Professional Documents

Culture Documents

Controller Design for Processes with Difficult Dynamics

Uploaded by

Muhammed AfnazOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Controller Design for Processes with Difficult Dynamics

Uploaded by

Muhammed AfnazCopyright:

Available Formats

3.

Controller Design for processes with Difficult Dynamics 1

2. CONTROLLER DESIGN FOR PROCESSES

WITH DIFFICULT DYNAMICS

1. Difficult Process Dynamics

For normal system, if the input variable were increased from an initial steady-state value of u1 to

a new value u1 + ∆u, the dynamic behavior is considered normal if the output variable responds

qualitatively as one of the responses depicted in following Figures

These response satisfy:

1. It begins to respond quickly without significant delay.

2. It heads directly for a new steady-state value without first taking an excursion in the

opposite direction.

3. It finally settles to a new steady-state value.

The control system structures studied before can control normal processes reasonably well.

However, these conventional control systems often do a poor job for the following three classes

of processes with difficult dynamics. Thus, we need to analyze the key features of these difficult

processes and provide new control system designs for improved closed loop performance of

these processes.

Characteristics of Difficult Process Dynamics

The presence of any of difficult characteristics in the dynamic behavior of a process can be

identified below:

• Time delay

• Inverse response

• Open loop instability

A process with time delay violates the first condition noted above normal dynamic behavior: it

does not respond instantaneously to input change. A substantial number of chemical processes

exhibit time-delay behavior.

Processes with time delays have a significant delay before they respond to control action, so that

controller with aggressive action (high controller gain) will tend to overcompensate and process

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 2

become unstable. Thus there is a limit on the controller gain that can be used for a process with

time delay.

A process with inverse response violates the second condition for normal dynamic behavior.

The response, even though its step response eventually ends up heading in the direction of the

new steady state, it starts out initially heading in the opposite direction, away from the new

steady state, changing direction somewhere during the course of time.

Processes with inverse response will initially move in the wrong direction as they respond to

control action. Thus if the controller is tuned too tightly (high controller gain) it will attempt to

correct for the movement in the wrong direction and overcompensate. Again there is a limit on

the controller gain that can be used for a process having inverse response.

A process for which the step response is unbounded, i.e., the output increases (or decreases)

indefinitely with time, is said to be open loop unstable. An open loop unstable process violates

the third condition noted above; its output fails to settle to a new steady-state value in response

to a step change in the input.

Processes that are open-loop unstable will "run away" without control, so most of the controller

tuning procedures cannot be applied. In addition, open loop unstable processes can be unstable

for various reasons so that simple PI control may not be enough to stabilize them.

These difficult dynamics translate into unusual phase behavior as non-minimum-phase system.

Non-minimum Phase (NMP) systems

Minimum Phase systems: A normal process with n poles and m zeros, its phase angle

approaches (n - m) x (-90) asymptotically at high frequencies.

For a given system

g ( s ) s = jω = g ( jω ) = Re(ω ) + j Im(ω )

with

AR =| g ( jω ) |= Re(ω ) 2 + Im(ω ) 2

and

⎡ Im(ω ) ⎤

φ = arg[ g ( jω )] = tan −1 ⎢ ⎥

⎣ Re(ω ) ⎦

For a class of processes (g1(s), g2(s), ..., gn(s)) having same amplitude ratio characteristics (i.e.,

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 3

AR1 = AR2 = ... = ARn), and phase angles (φ1, φ2, … φn) of which the minimum is designated

φmin. if φi ≠ φmin then the systems are referred to as non-minimum phase systems.

• Time delay system: For a normal system g1(s):

g 2 ( s ) = g 1 ( s ) e −α s

We have

AR1 = AR2

but

φ2=φ1-αω

• Inverse response system: the two processes having transfer functions:

g1(s) = g0(s)(l + ηs)

and

g2(s) = g0(s)(1- ηs)

We have

AR1 = AR2

but

φ2=φ1-1800

• Open loop unstable system: Consider the first order process

K

g1 ( s ) =

τs + 1

and

K

g 2 (s) =

τs − 1

We have

AR1 = AR2

but

φ2=-1800+φ1

In general, a system which contains any non-minimum phase element: a RHP pole, a RHP zero,

or a time delay, is a NMP system.

2. Control of Time-delay Systems

Control problems with time-delay elements are:

1. Measuring device delay: control action is based on delayed, obsolete, process information

that is not representative of the current situation.

2. Process input delay: the process will not feel the control action immediately.

Delay cause system instability: consider the system

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 4

a)

K

g1 ( s ) =

τs + 1

A normal first-order system, the phase angle asymptotically approaches a limiting value of -900

Thus, the normal system can never be unstable under proportional feedback control since the

phase angle can never attain the critical value of -1800.

b)

K −αs

g1 ( s ) = e

τs + 1

A first-order system with time delay: the phase angle decreases monotonically with frequency, a

limiting value of proportional controller gain (phase angle crosses 1800) at which the system

becomes unstable. It is proportional to the value of the time delay.

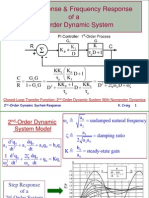

Conventional Feedback Controller Design

Consider the general model for a process with time delay:

g ( s ) = g * ( s )e −αs

where g*(s) has normal dynamics.

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 5

Under conventional feedback, the closed-loop system has

1 + g c ( s) g * ( s)e −αs = 0

The increased phase lag of the delay term requires a reduction in the allowable value of the

controller gain. The closed-loop system will have to be more sluggish than the corresponding

system without delay.

