67% found this document useful (3 votes)

2K views1 pageIsometric Check List

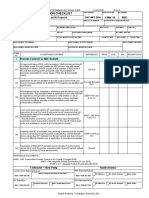

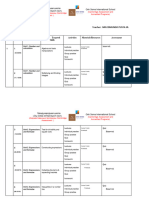

The document is a checklist for reviewing piping isometric drawings with 26 items to verify including line numbers and sizing matching P&IDs, line connections and branches matching latest PIDs, iso continuation sheet numbers shown in order, piping classes and specifications verified with PIDs, north direction and flow direction indicated correctly, pockets lines conforming to process requirements, elevations and distances properly marked, straight lengths and instrument requirements verified, tag numbers of all connected equipment marked, slope requirements for flare headers and process lines shown, orientation of check valves and instruments correct regarding process flow, break flange requirements verified and provided, vents and drains at low and high points, critical line routing verified by stress analysis, supports indicated per standards and

Uploaded by

Rajesh KheraCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

67% found this document useful (3 votes)

2K views1 pageIsometric Check List

The document is a checklist for reviewing piping isometric drawings with 26 items to verify including line numbers and sizing matching P&IDs, line connections and branches matching latest PIDs, iso continuation sheet numbers shown in order, piping classes and specifications verified with PIDs, north direction and flow direction indicated correctly, pockets lines conforming to process requirements, elevations and distances properly marked, straight lengths and instrument requirements verified, tag numbers of all connected equipment marked, slope requirements for flare headers and process lines shown, orientation of check valves and instruments correct regarding process flow, break flange requirements verified and provided, vents and drains at low and high points, critical line routing verified by stress analysis, supports indicated per standards and

Uploaded by

Rajesh KheraCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd