Professional Documents

Culture Documents

Production Includes: Performances Range

Uploaded by

shahin_bOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Production Includes: Performances Range

Uploaded by

shahin_bCopyright:

Available Formats

PRODUCTION INCLUDES

The present range is manufactured for well diameters from 6” to 25”.

• The hydraulical design has been oriented to obtain the maximum efficiencies and a stable Q / H performance curve.

• In order to optimize the pump life the mechanical design limited the number of wear and tear components.

• The impellers are dynamically balanced and splined to the shaft with entrainment key.

• The shafts are driven by coaxial bearing bushes and fully protected by sleeves to ease disassembling.

• All the pumps are provided with a build-in non-return valve, threaded and/or flanged, and low friction losses.

• All the pumps are manufactured in different materials (cast iron / bronze / stainless steel / douplex) to suit various applications.

RADIAL – FLOW PUMPSETS MIXED - FLOW PUMPSETS

Radial solution allows the use of a high number of stages, Semiaxial solution is used when higher flows are required

to reach very high heads for the same well diameter.

TYPES WELLS TYPES WELLS

APN 14 6” XRN 6 6”

APM 14 6” XN 6 6”

BG 8 8” XN 8 8”

CG 10 10” XN 10 10”

DG 12 12” X 12 12”

XN 14 14”

6” Submersible Pumpsets meet the required Minimum Efficiency Index (MEI) of >=0.1

which has to be fulfilled from the 1st of January 2013

PERFORMANCES RANGE

700

600

500 APM14

400 BG8 CG10 DG12

300

H

(m)

200

100

APN14 - APM14 XRN6 XN6 XN8 XN10 X12 XN14

80

60

50

40

30

10 20 30 Q:(m3/h) 60 80 100 200 300 600 800

TECHNICAL SPECIFICATIONS

RADIAL-FLOW PUMPSETS MIXED-FLOW PUMPSETS

- Flow rates up to 200 m³/h - Flow rates up to 800 m³/h

- Heads up to 700 m - Heads up to 330 m

- Power up to 300 kW - Power up to 400 kW

- Max. content of solids (silt) 30 g/m³ - Max. content of solids (silt) 50 g/m³

You might also like

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Submersible Electric Pumps: 3-Horizontal Installation As Booster PumpDocument6 pagesSubmersible Electric Pumps: 3-Horizontal Installation As Booster Pumpshahin_bNo ratings yet

- Pac H64 Fsc03 Skid: Diesel - Qmax 460 M /H (2,030 Usgpm) - Hmax 153 M (502 FT)Document4 pagesPac H64 Fsc03 Skid: Diesel - Qmax 460 M /H (2,030 Usgpm) - Hmax 153 M (502 FT)xdanielleye_98868485No ratings yet

- DS 6822MXDocument2 pagesDS 6822MXThero T KemeloNo ratings yet

- Canrig 6027 E PDFDocument7 pagesCanrig 6027 E PDFAnonymous 1AAjd0100% (1)

- MSD-RO Axially Split Multistage PumpDocument6 pagesMSD-RO Axially Split Multistage PumpSebastian GarzonNo ratings yet

- The Powerful Gem: Yanmar Type 6SY-STPDocument2 pagesThe Powerful Gem: Yanmar Type 6SY-STPAlbertoNo ratings yet

- Surface Pumps: Performance & SolutionsDocument12 pagesSurface Pumps: Performance & SolutionsBJ Abela100% (1)

- GSP600 Sub-Prime® Electric Submersible Dewatering Pumps: Features SpecificationsDocument2 pagesGSP600 Sub-Prime® Electric Submersible Dewatering Pumps: Features SpecificationsAbcehmu EgiNo ratings yet

- Data Sheet PAS 200MF 310 FKL65 CNP ITH 2960 3940 00 ENDocument4 pagesData Sheet PAS 200MF 310 FKL65 CNP ITH 2960 3940 00 ENJuan Jose MagañaNo ratings yet

- Brochure EBA 200 ENDocument4 pagesBrochure EBA 200 ENSerhii HolovizninNo ratings yet

