Professional Documents

Culture Documents

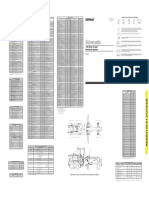

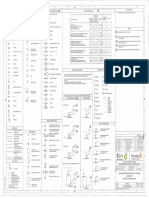

Aaaa-A (Aaa) - NNNNNN (A) : Piping Class

Uploaded by

sanjay masoodOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aaaa-A (Aaa) - NNNNNN (A) : Piping Class

Uploaded by

sanjay masoodCopyright:

Available Formats

1 2 3 4 5 6 7 8 9 10

REV. No.

C02

SHT. No.

MISCELLANEOUS IDENTIFICATIONS

001

PIPING CLASS EQUIPMENT IDENTIFICATION SYSTEM

Project Location ID

A Piping Material Code

Equipment Code A

Piping Class Flange Rating

Corrosion Allowance Primary, SubSystem & Train

Sequence Number NOTES

LINE IDENTIFICATION SYSTEM Sequence Number

REVISION CLOUD

Suffix (*) 1 ALL NON ACTUATED VALVES AND CHECK VALVES SHALL BE IDENTIFIED USING EQUIPMENT

KZ01-PR-PID-53-00006

ANNAN IDENTIFICATION "HV". THE "HV" TAG NUMBER IS BUILT UP IN THE SAME WAY AS THE

EQUIPMENT IDENTIFICATION, HOWEVER AN EXTRA DIGIT IS ALLOWED IN THE SEQUENCE

Line Size (Inches)

AAAA-A(AAA)-NNNNNN(A) NUMBER TO CATER FOR THE QUANTITY OF NON-ACTUATED VALVES.

Project Location ID

PIPING CLASS - MATERIAL CODE

2

DWG. No.

Fluid Service Code REFER TO GENERAL DRAWING LIST P&ID, KZ01-PR-PID-53-00001, KZ01-PR-PID-53-00002,

System Number

C ode Mat erial EG. FAC1-P-232101A KZ01-PR-PID-53-00003 FOR SYSTEM NUMBERS.

Sequence Number A Carbon St eel (*) SUFFIX SHALL BE USED TO INDICATE 2 OR MORE EQUIPMENT OPERATING IN PARALLEL WITHIN A TRAIN E.G. DUTY/ STANDBY

B Low Temperat ure Carbon St eel PUMPS

B Piping Class B

C St ainless St eel (316/ 316L Dual Cert if ied)

Insulation Code

D Duplex St ainless St eel AAAA-C-NNNNNN AAAA-F-NNNNNN

E Super Duplex St ainless St eel COMPRESSOR FILTER

F Cu-Ni ( 90/ 10 Copper/ Nickel) CAPACITY: 1.0 m3/ h SIZE: 1mm ID X 1mm T/ T

NNNNN"-AAAA-AA-NNNNNNN-A NNAN-AA G Galvanised Low Temperat ure Carbon St eel ABSORBED POWER: 1.1kW CAPACITY: 1.0 m3/ h

WHERE A = ALPHABETIC CHARACTER ONLY 2 H GRE MATERIAL: DP/ DT: 100 kPa-g / 1°C

N = NUMERIC CHARACTER ONLY I Undef ined INSULATION/ THK: MATERIAL:

INSULATION/ THK:

EXAMPLE 1_1/2"-FAC1-AM-2461001-A01B1-PP L Carbon St eel Lined (Plast ic) PARTICULE SIZE: 1µm

M 1¼Cr ½Mo Alloy St eel

AAAA-FC-NNNNNN AAAA-H-NNNNNN

N Inconel 625

STACKED FLARE HEAT EXCHANGER (S/ T)

C O Undef ined (Not t o be used) C

PROJECT LOCATION ID P High Densit y Poly Et hylene ( HDPE)

SIZE: 1mm ID X 1mm H DUTY: 1.0 MW

ID D ES C R I P T I ON

CAPACITY: 1m3 SHELL DP/ DT: 100 kPa-g / 1°C

EXPT EXPORT SYSTEMS DP/ DT: 100 kPa-g / 1°C TUBE DP/ DT:

S Carbon St eel (Int ernally Coat ed / St ainless St eel)

FAC1 CENTRAL PROCESSING FACILITY MATERIAL: MATERIAL (SHELL/ TUBE):

