Professional Documents

Culture Documents

O0609112116 PDF

O0609112116 PDF

Uploaded by

Arham SheikhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

O0609112116 PDF

O0609112116 PDF

Uploaded by

Arham SheikhCopyright:

Available Formats

American Journal of Engineering Research (AJER) 2017

American Journal of Engineering Research (AJER)

e-ISSN: 2320-0847 p-ISSN : 2320-0936

Volume-6, Issue-9, pp-112-116

www.ajer.org

Research Paper Open Access

Effect of Aggregate Size and Gradation on Compressive Strength

of Normal Strength Concrete for Rigid Pavement

*

Ekwulo E. O1. and Eme D. B2.

1

Department of Civil Engineering, Rivers State University, Nkpolu-Oroworukwo, Port Harcourt, Nigeria

2

Department Civil Engineering, University of Port Harcourt, Port Harcourt, Nigeria

Corresponding Author: *Ekwulo E. O

ABSTRACT: In road or most base constructions, uniform size and graded (mixed) aggregates of different

sizes have been used without adequate consideration for its implications in terms of compressive strength. This

study was carried out to investigate the effect of aggregate size and gradation on the compressive strength of

concrete used for rigid pavements. The study investigated four concrete specimens made from aggregate size of

9.5mm, 12.7mm, 19.1mm and graded aggregate specimen made from a combination of 9.5mm, 12.7mm and

19.1mm aggregates. A concrete mix of 1:1.5:3 with a constant water-cement ratio (w/c) of 0.6 was used and

tested for slump. Concrete cubes were produced from same mix, cured and tested for compressive strength at 14

and 28 days. The result showed that the concrete made from aggregate sizes of 9.5mm, 12.7mm and 19.1mm

recorded slumps of 60mm, 50mm and 30mm respectively, while concrete made from the graded aggregates

recorded the least slump of 20mm. Also, the concrete made from 9.5mm, 12.7mm, 19.1mm aggregates recorded

mean compressive strengths of 18.2N/mm2, 20.0N/mm2 and 20.9N/mm2 respectively at 28days while concrete

made from the graded aggregates recorded mean compressive strength of 17.3N/mm2at 28 days. It was

concluded that workability (slump) of fresh concrete decreases with increase in aggregate size and that

compressive strength increases with increase in aggregate size. The study also noted that grading aggregates

using the Cement Treated Aggregate gradation procedure does not necessarily increase compressive strength of

concrete for rigid pavements.

Keywords: Aggregate Size, Slump, Aggregate Gradation, Compressive Strength

------------------------------------------------------------------------------------------------------------------------------ ---------

Date of Submission: 26 -08-2017 Date of acceptance: 09-09-2017

----------------------------------------------------------------------------------------------------------------------------- ----------

I. INTRODUCTION

Coarse aggregates play significant role in concrete production. Concrete is a composite material made

of aggregates bonded together by liquid cement which hardens over time [1]. Concrete can be used as plain or

reinforced concrete in civil engineering construction to build durable and long lasting structures. The major

components of concrete are cement, water, and aggregates (fines and coarse aggregate) with coarse aggregates

occupying over one-third of the volume of concrete. Research has shown that changes in coarse aggregate can

change the strength properties of concrete. To predict the behavior of concrete under general loading requires an

understanding of the effects of aggregate size. The compressive strength of concrete is one of the major

properties that structural engineers take into consideration before erecting any structure [2]. Compressive

strength of concrete can be affected by many factors including water to cement ratio, aggregate size, degree of

compaction and shape. Aggregate gradation plays an important role in concrete mixing. Unsatisfactory

gradation of aggregates leads to segregation of mortar from the coarse aggregates, internal bleeding, need for

chemical admixtures to restore workability, excessive water use and increased cement use [3]. Coarse

aggregates constitute about 50 to 60% of the concrete mix depending on the mix proportion used. Research

indicates that the larger aggregate percentage in concrete mix contributes to a lot to its strength [4]. Aggregates

are the most mined material in the world. They are a component of composite materials such as concrete and

asphalt concrete. Aggregates are responsible for the unit weight, elastic modulus and dimensional stability of

concrete because these properties depend on the physical characteristics (strength and bulk density) of the

aggregate [5].

www.ajer.org Page 112

American Journal of Engineering Research (AJER) 2017

There is much controversy concerning the effects of coarse aggregate size on concrete compressive

strength. Tests by Zhou, Barr, and Lydon [6] show that compressive strength increases with increase in coarse

aggregate size. However, most other studies disagree. Walker and Bloem [7] and Bloem and Gaynor [8]

concluded that an increase in aggregate size results in a decrease in the compressive strength of concrete. Cook

