Professional Documents

Culture Documents

Section2 2 PDF

Uploaded by

Gopu ROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section2 2 PDF

Uploaded by

Gopu RCopyright:

Available Formats

Prestressed Concrete Structures Dr. Amlan K Sengupta and Prof.

Devdas Menon

2.2 Losses in Prestress (Part II)

This section covers the following topics

• Friction

• Anchorage Slip

• Force Variation Diagram

2.2.1 Friction

The friction generated at the interface of concrete and steel during the stretching of a

curved tendon in a post-tensioned member, leads to a drop in the prestress along the

member from the stretching end. The loss due to friction does not occur in pre-

tensioned members because there is no concrete during the stretching of the tendons.

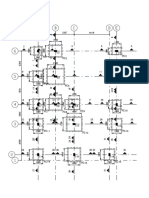

The friction is generated due to the curvature of the tendon and the vertical component

of the prestressing force. The following figure shows a typical profile (laying pattern) of

the tendon in a continuous beam.

Figure 2-2.1 A typical continuous post-tensioned member

(Reference: VSL International Ltd.)

In addition to friction, the stretching has to overcome the wobble of the tendon. The

wobble refers to the change in position of the tendon along the duct. The losses due to

friction and wobble are grouped together under friction.

The formulation of the loss due to friction is similar to the problem of belt friction. The

sketch below (Figure 2-2.2) shows the forces acting on the tendon of infinitesimal length

dx.

Indian Institute of Technology Madras

Prestressed Concrete Structures Dr. Amlan K Sengupta and Prof. Devdas Menon

dα

P dα/2

R

N

P + dP

N P + dP

Force triangle

P

dx

Figure 2-2.2 Force acting in a tendon of infinitesimal length

In the above sketch,

P = prestressing force at a distance x from the stretching end

R = radius of curvature

dα = subtended angle.

The derivation of the expression of P is based on a circular profile. Although a cable

profile is parabolic based on the bending moment diagram, the error induced is

insignificant.

The friction is proportional to the following variables.

• Coefficient of friction (µ) between concrete and steel.

• The resultant of the vertical reaction from the concrete on the tendon (N)

generated due to curvature.

From the equilibrium of forces in the force triangle, N is given as follows.

dα

N = 2Psin

2

dα

» 2P = Pdα (2-2.1)

2

The friction over the length dx is equal to µN = µPdα.

Thus the friction (dP) depends on the following variables.

• Coefficient of friction (µ)

• Curvature of the tendon (dα)

• The amount of prestressing force (P)

Indian Institute of Technology Madras

Prestressed Concrete Structures Dr. Amlan K Sengupta and Prof. Devdas Menon

The wobble in the tendon is effected by the following variables.

• Rigidity of sheathing

• Diameter of sheathing

• Spacing of sheath supports

• Type of tendon

• Type of construction

The friction due to wobble is assumed to be proportional to the following.

• Length of the tendon

• Prestressing force

For a tendon of length dx, the friction due to wobble is expressed as kPdx, where k is

the wobble coefficient or coefficient for wave effect.

Based on the equilibrium of forces in the tendon for the horizontal direction, the

following equation can be written.

P = P + dP + (µPdα + kPdx)

or, dP = – (µPdα + kPdx) (2-2.2)

Thus, the total drop in prestress (dP) over length dx is equal to – (µPdα + kPdx). The

above differential equation can be solved to express P in terms of x.

Px

dP

= - ⎛⎜ µ ∫ dα + k ∫ dx ⎞⎟

α x

∫

P P

0

⎝ 0 0 ⎠

or, lnP P = - ( µα + kx )

Px

0

Px

or, ln = - ( µα + kx )

P0

or, Px = P0e -( µα+kx ) (2-2.3)

Here,

P0 = the prestress at the stretching end after any loss due to elastic shortening.

For small values of µα + kx, the above expression can be simplified by the Taylor series

expansion.

Px = P0 (1– µα – kx) (2-2.4)

Thus, for a tendon with single curvature, the variation of the prestressing force is linear

with the distance from the stretching end. The following figure shows the variation of

Indian Institute of Technology Madras

Prestressed Concrete Structures Dr. Amlan K Sengupta and Prof. Devdas Menon

prestressing force after stretching. The left side is the stretching end and the right side

is the anchored end.

P0 Px

Figure 2-2.3 Variation of prestressing force after stretching

In the absence of test data, IS:1343 - 1980 provides guidelines for the values of µ and k.

Table 2-2.1 Values of coefficient of friction

Type of interface µ

For steel moving on smooth concrete 0.55.

For steel moving on steel fixed to duct 0.30.

For steel moving on lead 0.25.

The value of k varies from 0.0015 to 0.0050 per meter length of the tendon depending

on the type of tendon. The following problem illustrates the calculation of the loss due

to friction in a post-tensioned beam.