- EBA 200 - 200 S: Small CentrifugesDocument4 pagesEBA 200 - 200 S: Small CentrifugesAbdulrahman AssaidNo ratings yet

- ONRAM 1500: Diamond Core Drill Technical SpecificationDocument7 pagesONRAM 1500: Diamond Core Drill Technical SpecificationFedericoButronNo ratings yet

- Eba200-200s enDocument4 pagesEba200-200s enOsama Ben DawNo ratings yet

- Vortex TurbineDocument7 pagesVortex TurbineMariana Rios RochaNo ratings yet

- Technical Spec ONRAM 1500 0502 EngDocument7 pagesTechnical Spec ONRAM 1500 0502 Engdani sanNo ratings yet

- Hettich PDFDocument18 pagesHettich PDFEry PachecNo ratings yet

- Lowara e-GS Serie - BrochureDocument10 pagesLowara e-GS Serie - Brochurefernando.itt6No ratings yet

- Escavadeira CAT 6050 - 6050 - FSDocument12 pagesEscavadeira CAT 6050 - 6050 - FSgeilsom mouraNo ratings yet

- PRS Var 3-140 D 2960138000 - LDocument4 pagesPRS Var 3-140 D 2960138000 - LBJ AbelaNo ratings yet

- MS 400, MS 650: Series Submersible MixerDocument25 pagesMS 400, MS 650: Series Submersible MixerAnonymous CMS3dL1TNo ratings yet

- 1500 IngDocument10 pages1500 IngAhmadNo ratings yet

- PCI Meteor3000 ENDocument2 pagesPCI Meteor3000 ENHX WEINo ratings yet

- Water Rockdrills Are Key To Hydropowered Mining Technology. Driving Productivity Advantages, They Are Fast and EffectiveDocument4 pagesWater Rockdrills Are Key To Hydropowered Mining Technology. Driving Productivity Advantages, They Are Fast and Effectiverosel prudencio huamanNo ratings yet

- m8083 sc86c14 Spec SheetDocument2 pagesm8083 sc86c14 Spec SheetJamal HabbasNo ratings yet

- Pro WashDocument2 pagesPro WashabcNo ratings yet

- Pompe SUMO FCB - FIVES - SUGAR - BIOENERGY - SUMO - EN - 290316 - BDDocument4 pagesPompe SUMO FCB - FIVES - SUGAR - BIOENERGY - SUMO - EN - 290316 - BDSAHOMA OMARINo ratings yet

- MSDRO AxiallySplitMultistagePumps E10110Document6 pagesMSDRO AxiallySplitMultistagePumps E10110Patrick Mxolisi NkomoNo ratings yet

- m9050 Pioneer Pump Surface Pumps BrochureDocument12 pagesm9050 Pioneer Pump Surface Pumps BrochurecaomandanteNo ratings yet

- Pipe Jacking Accessories Keyhole Jacking FramesDocument2 pagesPipe Jacking Accessories Keyhole Jacking Framesfritz100% (1)

- Keisertools Catalogue 2022Document56 pagesKeisertools Catalogue 2022Raviyanantham RishabananthanNo ratings yet

- SANY SR250 Rotary Drilling RigDocument8 pagesSANY SR250 Rotary Drilling RigАлександр СупрягаNo ratings yet

- Catalog of 150 CDocument6 pagesCatalog of 150 CJorge Barradas OsornoNo ratings yet

- MPP High Performance Multi Phase Pump E00601Document6 pagesMPP High Performance Multi Phase Pump E00601chijioke ekekeNo ratings yet

- 730Sn, 730un, 730dun, 730Bpn, 730us, 730dus and 730enn PumpsDocument4 pages730Sn, 730un, 730dun, 730Bpn, 730us, 730dus and 730enn PumpsalexingmNo ratings yet

- Ocean Rig OlympiaDocument6 pagesOcean Rig OlympiaFateNo ratings yet

- 8x6 Flotation-Feed-PumpDocument1 page8x6 Flotation-Feed-PumpE Junior Estacion TamaraNo ratings yet