[9] showed that, for compressive strengths in excess of 69 MPa (10,000 psi), smaller sized coarse aggregate

produces higher strengths for a given water-to-cement ratio. Walker and Bloem [7] studied the effects of coarse

aggregate size on the properties of normal-strength concrete. Their work demonstrates that an increase in

aggregate size from 10mm to 64 mm (3/8 to 2 ½ inch.) results in a decrease in the compressive strength of

concrete, by as much as 10 percent. Bloem and Gaynor [8] studied the effects of size and other coarse aggregate

properties on the water requirements and strength of concrete. Their results confirm that increasing the

maximum aggregate size reduces the total surface area of the aggregate, thus reducing the mixing water

requirements; however, even with the reduction in water, a larger size aggregate still produces lower

compressive strengths in concrete compared to concretes containing smaller aggregate. Generally, in lower

strength concretes, the reduction in mixing water is sufficient to offset the detrimental effects of aggregate size.

However, in high-strength concretes, the effect of size dominates, and the smaller sizes produce higher

strengths. Cordon and Gillespie [10] also reported changes in concrete strength for mixes made with various

water-to-cement ratios and aggregate sizes. They found that, at water-to-cement ratios from 0.40 to 0.70, an

increase in maximum aggregate size from 19 mm to 38 mm decreases the compressive strength by about 30

percent. They also concluded that, in normal-strength concrete, failure typically occurs at the matrix-aggregate

interface and that the stresses at the interface which cause failure can be reduced by increasing the surface area

of the aggregate (decreasing the aggregate size). If the strength of the concrete is sufficiently high, such as with

high strength concrete, failure of the specimen is usually accompanied by the fracture of 5 aggregate particles;

therefore, in high-strength concrete, compressive strength depends on aggregate strength, not necessarily

aggregate size. Studies by Vilane and Sabelo [11] investigated compressive strength of concrete made from

9.5mm, 13.2mm and 19.0mm aggregates. Results indicates that compressive strength of concrete increased with

increase in aggregate size.

Rozalija and Darwin [12] studied the effect of Aggregate type, size and content on concrete strength

and fracture energy. The results indicates that compressive strength of both normal and high strength concrete is

little affected by aggregate size. In fact, it is generally agreed that, although larger coarse aggregates can be used

to make high-strength concrete, it is easier to do so with coarse aggregates below 12.5 mm (1/2 in.) [13].

Aggregates for use as pavement material must meet specifications in terms of gradation [14]. In some

developing countries like Nigeria, the use of single and/or graded aggregates for construction of rigid pavements

is a common practice. In most cases for economic reasons, construction managers treat concrete for rigid

pavement as Cement Treated Aggregate base (CTAB) in accordance with ASTM [15] hence producing concrete

with combination of coarse aggregates of different sizes.

Objectives

The arbitrary use of uniform size and mixed aggregates for rigid pavement concrete with no

consideration for the concrete compressive strength necessitated this research. This study attempts to investigate

the effect of coarse aggregate size and gradation on compressive strength of normal strength concrete for rigid

pavement.

II. MATERIALS, APPARATUS AND METHOD

2.1 Material

The selected materials to be used in this study are locally available and currently used in making concrete in

Nigeria. They are:

(a) Ordinary Portland cement

(b) Fine river sand as fines

(c) 3/8 in. (9.5mm) river sand as coarse aggregate

(d) ½ in. (12.7mm) crushed stone (granite chippings) as coarse aggregate

(e) ¾ in. (19.1) crushed stone (granite chippings) as coarse aggregate

(f) water

The crushed stone was sourced from a quarry site at Akampka, in Cross Rivers State, Nigeria and in the desired

sizes.

www.ajer.org Page 113

American Journal of Engineering Research (AJER) 2017

2.2 Apparatus

The equipment that were used in the study were: 150mm x 150mm x 1500mm steel moulds, tags sieves,

retainers, brush, weighing instrument, trowel, spanners, electric table vibrator, electric concrete mixer, slump

test cone, curing tank and concrete Universal Testing Machine.

III. METHODOLOGY

3.1 Experimental Design

The research involved experimental tests on four concrete specimen prepared with aggregate sizes of

9.5mm, 12.7mm, 19.1mm and graded aggregates comprising of a combination of 9.5mm, 12.7mm and 19.1mm

coarse aggregates. The aggregates were blended in accordance with the Cement Treated Aggregate Procedure

[13, 15]. The blending of the aggregates resulted concrete specimen comprising of 50% of 9.5mm aggregates,

30% of 12.7mm aggregates and 20% of 19.1mm aggregate and marked specimen “B”. There were three

replications of each specimen using a constant mix proportion of 1:1.5:3 and water-cement (w/c) ratio of 0.6.

3.2 Concrete Batching, Mixing and Curing

Coarse aggregate, fine aggregate and cement were thoroughly mixed together with the electric concrete

mixer, after which the required water estimated at 0.6 water-cement ratio (w/c) was added. The entire

constituents were mixed until an even paste was obtained.

3.3 Slump Test

The slump mould was filled in three layers, each layer was compacted by a steel rod with 25 blows

before pouring the next layer. The surface was leveled after filling the slump cone, and allowed for 2 minutes.

The slump cone was then lifted off the concrete, thus allowing the pile of unsupported concrete to collapse. The

difference between the initial and the final height of the concrete was measured and recorded as the slump.

3.4 Curing

For the four concrete specimen made from the uniform and graded aggregates, six (6) cubes were cast

for each specimen making a total of twenty four cubes (24). The cubes were cast by filling each mould in small

layers and compacting each layer by the electric vibrator before the next layer was poured. They were left in the

mould for 24 hours to set at laboratory temperature, after which they were demoulded and transferred into a

curing tank that contained clean water. For each specimen, three (3) cubes were cured for 14 days and the other

three (3) for 28 days.

3.5 Compressive Strength Test

The cubes were removed from the curing tank, weighed and tested at 14 and 28 days with the Universal

Testing Machine. The value of the load at which the test cube failed was recorded and used to calculate the

compressive strength at each curing age. The compressive strength was calculated using equation 1.

P

fc (N/mm2) (1)

A

Where;

P = Failure load in N

A = cross-sectional area of test cube in m2.

IV. RESULTS AND DISCUSSIONS

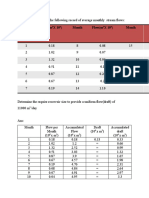

The results of workability (slump) and compressive strength test for the uniform size and graded

(mixed) aggregates are as summarized in Table 4.1:

Table 4.1: Slump and Compressive Strength of Single and blended Aggregates

Aggregate Slump Compressive Strength

Size/Content (mm) N/mm2

(mm) 14 days 28 days

(1) (2) (3) Mean (1) (2) (3) Mean (1) (2) (3) Mean

9.5 63 58 59 60 16.0 15.0 15.8 15.6 18.3 18.5 17.8 18.2

12.7 52 48 50 50 18.1 18,0 18.5 18.2 21.5 19.0 19.5 20.0

19.1 32 28 30 30 19.0 19.7 19.2 19.3 20.0 20.7 22.0 20.9

GRADED (MIXED) 19 21 20 20 10.9 10.7 10.5 10.7 16 18 17.9 17.3

AGGREGATES “B”

www.ajer.org Page 114

American Journal of Engineering Research (AJER) 2017

The effect of aggregate size and gradation on workability (slump) is shown in Table 4.1. The

result indicates that the workability (slump) of fresh concrete made from the various aggregates

decreases with increase in aggregate size, aggregate sizes of 9.5mm, 12.7mm, and 19.1mm recording

true slumps of 60mm, 50mm and 30mm respectively, while the concrete made from graded

aggregates recorded the least slump of 20mm.

The effect of aggregate size on compressive strength of uniform size and graded aggregates is

shown in Figure 4.2. The result indicates that compressive strength of the concrete made from various

aggregate sizes increased with age from 14 to 28 days. The uniform aggregates sizes of 9.5mm,

12.7mm, 19.1mm recording compressive strengths of 18.2N/mm2, 20.0N/mm2, 20.9N/mm2

respectively at 28 days while the graded aggregates “B” recorded the lowest strength of 17.3N/mm2 at

28 days . The result also shows that the 19.1mm aggregates recorded the highest compressive strength

of 20.9N/mm2 at 28 days. This result indicates that compressive strength of concrete made from

uniform size aggregates increases with increase in aggregate size and that aggregates mixed using the

Cement Treated Aggregate gradation procedure does not improve the compressive strength of

concrete used for rigid pavements.

Figure 4.2: Variation of compressive strength with aggregate size/gradation

V. CONCLUSION AND RECOMMENDATION

5.1 Conclusion

From the results of the study, the following conclusions are hereby made:

1. The aggregate size and gradation affect workability of fresh concrete and compressive strength of hardened

concrete.

2. Workability of concrete made from uniform size aggregates decreases as the aggregate size increases.

3. Compressive strength of concrete made from uniform size aggregates increases with increase in aggregate

size.

4. Blending aggregates using the Cement Treated Aggregate gradation procedure does not improve the

compressive strength of concrete used for rigid pavements relative to concrete made from uniform size

aggregates.