T Tit anium INSULATION/ THK: INSULATION/ THK:

GATH GATHERING SYSTEM

GEN1 GENERAL FOR SPPID LEGEND SHEET USE ONLY

FAC1-Z-NNNNNN

AAAA-H-NNNNNN AAAA-H-NNNNNN PACKAGE NAME

INF1 INFRASTRUCTURE ( E.G. ACCOMMODATION MODULES, AIRPORT, ROADS)

HEAT EXCHANGER (PLATES) AIR COOLER

WATR WATER INFRASTRUCTURE (EXTERIOR TO CPF) PIPING CLASS - FLANGE RATING DUTY: 1.0 MW DUTY: 1.0 MW

WTYP WELLS TYPICAL (TEMPORARY USE ONLY)

ANNN WELLS: P - PRODUCTION WELL, R - WATER WELL, J - WATER INJECTION WELL C ode R a t i ng SHELL DP/ DT: 100 kPa-g / 1°C TUBE DP/ DT: 100 kPa-g / 1°C

01 Class 150 (Accor ding t o ASME B16.5) PLATE DP/ DT: 100 kPa-g / 1°C MATERIAL

MATERIAL (SHELL/ PLATE):

LIST OF FLUID SERVICE CODES 03 Class 300 (Accor ding t o ASME B16.5)

INSULATION/ THK: AAAA-IMS-NNNNNN

D 06 Class 600 (Accor ding t o ASME B16.5) D

FLU I FLUI

D D 09 Class 900 (Accor ding t o ASME B16.5) AAAA-H-NNNNNN METERING

S ER VI C E S ER VI C E

C OD C OD 15 Class 1500 (According t o ASME B16.5) WASTE HEAT RECOVERY CAPACITY: 1.0 m3/ h

E E 25 Class 2500 (Accor ding t o ASME B16.5) DUTY: 1.0 MW DP/ DT: 100 kPa-g / 1°C VENDOR PACKAGE

AB Breat hing Air KW Micronut rient 10 Class 10000 ( According t o API 6A) MATERIAL:

AF Aviat ion Fuel MD Met hanol - Rich 30 Class 3000 Tubing (SAE 3000 PSI)

AK Combust ion Air MF Met hanol - Lean / Fresh AAAA-KF-NNNNNN AAAA-MA-NNNNNN

37 Class 370 bar ( According t o API 6A)

AM Inst rument Air MH MEG - Rich BLOWERS AGITATORS/ MIXERS

22 224.6 barg Design Pressure

AN Plant Air ML MEG - Lean / Fr esh CAPACITY: 1.0 Am3/ h ABSORBED POWER: 1.0 kW

24 245 barg @CAT design pressure

AU Ut ilit y Air OB Base Oil ABSORBED POWER: 1.0 kW MATERIAL:

CB Biocide OD Diesel Oil MATERIAL: INSULATION/ THK:

CD Demulsif ier OH Hydr aulic Oil PIPING CLASS - CORROSION ALLOWANCE INSULATION/ THK:

E CF Acid ( Hydrochloric Acid) OL Lube Oil E

CH Sodium Hypochlorit e OM Slop Oil, Miscellaneous Oils

C ode A l l o wa nc e AAAA-P-NNNNNN AAAA-T-NNNNNN

CJ Ant i Foam OS Seal Oil A Nil f or Non- Ferrous/ Exot ic Mat . NACE PUMP TANK

CL Scale Inhibit or PF Product ion Fluids ( Pr e Slugcat cher ) B 3.0mm Non -NACE CAPACITY: 1.0 m3/ h SIZE: 1mm ID X 1mm T/ T

CM Reverse Emulsion Breaker PH Tr eat ed Produced Wat er C Nil f or Non- Ferrous/ Exot ic Mat . Non- NACE ABSORBED POWER: 1.0 kW CAPACITY: 1m3

CN Caust ic (Sodium Hydroxide) PJ Process Hydr ocarbon Gas ( Inc. Exp./ Sales Gas) D 1.5mm NACE MATERIAL: DP/ DT: 100 kPa-g / 1°C

CO Oxygen Scavenger PK Process Condensat e

E 3.0mm NACE INSULATION/ THK: MATERIAL:

CU Miscellaneous Chemical PL Process Liquids

F 6.0mm NACE INSULATION/ THK: NON VENDOR PACKAGE

CW Wax Inhibit or/ Par af f in Inhibit or PM Wellst ream (Onshore Wellpads)

G 4.5mm Non-NACE OR MODULE PACKAGE

CX Cat alyst PW Produced Wat er AAAA-V-NNNNNN AAAA-Z-NNNNNN

DB Black Wat er Dr ains PX Tr eat ed Wat er

VESSEL FURNACES

DD Desanding Drains RH Air-Condit ioning Ref rigerant PIPING CLASS - SEQUENCE NUMBER SIZE: 1mm ID X 1mm T/ T DUTY: 1.0 MW XX NOTE REFERENCE SYMBOL

(XX-NOTE NUMBER)

DF Sludge RP Propane Ref riger ant

SEQUENCE NUMBER FOR NUMBERING VARIATIONS OF LINE CLASS. CAPACITY: 1m3 MATERIAL:

F DH Hazardous Open Drains (Cont inuous) TB Amine - Lean / Fresh HOLD REFERENCE SYMBOL F

DP/ DT: 100 kPa-g / 1°C INSULATION/ THK: XX

DJ Sanit ary Grey Wat er Dr ains TD Amine - Rich (XX-HOLD NUMBER)

MATERIAL:

DK Closed Drains TJ Polyelect rolyt e BATTERY LIMITS (OR MATCHLINE)

DM Chemical Dr ains TK Wat er Clarif ier

INSULATION CODE INSULATION/ THK: C02 12/01/2016 APPROVED FOR CONSTRUCTION AL/AVS RB/KP/KK TAM/IDD

DO Open Drains (Accident al Oil Cont aminat ed ) TL Flocculant C ode I n su l a t i o n T y p e C01 15/07/2015 APPROVED FOR CONSTRUCTION NP RB/KP/KK TAM/IDD

FF Fir e Fight ing Foam TM Glycol ( TEG) - Lean / Fr esh AC Ant i-Condensat ion MISC. PIPING EQUIPMENT CODES MISC. EQUIPMENT CODES B01 27/03/2015 APPROVED FOR DESIGN AL RB/KP/KK TAM/IDD

FJ Fir e Ext inguishing TN Glycol ( TEG) - Rich AI Acoust ic Insulat ion

HV HAND VALVE 1 CG COMPRESSOR GEARBOX A02 27/10/2014 ISSUED FOR HAZOP NP KP/KK IDD

FW Fir e Wat er TX Vessel Trim AT Acoust ic Insulat ion wit h Tracing

FX Primar y Flocculant VF LLP Flare CC Cold Conservat ion IM INLINE MIXER DD DIESEL ENGINE A01 12/09/2014 ISSUED FOR REVIEW AL SKG//KK TAM/IDD

GA Acid Gas VG Incinerat ion/ Thermal Oxidat ion Vent IP CHEMICAL INJECTION POINT EEH ELECTRIC HEATER CHK'D APP'D

FP Passive Fire Prot ect ion REV DATE DESCRIPTION ORIG

GB Seal Gas, Buf f er Gas VH HP Flare KY INTERLOCKING DEVICE FT FLARE TIP

HC Heat Conservat ion

GF Fuel Gas (Incl Blanket & Purge) VJ Vapour Collect ion NP TEMPORARY STRAINER G GENERATOR

ET Heat Conservat ion wit h Elect rical Tracing

GM Liquid Nit rogen VK LT Flare

G NI Not Insulat ed NT T STRAINER GD GENERATOR DRIVER G

GN Nit rogen Gas VL LP Flare

PP Personnel Prot ect ion NY Y STRAINER GG GENERATOR GEARBOX

GX Exhaust Gas VM Maint enance Vent

HG Heat ing Medium (Glycol / Wat er ) VO At mospheric Vent / Relief WI Wint er isat ion, Insulat ion Only RS REMOVABLE SPOOL KFM BLOWER MOTOR

HH St eam - High Pressur e VX Acid Gas Vent WT Wint er isat ion wit h Tracing SB SPECTACLE BLIND MAM AGITATOR / MIXER / STIRRER MOTOR CLIENT: BP EXPLORATION (EPSILON) LIMITED