- Hydraulic Test Pumps Models CPP1000-M, CPP1000-L, Hand Spindle Pump Models CPP1000-X, CPP1600-X, CPP7000-X, Comparison Test PumpDocument10 pagesHydraulic Test Pumps Models CPP1000-M, CPP1000-L, Hand Spindle Pump Models CPP1000-X, CPP1600-X, CPP7000-X, Comparison Test Pumppablo bazaesNo ratings yet

- Woma Uhp PumpDocument28 pagesWoma Uhp PumpJuliyanto STNo ratings yet

- Product Catalog: Compact Screen, Single Screen & Multi Screen FiltersDocument26 pagesProduct Catalog: Compact Screen, Single Screen & Multi Screen FiltersLuan NguyenNo ratings yet

- PCI MeteorTS900V ENDocument2 pagesPCI MeteorTS900V ENHX WEINo ratings yet

- Halco Dominator SeriesDocument10 pagesHalco Dominator Seriesamir_hayfaNo ratings yet

- CRC Evans Standard 32 60Document4 pagesCRC Evans Standard 32 60goomishNo ratings yet

- Raise BoreDocument2 pagesRaise BoreJosé Mercedes DomínguezNo ratings yet

- 9851 3139 01 - Cop 1238KDocument2 pages9851 3139 01 - Cop 1238Kbundajoseph148No ratings yet

- 06 1 Technspec1000eDocument6 pages06 1 Technspec1000eAnonymous Gh9egRKMNo ratings yet

- H / M P / Kpa: Application RangeDocument2 pagesH / M P / Kpa: Application RangeDavid SoaresNo ratings yet

- HCR 8Document3 pagesHCR 8FahirNo ratings yet

- Vogel - Multistage Pumps: Design P, Pva, MP 300 Sizes DN 80 - DN 300Document12 pagesVogel - Multistage Pumps: Design P, Pva, MP 300 Sizes DN 80 - DN 300Armin DoganNo ratings yet

- Smart Mag™ Non Rotating String Magnet WhiteDocument4 pagesSmart Mag™ Non Rotating String Magnet WhiteAjith MohandasNo ratings yet

- Aquagem InverSilence CatalogueDocument6 pagesAquagem InverSilence CatalogueChia MurphyNo ratings yet

- High-Performance Decanter: Applications Working PrincipleDocument4 pagesHigh-Performance Decanter: Applications Working PrincipleAnonymous uL3JlWfhNo ratings yet

- 5 09a e Adcamat Apst Automatic Pump Trap dn50 80Document6 pages5 09a e Adcamat Apst Automatic Pump Trap dn50 80Ian B. YtomNo ratings yet

- Hitachi - Excavator - ZX200LC-5G, ZX240LC-5G, ZX280LC-5G, ZX330LC-5G - KA-EN164Document11 pagesHitachi - Excavator - ZX200LC-5G, ZX240LC-5G, ZX280LC-5G, ZX330LC-5G - KA-EN164patrickhoyer93No ratings yet

- ABF SeriesDocument7 pagesABF SeriesKAVITANo ratings yet

- Data Sheet JE 4-160 G10 ET20 - Rev. 2016-11 - ENG PDFDocument4 pagesData Sheet JE 4-160 G10 ET20 - Rev. 2016-11 - ENG PDFHamzaHariateNo ratings yet

- Peerless Pump Brochures and Flyers - 8196Document2 pagesPeerless Pump Brochures and Flyers - 8196Gaudencio Rodriguez RomeroNo ratings yet

- DPC Serie Brochure enDocument2 pagesDPC Serie Brochure enabdu taliaNo ratings yet

- Salient Features: 1-SDR0808-00-00-001 Smooth Double Roll Crusher 800X800Document2 pagesSalient Features: 1-SDR0808-00-00-001 Smooth Double Roll Crusher 800X800patelchiragisNo ratings yet

- CH4 2 Welding Joint PreparationDocument46 pagesCH4 2 Welding Joint PreparationMatija BušićNo ratings yet

- ATURIA Sub PumpsDocument1 pageATURIA Sub Pumpsshahin_bNo ratings yet

- Selection: How To Select A Submersible PumpsetDocument1 pageSelection: How To Select A Submersible Pumpsetshahin_bNo ratings yet