5.2 Recommendation

i. Further research be carry out to investigate the use of appropriate aggregate gradation procedure for

blending aggregate for concrete used for highway pavement and its effect on compressive strength of

concrete.

ii. Construction engineers should exercise caution in the use of arbitrarily graded (mixed) aggregates for

design and construction purposes

www.ajer.org Page 115

American Journal of Engineering Research (AJER) 2017

ACKNOWLEDGMENT

The authors wish to acknowledge the good effort of Mr. Enos Enos Kpunueyirobe for the

hardwork during the laboratory works that resulted in this research findings.

REFERENCE

[1]. Woodford, C. (2016). Concrete and reinforced concrete. http://www.explainthatstuff.com/steelconcrete.html. Accessed November,

2016.

[2]. Hollaway, L. C., 2010. A review of the present and future utilisation of FRP composites in the civil infrastructure with reference to

their important in-service properties. Construction and Building Materials, 24 (12), pp. 2419-2445.

[3]. Loannides, M. A. and Mills, C. J. (2006). Effect Of Larger Sized Coarse Aggregates On Mechanical Properties Of Portland Cement

Concrete Pavements And Structures: State Job No: 148030. Vol. 1. 2006: 30-31.

[4]. Waziri B. S.; Bukar, A. G and Gaji, Y. Z. (2011). Applicability of quarry sand as a fine aggregate. Continental J. Engineering

Science.

[5]. Anonymous, (2012). Functions and requirements of ingredients of cement concrete. http://weebo.hubpages.com/hub/Functions-and-

requirementsof- ingredients-of-cement-concrete. Accessed October, 2016.

[6]. Zhou, F. P., Barr, B. I. G., and Lydon, F. D. (1995). Fracture Properties of High Strength Concrete with Varying Silica Fume

Content and Aggregates, Cement and Concrete Research, V. 25, No.3, pp. 543-552.

[7]. Walker, S. and Bloem, D. L. (1960) Effects of Aggregate Size on Properties of Concrete. ACI Journal, Proceedings V. 57, No.3,

September, pp. 283-298.

[8]. Bloem, D. L. and Gaynor, R. D. (1963) Effects of Aggregate Properties on Strength of Concrete, ACI Journal, Proceedings V. 60,

No. 10, October, pp. 1429-1456.

[9]. Cook, J. E. (1989) .I 0,000 psi Concrete, Concrete International, October, pp. 67-7 5.

[10]. Cordon, W. A. and Gillespie, H. A. (1963) Variables in Concrete Aggregates and Portland Cement Paste Which Influence the

Strength of Concrete, ACI Journal, Proceedings V. 60, No.8, August, pp. 1029-1052

[11]. Vilane, B.R.T and Sabelo, N. (2016). The Effect of Aggregate Size on the Compressive Strength of Concrete. Journal of

Agricultural Science and Engineering Vol. 2 No. 6 pp. 66-69

[12]. Rozalija, K and Darwin, David (1997) Effect of Aggregate Type, Size and Content on Concrete Strength and Fracture. The

Reinforced Concrete Research Council, Project 56, The U.S Department of Transportation, Federal Highway Administration, SM

Report No. 43.

[13]. ACI Committee 363. (1992) "State-of-the-Art Report on High-Strength Concrete (ACI 363R-92)," ACI Manual of Concrete

Practice, 1997 Edition, Part I, Farmington Hills, MI.

[14]. Aggregate Gradation for Concrete Pavement Mixtures. CP Road Map, Map Brief, October 2014

[15]. AASHTO/ARTBA Guide Specification for Base Course or sub base. American Association of State Highway and Transportation

Officials, Washington DC. 1988

*Ekwulo E. O “Effect of Aggregate Size and Gradation on Compressive Strength of Normal

Strength Concrete for Rigid Pavement” American Journal of Engineering Research (AJER),

vol. 6, no. 9, 2017, pp. 112-116

www.ajer.org Page 116

You might also like

- David Abram The Spell of The Sensuous (4 Chap)Document6 pagesDavid Abram The Spell of The Sensuous (4 Chap)kabshiel86% (7)

- Kohler 5e Parts ListDocument56 pagesKohler 5e Parts ListJazzOlve75% (4)

- NEW Chapter 13 Generator Protection PDFDocument70 pagesNEW Chapter 13 Generator Protection PDFWrya Saeed100% (1)

- DrSueMorter The Top 3 Mistakes E Book Final 9 18 19Document28 pagesDrSueMorter The Top 3 Mistakes E Book Final 9 18 19Subash Chandar100% (8)

- Interlab g26 User's Manual 1.2Document61 pagesInterlab g26 User's Manual 1.2Ali AminiNo ratings yet

- Water-Cement RatioDocument17 pagesWater-Cement RatioShazwanShahNo ratings yet

- Study The Correlation of Clinker Quality, Reside, PSD On The Performance of Portland CementDocument12 pagesStudy The Correlation of Clinker Quality, Reside, PSD On The Performance of Portland CementIAEME PublicationNo ratings yet

- 10 VI June 2022Document8 pages10 VI June 2022IJRASETPublicationsNo ratings yet

- FCE PrExamPapers 2 SsDocument23 pagesFCE PrExamPapers 2 SsSaung Ei Shoon Lei0% (1)

- Mandibular Orthognathic ProceduresDocument104 pagesMandibular Orthognathic ProceduresDrSusmi ChebroluNo ratings yet

- Mechanical Properties of Plastic Concrete Containing BentoniteDocument7 pagesMechanical Properties of Plastic Concrete Containing Bentonitejuan munera100% (1)

- Modeling of Strength of Concrete Produced With Fine Aggregates From Different SourcesDocument13 pagesModeling of Strength of Concrete Produced With Fine Aggregates From Different SourcesEmmanuel OgunjioforNo ratings yet

- Weldable Clips - W10: Raillok™ SeriesDocument2 pagesWeldable Clips - W10: Raillok™ SeriesBorislav StoychevNo ratings yet

- Aggregate EffectDocument1 pageAggregate EffectGaneshalingam Ramprasanna2No ratings yet

- Laboratory Investigation of Coarse AggregateDocument11 pagesLaboratory Investigation of Coarse AggregateComr A Y ZarginaNo ratings yet

- Effects of Fine/coarse Aggregate Size and Shape On The Compressive Strength of ConcreteDocument7 pagesEffects of Fine/coarse Aggregate Size and Shape On The Compressive Strength of ConcreteELLA JOTOJOTNo ratings yet

- Effects of Aggregate Gradation On The Properties of Concrete Made From Granite ChippingsDocument5 pagesEffects of Aggregate Gradation On The Properties of Concrete Made From Granite ChippingsArham Sheikh100% (1)

- Literature SurveyDocument6 pagesLiterature SurveyNatarajan SaravananNo ratings yet

- 70030252Document4 pages70030252engrfarhanAAA100% (1)

- Alfa Hammed ProjectDocument47 pagesAlfa Hammed ProjectOyekunle GbohunmiNo ratings yet

- Influence of Aggregate Type and Size On Properties of Pervious ConcreteDocument8 pagesInfluence of Aggregate Type and Size On Properties of Pervious ConcretejayanthNo ratings yet

- An Empirical Study of Agro-Waste As Coarse Aggregate in Triple-Layer RCC BeamsDocument6 pagesAn Empirical Study of Agro-Waste As Coarse Aggregate in Triple-Layer RCC BeamsIJEACS UKNo ratings yet

- Civil Engineering Journal: Effect of Maximum Aggregate Size On The Strength of Normal and High Strength ConcreteDocument11 pagesCivil Engineering Journal: Effect of Maximum Aggregate Size On The Strength of Normal and High Strength ConcreteandoNo ratings yet

- 3-83-Article Text-160-1-10-20170821 PDFDocument8 pages3-83-Article Text-160-1-10-20170821 PDFLawend KoramarkiNo ratings yet

- Development of Geopolymer ConcreteDocument13 pagesDevelopment of Geopolymer Concreteपाँशुल जम्वाल राजपूतNo ratings yet

- Effects of Concrete Grades On Strength Characteristics of Reinforced Concrete Slender Beams Olanitori, LM Gbadamosi, IaDocument4 pagesEffects of Concrete Grades On Strength Characteristics of Reinforced Concrete Slender Beams Olanitori, LM Gbadamosi, IaAbhishek MishraNo ratings yet

- Compressive Strength and Abrasion Resistance of CoDocument18 pagesCompressive Strength and Abrasion Resistance of CoAbeer AlwardNo ratings yet

- Effect of Water-Cement Ratio On The Compressive Strength of Gravel - Crushed Over Burnt Bricks ConcreteDocument10 pagesEffect of Water-Cement Ratio On The Compressive Strength of Gravel - Crushed Over Burnt Bricks ConcreteToufiq BhatiNo ratings yet

- Sriravindrarajah2012 PDFDocument8 pagesSriravindrarajah2012 PDFLokesh KNo ratings yet

- ConcreteDocument4 pagesConcretegeonikoNo ratings yet

- Improving Strength of Concrete Using Crushed Tiles and Nylon FiberDocument16 pagesImproving Strength of Concrete Using Crushed Tiles and Nylon FiberIJRASETPublicationsNo ratings yet