Example 2-2.1

A post-tensioned beam 100 mm × 300 mm (b × h) spanning over 10 m is stressed

by successive tensioning and anchoring of 3 cables A, B, and C respectively as

shown in figure. Each cable has cross section area of 200 mm2 and has initial

stress of 1200 MPa. If the cables are tensioned from one end, estimate the

percentage loss in each cable due to friction at the anchored end. Assume µ =

0.35, k = 0.0015 / m.

Indian Institute of Technology Madras

Prestressed Concrete Structures Dr. Amlan K Sengupta and Prof. Devdas Menon

CL

50

50 CGC

Cable A

Cable B

Cable C

Solution

Prestress in each tendon at stretching end = 1200 × 200

= 240 kN.

To know the value of α(L), the equation for a parabolic profile is required.

dy 4ym

= (L - 2 x )

dx L2

ym x

y α(L)

Here,

ym = displacement of the CGS at the centre of the beam from the ends

L = length of the beam

x = distance from the stretching end

y = displacement of the CGS at distance x from the ends.

An expression of α(x) can be derived from the change in slope of the profile. The slope

of the profile is given as follows.

dy 4ym

= (L - 2 x )

dx L2

At x = 0, the slope dy/dx = 4ym/L. The change in slope α(x) is proportional to x.

The expression of α(x) can be written in terms of x as α(x) = θ.x,

where, θ = 8ym/L2. The variation is shown in the following sketch.

Indian Institute of Technology Madras

Prestressed Concrete Structures Dr. Amlan K Sengupta and Prof. Devdas Menon

α

8ym/L

4ym/L

θ

0 L/2 L x

The total subtended angle over the length L is 8ym/L.

The prestressing force Px at a distance x is given by

Px = P0e–(µα + kx) = P0e–ηx

where, ηx = µα + kx

For cable A, ym = 0.1 m.

For cable B, ym = 0.05 m.

For cable C, ym = 0.0 m.

For all the cables, L = 10 m.

Substituting the values of ym and L

⎧0.0043x for cable A

⎪

ηx = ⎨0.0029x for cable B

⎪0.0015x for cable C

⎩

The maximum loss for all the cables is at x = L = 10, the anchored end.

⎧0.958 for cable A

-ηL ⎪

e = ⎨0.971 for cable B

⎪0.985 for cable C

⎩

Percentage loss due to friction = (1 – e–ηL) × 100%

⎧ 4.2% for cable A

⎪

= ⎨ 2.9% for cable B

⎪1.5% for cable C

⎩

Indian Institute of Technology Madras

Prestressed Concrete Structures Dr. Amlan K Sengupta and Prof. Devdas Menon

CL

CGC

Cable A

Cable B

Cable C

240 kN

Variation of prestressing forces

The loss due to friction can be considerable for long tendons in continuous beams with

changes in curvature. The drop in the prestress is higher around the intermediate

supports where the curvature is high. The remedy to reduce the loss is to apply the

stretching force from both ends of the member in stages.

2-2.2 Anchorage Slip

In a post-tensioned member, when the prestress is transferred to the concrete, the

wedges slip through a little distance before they get properly seated in the conical space.

The anchorage block also moves before it settles on the concrete. There is loss of

prestress due to the consequent reduction in the length of the tendon.

The total anchorage slip depends on the type of anchorage system. In absence of

manufacturer’s data, the following typical values for some systems can be used.

Table 2-2.2 Typical values of anchorage slip

Anchorage System Anchorage Slip (∆s)

Freyssinet system

12 - 5mm Φ strands 4 mm

12 - 8mm Φ strands 6 mm

Magnel system 8 mm

Dywidag system 1 mm

(Reference: Rajagopalan, N., Prestressed Concrete)

Indian Institute of Technology Madras

Prestressed Concrete Structures Dr. Amlan K Sengupta and Prof. Devdas Menon

Due to the setting of the anchorage block, as the tendon shortens, there is a reverse

friction. Hence, the effect of anchorage slip is present up to a certain length (Figure 2-

2.4). Beyond this setting length, the effect is absent. This length is denoted as lset.

P0

Px

Figure 2-2.4 Variation of prestressing force after anchorage slip

2.2.3 Force Variation Diagram

The magnitude of the prestressing force varies along the length of a post-tensioned

member due to friction losses and setting of the anchorage block. The diagram

representing the variation of prestressing force is called the force variation diagram.

Considering the effect of friction, the magnitude of the prestressing force at a distance x

from the stretching end is given as follows.

Px = P0e -ηx (2-2.5)

Here, ηx = µα + kx denotes the total effect of friction and wobble. The plot of Px gives

the force variation diagram.

The initial part of the force variation diagram, up to length lset is influenced by the setting

of the anchorage block. Let the drop in the prestressing force at the stretching end be

∆P. The determination of ∆P and lset are necessary to plot the force variation diagram

including the effect of the setting of the anchorage block.

Considering the drop in the prestressing force and the effect of reverse friction, the

magnitude of the prestressing force at a distance x from the stretching end is given as

follows.

Px' = ( P0 - ∆P ) e η'x (2-2.6)

Indian Institute of Technology Madras

Prestressed Concrete Structures Dr. Amlan K Sengupta and Prof. Devdas Menon

Here, η’ for reverse friction is analogous to η for friction and wobble.

At the end of the setting length (x = lset), Px = P’x

Px

P0

∆P

Px after stretching

Px Px’ P’x after setting

Px beyond lset

lset x

Figure 2-2.5 Force variation diagram near the stretching end

Substituting the expressions of Px and Px’ for x = lset

Since it is difficult to measure η’ separately, η’ is taken equal to η. The expression of

∆P simplifies to the following.

P0e -ηlset = ( P0 - ∆P ) e η'lset

P0e - ( η+η' )lset = P0 - ∆P

P0 ⎡⎣1- ( η+ η' ) l set ⎤⎦ = P0 - ∆P

⎛ η' ⎞

∆P = P0 ( η+ η' ) l set = P0 ηl set ⎜ 1+ ⎟ (2-2.7)

⎝ η⎠

∆P = 2P0ηlset (2-2.8)

The following equation relates lset with the anchorage slip ∆s.

1 ∆P

∆s = lset

2 Ap E p

1 lset ⎛ η' ⎞ (2-2.9)

∆s = P0ηlset ⎜ 1+ ⎟

2 Ap E p ⎝ η⎠

Transposing the terms,

2 2 Ap E p

lset = ∆s

⎛ η' ⎞

P0 η ⎜ 1+ ⎟

⎝ η⎠

∆s Ap E p

= for η' = η

P0η

Indian Institute of Technology Madras

Prestressed Concrete Structures Dr. Amlan K Sengupta and Prof. Devdas Menon

Therefore,

∆s Ap E p

lset = (2-2.10)

P0 η

The term P0η represents the loss of prestress per unit length due to friction.

The force variation diagram is used when stretching is done from both the ends. The

tendons are overstressed to counter the drop due to anchorage slip. The stretching from

both the ends can be done simultaneously or in stages. The final force variation is more

uniform than the first stretching.

The following sketch explains the change in the force variation diagram due to

stretching from both the ends in stages.

a) After stretching from right end

b) After anchorage slip at right end

c) After stretching from left end

d) After anchorage slip at left end

Figure 2-2.6 Force variation diagrams for stretching in stages

Indian Institute of Technology Madras

Prestressed Concrete Structures Dr. Amlan K Sengupta and Prof. Devdas Menon

The force variation diagrams for the various stages are explained.

a) The initial tension at the right end is high to compensate for the anchorage

slip. It corresponds to about 0.8 fpk initial prestress. The force variation

diagram (FVD) is linear.

b) After the anchorage slip, the FVD drops near the right end till the length lset.

c) The initial tension at the left end also corresponds to about 0.8 fpk initial prestress.

The FVD is linear up to the centre line of the beam.

d) After the anchorage slip, the FVD drops near the left end till the length lset. It is

observed that after two stages, the variation of the prestressing force over the length

of the beam is less than after the first stage.

Example 2-2.2

A four span continuous bridge girder is post-tensioned with a tendon consisting

of twenty strands with fpk = 1860 MPa. Half of the girder is shown in the figure

below. The symmetrical tendon is simultaneously stressed up to 75% fpk from

both ends and then anchored. The tendon properties are Ap = 2800 mm2, Ep =

195,000 MPa, µ = 0.20, K = 0.0020/m. The anchorage slip ∆s = 6 mm.

Calculate

a) The expected elongation of the tendon after stretching,

b) The force variation diagrams along the tendon before and after anchorage.

CL

0.76 0.6 0.76 0.6

13.7 13.7 3 3.7 15.2 15.2 3.7

All dimensions are in metres

Inflection points

Indian Institute of Technology Madras

Prestressed Concrete Structures Dr. Amlan K Sengupta and Prof. Devdas Menon

Solution

Initial force at stretching end

0.75fpk = 1395 MPa

P0 = 0.75fpk Ap

= 3906 kN

The continuous tendon is analysed as segments of parabola. The segments are

identified between the points of maximum eccentricity and inflection points. The

inflection points are those where the curvature of the tendon reverses. The different

segments are as follows: 1-2, 2-3, 3-4, 4-5, 5-6, 6-7 and 7-8.

CL

3 5 7

1 2 4 6 8

The following properties of parabolas are used. For segment 1-2, the parabola in the

sketch below is used.

L α

y

0 x

The change in slope from the origin to the end of the parabola is same as the slope at

the end of the tendon which is α = 2e/L, where

L = length of the segment

e = vertical shift from the origin.

For segments 2-3 and 3-4 and subsequent pairs of segments, the following property is

used.

Indian Institute of Technology Madras

Prestressed Concrete Structures Dr. Amlan K Sengupta and Prof. Devdas Menon

λL

α e2

e1

For the two parabolic segments joined at the inflection point as shown in the sketch

above, the slope at the inflection point α = 2(e1 + e2)/λL.

Here,

e1, e2 = eccentricities of the CGS at the span and support respectively

L = length of the span

λL = fractional length between the points of maximum eccentricity

The change in slope between a point of maximum eccentricity and inflection point is

also equal to α.

The change in slope (α) for each segment of the tendon is calculated using the above

expressions. Next the value of µα + kx for each segment is calculated using the given

values of µ, k and x, the horizontal length of the segment. Since the loss in prestress

accrues with each segment, the force at a certain segment is given as follows.

Px = P0 e -Σ(µα+kx)

The summation ∑ is for the segments from the stretching end up to the point in the

segment under consideration. Hence, the value of ∑(µα + kx) at the end of each

segment is calculated to evaluate the prestressing force at that point (Px, where x

denotes the point).

Indian Institute of Technology Madras

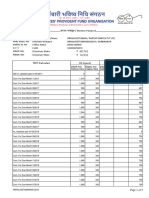

Prestressed Concrete Structures Dr. Amlan K Sengupta and Prof. Devdas Menon

α 0.163

0.111 0.163 0.144 0.144 0.144 0.144

µα +kx 0.039

0.050 0.060 0.036 0.059 0.059 0.036

Σ(µα +kx) 0.149

k ) 0.050 0.110 0.185 0.244 0.303 0.339

e-Σ(µα + kx) 0.712

0.861

1.000 0.952 0.896 0.831 0.783 0.738

Px (kN) 3363 2781

3906 3718 3500 3246 3058 2883

The force variation diagram before anchorage can be plotted with the above values of

Px. A linear variation of the force can be assumed for each segment. Since the

stretching is done at both the ends simultaneously, the diagram is symmetric about the

central line.

a) The expected elongation of the tendon after stretching

First the product of the average force and the length of each segment is summed up to

the centre line.

1 1

PavL = [3906 + 3718] ×13.7 + [3718 + 3500] ×13.7

2 2

1 1

+ [3500 + 3363] ×3 + [3363 + 3246] × 3.7

2 2

1 1

+ [3246 + 3058] ×15.2 + [3058 + 2883] ×15.2

2 2

1

+ [ 2883 + 2718] ×3.7

2

= 227612.2 kN

Indian Institute of Technology Madras

Prestressed Concrete Structures Dr. Amlan K Sengupta and Prof. Devdas Menon

The elongation (∆) at each stretching end is calculated as follows.

Pav L

∆=

AP EP

227612×103

=

2800×195000

= 0.417 m

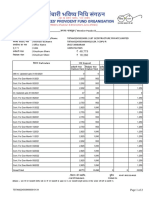

b) The force variation diagrams along the tendon before and after anchorage

After anchorage, the effect of anchorage slip is present up to the setting length lset. The

value of lset due to an anchorage slip ∆s = 6 mm is calculated as follows.

∆s AP EP

lset =

P0 µ

6× 2800×195000

=

13.7

= 15.46 m

The quantity P0µ is calculated from the loss of prestress per unit length in the first

segment. P0µ = (3906 – 3718) kN /13.7 m = 13.7 N/mm. The drop in the prestressing

force (∆p) at each stretching end is calculated as follows.

∆p = 2P0 µlset

= 2×13.7 ×15464

= 423.7 kN

Thus the value of the prestressing force at each stretching end after anchorage slip is

3906 – 424 = 3482 kN. The force variation diagram for lset = 15.46 m is altered to show

the drop due to anchorage slip.

The force variation diagrams before and after anchorage are shown below. Note that

the drop of force per unit length is more over the supports due to change in curvature

over a small distance.

Indian Institute of Technology Madras

Prestressed Concrete Structures Dr. Amlan K Sengupta and Prof. Devdas Menon

Prestressing force (kN)

4000

3500

3000

2500

0 20 40 60 80

Distance from end (m)

After anchorage Before anchorage

Indian Institute of Technology Madras

You might also like

- Section2.2 - Losses of StressDocument16 pagesSection2.2 - Losses of StressTOP ERNo ratings yet

- Lecture Presentation 1Document105 pagesLecture Presentation 1Ahmet SancakNo ratings yet

- 0039 - Cable and Membrane: DescriptionDocument4 pages0039 - Cable and Membrane: DescriptionmishikhanNo ratings yet

- The Kubelka-Munk theory, applications and modificationsDocument28 pagesThe Kubelka-Munk theory, applications and modificationsAziz100% (1)

- Brownian Dynamics of Polymers Dumbbell and Rouse Models: G. Marrucci Università Di Napoli Federico IIDocument25 pagesBrownian Dynamics of Polymers Dumbbell and Rouse Models: G. Marrucci Università Di Napoli Federico IIDean EspositoNo ratings yet

- Ems ch9 NTDocument19 pagesEms ch9 NTPurna YalamanchiliNo ratings yet

- Strength of Material (Basic Theory) For Competitive ExamsDocument63 pagesStrength of Material (Basic Theory) For Competitive Examssudesh_jain_2No ratings yet

- Week4 - Solved TutorialDocument9 pagesWeek4 - Solved TutorialRudra Sai SandeepNo ratings yet

- Direct numerical simulation of particle detachmentDocument14 pagesDirect numerical simulation of particle detachmentAntonio Martín AlcántaraNo ratings yet

- Lecture-12: P-N JunctionDocument24 pagesLecture-12: P-N Junctionksooryakrishna1No ratings yet

- Differential Calculus - Das and Mukherjee (Chapter 15-21) PDFDocument119 pagesDifferential Calculus - Das and Mukherjee (Chapter 15-21) PDFArnab Dipra100% (2)

- X Ray Diffraction 1Document9 pagesX Ray Diffraction 1mustafa alasadyNo ratings yet

- Ch. - 5 - DeflectionsDocument5 pagesCh. - 5 - DeflectionsJibril JundiNo ratings yet

- 21Document4 pages21AbbasNo ratings yet

- Tesch - On Invariants of Fluid Mechanics TensorsDocument8 pagesTesch - On Invariants of Fluid Mechanics TensorsSandeepNo ratings yet

- On Discrete-Kirchhoff Plate Finite Elements: Implementation and Discretization ErrorDocument24 pagesOn Discrete-Kirchhoff Plate Finite Elements: Implementation and Discretization ErrorNourhan AymanNo ratings yet

- University of British Columbia - St. Venant TorsionDocument15 pagesUniversity of British Columbia - St. Venant TorsionFrancisco ContrerasNo ratings yet

- Coupling of Elasticity, Flow and Material BalanceDocument29 pagesCoupling of Elasticity, Flow and Material BalanceDicky AlviansyahNo ratings yet

- SheetDocument2 pagesSheetmehdiNo ratings yet

- Bernoulli's Equation ExplainedDocument15 pagesBernoulli's Equation Explainedali sheetNo ratings yet

- Civil Engineering (Objective Questions With Basic Theory)Document115 pagesCivil Engineering (Objective Questions With Basic Theory)Aarushi Publications100% (1)

- Talkrenyi 3Document19 pagesTalkrenyi 3Srivatsan BalakrishnanNo ratings yet

- Analysis Spectral MethodDocument14 pagesAnalysis Spectral MethodmelaNo ratings yet

- 4.3.8. The Hetero P-N Junction: 4.3.8.1.band Diagram of A Heterojunction P-N Diode Under Flatband ConditionsDocument9 pages4.3.8. The Hetero P-N Junction: 4.3.8.1.band Diagram of A Heterojunction P-N Diode Under Flatband ConditionsRupanitaDasNo ratings yet

- FOURIER STATISTIK Halaman 103 130Document28 pagesFOURIER STATISTIK Halaman 103 130Wulan DariNo ratings yet

- Marc's Formula Sheet for Fall 2019Document1 pageMarc's Formula Sheet for Fall 2019Atif MoeezNo ratings yet

- On Discrete-Kirchhoff Plate Finite Elements: Implementation and Discretization ErrorDocument24 pagesOn Discrete-Kirchhoff Plate Finite Elements: Implementation and Discretization ErroreggedNo ratings yet

- Pecan: A Canadian Parabolic Equation Model For Underwater Sound PropagationDocument30 pagesPecan: A Canadian Parabolic Equation Model For Underwater Sound PropagationAneri JainNo ratings yet

- TUPMN038Document3 pagesTUPMN038Particle Beam Physics LabNo ratings yet

- Chapter 2: Turbulent Flow in Pipes Characteristics of Turbulent Flow in PipesDocument27 pagesChapter 2: Turbulent Flow in Pipes Characteristics of Turbulent Flow in PipesNigel Joseph KabigtingNo ratings yet

- Nonlinear Standingwaves in Acoustic ResonatorsDocument4 pagesNonlinear Standingwaves in Acoustic ResonatorsJmeno PrijmeniNo ratings yet

- Displacements using Castigliano's theorem and strain energy methodDocument8 pagesDisplacements using Castigliano's theorem and strain energy methodsameshni pillayNo ratings yet

- Coil SpringDocument14 pagesCoil SpringLeti HanajNo ratings yet

- Uplift Capacity T-Z MethodDocument5 pagesUplift Capacity T-Z MethodPalak ShivhareNo ratings yet

