Professional Documents

Culture Documents

The Ultimate Moisture & Water Guide: Proven Methods & Procedures

Uploaded by

Long ManOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Ultimate Moisture & Water Guide: Proven Methods & Procedures

Uploaded by

Long ManCopyright:

Available Formats

Food Analysis

Determination of

Moisture and Water

Content in Food

Moisture Analyzer

Karl Fischer Titration

Analytical Balances

The Ultimate Moisture & Water Guide

Proven Methods & Procedures

Moisture and water content are among the most important parameters measured in food.

The content of moisture is inversely related to the dry matter of a food item – hence there

are direct economic effects on consumers and processors. More importantly, the moisture

content in food also influences its stability and quality. Needless to say that moisture is a

topic of many regulations and legislation.

The following guide will:

• Give an introduction to the topic

• Present the different methods of moisture and water content determination

• Provide for selected applications and results

• Give tips and tricks for easier water content and moisture determination

Content

1. Determining Moisture and Water Content in the Food Industry 3

1.1 Water Binds in Different Ways 3

1.2 Technologies for Moisture Analysis 3

2. Thermogravimetric Methods for Moisture Analysis 4

2.1 The Measurement Principle 4

2.2 Thermogravimetric Methods with Drying Ovens 5

2.3 Moisture Analysis with a Moisture Analyzer 7

3. Determining Water Content Using the Karl Fischer Method 8

3.1 The Measurement Principle 8

3.2 Solutions for More Reliability and User Comfort 9

4. Conclusion 10

Overview of Advantages/Disadvantages of Presented Methods 11

METTLER TOLEDO Moisture Guide 2

1. Determining Moisture and Water Content in the Food Industry

Moisture analysis, or water content determination, play an important role in all areas of the food industry, from

incoming/outgoing goods inspections, production and storage, to the development of new versions of products.

The industry is under high pressure to keep prices low while at the same time producing enormous volumes,

and for this reason moisture analysis must be very fast, precise, and reliable. Furthermore, there are an increas-

ing number of regulations which must be observed. Results and measurement procedures must therefore be

reliably documented.

Technically there are several moisture analysis procedures available. Which option is right depends on very dif-

ferent factors. The main features, advantages, and risks of these procedures are presented in the following.

1.1 Water Binds in Different Ways

Almost every natural substance contains water. In the simplest case, water is adsorbed from the air humidity on

the surface of particles. It can also be stored deep in the pore systems of solid substances, or exist as chemi-

cally bound water. Almost all forms exist in foods and ingredients. In addition to well defined products such as

all-purpose sugar or alcoholic drinks, there are also complex cellular structures such as dried fruits or meats,

in which water is bound both by sorption on the surface and by capillarity between particles. Water also exists

deep in cells where it is very difficult to measure. For this reason, analysis and sample preparation methods

must be selected based on the properties of the product being examined.

1.2 Technologies for Moisture Analysis

There are four types of methods for analyzing moisture:

– thermogravimetric analysis

(oven drying, halogen/IR drying, microwave drying, etc.)

– chemical analysis

(Karl Fischer titration, calcium carbide testing)

– spectroscopic analysis

(IR spectroscopy, microwave spectroscopy, H-NMR spectroscopy)

– other types of analysis

(gas chromatography, density determination, refractometry, etc.)

A range of factors must be weighed up when selecting a method of analysis: the available sample volume, the

number of samples, the measurement speed, the feasibility of automation, the accuracy, or even the physical

chemical properties of the sample – all play a large role in the decision-making process.

HX204 Moisture Analyzer XPE205 Analytical Balance V30S Karl Fischer Titrator

Automatic moisture determination Moisture determination Water content determination

with Halogen Moisture Analyzer by loss on drying method with Karl Fischer titration

Fig. 1: Moisture analysis made easy with powerful and reliable measuring instruments.

METTLER TOLEDO Moisture Guide 3

Temperature-sensitive or liquid samples and substances, which include many foods, must be analyzed care-

fully with thermogravimetric methods. As with most vitamins, enzymes, or flavoring agents, thermogravimetric

methods are not feasible.

Insoluble solids with chemically combined water or distinct pore systems, however, can be titrated with the Karl

Fischer method if the water is made accessible e.g. using a homogenizer or an oven to evaporate the sample’s

water.

METTLER TOLEDO provides a variety of solutions for moisture analysis. Two thermogravimetric methods and the

Karl Fischer titration method are described here in detail.

2. Thermogravimetric Methods for Moisture Analysis

All moisture analysis methods that follow the principle of differential weighing can be called thermogravimetric

methods. Thermogravimetric analysis is historically the classical method of analysis. It is used as a reference

method and is defined in many regulations governing the food industry. The principle is simple, but in practice

there are several potential sources of error to be noted.

The central element in all thermogravimetric methods is the balance.

2.1 The Measurement Principle: A sample is weighed and then heated so that the moisture content is released.

Once the sample is cooled in the desiccator, it is weighed again. The difference between the initial weighing and

the second weighing is used to calculate the moisture content. In this procedure, the heating temperature and

heating duration are important considerations. Reproducible and traceable results can only be obtained under

identical conditions.

For this reason, results obtained through alternative methods, such as using a moisture analyzer, must be refer-

enced against this drying over method.

Advantages: This method produces very precise results. It is simple and cost effective. The use of intelligent in-

struments reduces the risk of error significantly and can be automated to a great extent. This allows for a greater

sample throughput to be achieved.

Disadvantages: Many substances decompose to some extent when heated, leading to a loss in weight. Further-

more, heating causes calcination of all substances that evaporate or form volatile azeotropes below 100 °C. This

includes many alcohols, flavoring agents, or acetic acid. Another consideration is that parts of the sample may

evaporate along with the water. Handling is very laborious. There is a risk of mixing up the samples, and simple

errors in calculation or the transfer of the weighing results are virtually impossible to prevent with large sample

volumes and manual documentation.

Fig. 2: Typical sources of error during

manual processing: mixing up samples,

miscalculation, and mistakes when

transferring data.

METTLER TOLEDO Moisture Guide 4

2.2 Thermogravimetric Methods with Drying Ovens

The two important advantages of drying ovens in moisture analysis are the

sample throughput and the flexibility when it comes to sample volumes/

sizes. On the other hand, the time it takes to obtain a result must be taken

into consideration, because extended heating periods and cooling phases

must be observed.

Fig. 3: The XPE205 analytical balance from METTLER TOLEDO offers high

performance, ease of use, and minimal risk of error thanks to its clever design.

Clever Solutions Reduce the Risk of Error

Many of the mentioned risks can be eliminated with balances from METTLER TOLEDO's Excellence Line. In the

XPE models, the differential weighing method is integrated in the user software of the balances.

The method can be started from the touch screen and the software guides the user through the entire process

from taring and initial weighing to the final weighing procedure. All measurement data are automatically saved

and can be accessed for years after. A connected label printer can automatically print out heat-resistant labels

with barcodes for identifying each sample. After heat treatment in the drying oven (generally three hours at

105 °C) and then cooling in the desiccator, the sample is uniquely identified via the barcode, the second weigh-

ing result is assigned to this code, and all calculations are carried out automatically by the software. The bal-

ance displays the result. Complete documentation with all measurement results can be printed by a connected

printer. These technical solutions provided by the Excellence balances from METTLER TOLEDO significantly re-

duce the risk of error, particular with large sample volumes and high throughputs. In additional to being easy to

use, the balances also offer several clever solutions that provide more user comfort and measuring reliability in

and around the weighing chamber.

1 2 3 4 5

One Click® Weight Dry Result Calculation Docunebtatuib

Fig. 4: The display shows the entire process step by step: OneClick start, unique sample identification via barcodes, initial weighing,

drying, second weighing, automatic calculation and logging of measurement results, and complete documentation

Ideas for Better User Comfort

The large weighing chambers of the XPE analytical balances allow for easy weighing and provide plenty of

space even for large weighing containers. A particular advantage in terms of comfort and handling are the

hands-free doors on the Excellence XPE analytical balances, which open automatically. The doors are controlled

by the SmartSense infrared sensors on both sides of the terminal, which react as soon as an object or the hand

of the operator approaches them.

METTLER TOLEDO Moisture Guide 5

The SmartGrid® grid weighing pan is another special feature of these balances. It prevents incorrect results due

to the weighed goods falling next to the tare container and also reduces the influence of drafts in the weighing

chamber. The stabilization time, during which the measurement data fluctuates before reaching a stable value, is

therefore much faster than with conventional balances. Measurement results can be obtained more quickly as a

result. SmartGrid makes the weighing chamber extremely easy to clean.

In addition to the SmartGrid grid weighing pan, METTLER TOLEDO also offers

a number of holders, ErgoClips, which are especially made to fit any tare

container imaginable, in order to ensure its secure hold and work-friendly

position.

Fig. 5: No measurement errors caused by spills, fast measurement stabilization, and easy to

clean: SmartGrid® from METTLER TOLEDO.

Ideas for Ensuring Accurate Results with GWP Recommendation and Verification

The free GWP Recommendation service helps you to select the right weighing device by matching its metrologi-

cal performance to your exact measurement needs. Each GWP Recommendation report includes minimum

weight and safety factor calculations to confirm that you have selected the right device for your process.

www.mt.com/gwp-recommendation

The GWP Verification service calibrates your weighing equipment, assesses risks, recommends measures to

improve accuracy and ensures compliance with process and regulatory requirements. GWP Verification can be

issued for any weighing device independent of model or manufacturer. It provides all necessary information to

maintain lifelong accuracy of your balances and scales; an audit-proof documentation included.

www.mt.com/gwp-verification

Compliance, Networking, and Central Control with LabX

LabX is another step that contributes to more reliability, traceability, compliance with regulations, and increased

user comfort. This software module links all balances into one network. A PC does not need to be connected to

the balance itself. Access to the database via an Ethernet interface, for example, would suffice.

Fig. 6: LabX links the METTLER TOLEDO

instruments in your lab and allows central

control and monitoring.