- 1778390Document25 pages1778390Ibrahim Tuhin PICUNo ratings yet

- Investigation of The Effect of Water-Cement Ratio On The Modulus of Rupture of ConcreteDocument8 pagesInvestigation of The Effect of Water-Cement Ratio On The Modulus of Rupture of ConcreteRevati PatilNo ratings yet

- Seminar Rubber Is Ed ConcreteDocument19 pagesSeminar Rubber Is Ed ConcreteTeny VargheseNo ratings yet

- Developing A Higher Performance and Less Thickness Concrete Pavement Using A Nonconventional Concrete MixtureAdvances in Civil EngineeringDocument8 pagesDeveloping A Higher Performance and Less Thickness Concrete Pavement Using A Nonconventional Concrete MixtureAdvances in Civil EngineeringJuan ReyesNo ratings yet

- Effect of Water-Cement Ratio On The Compressive Strength of Gravel - Crushed Over Burnt Bricks Concrete.Document9 pagesEffect of Water-Cement Ratio On The Compressive Strength of Gravel - Crushed Over Burnt Bricks Concrete.Alexander DeckerNo ratings yet

- Adeniji ObawoleDocument46 pagesAdeniji ObawoleMarshallNo ratings yet

- Comparison of Strength Performance of Concrete WitDocument5 pagesComparison of Strength Performance of Concrete WitChidi OkoloNo ratings yet

- Effect of Types of Fine Aggregate On Mechanical Properties of Cement ConcreteDocument4 pagesEffect of Types of Fine Aggregate On Mechanical Properties of Cement ConcreteKiranSDNo ratings yet

- Huang 2020Document8 pagesHuang 2020Chamux skalNo ratings yet

- Effect of Sand Content On Strength and Pore Structure of Cement MortarDocument10 pagesEffect of Sand Content On Strength and Pore Structure of Cement Mortarzain aliNo ratings yet

- Resume 3 JurnalDocument11 pagesResume 3 Jurnalanindia.nurauliaNo ratings yet

- Kalra 2018Document8 pagesKalra 2018Brenda Araceli Calderon CalderonNo ratings yet

- As PpruDocument6 pagesAs PpruOmoyemi Oluwaseyi FrancisNo ratings yet

- Effect of Batching Methods On The Fresh and Hardened Properties of ConcreteDocument7 pagesEffect of Batching Methods On The Fresh and Hardened Properties of ConcreteAbhishek KoliNo ratings yet

- Jeas 0317 5816Document15 pagesJeas 0317 5816Prof. Dr. Adel Al-AzzawiNo ratings yet

- Adeniji Oluwafemi WillliamsDocument46 pagesAdeniji Oluwafemi WillliamsMarshallNo ratings yet

- Improvement of Engineering Properties of Fibre Reinforced Self Compacting Concrete With Addition of Granite WasteDocument6 pagesImprovement of Engineering Properties of Fibre Reinforced Self Compacting Concrete With Addition of Granite WasteEditor IJTSRDNo ratings yet

- Effect of Aggregate Proportion For Different Types On Porous Concrete PropertiesDocument12 pagesEffect of Aggregate Proportion For Different Types On Porous Concrete PropertiesalpegambarliNo ratings yet

- Zhang 2013Document6 pagesZhang 2013Anandro AmellonadoNo ratings yet

- Application of Woven Waste Tires Gabion Wall As SLDocument8 pagesApplication of Woven Waste Tires Gabion Wall As SLXzk MallaboNo ratings yet

- Related Review LiteratureDocument3 pagesRelated Review LiteratureNicko Jay BajaoNo ratings yet

- Geopolymer Concrete To Reduce The Anthropogenic Greenhouse Gas Emissions Associated With The Concrete and Construction IndustryDocument3 pagesGeopolymer Concrete To Reduce The Anthropogenic Greenhouse Gas Emissions Associated With The Concrete and Construction IndustrylotushNo ratings yet

- Investigation of Compaction On Compressive Strength and Porosity of Pervious ConcreteDocument16 pagesInvestigation of Compaction On Compressive Strength and Porosity of Pervious ConcretesadalpNo ratings yet

- Applied Sciences: Special Issue: New Trends in Recycled Aggregate ConcreteDocument5 pagesApplied Sciences: Special Issue: New Trends in Recycled Aggregate ConcreteYashaswini k yNo ratings yet

- Effect of Water Cement Ratio On The CompDocument9 pagesEffect of Water Cement Ratio On The CompIndriani MandalikaNo ratings yet

- Effect of Aggregate Type On Compressive Strength of ConcreteDocument10 pagesEffect of Aggregate Type On Compressive Strength of ConcreteamelialoritaNo ratings yet