Conventional controllers can be used for time-delay systems, but have to sacrifice speed of

response in order to have closed loop stability.

Example: Three Water Tank System

A linear model for the liquid level hi of each tank is

dh1

A1 = F0 − c1h1

dt

dh2

A2 = c1h1 − c2 h2

dt

dh3

A3 = c2 h2 − c3h3

dt

where Aj, Cj, j=1,2,3, are the cross section area and the outlet valve discharge constant for each

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 6

tank. In terms of deviation variables

yi = hi − his , u = F0 − F0 s

It becomes

dy1

τ1 = − y1 + K1u

dt

dy2

τ2 = K 2 y1 − y2

dt

dy3

τ3 = k 3 y 2 − y3

dt

Aj 1 c c

τj = , k1 = , k 2 = 1 , k3 = 2 ,

cj c1 c2 c3

The transfer function,

K

y3 =

(τ 1s + 1)(τ 2 s + 1)(τ 2 s + 1)

Assume τ 1 = 2 , τ 2 = 4 , τ 3 = 6 , K = k1k 2 k3 . Then

6

g ( s) =

(2s + 1)(4s + 1)(6 s + 1)

Approximated Model:

6

g1 ( s ) = e −3 s

15 s + 1

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 7

PI Control

PID Control

Smith Predictor

Introduce a minor feedback loop around the conventional controller and a model with subscript

m

ym ( s) = g m* ( s)e −α ms u ( s)

Define:

y * ( s ) = g * ( s )u ( s )

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 8

and

y m* ( s ) = g m* ( s )u ( s )

Since

y ( s ) = g * ( s ) e −α s u ( s )

y*(s) is the output of un-delayed process output y(s).

Assuming that there are no model errors g*m(s) = g*(s) and αm = α, the signal reaching the

controller is a "corrected" error signal.

Then:

εc = yd − y(s) − ( y*(s) − y(s))

or

ε c = yd − y * (s)

The equivalent block diagram for the closed loop system is shown as:

The net result of the introduction of the minor loop is therefore to eliminate the time-delay factor

from the feedback loop - where it causes stability problems - and "move" it outside of the loop,

where it has no effect on closed loop system stability.

The characteristic equation of the equivalent system is

1 + g c ( s) g * ( s) = 0

which no longer contains the time-delay element and therefore allows the use of higher

controller gains without placing the closed-loop stability in jeopardy.

To establish the characteristic equation directly, assuming that there are no model errors.

Considering

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 9

u = g c*ε

where

gc

g c* =

1 + g c g (1 − e −αs )

*

The overall closed loop transfer function is

g * ( s )e −αs g c*

y= yd

1 + g * ( s )e −αs g c*

Using g c* , we obtain:

g * g c e − αs

g * ( s )e −αs g c* =

1 + g c g * − g c g *e −αs

and

−αs 1 + g * gc

1 + g ( s )e

*

g =

*

1 + g c g * − g c g *e −αs

c

Substitute both equations into the closed loop transfer function

⎛ g * gc ⎞ −αs

y = ⎜⎜ ⎟⎟e yd

⎝ 1 + g gc

*

⎠

The specialized control scheme is known as time-delay compensation because, the minor loop

was introduced to compensate for the presence of the time delay. It is referred to as a

compensator.

Note:

1. The effective action of the compensator is to feed the signal y* to the controller instead

of the actual process output y.

2. By

y * ( s ) = g * ( s )u ( s )

and

y ( s ) = g * ( s )e −αs u ( s )

we have

y * ( s ) = eαs y ( s )

and

y * (t ) = y (t + α )

It is clear that y*(t) is a prediction of y(t) exactly α time units ahead, the name "Smith

predictor" generally associated with the scheme.

3. The scheme will work perfectly if process model is perfectly known, modeling errors

will affect its performance. The most significant criticism of the Smith predictor

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 10

technique is its sensitivity to modeling errors.

4. In those processes where the time delays are due to transport of material and/or energy

through long pipes, the time delays will vary with the fluid flowrate; an increase in

flowrate giving rise to lower time delays, and vice-versa. The Smith predictor scheme is

designed for constant time delays and may therefore not perform as well for systems

with time delays which vary significantly over time.

Design Procedure

1. Design the Smith Predictor (the minor loop)

The design of the minor loop involves setting up a means by which y* and y are

produced from the process model, y is obtained directly from the process model, and

y* is obtained from the undelayed version of the process model.

2. Design gc

According to the Smith predictor scheme, the controller is designed for the undelayed

system. This permits the use of much higher controller gains than would otherwise be

allowable.

However, the Smith predictor requires a perfect model, and real models are never perfect, we

must be cautious in choosing the controller parameters. In practice, one would choose controller

parameters large enough to achieve much better performance than feedback control alone, but

not so large as to cause serious deterioration in performance resulting from inevitable

plant/model mismatch.

Assuming there is a variation in dead-time, td can only be approximated. The Smith predictor

cannot fully compensate the dead-time effects; there is dead-time residual in the system. The

uncompensated dead-time give rise to additional phase lag and leads eventually the reduction of

crossover frequency and ultimate gain margin. In this case, too big gain will lead unstable

system.

Another problem is the disturbance, Smith predictor has no real effect to disturbance rejection

improvement.