METTLER TOLEDO Moisture Guide 6

Quality supervisors or lab managers can freely define their own methods, user authorizations, read/write rights,

and a number of other security parameters and then apply to either certain balances or all connected devices.

The "Loss on Drying" method is integrated in LabX as standard and can be started on the balance by One Click®.

The user is guided through the process step by step. All entries are shown on the balance display and the

measurement results are automatically and digitally calculated. The laborious and error-prone entry of weighing

results and the subsequent manual calculation of the moisture content are now a thing of the past.

This multifaceted combination of solutions, additional functions, and auxiliary measures significantly reduces

the risk of error in the "Loss on Drying" method. The risk of incorrect weighing results is virtually eliminated with

these tools. User comfort is increased at the same time. Without these numerous safety functions, the "Loss on

Drying" method is not sustainable in the long term without errors occurring. In particular, without these clever

solutions, the often large number of samples increases the risk of mixing up samples or writing down the wrong

measurement results.

2.3 Moisture Analysis with a Moisture Analyzer

A moisture analyzer produces moisture content results much more quickly. The measurement principle is the

same as the thermogravimetric method.with the only difference being the type of heat source. The sample is

heated by absorption of infrared radiation. METTLER TOLEDO moisture analyzers use fast and durable halogen

lamps to heat the samples.

Advantages: The most important advantage is the significantly reduced measurement time, thanks to the

efficient heat source. Results can be obtained within 2–10 minutes. The samples are heated quickly and evenly,

and measurements provide very good reproducibility with very easy handling. Large sample volumes can be

measured, which is an important factor with inhomogeneous samples. Because of the automated procedure the

risk of error is overall reduced.

Disadvantages: All gravimetric methods, even the moisture analyzer, carry the risk of substances decomposing

to some extent or other volatile components besides water evaporating. Samples can only be measured one at a

time.

Halogen Technology

Halogen technology is the key to moisture analyzers. Halogen technology makes it possible to heat the samples

more quickly and precisely. All moisture analyzers from METTLER TOLEDO are fitted with this innovative heating

technology.

Fig. 7: It doesn't get better than this: fast moisture

analysis with the HX204 from METTLER TOLEDO

with 0.001% readability.

METTLER TOLEDO Moisture Guide 7

Transfer and calculation errors are virtually eliminated thanks to minimal user intervention and automatic logging

within the devices. Customized methods are started with One Click® and the user is guided through the process

by the display. Similarly to the balances, METTLER TOLEDO moisture analyzers also allow users to set individual

user rights to ensure that quality criteria are met. The calculated results can be printed out or transferred to PC

via USB.

Large Library of Validated Measurement Methods

The drying oven method is typically the reference method. It is recommended to compare the results of the

moisture analyzer to this reference due to the strong dependence of the results on the temperature and heating

duration. METTLER TOLEDO has an intensive library of validated moisture methods for more than 100 samples

giving users a great start for their specific samples (www.mt.com/moisture-methods). If a user is examining

substances which are not included in this library, comparable components can be selected and then the method

just needs to be adapted. This approach ensures compliant results and saves valuable time of method develop-

ment.

Use for Process Control

The instruments are easy to clean, and the easy handling reduces the risk of error. Thanks to their automatic

documentation of results, the moisture analyzers are perfect for use in at-line process control, for high sample

throughputs, or in regulated areas.

In contrast to the "Loss in Drying" method, however, measurements can

only be performed one at a time rather a large number simultaneously.

Results can be obtained within 2 – 10 minutes instead of several hours.

The large sample pans also allow for larger samples to be measured. This

is an advantage when the sample material is inhomogeneous, as is com-

mon with foods.

Fig. 8: Large sample pans and easy cleaning make the halogen moisture analyzers perfect

for quick measurement tasks

3. Determining Water Content Using the Karl Fischer Method

In contrast to thermogravimetric analysis, Karl Fischer titration is a specific method that only determines water

content. Bound and adsorbed water and water deep inside a solid substance can be analyzed. The water con-

tent can be determined within a range of just a few ppm to 100%. The measurement results are extremely pre-

cise and very reproducible.

3.1 The Measurement Principle

The chemical principle of the method is based on the oxidation of sulfur dioxide by iodine in an alcoholic solu-

tion in the presence of a base (derived from the Bunsen reaction) according to the general formula:

2 H2O + SO2 + I2 + CH3OH + 3 Base → BaseHSO4CH3 + 2 BaseHI

Karl Fischer used pyridine as his base, which posed high health and ecological risks and produced a slower

reaction than the reagents used today. Methanol was used as a solvent and also presented a health risk.

METTLER TOLEDO Moisture Guide 8

Modern Karl Fischer reactions use imidazole as a base, for example, and ethanol as a solvent. These chemicals

significantly reduce the poisonous properties of the reagents. Imidazole or other amines increase the speed of

the reaction.

Various studies have shown that the reaction occurs as follows:

H2O + SO2 + I2 + ROH + 3 Base → BaseHSO4R + 2 BaseHI

Karl Fischer titration can be volumetric or coulometric. Both methods are different only in the way the iodine

is introduced to the reaction. While volumetric titration is performed with a burette, coulometric titration is per-

formed with a generator electrode. As soon as the iodine stays a solution, the end point is reached. Coulometric

titration is mainly suitable to determine very low water content. In the food industry, however, the majority of

substances have a high water content; therefore usually volumetric titration is performed. Auxiliary solvents can

easily be used to dissolve fat, oils, or sugar, for example.

Advantages: The Karl Fischer method is very accurate, selective for water, and a recognized reference method.

It is suitable for trace analysis as well as very high water content. The method can be extensively automated

through suitable sample changers and thus allows for very high sample throughputs. Furthermore, Karl Fischer

titration can virtually be used for any water content determination task.

Disadvantages: As a chemical process, Karl Fischer titration requires a certain amount of chemical knowledge

in order to handle the chemicals properly, organize the space for the safe storage of the reagents, and properly

dispose of used reagents.

The titer of the Karl Fischer solution must be regularly checked. This task is greatly simplified by modern titrators.

The methods usually have to be adapted to the sample matrix in order for the water to be accessible for titration.

Due to the sensitivity particularly of coulometric titration, the risk of error caused by external water sources such

as from the air, solution, container, or carrier gas increases.

3.2 Solutions for More Reliability and User Comfort

METTLER TOLEDO offers suitable instruments for both Karl Fischer methods, which provide efficiency, user com-

fort, and measurement reliability. The optimal solution can be found in a range of titrators. Accessory systems

and sample changers make it possible to accelerate the water content determination process significantly and

automate extensively.

Large, easy-to-read color touch screens guide the user safely through all steps of the analysis. Customized

home screens with set shortcuts are available in order to simplify use and ensure that only reliable methods can

be used. Additional functions, such as titer or blank determination, can be triggered via One Click®.

The titrators automatically detect which titrant is being used as soon as the

burette is inserted. An RFID chip enables communication and stores the

concentration and shelf-life information. This technology protects against

using expired or incorrect titrants.

Fig. 9: Burettes with RFID technology. The burettes and titrants are automatically detected. In

other words, accidentally using expired or incorrect titrants is now a thing of the past

METTLER TOLEDO Moisture Guide 9

Homogenizer: A high-speed agitator breaks up solid samples that are insol-

uble in Karl Fischer reagents. The water contained in the sample is released

for measurement. The homogenizer is controlled via TTL IO interface by the

titrator.

Fig. 10: The volumetric Karl Fischer titrator with homogenizer is the perfect combination for

solid and pasty samples.

Oven sample changers: The Stromboli oven sample changer makes it possible for up to 14 solid or pasty sam-

ples to be titrated, for example, without supervision. A gas flow transports the water extracted from the sample

by the increased oven temperature directly to the titrator. As with drying methods, however, this method also

risks the sample material to be decomposed and thus producing additional water.

Solvent Manager: The Solvent Manager is a practical and helpful accessory controlled by the titrator. Used re-

agents are removed from the titration cell and fresh reagents are supplied, all fully automatically. The process

starts via One Click®. This prevents contact between lab personnel and the chemicals.

LabX PC Software: LabX can be used to operate and monitor all connected titrators from a central point. All

measurement values are automatically saved and can be accessed in the long term via sample identification.

This meets the requirements of important regulations such as 21 CFR Part 11. This chapter of the Code of Federal

Regulations in the USA covers topics such as electronic records, their archiving, electronic signatures, and trace-

ability.

4. Conclusion

Water/moisture content is a universal factor. It indicates the quality, storage shelf life, and processability of a

raw material, intermediate, or end product. For example, substances which are too dry in production may cause

problems with static discharge or affect the consistency of the end product. If substances are too moist, they

may agglomerate or get stuck inside the pipes. They may have a reduced shelf life.

Moisture/water content is also an important quality criterion influencing taste and consistency.

International and national standards define the permitted thresholds for moisture/water content for products sold

commercially. Regulators such as the BRC (British Retail Consortium), IFS (International Featured Standards), or

GFSI (Global Food Safety Initiative) are having an increasing impact on the production, processing, and sale of

foods. This increases the work involved in quality assurance and demands more and more modern and efficient

solutions. Analysis methods must be clearly described and tested. The method, its parameters, and the permit-

ted measurement tolerance are defined.

Many food producers themselves have strict criteria for measurement accuracy, reliability, and traceability in or-

der to ensure the quality of their products. These SOPs (Standard Operating Procedures) describe the entire mea-

surement process, including sample volume, number of required measurements, maximum tolerable deviation,

and procedures when errors are discovered.

METTLER TOLEDO's solutions support customers in the food production and processing industry, in food retail,

and in the control and testing of food products.

METTLER TOLEDO Moisture Guide 10

Clever ideas and solutions ensure high efficiency, user comfort, and measurement reliability. Each of the pre-

sented methods has its own advantages and disadvantages. Moisture analyzers and Karl Fischer titrators are

unbeaten when it comes to measurement duration. The drying oven method is better with large sample quanti-

ties and volumes. Karl Fischer titrators offer selectivity for water from low to high water content levels, and make

it possible to automate the water content determination process.

All users can find the right solution for their individual requirements in METTLER TOLEDO's range of sophisticated

instruments.

Overview of Advantages/Disadvantages of Presented Methods

Drying Ovens Moisture Analyzers Karl Fischer

Advantages • large number of samples • fast measurement • fast measurement

at same time, thus higher (approx. 2– 10 min.) (approx. 2 – 5 min.)

throughput possible • large sample volumes • very accurate

• large sample volumes possible (also suitable for trace

possible • easy handling analysis)

• high accuracy • reduced risk of error • selective for water

• high throughput possible

with automation

• universal

Disadvantages • measurements only avail- • sample material may • methods depend on

able after several hours decompose or evaporate sample matrix

• sample material may • no automation possible • risk of error caused by

decompose • only one measurement can incorrectly entered water

• other liquid components be performed at a time (ambient air, solvent)

such as alcohol, flavors, • other volatile components • use and storage of

or acetic acid evaporate such as alcohol, flavors, chemical reagents

• laborious procedure with or acetic acid evaporate

several working steps

• very high risk of error

(particularly during man-

ual data entry and calcu-

lation)

• high risk of error when

using hygroscopic sample

material

METTLER TOLEDO Moisture Guide 11

Good Measuring Practices

Five Steps to Improved Measuring Results

Good Measuring Practices by METTLER TOLEDO is a global program sup-

porting you in laboratory and production environments with quality assur-

ance measures for balances, scales, pipettes and analytical instruments.

The five steps of all Good Measuring Practices guidelines start with an

evaluation of the measuring needs of your processes and their associated

risks. We also take into account regulatory requirements and norms

relevant to your industry.

With this information, Good Measuring Practices provide straight forward

recommendations for selecting, installing, calibrating and operating of

weighing and measuring instruments.

www.mt.com/gwp for weighing

www.mt.com/gtp for titration

www.mt.com/gpp for pipetting

www.mt.com/gdrp for density and refractometry

5

Routine 1

Operation Evaluation

Good

Measuring

4

Calibration / Practices 2

Qualification Selection

3

Installation /

Training

www.mt.com

For more information

Mettler-Toledo Group

Laboratory Division

www.mt.com/contacts

Subject to technical changes

©05/2017 Mettler Toledo. All rights reserved.

Global MarCom Switzerland

You might also like

- Lab Report Food Analaysis-MoistureDocument11 pagesLab Report Food Analaysis-MoistureSHAFIKANOR366193% (15)

- Astm D 6980Document5 pagesAstm D 6980Samuel Gaytan Ramirez100% (5)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Powders and Bulk Solids Behavior Characterization PDFDocument517 pagesPowders and Bulk Solids Behavior Characterization PDFLong Man100% (1)

- BSW Laboratory and Field TestDocument4 pagesBSW Laboratory and Field TestRonald Figo Torres EcheNo ratings yet

- Accurate BS&W Testing Important For Crude-Oil Custody TransferDocument9 pagesAccurate BS&W Testing Important For Crude-Oil Custody Transferأصلان أصلان100% (1)

- Drying and Storage EngineeringDocument98 pagesDrying and Storage EngineeringReyansh MauryaNo ratings yet

- Lecture 4 - FP2104Document47 pagesLecture 4 - FP2104Henriettah NakisoziNo ratings yet

- OILM R59 Moisture Meter of CerealDocument40 pagesOILM R59 Moisture Meter of Cerealharry mahfuzanNo ratings yet

- 2008 11 25 Methods Method Biological 1684-BioDocument16 pages2008 11 25 Methods Method Biological 1684-Bioகுமார் எஸ்No ratings yet

- FAQDocument30 pagesFAQPhong LeNo ratings yet

- MT - Drying Oven Vs Halogen Moisture AnalyzerDocument16 pagesMT - Drying Oven Vs Halogen Moisture AnalyzerJLNo ratings yet

- Horno Vs Analizador de HumedadDocument4 pagesHorno Vs Analizador de HumedadGabrielsalas08No ratings yet

- Moisture MethodsDocument35 pagesMoisture Methodsswatkate3792No ratings yet

- Methods of Determining Moisture ContentDocument4 pagesMethods of Determining Moisture ContentwycliffkamajowaNo ratings yet

- Moisture Methods: Food IndustryDocument28 pagesMoisture Methods: Food IndustryBenjamin EstrelladoNo ratings yet

- Qno1 What Is Moisture Content Analysis?Document6 pagesQno1 What Is Moisture Content Analysis?Engr MahwishNo ratings yet

- Moisture DeterminationDocument5 pagesMoisture Determinationblehhh080No ratings yet

- Lab Manual 4Document7 pagesLab Manual 4zexoditeNo ratings yet

- Laboratory Activity No. 1Document4 pagesLaboratory Activity No. 1Christopher Andrei Salonga LimNo ratings yet

- Assignment 2 SBI3013 - Data LoggerDocument10 pagesAssignment 2 SBI3013 - Data Loggerojie folorennahNo ratings yet