- Construction and Building Materials: M.N. Soutsos, T.T. Le, A.P. LampropoulosDocument7 pagesConstruction and Building Materials: M.N. Soutsos, T.T. Le, A.P. LampropoulosAhmad MuhammadNo ratings yet

- Strength Behavior of Bamboo Reinforced CDocument9 pagesStrength Behavior of Bamboo Reinforced CBRYLLE KYLLE OIDEMNo ratings yet

- Journal of Constructional Steel Research: Ying Xing, Qinghua Han, Jie Xu, Qi Guo, Yihong WangDocument14 pagesJournal of Constructional Steel Research: Ying Xing, Qinghua Han, Jie Xu, Qi Guo, Yihong WangAvinash Bhakta 18MST0043No ratings yet

- HGFDSASDFGHDocument9 pagesHGFDSASDFGHD For DecoreNo ratings yet

- Characterization of Recycled Aggregate ConcreteDocument10 pagesCharacterization of Recycled Aggregate ConcreteKrittiya KaewmaneeNo ratings yet

- Glasss EDITEDDocument26 pagesGlasss EDITEDJakir Hussain SyedNo ratings yet

- Review On Related LiteratureDocument2 pagesReview On Related LiteratureYem Verganio-Alterado100% (2)

- Analysis & Compressive Strength Study of Eco-Friendly Concrete by Partial Replacement of Recycle Brick With Over-Burnt Brick AggregateDocument5 pagesAnalysis & Compressive Strength Study of Eco-Friendly Concrete by Partial Replacement of Recycle Brick With Over-Burnt Brick AggregateAsif KhanNo ratings yet

- Reference ThesisDocument7 pagesReference Thesisprencessepis2902No ratings yet

- Enhancing Flexural Performance of GFRC Square Foundation Footings Through Uniaxial Geogrid ReinforcementDocument8 pagesEnhancing Flexural Performance of GFRC Square Foundation Footings Through Uniaxial Geogrid ReinforcementPoonam KilaniyaNo ratings yet

- New Doc 12-05-2023 12.51 - OrganizedDocument16 pagesNew Doc 12-05-2023 12.51 - OrganizedZain Ali AwanNo ratings yet

- Annexure B CE 2023Document1 pageAnnexure B CE 2023Zain Ali AwanNo ratings yet

- PHYSICAL SCINCES Lec#01Document32 pagesPHYSICAL SCINCES Lec#01Zain Ali AwanNo ratings yet

- Nov 09 Dawn VocabularyDocument3 pagesNov 09 Dawn VocabularyZain Ali AwanNo ratings yet

- Pak Affairs Lec 1 PDFDocument5 pagesPak Affairs Lec 1 PDFZain Ali AwanNo ratings yet

- DE 09 November 2022Document3 pagesDE 09 November 2022Zain Ali AwanNo ratings yet

- Keyboard ShortcutsDocument9 pagesKeyboard ShortcutsZain Ali AwanNo ratings yet

- Pak MCQs 38 Pages PedagogyDocument33 pagesPak MCQs 38 Pages PedagogyZain Ali AwanNo ratings yet

- Urdu MPTDocument9 pagesUrdu MPTZain Ali AwanNo ratings yet

- My FatherDocument19 pagesMy FatherZain Ali AwanNo ratings yet

- Freelancer ....Document17 pagesFreelancer ....Zain Ali AwanNo ratings yet

- Threat of Global Recession World BankDocument3 pagesThreat of Global Recession World BankZain Ali AwanNo ratings yet

- What Is Eutrophication?Document6 pagesWhat Is Eutrophication?Zain Ali AwanNo ratings yet

- DE 10 November 2022-1Document3 pagesDE 10 November 2022-1Zain Ali AwanNo ratings yet

- Name: Kashif AkramDocument10 pagesName: Kashif AkramZain Ali AwanNo ratings yet

- DE 05 October 2022 - FinalDocument6 pagesDE 05 October 2022 - FinalZain Ali AwanNo ratings yet

- Leaflet IGS 2021 AGEEDocument2 pagesLeaflet IGS 2021 AGEEZain Ali AwanNo ratings yet

- ICEP CSS Institute Sep 25 - Oct10 Dawn Deconstructed File by ICEP Team - Best Current Affairs Bi-Weekly MagazineDocument154 pagesICEP CSS Institute Sep 25 - Oct10 Dawn Deconstructed File by ICEP Team - Best Current Affairs Bi-Weekly MagazineZain Ali AwanNo ratings yet

- Paper: (100 MARKS) : Environmental ScienceDocument11 pagesPaper: (100 MARKS) : Environmental ScienceZain Ali AwanNo ratings yet

- Climate Change TBADocument8 pagesClimate Change TBAZain Ali AwanNo ratings yet

- What Is Eutrophication?Document6 pagesWhat Is Eutrophication?Zain Ali AwanNo ratings yet