• Stability

• Disturbance rejection

• Transient characteristic

• Robustness

Improved Smith Predictor-1

Adding a transfer function Gf(s) in feedback loop, input disturbance can be rejected. From the

block diagram, we can write the closed loop transfer function from D(s) to Y(s) as:

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 11

y(s) g *e −αs

=

d (s) g * g c e −αs

1+

1 + g * g f + g * g c (1 − e −αs )

[1 + g * g f + g * g c (1 − e −αs )]g *e −αs

=

1 + g * g f + g * gc

To reject disturbance, it should have

1 + g * g f + g * g c (1 − e −αs ) = 0

we obtain:

1 + g * g c (1 − e −αs )

gf =−

g*

Writing the closed loop transfer function

y ( s) g * g c e −αs

=

yd (s) 1 + g * g f + g * g c

Substitute gf(s) into above equation, we obtain

* −αs

y(s) g g c e

= =1

y d ( s ) g * g c e −αs

It means that the system can exactly following the reference signal and disturbance has been

totally rejected.

3. Inverse Response System Control

Inverse Response System

Definition: When the initial direction of a process systems step response is opposite to the

direction of the final steady state, it exhibits inverse response.

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 12

Consider a system

g(s) = g1(s)-g2(s)

g1(s): representing the "main mode";

g2(s): as the "opposition mode";

The second model g2(s) has negative sign, opposite to the first model g1(s).

Example: a system composed of two opposing first-order modes,

K1 K2

g ( s) = −

1 + τ 1s 1 + τ 2 s

Assume K1 > K2, the dynamic behavior by transfer function model:

y(s) = g(s) u(s)

is given by:

y(s) = g1(s)u(s) - g2(s)u(s)

or

y(s) = Y1(s)-Y2(s)

The overall unit step response will be the difference between system 1 and 2.

Steady-State Considerations

The overall steady-state value of the system for unit step response is:

y(∞) = K1-K2

and since K1 > K2 this quantity is positive.

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 13

Initial Slope For all t > 0:

dy dy1 dy2

= −

dt dt dt

The net initial slope of the composite system response is the difference between the initial slope

of the "main" and "opposition" system. For first-order step responses it is:

dy K1 K2

t =0 = −

dt τ1 τ2

suppose

K1 K2

≤

τ1 τ2

The net initial slope of the overall system response will be negative, if the initial slope of the

opposing system response is greater than the initial slope of the "main" system response.

Summary

Inverse response is possible only when the "opposition" mode

1. Has a lower steady-state gain than the "main" mode (K2 <K1), and

2. Responds with a faster initial slope than that of the "main" mode,

To illustrate the characteristics of linear systems that show inverse response, consider the

transfer functions of the two processes.

K1 K2

g (s) = −

1 + τ 1s 1 + τ 2 s

( K1τ 2 − K 2τ 1 ) s + ( K1 − K 2 )

=

(1 + τ 1s )(1 + τ 2 s )

Note that this is the form of a (2,1)-order system

K ( −ηs + 1)

g (s) =

(1 + τ 1s )(1 + τ 2 s )

With

K = K1-K2

And

( K1τ 2 − K 2τ 1 ) ⎛ K1 K 2 ⎞ τ 1τ 2

−η = = ⎜⎜ − ⎟⎟

( K1 − K 2 ) ⎝ τ 1 τ 2 ⎠ ( K1 − K 2 )

To obtain the inverse response, it required both K1, K2 are positive, K1 > K2, and also K2/ τ2>

K1/τ1, Which means K>0, -η<0.

For reverse response system, having taken the proper action, it will eventually yield the desired

result. However, the controller is first took the wrong action and is liable to compound the

problem further that may affect such a system’s closed-loop stability.

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 14

Inverse Response System Control

Consider a system, the Bode diagram for the process whose open-loop transfer function is:

(−3s + 1)

g (s) =

(1 + 2 s )(1 + 5s )

1. Without the RHP zero in the numerator, the transfer function will be second order, the

phase angle will asymptotically approach a limiting value of 1800 implying that the

closed loop system will always be stable.

2. With the RHP zero, the limiting value for the phase angle has been altered to 2700 and

there is now a finite (crossover) frequency at which φ = 1800, and there is a limiting

value of Kc for system to be stable.

Conventional Feedback Controller Design

Logic of PID controller:

Because the derivative mode of the PID controller, it can anticipate the "wrong way behavior"

and appropriately accommodating it by:

1. At the initial stage of the process response, it increases error because of the inversion.

However, the derivative of the response is negative during this period, and when this

information is incorporated into the controller equation, the result is a net reduction in

the magnitude of the control action.

2. After the inversion is over, and the response begins heading in the right direction, the

derivative is positive and usually quite large; with the PID controller, this translates to a

net increase in control action.

Approximate Time-delay Model for the Inverse-Response System:

By reversing the Pade approximation, a RHP zero can also be approximated by a time-delay

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 15

element and a mirror image LHP zero

α

1− s

e −αs = 2

α

1+ s

2

then, by the same token:

1 − ηs = (1 + ηs)e−2ηs

Example: Obtain an approximate time-delay model for the inverse-response system using the

reverse Pade approximation and compare the unit step responses.

( −3s + 1)

g (s) =

(1 + 2 s )(1 + 5s )

Solution: Since the model has a RHP zero η=3, using reverse Pade' approximation requires

replacing it with (1+ 3s) e-6s. The approximate time-delay model is given by:

(1 + 3s )

g ( s) = e −6 s

(1 + 2 s )(1 + 5s )

Following Figure shows the unit step response of the two systems, indicating quite reasonable

agreement

Classical Techniques: Ziegler-Nichols Designs

Example: Design a PID controller for the following inverse-response system using the

frequency-response Ziegler-Nichols technique.