- Moisture Content Determination of Pharmaceutical Pellets by Near Infrared Spectroscopy: Method Development and ValidationDocument7 pagesMoisture Content Determination of Pharmaceutical Pellets by Near Infrared Spectroscopy: Method Development and ValidationMariana Vazquez CerritosNo ratings yet

- 02 Proximate Moisture Ash Analysis NDYDocument27 pages02 Proximate Moisture Ash Analysis NDYFahmilia PutriNo ratings yet

- Assets AMA Conferences AMA Conferences 2013 Proceedings 2013 SENSOR 2013 A5.4 SENSOR2013Document5 pagesAssets AMA Conferences AMA Conferences 2013 Proceedings 2013 SENSOR 2013 A5.4 SENSOR2013surendra061024No ratings yet

- Moisture Guide enDocument48 pagesMoisture Guide enJanet TudorNo ratings yet

- 108590202A GU Essential Laboratory Skills A4 en LRDocument52 pages108590202A GU Essential Laboratory Skills A4 en LRJesuloluwa OmotadeNo ratings yet

- 12768Document4 pages12768gokcegursoyNo ratings yet

- Hydration Properties of Dietary Fibre and Resistant Starch: A European Collaborative StudyDocument8 pagesHydration Properties of Dietary Fibre and Resistant Starch: A European Collaborative StudyFatty Bambi ShirotanNo ratings yet

- Moisture MeasurementDocument15 pagesMoisture Measurementparitosh kushwahaNo ratings yet

- Quality ControlDocument8 pagesQuality Controlkiki loNo ratings yet

- Laboratory Activities QC2Document14 pagesLaboratory Activities QC2ampay ayubNo ratings yet

- Sensors: Use of Temperature and Humidity Sensors To Determine Moisture Content of Oolong TeaDocument17 pagesSensors: Use of Temperature and Humidity Sensors To Determine Moisture Content of Oolong TeaJanuel BorelaNo ratings yet

- Technological University of The Philippines College of EngineeringDocument10 pagesTechnological University of The Philippines College of EngineeringNakanakanaknakNo ratings yet

- Laporan Final Shelf LifeDocument22 pagesLaporan Final Shelf LifeCarolineGunawan100% (1)

- Moisture ContentDocument8 pagesMoisture ContentHafrizDaniel0% (1)

- The Ultimate Formulation Guide: Proven Methods & ProceduresDocument12 pagesThe Ultimate Formulation Guide: Proven Methods & ProceduresdheaNo ratings yet

- Cfb40503 Lab ManualDocument21 pagesCfb40503 Lab ManualAziemah AulanNo ratings yet

- Nutrition Labelling and Proximate AnalysisDocument79 pagesNutrition Labelling and Proximate AnalysisVeni DarmaNo ratings yet

- AquaFit4Use - Methodology Water Quality ControlDocument33 pagesAquaFit4Use - Methodology Water Quality ControlIbou DiopNo ratings yet

- Water in Foods PrelabDocument6 pagesWater in Foods PrelabNour IssaNo ratings yet

- Lab. 2-Moisture and Determination (Gravimetric Method)Document5 pagesLab. 2-Moisture and Determination (Gravimetric Method)Ralph Aubrey CulhiNo ratings yet

- Effect of Preservation Technologies On Microbial Inactivation in FoodsDocument4 pagesEffect of Preservation Technologies On Microbial Inactivation in FoodsTrysh IoanaNo ratings yet

- LWT - Food Science and Technology: Zhenfeng Li, G.S. Vijaya Raghavan, Ning WangDocument7 pagesLWT - Food Science and Technology: Zhenfeng Li, G.S. Vijaya Raghavan, Ning WangIkhsan ZellNo ratings yet

- Use of Salt Solutions For Assuring Constant Relative Humidity Conditions in Contained EnvironmentsDocument33 pagesUse of Salt Solutions For Assuring Constant Relative Humidity Conditions in Contained EnvironmentsFamiloni LayoNo ratings yet

- User Com 1Document12 pagesUser Com 1Clint FosterNo ratings yet

- Standard Test Method For Total Evaporable Moisture Content of Aggregate by DryingDocument4 pagesStandard Test Method For Total Evaporable Moisture Content of Aggregate by DryingKaren OrtizNo ratings yet

- Calibration Guideline For The Infusion Pump AnalyzerDocument5 pagesCalibration Guideline For The Infusion Pump AnalyzerNop CalplusNo ratings yet

- Mri PDFDocument9 pagesMri PDFMuh. rikzaningrat TaslimNo ratings yet

- Standard Method For BiomassDocument186 pagesStandard Method For Biomassqiwe0001No ratings yet

- Arlene G. Estacio, Vilma C. Pagtalunan, Rio S. Pagtalunan, Ira C. Valenzuela, Lean Karlo S. Tolentino, and Jennifer C. Dela CruzDocument5 pagesArlene G. Estacio, Vilma C. Pagtalunan, Rio S. Pagtalunan, Ira C. Valenzuela, Lean Karlo S. Tolentino, and Jennifer C. Dela CruzGlobal QualityNo ratings yet

- Plagiarism Scan Report: Exclude Url: NoneDocument2 pagesPlagiarism Scan Report: Exclude Url: NoneMr-Mk MughalNo ratings yet

- HonDocument4 pagesHonbassamNo ratings yet

- Fe School CodesDocument58 pagesFe School Codesvzimak2355No ratings yet

- A Simple Method For The Calibration of An Open Surface Water BathDocument6 pagesA Simple Method For The Calibration of An Open Surface Water BathNdra PompomorinNo ratings yet

- 2011 WGMH New Orleans Moisture Determination Draft RecommendationDocument11 pages2011 WGMH New Orleans Moisture Determination Draft RecommendationKristiene Balatbat SadiwaNo ratings yet

- Humidity Sensor SelectionDocument10 pagesHumidity Sensor Selectionmythri100% (1)

- Determination of Effective Moisture Diffusivity of Banana Using Thermogravimetric AnalysisDocument6 pagesDetermination of Effective Moisture Diffusivity of Banana Using Thermogravimetric AnalysisMonowarul IslamNo ratings yet

- Lab Report 1Document8 pagesLab Report 1nikhil reddyNo ratings yet

- Gravimetric Determination of Moisture in Fertilizer Samples Chem 28Document2 pagesGravimetric Determination of Moisture in Fertilizer Samples Chem 28Frances Abegail QuezonNo ratings yet

- Cleaning and disinfection of food factories: a practical guideFrom EverandCleaning and disinfection of food factories: a practical guideNo ratings yet

- LABORATORY MANUAL FOR A MINI PROJECT: MSCB 1113 BIOCHEMISTRY & MICROBIAL PHYSIOLOGYFrom EverandLABORATORY MANUAL FOR A MINI PROJECT: MSCB 1113 BIOCHEMISTRY & MICROBIAL PHYSIOLOGYNo ratings yet

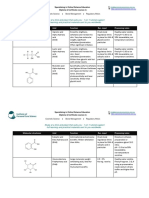

- Molecular Structures Acid Function Rec. Input Processing NotesDocument5 pagesMolecular Structures Acid Function Rec. Input Processing NotesLong ManNo ratings yet

- Vision Life TechnologiesDocument28 pagesVision Life TechnologiesLong ManNo ratings yet

- BNB G19Document4 pagesBNB G19Long ManNo ratings yet

- Dầu cám gạo lot 2319SVA2021Document1 pageDầu cám gạo lot 2319SVA2021Long ManNo ratings yet

- Bio-Oil Product InformationDocument9 pagesBio-Oil Product InformationLong ManNo ratings yet

- Celluloses: 2010 Elsevier Ltd. All Rights ReservedDocument47 pagesCelluloses: 2010 Elsevier Ltd. All Rights ReservedLong ManNo ratings yet

- 9P CX4 Dept PDFDocument2 pages9P CX4 Dept PDFLong ManNo ratings yet

- P CoumaricDocument15 pagesP CoumaricLong ManNo ratings yet

- BioGenic Sallic 210Document2 pagesBioGenic Sallic 210Long Man100% (1)

- O CoumaricDocument24 pagesO CoumaricLong ManNo ratings yet

- Tác D NG C A P-Coumaric AcidDocument8 pagesTác D NG C A P-Coumaric AcidLong ManNo ratings yet

- 79 How To Buy HPLC Technology 2020Document18 pages79 How To Buy HPLC Technology 2020Long ManNo ratings yet

- 07 Solutions For Taste-Masking and PalatabilityDocument49 pages07 Solutions For Taste-Masking and PalatabilityLong ManNo ratings yet

- Metabolism of Rosmarinic Acid in Rats: Frutescens Britton Var. Acuta Kudo (Labiatae), Has BeenDocument4 pagesMetabolism of Rosmarinic Acid in Rats: Frutescens Britton Var. Acuta Kudo (Labiatae), Has BeenLong ManNo ratings yet

- HPTLC Asia 2018 - Abstract Book - FinalDocument102 pagesHPTLC Asia 2018 - Abstract Book - FinalLong ManNo ratings yet

- phát hiện vết trong Cối xay PDFDocument12 pagesphát hiện vết trong Cối xay PDFLong ManNo ratings yet

- Thakor 2016Document12 pagesThakor 2016Long ManNo ratings yet

- Ali 2009Document5 pagesAli 2009Long ManNo ratings yet

- Kuo 2008Document6 pagesKuo 2008Long ManNo ratings yet

- 10 5530pj 2015 6 2Document3 pages10 5530pj 2015 6 2BharathiNo ratings yet

- HPLC Columns 186-234Document49 pagesHPLC Columns 186-234Long ManNo ratings yet

- Columnas CromatograficasDocument2 pagesColumnas CromatograficasDANIBATANo ratings yet

- Application Note: Ultrapure Water For HPLC AnalysisDocument5 pagesApplication Note: Ultrapure Water For HPLC AnalysisLong ManNo ratings yet

- Phytochemical Analysis of Leaves Extract of Abutilon Chromatography-Mass Spectrometry (GC-MS)Document10 pagesPhytochemical Analysis of Leaves Extract of Abutilon Chromatography-Mass Spectrometry (GC-MS)Long ManNo ratings yet