- Doctors 2023Document24 pagesDoctors 2023Helen DoctorsNo ratings yet

- Lecture 24: Rolling: Dept. of Mechanical Engg., NIT CalicutDocument15 pagesLecture 24: Rolling: Dept. of Mechanical Engg., NIT CalicutManoj MallickNo ratings yet

- Aircraft Design Day8Document64 pagesAircraft Design Day8arun_sanga1233515No ratings yet

- Electromagnetic Induction: Φ= B⋅D ⃗A=BacosθDocument11 pagesElectromagnetic Induction: Φ= B⋅D ⃗A=BacosθshuaryaNo ratings yet

- Physics 361 Solutions To Problem Sets 3,4: 1 Typical Compressibilities and FrequenciesDocument4 pagesPhysics 361 Solutions To Problem Sets 3,4: 1 Typical Compressibilities and FrequenciessfdafNo ratings yet

- Mechanics of Deformable Bodies (CRP) learning moduleDocument12 pagesMechanics of Deformable Bodies (CRP) learning moduleRetro GamerNo ratings yet

- Arfken MMCH 7 S 2 e 14Document1 pageArfken MMCH 7 S 2 e 14Helen MenaNo ratings yet

- Report: Weldon-Breit-Wigner Formula I: (Dated: March 16, 2016)Document15 pagesReport: Weldon-Breit-Wigner Formula I: (Dated: March 16, 2016)Masoud ShokriNo ratings yet

- Prestressed Concrete: Load Balancing and DeflectionsDocument20 pagesPrestressed Concrete: Load Balancing and Deflections16052169No ratings yet

- Seismic design criteria local member displacement capacityDocument16 pagesSeismic design criteria local member displacement capacityDiego Castillo JaramilloNo ratings yet

- Open Doorsecond Round Task Exam DemoDocument19 pagesOpen Doorsecond Round Task Exam DemoHayleyesus100% (3)

- Light Emitting Diode (LED) PrinciplesDocument18 pagesLight Emitting Diode (LED) PrinciplesSrinivas MishraNo ratings yet

- BLecture 7Document5 pagesBLecture 7Carolina LizaNo ratings yet

- Potential Calculation of Pipelines with Clay LinersDocument6 pagesPotential Calculation of Pipelines with Clay LinersSenthil KesavanNo ratings yet

- Griffiths QMCH 1 P 12Document4 pagesGriffiths QMCH 1 P 12abc xyzNo ratings yet

- Device Modeling For Sige Heterojunction Bipolar Transistor: Prof. Swapna Banerjee Department of Electronics & EceDocument59 pagesDevice Modeling For Sige Heterojunction Bipolar Transistor: Prof. Swapna Banerjee Department of Electronics & EceenkannaNo ratings yet

- (Anikin, I.V. Et Al.) QCD Factorization Beyond Leading Twist in Exclusive Rho-Meson ProductionDocument8 pages(Anikin, I.V. Et Al.) QCD Factorization Beyond Leading Twist in Exclusive Rho-Meson Productionlev76No ratings yet

- posterCHT08 1Document1 pageposterCHT08 1carlosfnbsilvaNo ratings yet

- EMT 272 Semiconductor Fundamentals - PN Junction Characteristics and BreakdownDocument39 pagesEMT 272 Semiconductor Fundamentals - PN Junction Characteristics and Breakdownayuni2602No ratings yet

- Cambridge International AS & A Level: PHYSICS 9702/43Document24 pagesCambridge International AS & A Level: PHYSICS 9702/43agnesasus123No ratings yet

- KT Lecture NotesDocument11 pagesKT Lecture NotesHana DjatNo ratings yet

- 11 .C11.strainDocument13 pages11 .C11.strainLộc Phạm vănNo ratings yet

- Relativity - Set Ii: Lorentz TransformationsDocument4 pagesRelativity - Set Ii: Lorentz TransformationsArun PillaiNo ratings yet

- D (T) QT,: (E, D, B H. - M (EDocument1 pageD (T) QT,: (E, D, B H. - M (EEddieNo ratings yet

- Lect3 - Eqivalent Load - 1151Document17 pagesLect3 - Eqivalent Load - 1151CheongNo ratings yet

- The Spectral Theory of Toeplitz Operators. (AM-99), Volume 99From EverandThe Spectral Theory of Toeplitz Operators. (AM-99), Volume 99No ratings yet

- Exam Preparation Chartered Member Past Paper 20230208Document16 pagesExam Preparation Chartered Member Past Paper 20230208Gopu RNo ratings yet

- Event Board: Gopu RDocument5 pagesEvent Board: Gopu RGopu RNo ratings yet

- Statement of Axis Account No:915010044957298 For The Period (From: 01-04-2022 To: 09-04-2022)Document2 pagesStatement of Axis Account No:915010044957298 For The Period (From: 01-04-2022 To: 09-04-2022)Gopu RNo ratings yet

- Event Board: Gopu RDocument5 pagesEvent Board: Gopu RGopu RNo ratings yet

- Event Board: Gopu RDocument5 pagesEvent Board: Gopu RGopu RNo ratings yet

- Wall Planner-2023 - HQDocument1 pageWall Planner-2023 - HQGopu RNo ratings yet

- Winter Reboot Bags EditionDocument15 pagesWinter Reboot Bags EditionGopu RNo ratings yet

- Designing an anchored diaphragm wall for excavation pit protectionDocument9 pagesDesigning an anchored diaphragm wall for excavation pit protectionnirgun sherchanNo ratings yet

- Calibration of Load Factors For Combinations of Extreme EventsDocument51 pagesCalibration of Load Factors For Combinations of Extreme EventsGopu RNo ratings yet

- FOOTING DETAILED-ModelDocument1 pageFOOTING DETAILED-ModelGopu RNo ratings yet

- Recommended Modifications to AASHTO LRFD Bridge Design SpecificationsDocument14 pagesRecommended Modifications to AASHTO LRFD Bridge Design SpecificationsGopu RNo ratings yet

- Plastic Hinge Length and Depth For Piles in Marine Oil Terminals Including Nonlinear Soil PropertiesDocument10 pagesPlastic Hinge Length and Depth For Piles in Marine Oil Terminals Including Nonlinear Soil PropertiesGopu RNo ratings yet

- Delhi - Manali - DelhiDocument2 pagesDelhi - Manali - DelhiGopu RNo ratings yet

- Professional Development Courses: 2021 ProgrammeDocument46 pagesProfessional Development Courses: 2021 ProgrammeGopu RNo ratings yet

- Book 2Document1 pageBook 2Gopu RNo ratings yet

- Science Direct JournalDocument6 pagesScience Direct JournalMadhusudhanReddy SappidiNo ratings yet

- Payment Successful '719.00: Mobile Jiofiber Business Shop AppsDocument1 pagePayment Successful '719.00: Mobile Jiofiber Business Shop AppsGopu RNo ratings yet

- 6m YTD 1y: Max, Min and Average Temperature (°c) ZoomDocument1 page6m YTD 1y: Max, Min and Average Temperature (°c) ZoomGopu RNo ratings yet

- L&T Construction, Chennai G-O20002: Subarnarekha - Main Bridge SubstrcutureDocument7 pagesL&T Construction, Chennai G-O20002: Subarnarekha - Main Bridge SubstrcutureGopu RNo ratings yet

- Permanent Strand Anchor System: Main StandardsDocument7 pagesPermanent Strand Anchor System: Main StandardsGopu RNo ratings yet

- Congratulations Gopu R On Your Stint As CEO of Eureka: Business Reality That We FaceDocument3 pagesCongratulations Gopu R On Your Stint As CEO of Eureka: Business Reality That We FaceGopu RNo ratings yet

- 40 M Span Staad SnapshotsDocument2 pages40 M Span Staad SnapshotsGopu RNo ratings yet

- Member Passbook DetailsDocument2 pagesMember Passbook Detailshr pslNo ratings yet

- Thesis Document Final G. Versteegt 1537911 PDFDocument127 pagesThesis Document Final G. Versteegt 1537911 PDFjesusgameboyNo ratings yet

- Effect of Coarse Aggregate Size On The Shear Behavior of Beams Without Shear ReinforcementDocument13 pagesEffect of Coarse Aggregate Size On The Shear Behavior of Beams Without Shear ReinforcementGopu RNo ratings yet

- Member Passbook DetailsDocument2 pagesMember Passbook DetailsGopu RNo ratings yet

- Abbreviated Methodology for Building, Civil Engineering, and Construction IndicesDocument2 pagesAbbreviated Methodology for Building, Civil Engineering, and Construction IndicesGopu RNo ratings yet

- Effect of Coarse Aggregate Size On The Shear Behavior of Beams Without Shear ReinforcementDocument13 pagesEffect of Coarse Aggregate Size On The Shear Behavior of Beams Without Shear ReinforcementGopu RNo ratings yet

- Assessment of Stress Loss Evaluation Capability of Design Software and IRC Codes in Post-Tensioning MembersDocument5 pagesAssessment of Stress Loss Evaluation Capability of Design Software and IRC Codes in Post-Tensioning MembersGopu RNo ratings yet

- PL Issue - No - 2 - WallsDocument44 pagesPL Issue - No - 2 - WallsJelena MarinNo ratings yet

- Agp PDFDocument9 pagesAgp PDFNeelakantNo ratings yet

- Circumferential Road, Bitoon-Aguada, Ozamiz City, Misamis OccidentDocument3 pagesCircumferential Road, Bitoon-Aguada, Ozamiz City, Misamis OccidentMaria Angelica Rodriguez AlonsoNo ratings yet

