERVICE EQUIPMENT INSPECTION - NDT MATRIX - JANUARY 14TH 2020

OEM / 5 YR

D&WO DRILLING RIG AND SERVICE EQUIPMENT INSPECTION - API RP 8B CAT III - CAT IV INSPECTION /

INITIAL EXAM / TEST CAT I CAT II REPAIR /

OTHER SAUDI ARAMCO INSPECTION DEPARTMENT APPROVED (CNDT) CONVENTIONAL NDT SERVICE PROVIDERS

NDT MATRIX - JANUARY 14TH 2020 INCLUDING NDT

OVERHAUL

AFTER MODIFICATION / REPAIR / OVERHAUL

BASED ON OEM RECOMMENDATIONS / API

PRIOR TO FIRST USAGE INSTALLATION OEM

STANDARDS / REFER TO REFERENCES

RECOMMENDATIONS / INDUSTRY

AFTER REPAIR - MODIFICATION

EQUIPMENT REGISTER

EVERY 6 MONTHS

SECTION BELOW

CERTIFICATION

EVERY 90 DAYS

COLOR CODE

BI ANNUAL

ANNUALLY

I.D. LABEL

10 YEARS

ANNUAL

WEEKLY

2 YEARS

5 YEARS

STICKER

ARAMCO MANUFACTURING SAUDI ARAMCO INSPECTION DEPARTMENT APPROVED CNDT INSPECTION SAUDI ARAMCO INSPECTION DEPARTMENT APPROVED CNDT INSPECTION

DAILY

EQUIPMENT TYPE

STANDARDS CODES / STANDARDS COMPANIES COMPANIES

66 MAST - SUBSTRUCTURE - DERRICK SWIM-4 API RP 4G Y Y I IV III IV Y Y 1 Petrol & Petrochemical Co. for Industrial Support Services (Petrochem) 18 Deem Inspection Co. (Deem)

67 CROWN BLOCK SHEAVES AND BEARINGS SWIM-4 API RP 8B Y Y I II IV III IV Y Y 2 Branch of SGS Inspection Services Saudi Arabia Co. LTD. (SGS) 19 NDT & Corrosion Control Services Co. (NDT&CCS)

68 DRILLING HOOK SWIM-5 API RP 8B Y Y I II IV III IV Y Y 3 Rawabi Industrial Support Services Co. LTD. (RISS) 20 Industrial Support Services Co. (ISS)

69 KELLY SPINNER - IF BEING USED AS HOISTING EQUIPMENT API RP 8B Y Y I II III IV OEM Y 4 Integrated Technologies for Industrial Services Co. LTD. (IT IS) 21 Geotechnical Testing Center (GTC)

70 ROTARY TABLES API RP 7L Y Y I OEM Y 5 Cooperheat Saudi Arabia Co. LTD (Cooperheat) 22 Abdallah I. Altamimi Industrial Services Est. (Tamimi)

71 POWER TONGS API RP 7L Y Y I III IV OEM Y 6 Sievert Arabia Co. (Sievert) 23 Petrospect Inspection Services EST. (Petrospect)

72 HIGH PRESSURE MUD LINES - STANDPIPE Y Y Y OEM OEM Y 7 Gulf Quality Control Co. LTD. (GQCCO) 24 Advance Inspection Services Co. (AIS)

73 AUTOMATED CAT WALKS / PIPE HANDLERS SWIM-No 12 Y Y Y IV III IV OEM Y 8 Riyadh geo-technique & Foundations Co. (RGF) 25 Technology Precision & Quality Saudi Cont. Co. (Qtech)

74 TOP DRIVES AND RAIL LINKS API RP 8B Y Y I II IV III IV Y Y 9 Universal Inspection Co. (UI) 26 Engineering Corner Co. (ECI)

75 DEADLINE TIE DOWN - WIRELINE ANCHORS API RP 8B Y Y I II III Y Y 10 Inspection Technology Co. (ITCO) 27 APN Inspection International Co. LTD. (APN)

76 TRAVELLING BLOCK SWIM-6 API RP 8B Y Y I II IV III IV Y 11 Brach of Zeppelin Systems Gulf Co. for Inductrial Services (Zeppelein) 28 Quality Control Services Co. (QCS)

77 ROTARY SWIVELS API RP 8B Y Y II II III IV Y 12 Durat Al Jubail Co. LTD. BR (DJC) 29 Abdulaziz Mohammed Al-Othman & Partners Engineering Co. (AMO)

78 POWER SWIVELS API RP 8B Y Y I II III IV Y 13 Specialized Oil & Gas Engineering Co. (SOGEC) 30 Makamin Petroleum Services Co. (Makamin)

79 DRAWWORKS COMPONENTS SWIM-14 API RP 7L / L.O.L.E.R. Reg.9 Y Y I Y 14 Gulf Engineering House (GEH) 31 BISCO Integrated Services (BISCO)

80 MAST / SUBSTRUCTURE RAISING CYLINDERS API RP-4F Y Y Y 15 Branch odf Al-Yamamah Co.for Trading & Contracting (Al-Yamamah) 32 TUV Rheinland Arabia LLC Co. (TUV Rheinland)

81 IRON ROUGHNECK Y Y Y 16 Pipe & Well Operation & Maint. Services Co. (Pipe & Well) 33 KNDT Arabia & Al-Joaib Group Co, (KNDT)

82 STABBING BOARDS SWIM 3 PUWER / LOLER / OEM Guidance Y Y Y Y III IV OEM 17 Al-Hoty Stanger LTD. Co. Independent Laboratory & Materials Testing (Al-Hoty)

83 DRILL STRING MONTION COMPENSATORS API RP 8B Y Y II III IV OEM Y

84 RISER AND WELLHEAD IF USED AS HOISTING EQUIPMENT API RP 8B Y Y II III IV OEM Y

85 SAFETY CLAMPS IF BEING USED AS HOISTING EQUIPMENT API RP 8B Y Y II IV OEM Y LEGEND

86 PICK UP ELEVATORS API RP-7K / DACC-IRP15 Y 3YR OEM Y STATUTORY REQUIREMENT

D&WO DRILLING RIG AND SERVICE EQUIPMENT INSPECTION

87 SHEAVES API RP-7K / DACC-IRP15 Y Y 3YR OEM OEM O.E.M - RECOMMENDATIONS / OWNER RECOMMENDATIONS TO BE FOLLOWED

88 ELEVATOR LINKS API RP-7K / DACC-IRP15 Y Y 5YR OEM 1 STATUTORY REQUIREMENT = ANNUALLY

89 RACK AN PINION API RP-7K / DACC-IRP15 Y Y 5YR OEM 3 STATUTORY REQUIREMENT = 3 YEARS

90 SPREADER BAR API RP-7K / DACC-IRP15 Y x Y 5YR OEM 5 STATUTORY REQUIREMENT = 5 YEARS

91 STAND UP HOISTS API RP-7K / DACC-IRP15 Y Y 5YR OEM x REPLACE - MODIFICATIONS NOT ALLOWED

92 TONG RAISING RAM ASSEMBLY API RP-7K / DACC-IRP15 Y Y 5YR OEM FT FUNCTION TEST

93 FALL ARREST SUPPORT DACC-IRP15 Y Y 5YR OEM I API Category I Inspection

94 JACK CYLINDER DACC-IRP15 Y Y 5YR OEM II API Category II Inspection

95 LOAD PLATE - (Not part of BOP system) DACC-IRP15 Y Y 5YR OEM III API Category III Inspection

96 ROTARY BEARING ASSY DACC-IRP15 Y Y 5YR OEM IV API Category IV Inspection

97 SLIP BOWLS DACC-IRP15 Y Y 5YR OEM

98 SLIP WINDOWS DACC-IRP15 Y Y 5YR OEM

DRILLING CONTRACTORS - SERVICE COMPANIES RESPONSIBILITIES

99 SUPPORT LEGS AND / OR ANGLE IRON DACC-IRP15 Y Y 5YR OEM

100 TRAVELLING PLATE DACC-IRP15 Y Y 5YR OEM

101 WINDOW PLATE DACC-IRP15 Y Y 5YR OEM

It is the responsibility of the Drilling contractors and the Service Companies to provide a register or other identification process for all equipment which requires

102 LOAD BOLTS AND NUTS DACC-IRP15 Y Y OEM OEM

maintenance inspections, including NDT as per the OEM recommendations and Industry standards. The inspection information shall include, the critical components,

103 CONNECTORS AND LINK ADAPTORS API RP 8B Y Y I II III IV Y Y 1

areas to be inspected, identification of applicable wear limits and wear tolerances. This information shall be available on each Drilling Contractor Rig / Service Company.

104 TUBING HOOKS API RP 8B Y Y I II III IV Y Y

This information for the service providers equipment shall be available at their base facility in KSA and available upon request.

105 ELEVATOR LINKS API RP 8B Y Y I II III IV Y Y

106 CASING ELEVATORS / TUBING ELEVATORS API RP 8B Y Y II III IV Y Y

107 DRILL PIPE ELEVATORS / DRILL COLLAR ELEVATORS API RP 8B Y Y II III IV Y Y

Whether it is the drilling contractor or the service provider requesting an inspection, this shall be planned with the Inspection company in line with the OEM

108 CASING RUNNIING TOOLS API RP 8B Y Y II III IV Y Y

recommendations and Industry standards.

109 POWER SUBS API RP 8B Y Y I II III IV Y Y

Before carrying-out non-destructive testing, the following items shall be included in the inspection request.

110 SPIDERS - IF CAPABLE OF BEING USED AS ELEVATORS API RP 8B Y Y I II III IV Y Y

111 CASING / TUBING SLIPS/ POWER SLIPS API RP 7L Y Y I III IV Y a. Specific Testing Procedure

112 ROTARY BUSHINGS / MASTER BUSHING AND INSERTS API RP 7L Y Y I III IV Y 2 b. Extent of Testing – OEM – Industry Standards

113 ROTARY HOSES API RP 7L Y Y I Y c. Testing Plan

114 SLUSH PUMP COMPONENTS API RP 7L Y Y I Y d. Testing Equipment

115 SPIDERS NOT CAPABLE - USED AS ELEVATORS API RP 7L Y Y I Y e. Calibration of Equipment

116 MANUAL TONGS API RP 7L Y Y I III IV Y f. Acceptance Level

117 SAFETY CLAMPS IF NOT USED AS LIFTING DEVICES API RP 7L Y Y I III IV Y g. Actions necessary for unacceptable indications

118 MANUAL ELEVATORS API RP 8B Y Y Y III IV Y

ABBREVIATIONS

119 SINGLE JOINT ELEVATORS API RP 8B Y Y Y

120 SIDE DOOR ELEVATORS API RP 8B Y Y Y III IV Y Magnetic Particle Testing (MPI) Penetrant Testing (PT)

121 CENTRE LATCH ELEVATORS API RP 8B Y Y Y

122 SAFETY CLAMP API 7K 6th Addition 2016 Y Y Y

123 INSERT BOWL API 7K 6th Addition 2016 Y Y Y

124 MASTER BUSHING API 7K 6th Addition 2016 Y Y Y III IV Y Visual Testing (VT) Positive Material Identification (PMI)

125 BUSHING INSERTS API 7K 6th Addition 2016 Y Y

126 DRILL PIPE SLIPS API 7K 6th Addition 2016 Y Y Y

127 ROTARY SLIPS API 7K 6th Addition 2016 Y Y Y

128 DRILLING WIRE ROPE API SPEC 9A / API RP 9B Y x Y Post Weld Heat Treatment (PWHT) Hardness Testing (HDT)

129 LOOPS / CHICKSANS / SERVICE LOOPS / SWIM-36 Y Y Y Y

130 PRESSURE RELEIF DEVICES SWIM-33 API 576 Y Y OEM Y

131 OFFSHORE FLARE BOOMS - KING POSTS SWIM -No.3 API RP 7L & 7K DNV-2.22 Y Y Y Y 5 5 Y Holding Testing (HT) Ultrasonic Testing (UT)

# Saudi Aramco: Company General Use

You might also like

- Drilling and Workover - (LEM) Lifting Equipment Matrix - January 14th 2020 Final RevisionDocument2 pagesDrilling and Workover - (LEM) Lifting Equipment Matrix - January 14th 2020 Final Revisionengmuhmud100% (1)

- RA For Assessment For Lifting OperationsDocument19 pagesRA For Assessment For Lifting OperationsMohamedSaidNo ratings yet

- Mobile Crane Check ListDocument4 pagesMobile Crane Check Listhafidi.hse18No ratings yet

- PH C L C 4 - RIG MATRIX TRAININGDocument2 pagesPH C L C 4 - RIG MATRIX TRAININGThem Bui XuanNo ratings yet

- CHECKLIST FOR LIFTING PLANDocument1 pageCHECKLIST FOR LIFTING PLANAndrianoNo ratings yet

- Moving RIG Mobilization & Risk Assessment: Harmand - Cv. Marga Sari UtamaDocument28 pagesMoving RIG Mobilization & Risk Assessment: Harmand - Cv. Marga Sari UtamaHSE PT. GROGOL SARANA TRANSJAYANo ratings yet

- Rigging Up Checklist: Rig ModelDocument2 pagesRigging Up Checklist: Rig Model89simbuNo ratings yet

- Dismantling of Concrete Pump TowerDocument1 pageDismantling of Concrete Pump TowerChandruNo ratings yet

- Rig Move Operational Process Flowchart New A4Document1 pageRig Move Operational Process Flowchart New A4aymenmoatazNo ratings yet

- DAILY CHECK LIST Tyre Mounted CraneDocument1 pageDAILY CHECK LIST Tyre Mounted CraneAditya Enterprise100% (1)

- Lull Telehandler 944-E42Document200 pagesLull Telehandler 944-E42Allan DelormeNo ratings yet

- PROMECH Company ProfileDocument38 pagesPROMECH Company ProfileAbu UmarNo ratings yet

- Mewps Operator Practical Only Assessment Sheets 2021 MercuryDocument4 pagesMewps Operator Practical Only Assessment Sheets 2021 MercuryWILLIAM KEAGUE100% (1)

- F0810 - Pre-Post Rig Move Meetings FormsDocument18 pagesF0810 - Pre-Post Rig Move Meetings FormsPaulNo ratings yet

- Wilco External Stairs Lift PlanDocument25 pagesWilco External Stairs Lift PlanEdgar ChecaNo ratings yet

- Risk Assessment PDFDocument4 pagesRisk Assessment PDFAnonymous iI88LtNo ratings yet

- HSE Alert 07-16 Damage To Drilling Mast IncidentDocument1 pageHSE Alert 07-16 Damage To Drilling Mast IncidentSajid HussainNo ratings yet

- Arabian Drilling Company Rig Specific Procedure AD - 32 Manriding OperationDocument5 pagesArabian Drilling Company Rig Specific Procedure AD - 32 Manriding OperationinfonexusNo ratings yet

- Khan Niazi: On Outriggers Fully Extended: 360 On Outriggers Fully Extended: Over FrontDocument1 pageKhan Niazi: On Outriggers Fully Extended: 360 On Outriggers Fully Extended: Over FrontTahir Iqbal. Kharpa RehanNo ratings yet

- Cranes, Derricks, Hoists, Elevators, and ConveyorsDocument19 pagesCranes, Derricks, Hoists, Elevators, and ConveyorsAmeerUlHaqNo ratings yet

- Lifting Hoisting Hazard HuntDocument1 pageLifting Hoisting Hazard Hunt曹庆园100% (1)

- Derrick Escape Descender - Instruction ManualDocument12 pagesDerrick Escape Descender - Instruction ManualSteve WatsonNo ratings yet

- SAB - Incident Report 024-06-13Document3 pagesSAB - Incident Report 024-06-13aymenmoatazNo ratings yet