- Review Article: Atibala: An OverviewDocument9 pagesReview Article: Atibala: An OverviewLong ManNo ratings yet

- Sampling For Chemical Analysis (Analytical Chemistry)Document9 pagesSampling For Chemical Analysis (Analytical Chemistry)Long ManNo ratings yet

- The Ultimate Moisture & Water Guide: Proven Methods & ProceduresDocument12 pagesThe Ultimate Moisture & Water Guide: Proven Methods & ProceduresLong ManNo ratings yet

- Methods of Sampling & Analysis PDFDocument8 pagesMethods of Sampling & Analysis PDFAnonymous BcT42WLnNo ratings yet

- Pipetting Handbook enDocument40 pagesPipetting Handbook enbluedolphin7No ratings yet

- Is 2362 1993Document14 pagesIs 2362 1993qcNo ratings yet

- Karl Fischer - NewDocument4 pagesKarl Fischer - Newfadlysuriansyah100% (1)

- ASTM D 4377 - 00 (Reapproved 2006) PDFDocument7 pagesASTM D 4377 - 00 (Reapproved 2006) PDFJulian Felipe Noguera CruzNo ratings yet

- Karl Fischer Over Titration and 7 Things You Should Know About It PDFDocument4 pagesKarl Fischer Over Titration and 7 Things You Should Know About It PDFJesús María González MogollónNo ratings yet

- ASTM D4377-00 (Metodo de Prueba Estandar para Agua en Aceites Crudos Por Valoracion Potenciometrica Karl Fischer)Document7 pagesASTM D4377-00 (Metodo de Prueba Estandar para Agua en Aceites Crudos Por Valoracion Potenciometrica Karl Fischer)Anonymous gBMz178No ratings yet

- Moisture Methods Plastic EN PDFDocument24 pagesMoisture Methods Plastic EN PDFAttef BedaweNo ratings yet

- KarFisher ASTM D4928Document5 pagesKarFisher ASTM D4928nguyennha1211100% (3)

- D4928-12R18 Karl FisherDocument6 pagesD4928-12R18 Karl FisherAngel MurilloNo ratings yet

- D 2627 - 97 - Rdi2mjctukveDocument3 pagesD 2627 - 97 - Rdi2mjctukveRaphael CordovaNo ratings yet

- Instrument CalibrationDocument16 pagesInstrument Calibrationditi17p50% (2)

- Acetazolamide PPT@Document39 pagesAcetazolamide PPT@SREEDHAR ATTLANo ratings yet

- Jis 2275 1989 PDFDocument35 pagesJis 2275 1989 PDFsud1313100% (1)

- Karl Fischer (Water Determination)Document4 pagesKarl Fischer (Water Determination)Alfonso Dominguez Gonzalez100% (1)

- Quality Assurance in TitrationDocument50 pagesQuality Assurance in TitrationElena Petre100% (1)

- Water in Organic Liquids by Coulometric Karl Fischer TitrationDocument4 pagesWater in Organic Liquids by Coulometric Karl Fischer TitrationROHITNo ratings yet

- ASTM D1123 Contenido Agua en Glicol PDFDocument5 pagesASTM D1123 Contenido Agua en Glicol PDFdianacalixtogNo ratings yet

- Uji Moisture ContentDocument4 pagesUji Moisture ContentSuryadi WibowoNo ratings yet

- Titralab 580 and 585 Titration Workstations: Technical SpecificationsDocument4 pagesTitralab 580 and 585 Titration Workstations: Technical Specificationssr2007No ratings yet

- Water Content Determination in Biodiesel According To EN ISO 12937Document1 pageWater Content Determination in Biodiesel According To EN ISO 12937लक्ष चौधरीNo ratings yet

- Aquamax KF Portable EnglDocument4 pagesAquamax KF Portable EnglTosin FrankNo ratings yet

- Water Oil Products: 1. AbstractDocument5 pagesWater Oil Products: 1. AbstractWidya Okta UtamiNo ratings yet

- MSP 06 002 KFGTPDocument104 pagesMSP 06 002 KFGTPmohammed younesNo ratings yet

- Draft East African Standard: DEAS 909:2018Document8 pagesDraft East African Standard: DEAS 909:2018ahmed ismailNo ratings yet

- Guide ABC of Easy TitrationDocument40 pagesGuide ABC of Easy TitrationHarsha19111999No ratings yet

- Water in Crude Oils by Coulometric Karl Fischer Titration: Standard Test Methods ForDocument7 pagesWater in Crude Oils by Coulometric Karl Fischer Titration: Standard Test Methods FormahmutikizerNo ratings yet

- Appendix IX C. Determination of Water - British PharmacopoeiaDocument4 pagesAppendix IX C. Determination of Water - British PharmacopoeiaFarlane MtisiNo ratings yet

- Karl Ficher 3Document15 pagesKarl Ficher 3Essam Eldin Metwally AhmedNo ratings yet

- Titrasi Karl Fischer: Mustofa AhdaDocument13 pagesTitrasi Karl Fischer: Mustofa AhdaNovia Tri AstutiNo ratings yet