- Installation: 3-Horizontal Installation As Booster PumpDocument1 pageInstallation: 3-Horizontal Installation As Booster Pumpshahin_bNo ratings yet

- ATURIA Sub AgriDocument1 pageATURIA Sub Agrishahin_bNo ratings yet

- B16-34 Clarifications 2009Document77 pagesB16-34 Clarifications 2009RobertReinboldNo ratings yet

- Siemens SPPA P3000Document2 pagesSiemens SPPA P3000shahin_bNo ratings yet

- B16-34 Clarifications 2009Document77 pagesB16-34 Clarifications 2009RobertReinboldNo ratings yet

- B16-34 Clarifications 2009Document77 pagesB16-34 Clarifications 2009RobertReinboldNo ratings yet

- Khan NanaDocument4 pagesKhan Nanashahin_bNo ratings yet

- Dry Well RegreaseDocument1 pageDry Well Regreaseshahin_bNo ratings yet

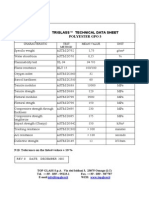

- Triglass™ Technical Data Sheet Polyester Gpo 3: Characteristic Test Method Mean-Value UnitDocument1 pageTriglass™ Technical Data Sheet Polyester Gpo 3: Characteristic Test Method Mean-Value Unitshahin_bNo ratings yet

- Hamon CatalogDocument16 pagesHamon Catalogshahin_bNo ratings yet

- Selecting A Vertical Turbine Pump: (Information Required From Client)Document6 pagesSelecting A Vertical Turbine Pump: (Information Required From Client)shahin_bNo ratings yet

- Gear ClassificationDocument13 pagesGear Classificationprkphani1984100% (1)

- Static and Dynamic Balancing: ObjectiveDocument5 pagesStatic and Dynamic Balancing: ObjectiveUNsha bee komNo ratings yet

- Gear ClassificationDocument13 pagesGear Classificationprkphani1984100% (1)

- D - 5. Technical - EBOOK - Gravity - Why Does Water Flo PDFDocument2 pagesD - 5. Technical - EBOOK - Gravity - Why Does Water Flo PDFshahin_bNo ratings yet

- Stainless ChartDocument8 pagesStainless ChartSujit NairNo ratings yet

- Burgmann BT-FNDocument28 pagesBurgmann BT-FNCarlos Cerón100% (1)

- ReadmeDocument2 pagesReadmeTan Yu AngNo ratings yet

- GPK-WR-XXX-2019-01-000 - Erixs Chandra PratamaDocument5 pagesGPK-WR-XXX-2019-01-000 - Erixs Chandra PratamaChandra PratamaNo ratings yet

- Standard Ib Clutch: Twin Disc Power Take-OffsDocument2 pagesStandard Ib Clutch: Twin Disc Power Take-OffsLeonardo Jiménez CastellanosNo ratings yet

- Journal of Ethiopian Law V 1Document206 pagesJournal of Ethiopian Law V 1yonasNo ratings yet

- Current Affairs Monthly Capsule January 2020 578ae9d7Document106 pagesCurrent Affairs Monthly Capsule January 2020 578ae9d7Udit PandeyNo ratings yet

- Las WK4Document3 pagesLas WK4Jessa TanNo ratings yet

- Um en Axc F XT SPLC 1000 109449 en 01Document202 pagesUm en Axc F XT SPLC 1000 109449 en 01Javier Alarcon VelazcoNo ratings yet

- Projet: Telecom Africa Distrubition Expertise Security (Tades)Document8 pagesProjet: Telecom Africa Distrubition Expertise Security (Tades)Maimouna NdiayeNo ratings yet

- CCNA Security v2.0 Chapter 9 Exam AnswersDocument13 pagesCCNA Security v2.0 Chapter 9 Exam AnswersIbrahim ElghawilNo ratings yet

- LogDocument23 pagesLogPrincess Dianne BalsaNo ratings yet

- Khalie Bang NSTP QuestionsDocument3 pagesKhalie Bang NSTP QuestionsLeeNo ratings yet

- ARCH592 4. Project Management in Architecture PDFDocument66 pagesARCH592 4. Project Management in Architecture PDFGlyrah Marie Dela TorreNo ratings yet