( −3s + 1)

g (s) =

(1 + 2 s )(1 + 5s )

Solution: Figure shows the Bode diagram for the system under proportional-only control: i.e.,

the open loop transfer function is given by:

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 16

K c (−3s + 1)

g (s) =

(1 + 2 s )(1 + 5s )

From this diagram, we obtain the following critical information required for the Ziegler-Nichols

design:

The crossover frequency: ωco= 0.55 radians/time

The magnitude ratio at this point: MR = AR/KKc = 0.5

The ultimate gain and period are given as: Ku =2

and

2π

Pu = = 11.42

ω co

By the following table

Controller K τi τD

P 0.5Ku

PI 0.4Ku 0.8Pu

PID 0.6Ku 0.5Pu 0.125Pu

The Ziegler-Nichols recommended values for the PID controller parameters are obtained as:

Kc=1.2; τI=5.7 τD=1.4

Inverse-Response Compensation

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 17

Consider the block diagram shown below:

Written conventional feedback control of an inverse-response system as g(s) = g0(s)(1 - ηs);

where g0(s) represents the transfer function factoring out the problematic RHP zero element. For

example

( −3s + 1)

g (s) =

(1 + 2 s )(1 + 5s )

than

1

g 0 (s) =

(1 + 2 s )(1 + 5s )

Introducing a minor loop as shown in following Figure with the transfer function g' given by:

g'(s) = g0(s)λs

Objective: choose the quantity λ such that the signal reaching the controller appears to be from a

"normal" system.

Define the variable y'

y'(s) = g'(s)u(s)

generated by the minor loop. As a result of this minor loop, the signal reaching the controller is

given by:

εc = yd − y(s) − y'(s)

or

ε c = yd − [g ( s ) + g ' ( s )]u ( s )

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 18

Now, let:

g * ( s) = g ( s) + g ' ( s)

and

y * ( s ) = g * ( s )u ( s )

then it becomes:

εc = yd − y*(s)

Introducing g and g' into g*, we obtain:

g*(s) = g0(s)(I - ηs) + g0(s)λs

or

g*(s) = g0(s)[l + (λ-η)s]

choose λ such that:

λ>η

y* no longer contains a RHP zero. Thus the minor loop provides a corrective signal that

eliminates the inverse response from the feedback loop.

In case of plant-model mismatch, choosing λ>η (as opposed to λ=η). Usually select

λ=2η

Example: Design an inverse-response compensator for the inverse-response system

(−3s + 1)

g ( s) =

(1 + 2 s )(1 + 5s )

Solution: For the process

1

g 0 (s) =

(1 + 2 s )(1 + 5s )

and

λs

g ' ( s) =

(1 + 2 s )(1 + 5s )

For this system η = 3, a good value of A to be used is λ =6 so that:

6s

g ' (s) =

(1 + 2 s )(1 + 5s )

is the transfer function to use in the inverse-response compensator loop. The apparent process

transfer function is given by:

1 + 3s

g * (s) =

(1 + 2 s )(1 + 5s )

with no RHP zero.

Example: Investigate the closed loop stability properties of the following system under

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 19

proportional-only feedback control, first without any compensation, and then with the inverse

response compensator

( −3s + 1)

g (s) =

(1 + 2 s )(1 + 5s )

Solution: Under conventional, proportional feedback control, the characteristic equation for the

closed loop system is:

K c (−3s + 1)

1+ =0

(1 + 2 s )(1 + 5s )

which rearranges to:

10s 2 + (7 − 3K c ) s + (1 + K c ) = 0

The condition for stability is:

Kc < 7 / 3

With the inverse-response compensator, using the minor loop

u = g c*ε

where

gc

g c* =

1 + gc g '

The overall closed loop transfer function is

gg c*

y= yd

1+ gg c*

and the characteristic equation is:

1 + gg c* = 0

the characteristic equation becomes:

10 s 2 + (7 + 3K c ) s + (1 + K c ) = 0

which is stable for all positive values of Kc

The inverse response compensation compared to conventional PID control, the response to a

unit set-point change with the inverse-response compensator combined with a PI controller (Kc

=10, τI=0.167) is shown in the Figure. Note that the inverse-response compensator produces the

smallest negative deviation and a rapid response without overshoot.

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 20

Design Procedure:

1. Design the inverse-response compensator loop, this involves obtaining the appropriate

transfer function g'(s) and find λ to use in the minor feedback loop.

2. Design gc: Once the compensator has been designed, it is simply design the controller for

g*(s) with absence of the RHP zero permits the use of higher controller.

However, because of process/model mismatch, one must be careful not to increase the controller

gains too much.

4. Open-loop Unstable Systems

Characteristic

The system transfer function has at least one RHP pole.

K

g (s) =

τs − 1

Dynamic Behavior

Any upset in any direction will result in unstable response.

Difficulties for Control System Design

Open loop model identification procedures are impossible, the process must keep under control

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 21

while carrying out the modeling experiments.

Determine open-loop model parameters: under feedback control with known controller

parameters using a sequence of set-point changes and disturbances.

A process is unstable in the open loop can usually be stabilized by carefully designed

conventional feedback control.

Example: Obtain the range of Kc values required to ensure that the closed-loop system

involving:

K

g (s) =

τs − 1

and a proportional controller is stable.