- Risk Assessment Worksheet: Page 1 of 2 P3-S01-F3Document2 pagesRisk Assessment Worksheet: Page 1 of 2 P3-S01-F3dede fitrianoNo ratings yet

- Eye Bolt Inspection Report: Last of ExaminationDocument7 pagesEye Bolt Inspection Report: Last of ExaminationRonniNo ratings yet

- Operator Daily ChecklistDocument5 pagesOperator Daily ChecklistkrissregionNo ratings yet

- ACS-RIG MOVE-MWS-TECHNICAL v1.0Document6 pagesACS-RIG MOVE-MWS-TECHNICAL v1.0saeed ghafooriNo ratings yet

- Foam InductorDocument6 pagesFoam InductorDipanjan Chakrabarti100% (1)

- Saudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechDocument32 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechAbdul Hafeez SoomroNo ratings yet

- Rig Moving EXCO - 7.00Document7 pagesRig Moving EXCO - 7.00R Fajar NugrohoNo ratings yet

- BOP Nipple Down 17-May-2010Document1 pageBOP Nipple Down 17-May-2010HAMDI RAFIEK100% (2)

- Frontier School Division Job Safety Analysis for Milling Machine OperationsDocument5 pagesFrontier School Division Job Safety Analysis for Milling Machine OperationsAshok SureshNo ratings yet

- Offshore Personnel Transfer by Crane Guidelines - Rev 0Document32 pagesOffshore Personnel Transfer by Crane Guidelines - Rev 0wahyu nugrohoNo ratings yet

- Counter Weight DrawingDocument1 pageCounter Weight Drawingrajaguru20003No ratings yet

- Hino Tipper Risk AssesmentDocument9 pagesHino Tipper Risk AssesmentGnamaSayaNo ratings yet

- 9.1.4 Admasco Rig Move Procedure PDFDocument52 pages9.1.4 Admasco Rig Move Procedure PDFkhaled100% (2)

- Job Safety Analysis for Workover OperationsDocument5 pagesJob Safety Analysis for Workover OperationsAshok SureshNo ratings yet

- Responsibilities of Rig Superintendent StudyDocument7 pagesResponsibilities of Rig Superintendent StudyAnonymous VNu3ODGavNo ratings yet

- LIFTING EQUIPMENT INSPECTION REPORTDocument3 pagesLIFTING EQUIPMENT INSPECTION REPORTMohamed Yasir100% (1)

- MFD Lifting Hoisting ProcedureDocument16 pagesMFD Lifting Hoisting ProcedureMohammed JassimNo ratings yet

- Attachment B1 Rig Move Plan ChecklistDocument4 pagesAttachment B1 Rig Move Plan ChecklistJennifer WangNo ratings yet

- Lars Diver Launch Recovery Systems Datasheet PDocument4 pagesLars Diver Launch Recovery Systems Datasheet Padrian luthfiNo ratings yet

- Yard Operations ChecklistDocument1 pageYard Operations ChecklistdnmuleNo ratings yet

- Introductory Manual GuideDocument47 pagesIntroductory Manual GuideAjay Kumar GuptaNo ratings yet

- Model m25 Free Fall Service ManualDocument44 pagesModel m25 Free Fall Service ManualManuel Rodriguez100% (1)

- Crane Assembling Check ListDocument2 pagesCrane Assembling Check ListBaldev SinghNo ratings yet

- JSA HEMP Well Services Pg11-15Document5 pagesJSA HEMP Well Services Pg11-15Ashok SureshNo ratings yet

- Health, Safety, Environment (HSE) Training Matrix - Houston: Today's DateDocument4 pagesHealth, Safety, Environment (HSE) Training Matrix - Houston: Today's Datemonica dwimandhaNo ratings yet

- Itp Mast TruckDocument3 pagesItp Mast TruckArisNo ratings yet

- Heavy Equipment Transporting Operation ProcedureDocument62 pagesHeavy Equipment Transporting Operation ProcedureaymenmoatazNo ratings yet

- Forklift Incident - Broken LegDocument1 pageForklift Incident - Broken LegAbdul Hameed OmarNo ratings yet