- 622 MBPS, 1310 NM Uncooled Fabry-Perot Laser Diode Module With MonitorDocument9 pages622 MBPS, 1310 NM Uncooled Fabry-Perot Laser Diode Module With MonitorIsaac Huixtlaca CuatecatlNo ratings yet

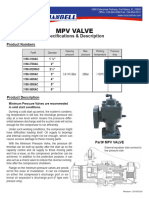

- Hanbell MPV Valve Spec SheetDocument1 pageHanbell MPV Valve Spec SheetDũng LêNo ratings yet

- Wire Terminal and Fixture Testing ToolsDocument1 pageWire Terminal and Fixture Testing ToolsPASCAL LANDSHEERENo ratings yet

- CR 35-X - Service Manual For DownloadDocument565 pagesCR 35-X - Service Manual For DownloadMohsenNo ratings yet

- Grinding of Tool SteelDocument20 pagesGrinding of Tool SteelJarek PlaszczycaNo ratings yet

- Antenna Design Lecture IntroductionDocument17 pagesAntenna Design Lecture IntroductionJesus AltamiranoNo ratings yet

- Low Voltage: General Performance IE3 Premium Efficiency Cast Iron MotorsDocument12 pagesLow Voltage: General Performance IE3 Premium Efficiency Cast Iron MotorsHEMANT RAMJINo ratings yet

- Acr 1 Final 2021Document5 pagesAcr 1 Final 2021CAROLYN RhoeNo ratings yet

- Out, Up, and Through - Fault Tolerant TennisDocument7 pagesOut, Up, and Through - Fault Tolerant TennishosoksnbNo ratings yet

- Paramagnetic Lab - Farheen & MowDocument8 pagesParamagnetic Lab - Farheen & MowFarheenNo ratings yet

- PDF Updated Class 11 Physics Formula Sheet CompressDocument22 pagesPDF Updated Class 11 Physics Formula Sheet CompressdrjbjpNo ratings yet

- ASSIG202Document2 pagesASSIG202Carolina Ticona VargasNo ratings yet

- Nelson NS40 SD Gun FlyerDocument2 pagesNelson NS40 SD Gun FlyerFher GVNo ratings yet

- Ch2 Atoms Molecules IonsDocument46 pagesCh2 Atoms Molecules IonsCalonanak Sithr2020No ratings yet

- Dynamic Design For AnchorsDocument6 pagesDynamic Design For AnchorsFlorin BodogaNo ratings yet

- Infrared LED Lights Product Lineup: Abundant Lineup, Total of 56 Models Available For Various ApplicationsDocument12 pagesInfrared LED Lights Product Lineup: Abundant Lineup, Total of 56 Models Available For Various ApplicationsKaiser MonterreyNo ratings yet

- Flanged Spherical Pipe Joints: - Elastomeric Expansion Joints / Flexible ConnectorsDocument2 pagesFlanged Spherical Pipe Joints: - Elastomeric Expansion Joints / Flexible ConnectorsKhaled Al AkhdarNo ratings yet

- Preventa Safety Products PDFDocument136 pagesPreventa Safety Products PDFBipinNo ratings yet

- ELK 371E Week IV - 11.10.22Document28 pagesELK 371E Week IV - 11.10.22Mehmet Onur UlusoyNo ratings yet

- Report of Investigation: National Institute of Standards & TechnologyDocument10 pagesReport of Investigation: National Institute of Standards & Technology박만진No ratings yet

- Basic Electrical Technology (ESC 101-A) Module 1: DC Circuits Superposition TheoremDocument13 pagesBasic Electrical Technology (ESC 101-A) Module 1: DC Circuits Superposition TheoremtusharNo ratings yet

- UPCAT 2020 Reviewer4Document21 pagesUPCAT 2020 Reviewer4Aye100% (4)

- SMI+100+am14 HTTPWWW - Endeavourenergy.com - auwpswcmconnectSMI+100+am14.pdfMOD AJPERESDocument30 pagesSMI+100+am14 HTTPWWW - Endeavourenergy.com - auwpswcmconnectSMI+100+am14.pdfMOD AJPERESnanda julianaNo ratings yet

- General Wave Properties 3 QPDocument8 pagesGeneral Wave Properties 3 QPAli SiddiqNo ratings yet

- Physics 1345Document24 pagesPhysics 1345Barney ParadoxNo ratings yet

- Anna University Chennai:: Chennai - 600 025 Curriculum 2004 B.Tech. Petroleum EngineeringDocument64 pagesAnna University Chennai:: Chennai - 600 025 Curriculum 2004 B.Tech. Petroleum EngineeringSc Sathish KumarNo ratings yet

- Maintaining Mathematical ProficiencyDocument64 pagesMaintaining Mathematical ProficiencySayed MikoNo ratings yet

- Ultra Low Freezer (Tower) ManualDocument53 pagesUltra Low Freezer (Tower) Manualadnan_hashmi786100% (1)