Solution: The characteristic equation for the closed loop system is:

1 + KKc/(τs-1) = 0

which is

τs - 1 + KKc = 0

the one root is located at

s = (1-KKc)/τ

The root will be negative, if

Kc > 1/K

which will stabilize the open-loop unstable system.

Place the closed loop system poles in pre-specified locations in the LHP.

Example: Design a PI controller for above Example with K=1/6 and τ =0.25 that will

stabilize the dosed-loop system with the closed-loop system poles located at s = -2 and at s = -

4.

Solution: PI Controller is given by

⎛ 1 ⎞

g c ( s ) = K c ⎜⎜ 1 + ⎟

⎝ τ I s ⎟⎠

The closed-loop characteristic equation

1+gc(s)g(s)=0

becomes:

ττIs2 + (KKc-1)τIs + KKc = 0

solving this equation, gives the required controller parameter values:

6τ + 1

Kc = Kc = 15.5

K

And

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 22

8τ

τI = τI = 0.775

KK c

However, not all open loop unstable processes can be stabilized by P or PI control.

Example: For open-loop transfer function

2

g (s) =

( 2 s − 1)(5s + 1)

It not difficult to check that it is impossible to stabilize the process using P or PI control. The

characteristic equation of closed loop transfer function is

1 + gc g = 0

2(kcτs + kc )

1+ =0

τs(2s − 1)(5s + 1)

results

10τs 3 − 3τs 2 + (2kc − 1)τs + kc = 0

which is unstable. In this case, either a PD or a PID controller is required for stabilization. It

means that open loop unstable systems may require special types of controllers to stabilize

them.

Open-loop unstable systems can also have conditional closed-loop stability, Kcl < Kc < Kcu

which stabilize the process.

Example: Consider the open loop unstable process:

2(− s + 1)

g ( s) =

(4s − 1)(2s + 1)

under proportional feedback control. Determine the range of controller gains for which the

closed-loop system is stable.

Solution: The characteristic equation for the closed-loop system is given by:

8s2+2(1-Kc)s+(2Kc-1) = 0

the stable range of controller gain is 0.5 < Kc <1.

Two step design

For controller design purpose, many of the unstable processes are adequately described by a

first-order plus dead-time transfer function:

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 23

K

G p (s) = e − Ls

Ts − 1

With P controller in the inner feedback loop, the internal closed-loop transfer function Gl (s)

can be obtained as

G p (s) Ke − Ls

Gl ( s ) = =

1 + K l G p (s) Ts − 1 + KK l e − Ls

Using Taylor series expansion

e − Ls ≅ 1 − Ls + 0.5L2 s 2

we obtain

Ke − Ls

G l ( s ) ≅ G 'p ( s ) =

0.5 KK l L2 s 2 + (T − KK l L) s + KK l − 1

'

Since the characteristic equation of G p ( s ) should have negative poles to be stable, the

following condition must be satisfied from the Routh-Hurwitz stability criterion

1 T

K min = < Kl < = K max

K LK

The above expression indicates that a condition T/L>1 for unstable processes should be

satisfied. That means that the proposed method is suitable for unstable processes with small time

delays.

For the optimum gain margin

1 T

K l = K min K max =

K L

which results

e − Ls

G 'p ( s) =

L 1 1 T

(0.5 TL ) s 2 + (T − TL ) s + ( − 1)

K K K L

As the integrating and unstable processes are stabilized with the P controller in the inner

feedback loop, we can design a PID controller for the stabilized processes which have second

order plus dead time process structure.

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

3. Controller Design for processes with Difficult Dynamics 24

e − Ls

G 'p ( s ) =

as 2 + bs + c

Writing PID controller transfer function as

⎛ As 2 + Bs + C ⎞

Gc (s ) = k ⎜⎜ ⎟⎟

⎝ s ⎠

Kd K K

where A = , B = p and C = i . Let controller zeros to be equal to the poles of model

k k k

G′p (s ) , i.e. A = a , B = b , C = c . Hence

ke− sL

G′p (s )Gc (s ) =

s

where k is determined based on gain and phase-margin specifications. Typical values of gain

margin and phase margin range from 2 to 5, and 30o to 60o , respectively. If assign Am = 3 , then

Φ m = 60 o and

π π

k= =

2 Am L 6L

Hence PID settings for unstable processes are given as

π T T

Kp = ( − )

6K L L

π T

Ki = ( − 1)

6 KL L

π

Kd = TL

12 K

Once the model is obtained, we can ignore the inner feedback loop and directly design PID

controllers for the unstable time delay processes. The tuning formulae are very simple and

straightforward.

KNU/EECS/ELEC835001 Dr. Kalyana Veluvolu

You might also like

- A Step by Step Approach To The Modeling of Chemical Engineering Processes, Using Excel For Simulation (2018)Document182 pagesA Step by Step Approach To The Modeling of Chemical Engineering Processes, Using Excel For Simulation (2018)Anonymous NxpnI6jC100% (7)

- GAGE CALIBRATION PROCESSDocument1 pageGAGE CALIBRATION PROCESSsemaphore689% (9)

- Lab # 6 Time Response AnalysisDocument10 pagesLab # 6 Time Response AnalysisFahad AneebNo ratings yet

- EE5104 Adaptive Control Systems Part IDocument57 pagesEE5104 Adaptive Control Systems Part IbastaaNo ratings yet

- Introduction To Transport Phenomena Momentum, Heat and MassDocument224 pagesIntroduction To Transport Phenomena Momentum, Heat and MassNamitNo ratings yet

- Week 4Document55 pagesWeek 4Raising StarNo ratings yet

- 10 1 1 623 275 PDFDocument28 pages10 1 1 623 275 PDFDamir MiletaNo ratings yet

- Chap02b.advanced Process Control PDFDocument15 pagesChap02b.advanced Process Control PDFAnthony PattersonNo ratings yet

- Block Diagram and The Closed-Loop Response: P D M C FDocument7 pagesBlock Diagram and The Closed-Loop Response: P D M C Fd_k_ÜNo ratings yet

- Inno2019 EMT4203 CONTROL II Chap1 Control ActionsDocument18 pagesInno2019 EMT4203 CONTROL II Chap1 Control Actionskabuej3No ratings yet

- CHP 11 Part 2Document24 pagesCHP 11 Part 2Valarmathi SaravananNo ratings yet

- Experiment No: 2 - Determine Dynamics of First and Second Order SystemsDocument11 pagesExperiment No: 2 - Determine Dynamics of First and Second Order SystemsYAKALA RAVIKUMARNo ratings yet

- 4 Microsoft Word - L-12 - SS - IA - C - EE - NPTELDocument10 pages4 Microsoft Word - L-12 - SS - IA - C - EE - NPTELRicky RawNo ratings yet

- UntitledDocument14 pagesUntitledCupa no DensetsuNo ratings yet

- Nonlinear repetitive controller improves dynamic responseDocument6 pagesNonlinear repetitive controller improves dynamic responsebacuoc.nguyen356No ratings yet

- Modul 3Document7 pagesModul 3Rifki YafiNo ratings yet

- EC - CE10 - Control Systems (2) : Test SummaryDocument18 pagesEC - CE10 - Control Systems (2) : Test Summarysaravanababu jayapalNo ratings yet

- Benchmark Systems For PID ControlDocument2 pagesBenchmark Systems For PID ControlRodrigo SchneiderNo ratings yet

- EEE338A FeedBack CharacteristicsDocument19 pagesEEE338A FeedBack CharacteristicsKenvyl PhamNo ratings yet

- Experiment E. Liquid Level Control Using Coupled TanksDocument29 pagesExperiment E. Liquid Level Control Using Coupled Tanks파랑No ratings yet

- Thuật Toán Điều Khiển1Document23 pagesThuật Toán Điều Khiển1Văn Nghĩa NguyễnNo ratings yet

- Design of PID controllersDocument4 pagesDesign of PID controllersFseha GetahunNo ratings yet

- Stability of Closed-Loop Control SystemsDocument19 pagesStability of Closed-Loop Control SystemsThrishnaa BalasupurManiamNo ratings yet

- Dynamic Behavior of More General SystemsDocument32 pagesDynamic Behavior of More General Systemsjasonbkyle9108No ratings yet

- CHE160 - 2022-2023 - Module 5Document36 pagesCHE160 - 2022-2023 - Module 5anthonyNo ratings yet

- L-12 (SS) (Ia&c) ( (Ee) Nptel) - P-I-D ControlDocument10 pagesL-12 (SS) (Ia&c) ( (Ee) Nptel) - P-I-D ControlRaymond EsmeraldaNo ratings yet

- Second-Order Dynamic Systems KCC 2011Document39 pagesSecond-Order Dynamic Systems KCC 2011Naguib NurNo ratings yet

- Mathematic Modelling of Dynamic SYSTEMS Ch. 2Document31 pagesMathematic Modelling of Dynamic SYSTEMS Ch. 2Irtiza IshrakNo ratings yet

- IN 227 Control Systems DesignDocument11 pagesIN 227 Control Systems DesignAbhinavNo ratings yet

- Notes-Nyquist Plot and Stability CriteriaDocument16 pagesNotes-Nyquist Plot and Stability CriteriaGanesh RadharamNo ratings yet

- Closed-Loop DynamicsDocument20 pagesClosed-Loop Dynamicsjunhao_tan_1100% (1)

- Department of Electromechanical Engineering Course Title: Control SystemDocument25 pagesDepartment of Electromechanical Engineering Course Title: Control SystemYidersal MarewNo ratings yet

- Department of Engineering Technology GET 431/EET 441 Controls Lab Spring, 2018Document5 pagesDepartment of Engineering Technology GET 431/EET 441 Controls Lab Spring, 2018Irfan HaiderNo ratings yet

- Topic 3 - Dynamic - BehaviorDocument42 pagesTopic 3 - Dynamic - Behaviornguyênx thanhNo ratings yet

- Chapter 5 - Dynamic Behavior of First-Order and Second-Order ProcessesDocument44 pagesChapter 5 - Dynamic Behavior of First-Order and Second-Order ProcessesFakhrulShahrilEzanieNo ratings yet

- ChE381 Process Dynamics & Control ExamDocument4 pagesChE381 Process Dynamics & Control ExamSushmitaNo ratings yet

- System Identification L7Document4 pagesSystem Identification L7hawrasdqNo ratings yet

- Introduction To Control EngineeringDocument25 pagesIntroduction To Control EngineeringMagarsaa Qana'iiNo ratings yet

- Speed of motor which I'd controlDocument15 pagesSpeed of motor which I'd controlsagarahir151No ratings yet

- Classical MechanicsDocument6 pagesClassical MechanicsSebastian Soto PerdomoNo ratings yet