HK St eam - Condensat e WB Seawat er SU SPADE PG PUMP GEARBOX

CENTRAL PROCESSING FACILITY (CPF) - KHAZZAN PROJECT

HL St eam - Low Pr essure WD Demineralised wat er INTERFACE IDENTIFICATION TK GAS TRAP PM PUMP MOTOR

HM St eam - Medium Pressure WF Fr esh Wat er SC SAMPLE CONNECTION TG SUMP CONTRACT NO. : ORIGINAL DWG SIZE : A1

HO Heat ing Medium (Hot Oil) WH RO Reject Wat er EQ. IDENTIFICATION - NNN TB BARRED TEE GT GAS TURBINE PETROFAC JOB NO. : SECURITY CLASS. :

KB Hydrogen Per oxide WJ Sand Jet t ing Wat er WHERE:

FN FLAME ARRESTER TITLE:

KD Drag Reducing Agent (DRA) WK Wat er Clarif ier NNN PROJECT CONNECTED TO

KG Cooling Medium (Glycol/ Wat er) WN Wat er Inject ion BN BIRD SCREEN ZF FIRE WATER PUMP PACKAGE PIPING AND INSTRUMENT DIAGRAM - GEN1 - SYSTEM 0000

N01 DIRECTLY TO THE EQ. NOZZLE

CP ELECTRICAL RESISTANCE PROBE ZG POWER GENERATION PACKAGES

KJ Corrosion Inhibit or (Gas) WO Oily Wat er T01 PIPING LEGEND SHEET

KZ01-PR-PID-53-00006.pid

KK Corrosion Inhibit or (wat er) WP Pot able Wat er CSC SCALE MONITORING COUPON ZDX OILY WATER TREATMENT PACKAGE

H

KL Phosphoric Acid WU Ut ilit y Wat er F SINGLE BASKET STRAINER ZFG FUEL GAS PACKAGE

LINE AND EQUIPMENT IDENTIFICATION H

KM Asphalt ene Inhibit or WW Wash Wat er HN HOSE COUPLING ZPW POTABLE WATER TREATMENT PACKAGE

WX Raw Wat er

HO FLEXIBLE HOSE ZR CHEMICAL INJECTION PACKAGES SCALE DRAWING No. SHEET No. REVISION

SG SIGHT FLOW INDICATOR ZS SEWAGE AND WASTE WATER TREATMENT PACKAGES

NONE KZ01-PR-PID-53-00006 001 C02

CAD Filename: KZ01-PR-PID-53-00006-001-C01.pid

1 2 3 4 5 6 7 8 9 10

You might also like

- AP-655C Asphalt Paver Electrical System: Machine Component LocationsDocument2 pagesAP-655C Asphalt Paver Electrical System: Machine Component Locationsjulio100% (1)

- Electr 460BDocument2 pagesElectr 460Bsebastian jaramillo trujilloNo ratings yet

- Plano Electrico 420E Pra0917Document4 pagesPlano Electrico 420E Pra0917Luis Gustavo Escobar Machado0% (1)

- D6N Track-Type Tractor Electrical System: Machine Harness Connector and Component LocationsDocument4 pagesD6N Track-Type Tractor Electrical System: Machine Harness Connector and Component LocationsAnonymous KOtSfT6qNo ratings yet

- Machine Harness Connector and Component Locations: 330D Excavator Electrical SystemDocument4 pagesMachine Harness Connector and Component Locations: 330D Excavator Electrical Systemafie hermanNo ratings yet

- Wiring 966f DiagramDocument2 pagesWiring 966f Diagrambasem elhosanyNo ratings yet

- UntitledDocument2 pagesUntitledMohamed GamalNo ratings yet

- For site useDocument2 pagesFor site usekundan37No ratings yet

- 420E and 430E Backhoe Loader Electrical SystemDocument4 pages420E and 430E Backhoe Loader Electrical SystemNestor HernándezNo ratings yet

- D10T Track-Type Tractor Electrical System: Harness and Wire Electrical Schematic SymbolsDocument4 pagesD10T Track-Type Tractor Electrical System: Harness and Wire Electrical Schematic SymbolsEdison PondaNo ratings yet

- Caterpillar 320d Excvataor Schematics ElectricalDocument2 pagesCaterpillar 320d Excvataor Schematics Electricalravirajendra959No ratings yet

- 330C Excavator Electrical System: Harness and Wire Electrical Schematic SymbolsDocument4 pages330C Excavator Electrical System: Harness and Wire Electrical Schematic SymbolsGerardo Balboa50% (2)

- 330C L Electrico CYA00240Document2 pages330C L Electrico CYA00240Mario BaldocedaNo ratings yet

- 12M and 120M Motor Grader Electrical SystemDocument6 pages12M and 120M Motor Grader Electrical SystemJulioBarrazaCoronadoNo ratings yet

- C11 and C13 On-Highway Truck Engines Electrical System: Right Side ViewDocument2 pagesC11 and C13 On-Highway Truck Engines Electrical System: Right Side Viewgaco88No ratings yet

- Diagrama Eléctrico 834HDocument4 pagesDiagrama Eléctrico 834HJuanNo ratings yet

- D7R Track Type Tractor Electrical System (Differential Steer)Document2 pagesD7R Track Type Tractor Electrical System (Differential Steer)Mauricio BellidoNo ratings yet

- KamranDocument1 pageKamranAnonymous BZQOJwWIh6No ratings yet

- CAT 834H PLANO ELECTRICO WHELLDOZERDocument4 pagesCAT 834H PLANO ELECTRICO WHELLDOZERbanny1971No ratings yet

- 980G Series II Electrical System Wheel Loader: Harness and Wire Electrical Schematic SymbolsDocument4 pages980G Series II Electrical System Wheel Loader: Harness and Wire Electrical Schematic SymbolsPlstina RamsNo ratings yet

- 14H ASE SchematicDocument2 pages14H ASE SchematicNovakurniawan100% (1)

- 980h ScemsaticDocument4 pages980h ScemsaticMukti Ali100% (1)

- 966H and 972H Wheel Loader With Steel Mill Electrical SystemDocument6 pages966H and 972H Wheel Loader With Steel Mill Electrical SystemPaulo Sousa100% (1)

- Caterpillar Wheel Loader 988H Electrical SystemsDocument4 pagesCaterpillar Wheel Loader 988H Electrical Systemsgire_3pich2005100% (1)

- Adt 735 - 740 - 740eDocument2 pagesAdt 735 - 740 - 740efebru100% (1)

- Machine Harness Connector and Component Locations: D10R Track Type Tractor Electrical SystemDocument2 pagesMachine Harness Connector and Component Locations: D10R Track Type Tractor Electrical Systemkhaled boulahlibNo ratings yet

- D3G, D4G, and D5G HYSTAT Electrical System Track-Type TractorsDocument4 pagesD3G, D4G, and D5G HYSTAT Electrical System Track-Type TractorsMaicol MorenoNo ratings yet

- 036909C-2BAE02-ISO-SSC-24163-01-0F1S3-Isometric Sketch-Field Isometric - Modifications-CDocument2 pages036909C-2BAE02-ISO-SSC-24163-01-0F1S3-Isometric Sketch-Field Isometric - Modifications-CNguyenCanhBaoNo ratings yet

- 773E (BDA1-258) & 775E (BEC1-201) Off-Highway Truck Electrical SystemDocument2 pages773E (BDA1-258) & 775E (BEC1-201) Off-Highway Truck Electrical SystemIbrahim BaswidanNo ratings yet

- 5230B Front Shovel and Mass Excavator Electrical System: Machine Harness Connector and Component LocationsDocument2 pages5230B Front Shovel and Mass Excavator Electrical System: Machine Harness Connector and Component LocationsGilvan JuniorNo ratings yet

- Lead Sheet 716-X000Document1 pageLead Sheet 716-X000Chandhu Kurian ThampiNo ratings yet

- 325C CRBDocument2 pages325C CRBMaranka AnkaraNo ratings yet

- M313C and M315C Electrical System Wheeled ExcavatorDocument4 pagesM313C and M315C Electrical System Wheeled ExcavatorevgeniNo ratings yet

- 725 and 730 Articulated Truck Electrical SystemDocument2 pages725 and 730 Articulated Truck Electrical SystemBrahian Mijael Garrado GonzalesNo ratings yet

- Pachara 416e ElectricoDocument4 pagesPachara 416e ElectricoGuillermo PreciadoNo ratings yet