- EHSDP0120.9 Crane Operation Pre-Lift ChecklistDocument1 pageEHSDP0120.9 Crane Operation Pre-Lift Checklistshravani mangalpalliNo ratings yet

- Caught Between - Spooling Cable Results in An InjuryDocument2 pagesCaught Between - Spooling Cable Results in An InjuryAbdul Hameed OmarNo ratings yet

- 012 Piling WorkDocument17 pages012 Piling WorkSarah HaiderNo ratings yet

- DNV GL Standard2-22Document1 pageDNV GL Standard2-22Sinoj V AntonyNo ratings yet

- Installation Guide: KS1000 XD Longspan X-Dek® Roof Panel Multiple Panels Eaves To RidgeDocument1 pageInstallation Guide: KS1000 XD Longspan X-Dek® Roof Panel Multiple Panels Eaves To RidgeGlavanRafaelNo ratings yet

- Drilling and Workover - (LEM) Lifting Equipment Matrix - January 14th 2020 Final RevisionDocument2 pagesDrilling and Workover - (LEM) Lifting Equipment Matrix - January 14th 2020 Final RevisionAfzaalUmairNo ratings yet

- Rfi Log 24.12.2020Document67 pagesRfi Log 24.12.2020Deepu CNo ratings yet

- Loler Matrix 2017 PDFDocument1 pageLoler Matrix 2017 PDFMulatua SiraitNo ratings yet

- Lifting - Equipment - Matrix1 (Under Constrution)Document1 pageLifting - Equipment - Matrix1 (Under Constrution)PradeepNo ratings yet

- Usha Martin Wirerope HandbookDocument72 pagesUsha Martin Wirerope Handbookhaydarburedah100% (2)

- 15003ADocument2 pages15003AMarwan HafizNo ratings yet

- 15003ADocument2 pages15003AMarwan HafizNo ratings yet

- uriserv-OJ C - 2015 054 01 0001 01 ENG-ENDocument79 pagesuriserv-OJ C - 2015 054 01 0001 01 ENG-ENMohammed Nabil AVNo ratings yet

- Calibrate Vernier Calipers ProcedureDocument2 pagesCalibrate Vernier Calipers Proceduregiamillia100% (2)

- MIDCO Lifting Manual SOWDocument47 pagesMIDCO Lifting Manual SOWMoetaz MohamedNo ratings yet

- BS 1290 PDFDocument19 pagesBS 1290 PDFAhmed IrakyNo ratings yet

- Process Description MT Black-White PDFDocument1 pageProcess Description MT Black-White PDFMohammed Nabil AVNo ratings yet

- FIS Services Spec BookDocument22 pagesFIS Services Spec BookLuis A G. C.No ratings yet

- Wire Rope Sling Load Chart Quic-SlingDocument3 pagesWire Rope Sling Load Chart Quic-SlingMohammed Nabil AVNo ratings yet

- Inspection and Maintenance of Drillpipe Ebook PDFDocument39 pagesInspection and Maintenance of Drillpipe Ebook PDFAntónio OliveiraNo ratings yet

- SSCW Tech 26Document10 pagesSSCW Tech 26Om Narayan TiwariNo ratings yet

- API Standards For Pipe Inspections PDFDocument38 pagesAPI Standards For Pipe Inspections PDFajayghosh3140100% (8)

- Inspection and Maintenance of Drillpipe Ebook PDFDocument39 pagesInspection and Maintenance of Drillpipe Ebook PDFAntónio OliveiraNo ratings yet

- BS 1290 1983 Wire Rope SlingsDocument21 pagesBS 1290 1983 Wire Rope SlingsMohammed Nabil AVNo ratings yet

- PuwerDocument106 pagesPuwerBenny Salazar BotonesNo ratings yet

- LEEA Course Tutors PDFDocument2 pagesLEEA Course Tutors PDFMohammed Nabil AVNo ratings yet

- Fire Lane Requirements for Emergency Vehicle AccessDocument4 pagesFire Lane Requirements for Emergency Vehicle AccessKiemNo ratings yet