- Stability of Control Systems Important Points: CHC3150 Process Dynamics and ControlDocument10 pagesStability of Control Systems Important Points: CHC3150 Process Dynamics and ControlOseribho ObohNo ratings yet

- CH 2Document23 pagesCH 2wehabekodaNo ratings yet

- Class20 (Second Order)Document11 pagesClass20 (Second Order)Audrey Patrick KallaNo ratings yet

- Automatic Generation Control in Four Area Interconnected Power System Using Evolutionary TechniqueDocument15 pagesAutomatic Generation Control in Four Area Interconnected Power System Using Evolutionary TechniqueDámaso DortaNo ratings yet

- T2Document3 pagesT2Kiran Jot SinghNo ratings yet

- Y y U E: The MIT Rule For Adaptive Control: Adaptive Flight Control System - X15Document9 pagesY y U E: The MIT Rule For Adaptive Control: Adaptive Flight Control System - X15maheshboobalanNo ratings yet

- Cascade control in reactor temperature regulationDocument6 pagesCascade control in reactor temperature regulationAmal GSNo ratings yet

- Rotary Double Inverted Pendulum - Laboratory GuideDocument21 pagesRotary Double Inverted Pendulum - Laboratory GuideSaqib KhattakNo ratings yet

- CONTROL THEORY EXERCISESDocument184 pagesCONTROL THEORY EXERCISESAdel AdenaneNo ratings yet

- t7 PDFDocument13 pagest7 PDFKj_bdNo ratings yet

- Sufficient Conditions For Invariance ControlDocument6 pagesSufficient Conditions For Invariance Controllenoirstephane42No ratings yet

- 8-Test Input Signal Transient and Steady-State Response of 1st Abd 2nd Order SystemsDocument32 pages8-Test Input Signal Transient and Steady-State Response of 1st Abd 2nd Order SystemsAzhar AliNo ratings yet

- Model Questions Class Test SolutionDocument22 pagesModel Questions Class Test SolutionAnanthan SrijithNo ratings yet

- Some Past Exam Problems in Control Systems - Part 1Document5 pagesSome Past Exam Problems in Control Systems - Part 1vigneshNo ratings yet

- CHP 6Document39 pagesCHP 6million shiferawNo ratings yet

- Assignment 5 2020 PDFDocument6 pagesAssignment 5 2020 PDFAmal GSNo ratings yet

- Ec Formula Notes 11Document369 pagesEc Formula Notes 11Tharun kondaNo ratings yet

- Green's Function Estimates for Lattice Schrödinger Operators and Applications. (AM-158)From EverandGreen's Function Estimates for Lattice Schrödinger Operators and Applications. (AM-158)No ratings yet

- The Spectral Theory of Toeplitz Operators. (AM-99), Volume 99From EverandThe Spectral Theory of Toeplitz Operators. (AM-99), Volume 99No ratings yet

- Influence of Fulvic Acid On PB (II) Removal From Water Using A Post-Synthetically Modified MIL-100 (Fe)Document9 pagesInfluence of Fulvic Acid On PB (II) Removal From Water Using A Post-Synthetically Modified MIL-100 (Fe)Muhammed AfnazNo ratings yet

- Reusable Heterogeneous Tungstophosphoric Acid-Derived Catalyst For Green Esteri Fication of Carboxylic AcidsDocument10 pagesReusable Heterogeneous Tungstophosphoric Acid-Derived Catalyst For Green Esteri Fication of Carboxylic AcidsMuhammed AfnazNo ratings yet

- Adsorption of CO On Amine-Functionalized Green Metal-Organic Framework: An Interaction Between Amine and CO MoleculesDocument12 pagesAdsorption of CO On Amine-Functionalized Green Metal-Organic Framework: An Interaction Between Amine and CO MoleculesMuhammed AfnazNo ratings yet

- Novel Co-MOF/Graphene Oxide Electrocatalyst For Methanol OxidationDocument11 pagesNovel Co-MOF/Graphene Oxide Electrocatalyst For Methanol OxidationMuhammed AfnazNo ratings yet

- Author's Accepted Manuscript: Journal of Membrane ScienceDocument33 pagesAuthor's Accepted Manuscript: Journal of Membrane ScienceMuhammed AfnazNo ratings yet

- AP Module - 1Document53 pagesAP Module - 1Muhammed AfnazNo ratings yet

- Cumulative probability tables and distributions appendixDocument59 pagesCumulative probability tables and distributions appendixfiresNo ratings yet

- Effects Zero Pole On System ResponseDocument4 pagesEffects Zero Pole On System Responsefancy_maskNo ratings yet

- Material Safety Data Sheet MONOAMMONIUMDocument9 pagesMaterial Safety Data Sheet MONOAMMONIUMMuhammed AfnazNo ratings yet

- Mass Transfer Operations I (CH3002D) Assignment - 1 (Set 1) : Question 1 - 2 MarksDocument3 pagesMass Transfer Operations I (CH3002D) Assignment - 1 (Set 1) : Question 1 - 2 MarksMuhammed AfnazNo ratings yet

- Module III Piping Fundamentals: Pipe Sizing, Materials, Design & LayoutDocument129 pagesModule III Piping Fundamentals: Pipe Sizing, Materials, Design & LayoutMuhammed AfnazNo ratings yet

- Cumulative probability tables and distributions appendixDocument59 pagesCumulative probability tables and distributions appendixfiresNo ratings yet

- Notes-Nyquist Plot and Stability CriteriaDocument16 pagesNotes-Nyquist Plot and Stability CriteriaGanesh RadharamNo ratings yet