- 993K Wheel Loader Electrical System: Harness and Wire Electrical Schematic SymbolsDocument6 pages993K Wheel Loader Electrical System: Harness and Wire Electrical Schematic SymbolsNorman CoetzeeNo ratings yet

- This Isometric Auto Generated from SPOOLGENDocument3 pagesThis Isometric Auto Generated from SPOOLGENNguyenCanhBaoNo ratings yet

- Bill of Material Sketch List: Reason For Modifications by Subcontractor: Adjustment Pipe Length As Per Actual SiteDocument2 pagesBill of Material Sketch List: Reason For Modifications by Subcontractor: Adjustment Pipe Length As Per Actual SiteNguyenCanhBaoNo ratings yet

- Reason For Modifications by Subcontractor: Adjustment Follow Actual Pipe Length, Add Detail Support As Per Site ConditionsDocument1 pageReason For Modifications by Subcontractor: Adjustment Follow Actual Pipe Length, Add Detail Support As Per Site ConditionsNguyenCanhBaoNo ratings yet

- Reason For Modifications by Subcontractor: Adjustment Follow Actual Pipe LengthDocument4 pagesReason For Modifications by Subcontractor: Adjustment Follow Actual Pipe LengthNguyenCanhBaoNo ratings yet

- Reason For Modifications by Subcontractor: Adjustment Follow Actual Pipe LengthDocument2 pagesReason For Modifications by Subcontractor: Adjustment Follow Actual Pipe LengthNguyenCanhBaoNo ratings yet

- 320 Deco PDFDocument2 pages320 Deco PDFJefferson SilvaNo ratings yet

- 735, 740 and 740E Electrical System Articulated Truck: Machine Harness Connector and Component LocationsDocument2 pages735, 740 and 740E Electrical System Articulated Truck: Machine Harness Connector and Component LocationsMiguel Bustamante100% (3)

- 321D LCR Excavator Electrical System: Harness and Wire Electrical Schematic SymbolsDocument2 pages321D LCR Excavator Electrical System: Harness and Wire Electrical Schematic Symbolsignacio andresNo ratings yet

- Quality Control Plan Machinery Installation (Blowers & Fans)Document11 pagesQuality Control Plan Machinery Installation (Blowers & Fans)rodolfostiNo ratings yet

- Instant Assessments for Data Tracking, Grade 5: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 5: Language ArtsNo ratings yet

- Instant Assessments for Data Tracking, Grade 4: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 4: Language ArtsRating: 5 out of 5 stars5/5 (1)

- Instant Assessments for Data Tracking, Grade 1: MathFrom EverandInstant Assessments for Data Tracking, Grade 1: MathRating: 4 out of 5 stars4/5 (1)

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- February Monthly Collection, Grade 5From EverandFebruary Monthly Collection, Grade 5Rating: 3 out of 5 stars3/5 (1)

- Pnid ExamplesDocument1 pagePnid Examplessecret soldierNo ratings yet

- Pnid ExamplesDocument1 pagePnid Examplessecret soldierNo ratings yet

- KZ01 PR Pid4Document1 pageKZ01 PR Pid4sanjay masoodNo ratings yet

- General Notes: S Piping and Instrument Diagram - Gen1 - System 0000Document1 pageGeneral Notes: S Piping and Instrument Diagram - Gen1 - System 0000sanjay masoodNo ratings yet

- KZ01 PR Pid7Document1 pageKZ01 PR Pid7sanjay masoodNo ratings yet

- KZ01 PR Pid2Document1 pageKZ01 PR Pid2sanjay masoodNo ratings yet

- Aaaa-A (Aaa) - NNNNNN (A) : Piping ClassDocument1 pageAaaa-A (Aaa) - NNNNNN (A) : Piping Classsanjay masoodNo ratings yet

- KZ01 PR Pid1Document1 pageKZ01 PR Pid1sanjay masoodNo ratings yet

- Aaaa-A (Aaa) - NNNNNN (A) : Piping ClassDocument1 pageAaaa-A (Aaa) - NNNNNN (A) : Piping Classsanjay masoodNo ratings yet

- Aaaa-A (Aaa) - NNNNNN (A) : Piping ClassDocument1 pageAaaa-A (Aaa) - NNNNNN (A) : Piping Classsanjay masoodNo ratings yet