- How To Make A #Superhero Resume - Amal AcademyDocument3 pagesHow To Make A #Superhero Resume - Amal AcademyZain Ali AwanNo ratings yet

- CE 403 - Final Exam - 16.01.2021Document3 pagesCE 403 - Final Exam - 16.01.2021Zain Ali AwanNo ratings yet

- Disinfection NumericalsDocument2 pagesDisinfection NumericalsZain Ali AwanNo ratings yet

- ZAIN UL HASSAN-Resume UpdatedDocument1 pageZAIN UL HASSAN-Resume UpdatedZain Ali AwanNo ratings yet

- Problem 1: From The Following Record of Average Monthly Stream Flows: Month Flow (M X10) Month Flow (M X10) MonthDocument2 pagesProblem 1: From The Following Record of Average Monthly Stream Flows: Month Flow (M X10) Month Flow (M X10) MonthZain Ali AwanNo ratings yet

- Assignment Equivalent Pipe Concept Numerical Problem Q.1Document2 pagesAssignment Equivalent Pipe Concept Numerical Problem Q.1Zain Ali AwanNo ratings yet

- Food Analysis Techniques and ToolsDocument4 pagesFood Analysis Techniques and ToolsZain Ali AwanNo ratings yet

- Hydraulics of Water Distribution System: Problem Number 01Document10 pagesHydraulics of Water Distribution System: Problem Number 01Zain Ali AwanNo ratings yet

- Flood Frequency Analysis of Chenab River (Group1)Document6 pagesFlood Frequency Analysis of Chenab River (Group1)Zain Ali AwanNo ratings yet

- Benefits of Clean EatingDocument2 pagesBenefits of Clean EatingZcianne A. DeliquiñaNo ratings yet

- Asera - BKM Id CardDocument35 pagesAsera - BKM Id CardYos JagusNo ratings yet

- 119 Ijctrt April2015Document47 pages119 Ijctrt April2015ZulfaNo ratings yet

- Decision 310-18 À 317-18 Du 22 Juin 2018 AffectationsDocument28 pagesDecision 310-18 À 317-18 Du 22 Juin 2018 AffectationsIvan Landry NyangonNo ratings yet

- 2.performance and Operating Characterstics of IC EngineDocument60 pages2.performance and Operating Characterstics of IC EngineSiraj MohammedNo ratings yet

- Aluminium Foil AB - 711 S/S: Cool - Comfort - Energy SavingDocument2 pagesAluminium Foil AB - 711 S/S: Cool - Comfort - Energy SavingcandraNo ratings yet

- Pruclinicare Panel ListDocument9 pagesPruclinicare Panel ListMeng Chua60% (5)

- Report On Bharti Airtel Limited: Institute of Marketing and ManagementDocument26 pagesReport On Bharti Airtel Limited: Institute of Marketing and Managementsimply_cooolNo ratings yet

- Polaroid FLM1911Document30 pagesPolaroid FLM1911videosonNo ratings yet

- CERDEC Fact Sheet - CREW Duke V3Document1 pageCERDEC Fact Sheet - CREW Duke V3RDECOM CERDECNo ratings yet

- Research Note Buddha'S Life Depicted in The Sculpturs of KakrebiharDocument7 pagesResearch Note Buddha'S Life Depicted in The Sculpturs of KakrebiharLekh LekhNo ratings yet

- LemnaDocument1 pageLemnaRusdi ToriqNo ratings yet

- WST 2100 Pbach R Me 0042Document206 pagesWST 2100 Pbach R Me 0042teamlc100% (1)

- Active Path I Zero First ConditionalDocument3 pagesActive Path I Zero First ConditionalMaria Palacios100% (1)

- Relay Module, Delay Off, Off, Trigger Delay, Cycle Timing Circuit SwitchingDocument6 pagesRelay Module, Delay Off, Off, Trigger Delay, Cycle Timing Circuit SwitchingNaumaan AkkramNo ratings yet

- Valley View University: School of Graduate StudiesDocument13 pagesValley View University: School of Graduate Studiesvida konadu AgyemanNo ratings yet

- AmmaDocument3 pagesAmmaABP SMART CLASSESNo ratings yet

- Desk Sputter Coater - DSR1Document3 pagesDesk Sputter Coater - DSR1mohamadazareshNo ratings yet

- Köppen Climate Classification PDFDocument21 pagesKöppen Climate Classification PDFJohann S M MendezNo ratings yet

- 1828 FullDocument6 pages1828 FullChikezie OnwukweNo ratings yet

- ece轮胎文件Document37 pagesece轮胎文件张正No ratings yet