- Traffic Signs Manual Chapter 05Document142 pagesTraffic Signs Manual Chapter 05Klenz CuraNo ratings yet

- U.S. Route 66Document18 pagesU.S. Route 66Lowtech23No ratings yet

- Grand Canyon Village Shuttle Map and GuideDocument1 pageGrand Canyon Village Shuttle Map and GuideJd LawyerNo ratings yet

- NHAI Four-Laning Ahmedabad-Godhra Highway Project Density TestDocument3 pagesNHAI Four-Laning Ahmedabad-Godhra Highway Project Density TestjitendraNo ratings yet

- Mulund DahanuDocument2 pagesMulund DahanuABNo ratings yet

- WaddDocument31 pagesWaddBen FaizNo ratings yet

- Getting Started HCS2010 PDFDocument51 pagesGetting Started HCS2010 PDFJose Luis CabanillasNo ratings yet

- Indian Roads Congress IrcDocument26 pagesIndian Roads Congress IrcKUNAL PAULNo ratings yet

- Dedham Bus RoutesDocument13 pagesDedham Bus RoutesDanLibonNo ratings yet

- Factors and Elements Guiding Highway Alignment and Cross-Section DesignDocument3 pagesFactors and Elements Guiding Highway Alignment and Cross-Section DesignRohit BhamareNo ratings yet

- NACTO Bike Share Siting Guide - FINAL PDFDocument74 pagesNACTO Bike Share Siting Guide - FINAL PDFarqsosagarciaNo ratings yet

- PSA SingaporeDocument3 pagesPSA SingaporeAmey DeshmukhNo ratings yet

- Lifting Equipment 04 11 2023Document22 pagesLifting Equipment 04 11 2023rome reyesNo ratings yet

- 0800-Epmo Egpc-Spamw BriefDocument9 pages0800-Epmo Egpc-Spamw Briefadamstaw1No ratings yet

- Case Studies of Selected Streets in ChennaiDocument74 pagesCase Studies of Selected Streets in ChennaiAdeeba IfrahNo ratings yet

- Power Point Aerodrome Traffic CircuitDocument14 pagesPower Point Aerodrome Traffic Circuitweed cokeNo ratings yet

- Pavement Condition Report 2017Document138 pagesPavement Condition Report 2017Hannah MichelleNo ratings yet

- Hornby High Level EquipmentDocument2 pagesHornby High Level EquipmentJohn GasparNo ratings yet

- MOS - Karakteristik FisikDocument41 pagesMOS - Karakteristik FisikAdetya PurbaNo ratings yet

- Kandhal Asphalt Literature With Web LinksDocument22 pagesKandhal Asphalt Literature With Web LinksProf. Prithvi Singh Kandhal100% (2)

- VattekunnamDocument341 pagesVattekunnamMahesh GopalakrishnanNo ratings yet

- DW Cage Lifting Plan PDFDocument13 pagesDW Cage Lifting Plan PDFMohamedAbdelnasserNo ratings yet

- New Traffic Signs in IndiaDocument6 pagesNew Traffic Signs in IndiaPratik SinhaNo ratings yet

- NorreportDocument17 pagesNorreportYiwu ZhangNo ratings yet

- TTDS Summary (Region 3)Document10 pagesTTDS Summary (Region 3)Aldrin SantosNo ratings yet

- CDC-Booklet On S&TDocument136 pagesCDC-Booklet On S&TAbhijitNo ratings yet

- Fake Navigation ControlDocument4 pagesFake Navigation ControlRahmatia Wulan DariNo ratings yet

- ESD-05-01 Common Signal Design PrinciplesDocument42 pagesESD-05-01 Common Signal Design PrincipleskvreddyNo ratings yet

- SS 497: 2011 Guide to Safe Design, Operation and Maintenance of Gantry, Overhead and Monorail CranesDocument20 pagesSS 497: 2011 Guide to Safe Design, Operation and Maintenance of Gantry, Overhead and Monorail CranesWang EnhaiNo ratings yet