- Pasture FatteningDocument15 pagesPasture FatteningKartika PurnamasariNo ratings yet

- Astm D2467-2013Document8 pagesAstm D2467-2013Renato CorrêaNo ratings yet

- Cse Reviewer - MathDocument58 pagesCse Reviewer - MathLyne LerinNo ratings yet

- Stereochemistry MSCDocument29 pagesStereochemistry MSCBapu Thorat50% (2)

- Collaboration Processes: Looking Inside the Black BoxDocument13 pagesCollaboration Processes: Looking Inside the Black Boxเข้าใจว่า น่าจะชื่อตุ้นNo ratings yet

- IQ 250/260 Transducer Quick Start GuideDocument2 pagesIQ 250/260 Transducer Quick Start GuideJoséEmmanuelCasasMunguíaNo ratings yet

- Essay - DnaDocument2 pagesEssay - Dnaapi-243852896No ratings yet

- NPT Pipe Thread Sizes and TapersDocument1 pageNPT Pipe Thread Sizes and TapersRajesh J BharadwajNo ratings yet

- CaseStudy AmtrakDocument14 pagesCaseStudy Amtraksnob_kNo ratings yet

- Pip Venix LRDocument2 pagesPip Venix LRThanh VoNo ratings yet

- Studyguide TracksDocument75 pagesStudyguide TracksAnonymous FabB2WJl485% (13)

- 4jj1tybw01 Spec Sheet PDFDocument10 pages4jj1tybw01 Spec Sheet PDFcpaolinodNo ratings yet

- Adding True Bypass To A Vintage Big MuffDocument8 pagesAdding True Bypass To A Vintage Big MuffOliver SuttonNo ratings yet

- S2 Papers FinalizedDocument149 pagesS2 Papers FinalizedRaffles HolmesNo ratings yet

- HydrotherapyDocument7 pagesHydrotherapyGialys MoretaNo ratings yet

- Mathematics 6 LAS Q4Document127 pagesMathematics 6 LAS Q4Jake Padua100% (1)

- Sliding, Overturning, Bearing Pressure and Bending Reinforcement Calculations for Retaining WallDocument4 pagesSliding, Overturning, Bearing Pressure and Bending Reinforcement Calculations for Retaining WallAbdul Aziz Julkarnain ZulkifliNo ratings yet

- Electronic V-MAC IV Vehicle Mgmt. and Control With Co-Pilot Display Operator ManualDocument133 pagesElectronic V-MAC IV Vehicle Mgmt. and Control With Co-Pilot Display Operator Manualsanach0412No ratings yet

- Practice Quiz M1 (Ungraded) - MergedDocument22 pagesPractice Quiz M1 (Ungraded) - MergedAbdullah Abdullah100% (1)

- Parapsychology QP - WikiDocument371 pagesParapsychology QP - WikiAdamNo ratings yet

- Image Forgery DetectionDocument17 pagesImage Forgery DetectionanlemacoNo ratings yet

- Mass DisasterDocument70 pagesMass DisasterJoseph RadovanNo ratings yet

- Columbus Files Motion To Dismiss Bankruptcy Claim by Latitude Five25 OwnersDocument38 pagesColumbus Files Motion To Dismiss Bankruptcy Claim by Latitude Five25 OwnersWSYX/WTTENo ratings yet

- vCloudPoint Sharing Computing Solution Data Sheet PDFDocument8 pagesvCloudPoint Sharing Computing Solution Data Sheet PDFkus satria dNo ratings yet

- 5020-Article Text-10917-1-10-20220808Document9 pages5020-Article Text-10917-1-10-20220808indah rumah4No ratings yet

- Encore 700 Diaphragm Pump 1Document12 pagesEncore 700 Diaphragm Pump 1bagurtoNo ratings yet

- Encapsulation and Inheritance in Object-Orlented Programming LanguagesDocument8 pagesEncapsulation and Inheritance in Object-Orlented Programming Languageszsolt kormanyNo ratings yet

- Tables in National Plumbing CodeDocument4 pagesTables in National Plumbing CodeMartin GragasinNo ratings yet

- Circuits Review P2Document44 pagesCircuits Review P2José CastilloNo ratings yet

- Interpuls Novinki 2014Document64 pagesInterpuls Novinki 2014BaklanovaSVNo ratings yet