- Web ArchitectureDocument284 pagesWeb ArchitecturedArKhAcKsNo ratings yet

- Sun Systems Fault Analysis Workshop Online AssessmentDocument36 pagesSun Systems Fault Analysis Workshop Online AssessmentRomeoNo ratings yet

- Cambridge International AS & A Level: BUSINESS 9609/12Document4 pagesCambridge International AS & A Level: BUSINESS 9609/12LounlNo ratings yet

- Rule CheckDocument2 pagesRule CheckdanNo ratings yet

- What Is Linear Text and Non Linear Text - Brainly - PHDocument4 pagesWhat Is Linear Text and Non Linear Text - Brainly - PHElmer Villegas67% (3)

- SYLVAC IP67 Digital Caliper S - Cal EVO Smart 150 MM (810.1506) Depth Rod 4x1,4 MMDocument1 pageSYLVAC IP67 Digital Caliper S - Cal EVO Smart 150 MM (810.1506) Depth Rod 4x1,4 MMgeetha raniNo ratings yet

- Analysis and Optimization of Spiral Plate Heat Exchanger Using Computational Fluid DynamicsDocument10 pagesAnalysis and Optimization of Spiral Plate Heat Exchanger Using Computational Fluid DynamicsIJRASETPublicationsNo ratings yet

- Q3 Tos English 8Document1 pageQ3 Tos English 8gayle badorayaNo ratings yet

- Serial Communication Protocol For Embedded Applica PDFDocument4 pagesSerial Communication Protocol For Embedded Applica PDFMarco RamirezNo ratings yet

- Nt920ahr Mkii ManualDocument14 pagesNt920ahr Mkii ManualKuang Ah HockNo ratings yet

- Cyber Tute 3Document1 pageCyber Tute 3amansri035No ratings yet

- ELE Proteus PCS StationDocument5 pagesELE Proteus PCS StationxxxNo ratings yet

- (TM) VRF - DVM S - Installation - GL - ES - 2016 - Ver1.03 Capacitacion Sep 2017 PDFDocument303 pages(TM) VRF - DVM S - Installation - GL - ES - 2016 - Ver1.03 Capacitacion Sep 2017 PDFwilliam ruizNo ratings yet

- DatasheetDocument13 pagesDatasheetJOSE MARIA DANIEL CANALESNo ratings yet

- ASBAS365630018ENR1ERRDocument31 pagesASBAS365630018ENR1ERRRaymond ZamoraNo ratings yet

- Palm Print Classification Based On InterDocument5 pagesPalm Print Classification Based On InterSaesario PutraNo ratings yet

- Lesson Plan - Term1, Week 4 (G6)Document3 pagesLesson Plan - Term1, Week 4 (G6)Miloud Hadj NAASNo ratings yet

- 31 - Temperature Control of A Boiler - Solution - ENGDocument3 pages31 - Temperature Control of A Boiler - Solution - ENGhaftu gideyNo ratings yet

- Namsung 2015 CatalogueDocument10 pagesNamsung 2015 CataloguekimsonvuNo ratings yet

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- A Pathway to Decarbonise the Shipping Sector by 2050From EverandA Pathway to Decarbonise the Shipping Sector by 2050No ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsFrom EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsRating: 4.5 out of 5 stars4.5/5 (2)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerFrom EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerNo ratings yet

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- Heat Transfer Engineering: Fundamentals and TechniquesFrom EverandHeat Transfer Engineering: Fundamentals and TechniquesRating: 4 out of 5 stars4/5 (1)

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceFrom EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceNo ratings yet

- Electric Motor Control: DC, AC, and BLDC MotorsFrom EverandElectric Motor Control: DC, AC, and BLDC MotorsRating: 4.5 out of 5 stars4.5/5 (19)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Smart Power Distribution Systems: Control, Communication, and OptimizationFrom EverandSmart Power Distribution Systems: Control, Communication, and OptimizationNo ratings yet

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Photovoltaic Solar Energy: From Fundamentals to ApplicationsFrom EverandPhotovoltaic Solar Energy: From Fundamentals to ApplicationsNo ratings yet

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)