- Humidity and Cooling Tower FundamentalsDocument11 pagesHumidity and Cooling Tower FundamentalsMuhammed AfnazNo ratings yet

- Simulink Application On Dynamic Modeling PDFDocument4 pagesSimulink Application On Dynamic Modeling PDFGerardo Andres Riaño BriceñoNo ratings yet

- CRE (Short Notes) - 1 PDFDocument14 pagesCRE (Short Notes) - 1 PDFMuhammed AfnazNo ratings yet

- Module 5 (Part 1)Document48 pagesModule 5 (Part 1)Muhammed AfnazNo ratings yet

- for Knowledge TestDocument250 pagesfor Knowledge TestMuhammed AfnazNo ratings yet

- LECTURE NOTES ON SCALE-UP/SCALE-DOWNDocument62 pagesLECTURE NOTES ON SCALE-UP/SCALE-DOWNLuthfiNo ratings yet

- FM QuestionsDocument20 pagesFM QuestionsMuhammed AfnazNo ratings yet

- Chemical Reaction Engineering - PDFDocument130 pagesChemical Reaction Engineering - PDFHimanshu Katheria100% (1)

- 1.2 CTDocument58 pages1.2 CTUditChoudharyNo ratings yet

- Fluid Mechanics-2 PDFDocument360 pagesFluid Mechanics-2 PDFMuhammed AfnazNo ratings yet

- LLM4OGDocument27 pagesLLM4OGShathikaNo ratings yet

- ISO 9001 Quality Management ProceduresDocument7 pagesISO 9001 Quality Management ProceduresFendi100% (1)

- Chapter Five: Interaction Design and HCI in The Software ProcessDocument52 pagesChapter Five: Interaction Design and HCI in The Software ProcessEyale AbebawNo ratings yet

- System Development Life Cycle AssignmentDocument5 pagesSystem Development Life Cycle AssignmentAugustine Barlow67% (3)

- Software Engg Lab Manual 2011-12Document61 pagesSoftware Engg Lab Manual 2011-12Kartik KolteNo ratings yet

- Week 3Document24 pagesWeek 3Mohammad BangeeNo ratings yet

- Principles of Information Systems 13th Edition Stair Test Bank 1Document17 pagesPrinciples of Information Systems 13th Edition Stair Test Bank 1maria100% (55)

- MLinAI" Machine Learning in Artificial Intelligence: Towards a Common UnderstandingDocument10 pagesMLinAI" Machine Learning in Artificial Intelligence: Towards a Common UnderstandingKeerthi KumarNo ratings yet

- The Potential Impact of Computers and Mis On A Different LevelDocument2 pagesThe Potential Impact of Computers and Mis On A Different LeveljainetiNo ratings yet

- Connections, Relationship, Networks, How Neural Network WorksDocument34 pagesConnections, Relationship, Networks, How Neural Network Workskatrina CalibuyoNo ratings yet

- ACS6110 Lab ReportDocument2 pagesACS6110 Lab ReportDiabloNo ratings yet

- Phase II Maintenance Management Plan Section VIIIDocument77 pagesPhase II Maintenance Management Plan Section VIIIsridhar30481647No ratings yet

- Augurys AI CapabilitiesDocument22 pagesAugurys AI CapabilitiesminaNo ratings yet

- State Machine Diagram Vs Activity DiagramDocument1 pageState Machine Diagram Vs Activity Diagramabouanane0% (1)

- HRM Session 3Document25 pagesHRM Session 3Yash NagarNo ratings yet

- I-PD Controller TuningDocument10 pagesI-PD Controller TuningAfonso AlbuquerqueNo ratings yet

- Social Context Influences Cognition in SLADocument19 pagesSocial Context Influences Cognition in SLAGabriela MicaelaNo ratings yet

- Hardware DevelopmentDocument11 pagesHardware DevelopmentTariku MantafoNo ratings yet

- Scholarships SINGA 2023-06-21-CISDocument152 pagesScholarships SINGA 2023-06-21-CISS RNo ratings yet

- Analysis of Common BPMN Process Modelling MistakesDocument3 pagesAnalysis of Common BPMN Process Modelling Mistakesleonard1971No ratings yet

- Introduction To Deep LearningDocument122 pagesIntroduction To Deep LearningSagar Photo1100% (1)

- Model Paper SQA - AnswersDocument6 pagesModel Paper SQA - Answersmaneka bandaraNo ratings yet

- GTU BE Semester VII AI Exam QuestionsDocument2 pagesGTU BE Semester VII AI Exam Questionsfeyayel988No ratings yet

- After-Sales Services Network Design of A HouseholdDocument12 pagesAfter-Sales Services Network Design of A HouseholdFabian ZárateNo ratings yet

- Block Diagram Representation of Control SystemsDocument49 pagesBlock Diagram Representation of Control Systemsdanish azhar100% (1)

- Data MiningDocument77 pagesData MiningSandip TiwariNo ratings yet

- Heart Disease Prediction Model: DissertationDocument4 pagesHeart Disease Prediction Model: DissertationGaurav MehraNo ratings yet

- Application of A Dual Simplex Method To Transportation Problem To Minimize The CostDocument5 pagesApplication of A Dual Simplex Method To Transportation Problem To Minimize The CostInternational Journal of Innovations in Engineering and ScienceNo ratings yet

- Exp5 TRMS PDFDocument8 pagesExp5 TRMS PDFPavan SinghNo ratings yet